Method and apparatus for preparing pure water by continuous electricity deionizing

A technology of electrodeionization and pure water, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high manufacturing cost, high price, easy scaling, etc. Achieve the effect of reducing manufacturing cost and reducing water and electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

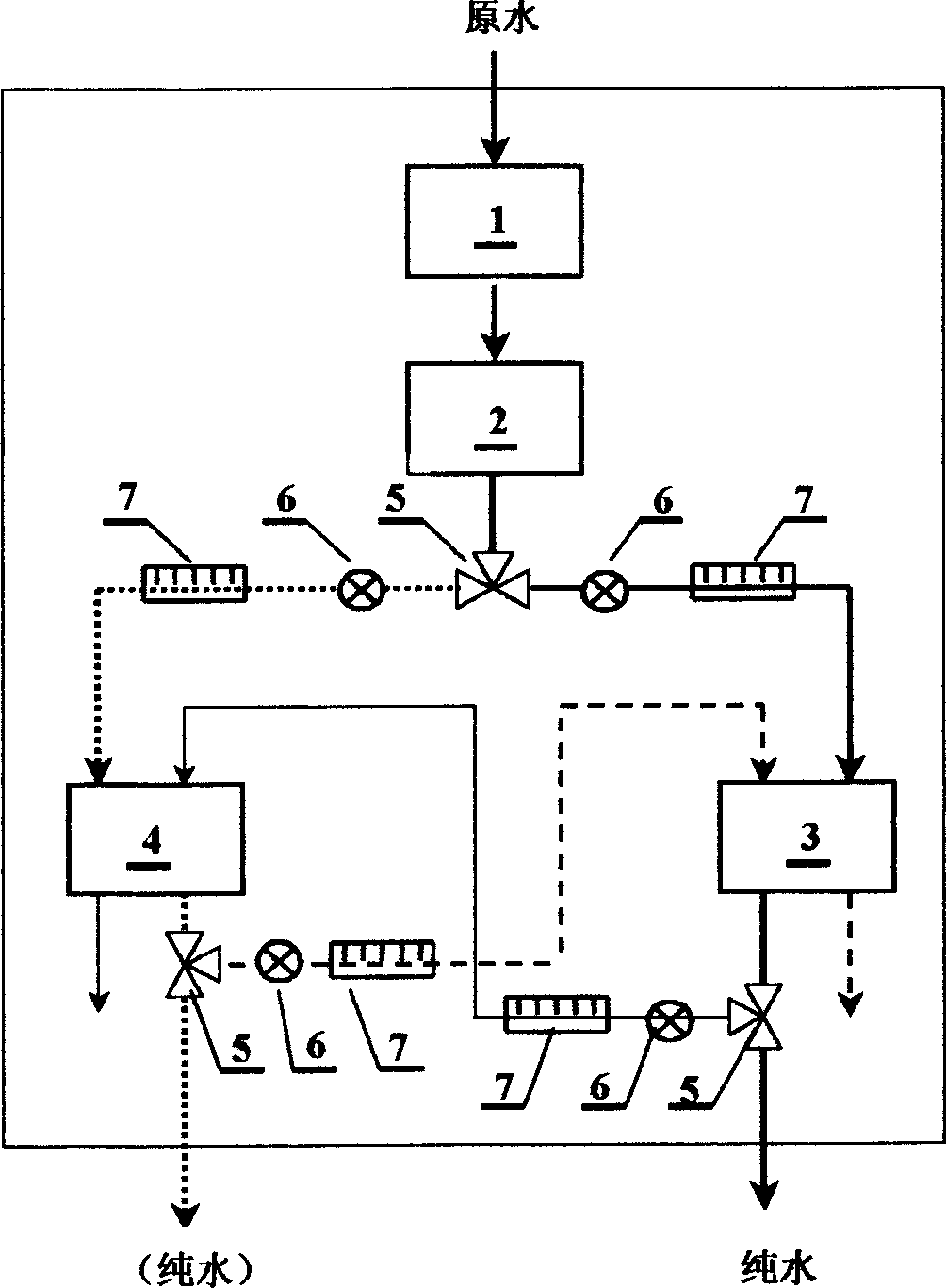

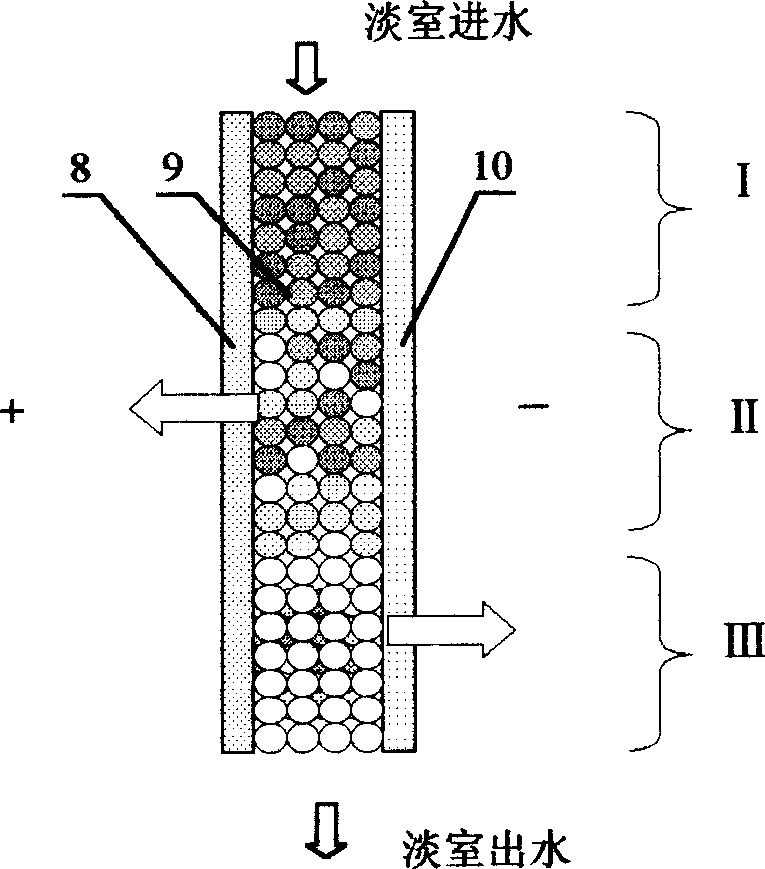

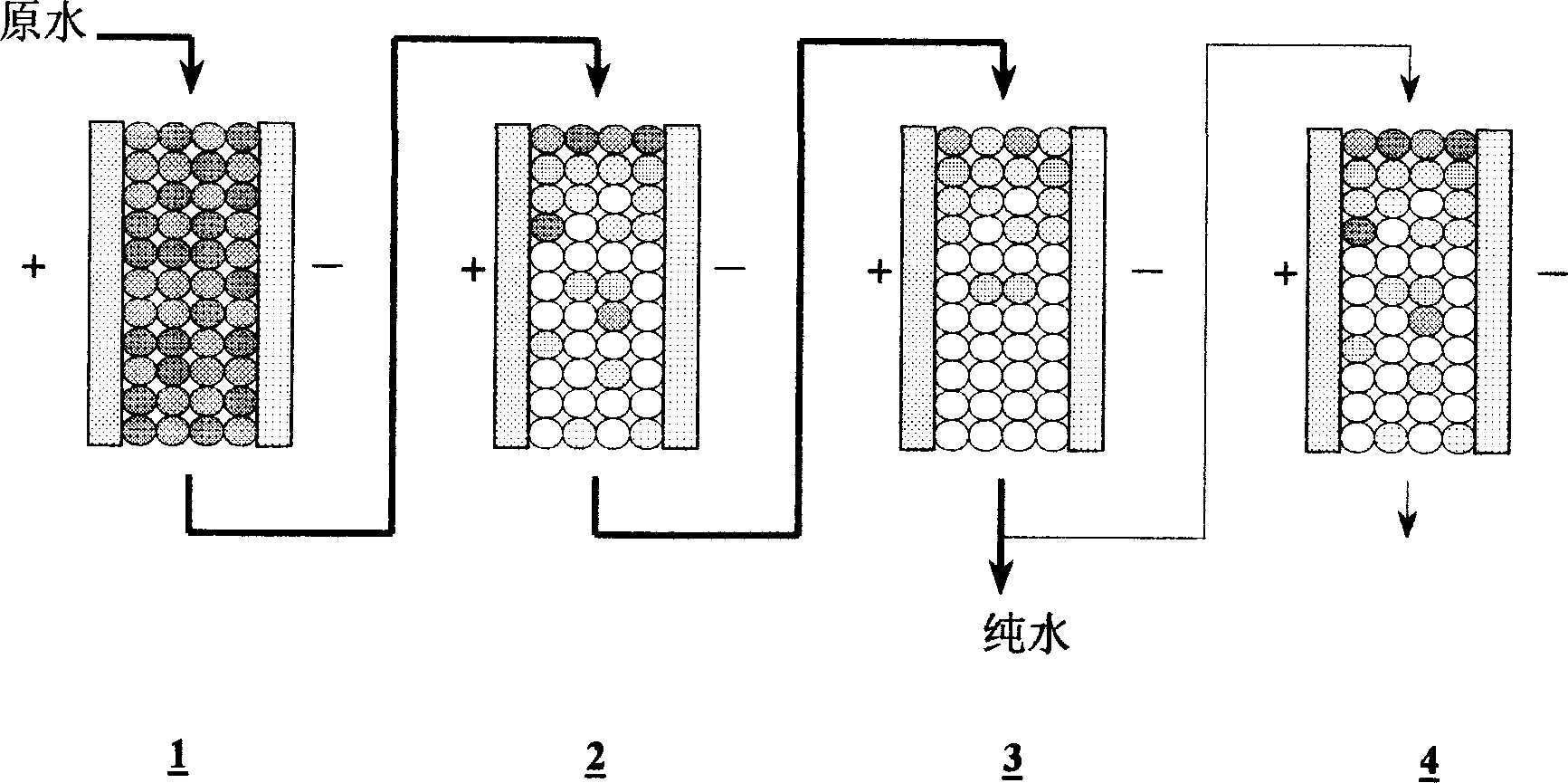

[0029] Such as figure 1 As shown, the raw water is prepared from tap water and distilled water in different proportions, and the ion-exchange membrane used is a domestic heterogeneous ion-exchange membrane. Raw water first enters EDI1(1), and 18V voltage is applied to both ends of the electrodes of EDI1(1) to perform primary desalination of raw water: EDI1(1)’s desalination chamber effluent enters EDI2(2), and is connected between the electrodes of EDI2(2). Add 25V voltage to the terminal to deeply desalinate the raw water; the water from the desalination chamber of EDI2(2) enters EDI3(3), and no voltage is applied to both ends of the electrodes of EDI3(3), and the desalination chamber of EDI3(3) is equivalent to ion exchange The mixed bed, through the exchange and adsorption of ion exchangers to the residual electrolyte ions in the water, makes the effluent of the desalination chamber of EDI3(3) reach the quality of pure water. EDI3 (3) fresh room effluent passes through te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com