Natural gas desulfurization process suitable for offshore floating platform

A desulfurization process and floating platform technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of unsuitable natural gas sulfur recovery, large floor space, complex equipment, etc., to improve catalyst oxidation regeneration efficiency, equipment size Small, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

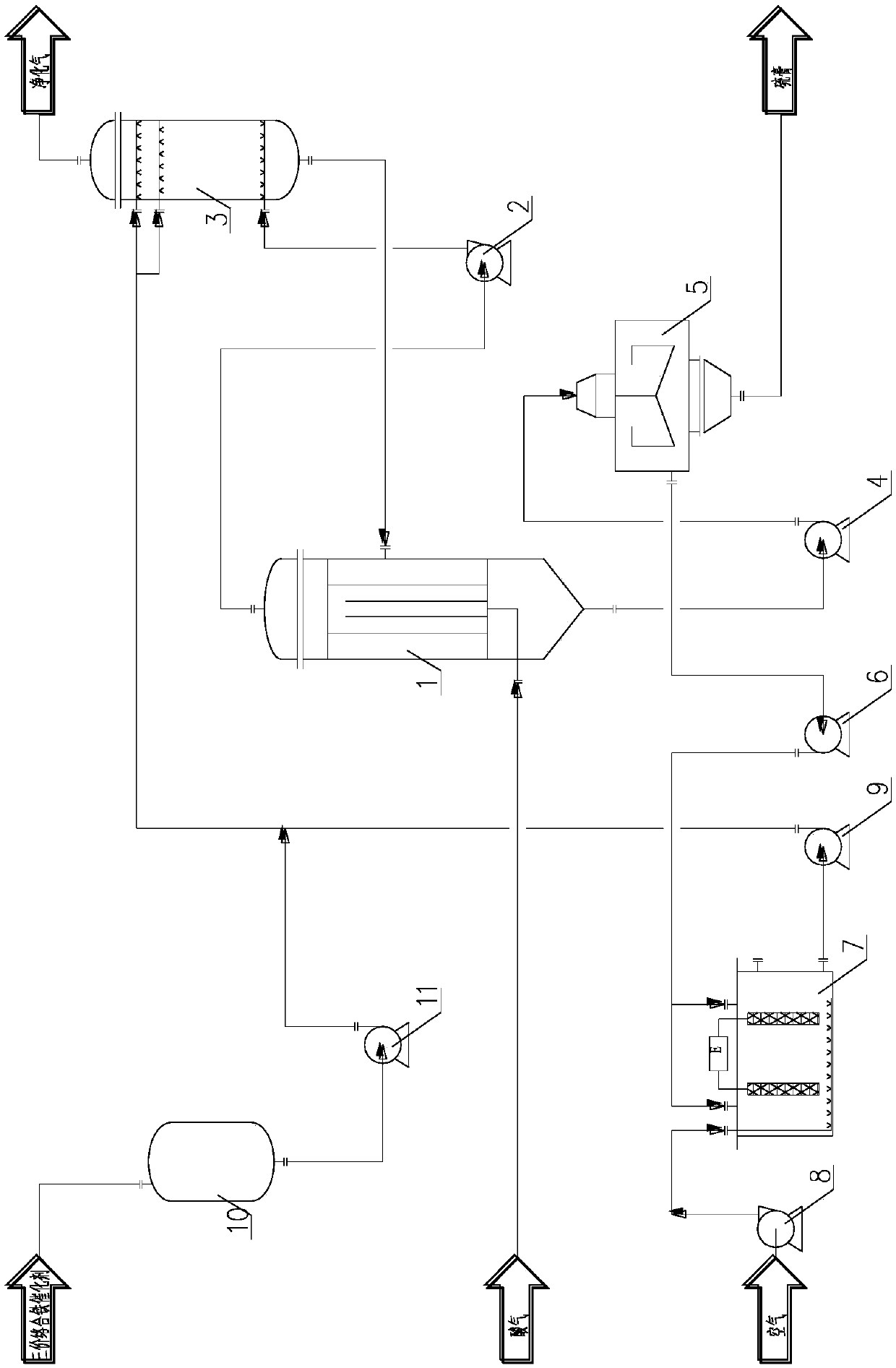

[0022] Such as figure 1 Shown: acid gas from boundary area (containing 25% H 2 S, mol%) enters reactor 1, contacts with trivalent complex iron catalyst countercurrently, following chemical reaction takes place:

[0023] h 2 S(g)+H 2 O→H 2 S(L)+H 2 O (1)

[0024] h 2 S(L)→H + +HS - (2)

[0025] HS - +2Fe 3+ L→S+2Fe 2+ L+H + (3)

[0026] o 2 (g)+H 2 O→O 2 (L)+H 2 O (4)

[0027] o 2 (L)+4Fe 2+ L+2H 2 O→4Fe 3+ L+4OH - (5)

[0028] In reactor 1, the temperature is 28-32°C, the pressure is 35-50kPa, the flow gas-liquid ratio is 0.56, and the residence time is 2min. Most of the H in the acid gas 2 S is oxidized to elemental sulfur, while ferric ions are reduced to ferrous ions. The acid gas that has been oxidized once is sent to the re-reactor 3 with the acid gas conveying fan 2, and is in countercurrent contact with the trivalent complex iron catalyst to further remove the possible residual H in the gas 2 S, the purified gas is sent to the boundary area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com