Activated carbon adsorption-electrochemical regenerating method for treating non-degradable organic wastewater

A technology for activated carbon adsorption and organic wastewater, applied in the field of water treatment, can solve the problems of high investment in regeneration furnace equipment, changes in the chemical structure of the carbon surface, and low regeneration efficiency, and achieve improved catalytic oxidation efficiency, small chemical structure changes, and high regeneration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

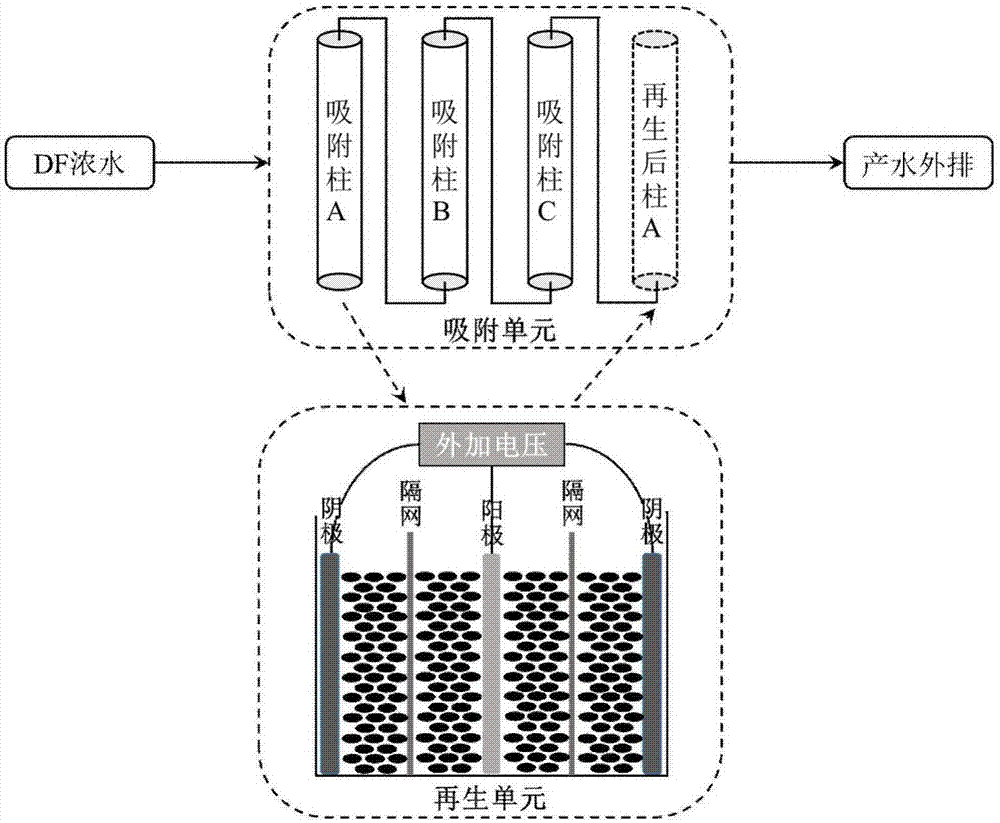

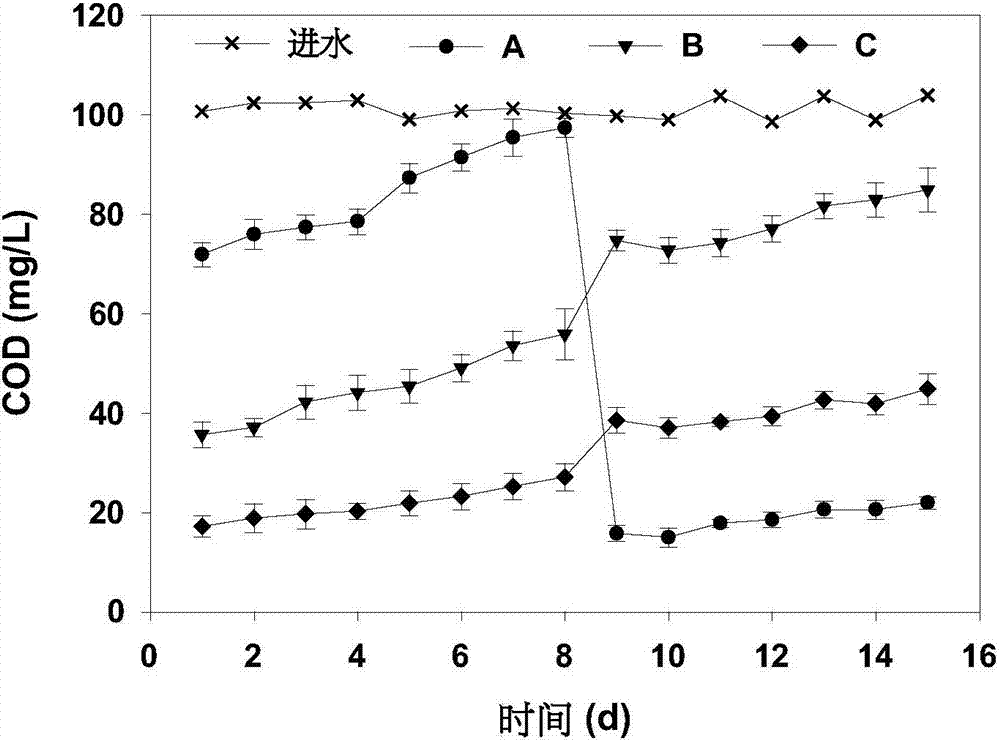

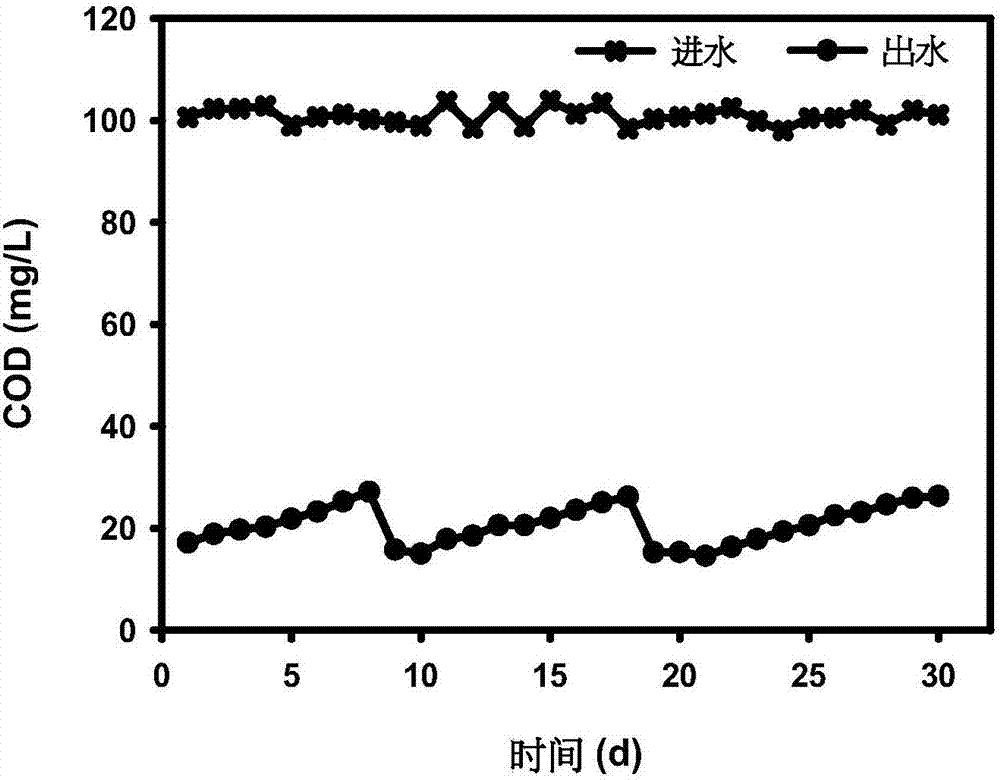

[0046] An activated carbon adsorption-electrochemical regeneration method for treating refractory organic wastewater, said method comprising the following steps: connecting an adsorption column A, an adsorption column B, and an adsorption column C in series, and said adsorption columns are filled with Fe, Mn The activated carbon of the catalyst adsorbs the organic matter in the concentrated water, and the produced water reaches the first-class A discharge standard, and is directly discharged; the COD of the effluent water of each column is monitored, and when the first adsorption column A penetrates, that is, the first adsorption column A The concentration of COD in the effluent of column A is equivalent to that of the influent COD. The activated carbon in the first column A is regenerated, the second adsorption column B acts as the first adsorption column, and the third adsorption column C acts as the second adsorption column. Column A is filled with regenerated activated carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com