Method for reverse osmosis concentrated water by adsorption-regeneration circular treatment

A technology for reverse osmosis concentrated water and recycling treatment, applied in the direction of adsorbed water/sewage treatment, etc., can solve the problems of non-compliance with environmental protection, water-saving policies, increased production wastewater discharge, energy consumption and operating costs, and achieve automation The effect of control, small investment and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

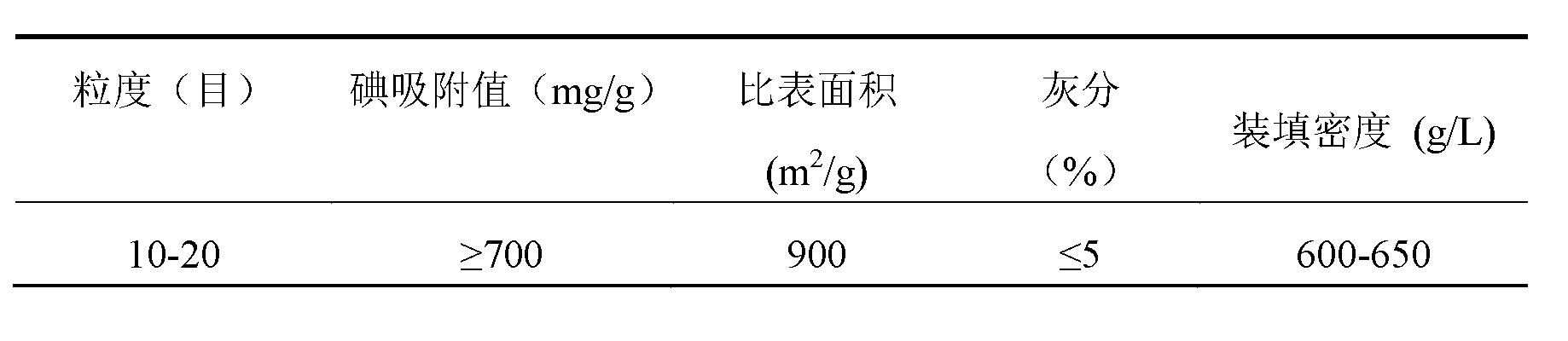

[0019] Process treatment of RO concentrated water in the oil refining industry. The adsorbent in the adsorption tower adopts activated carbon, and its performance parameters are shown in Table 1:

[0020] Table 1 Performance parameters of activated carbon

[0021]

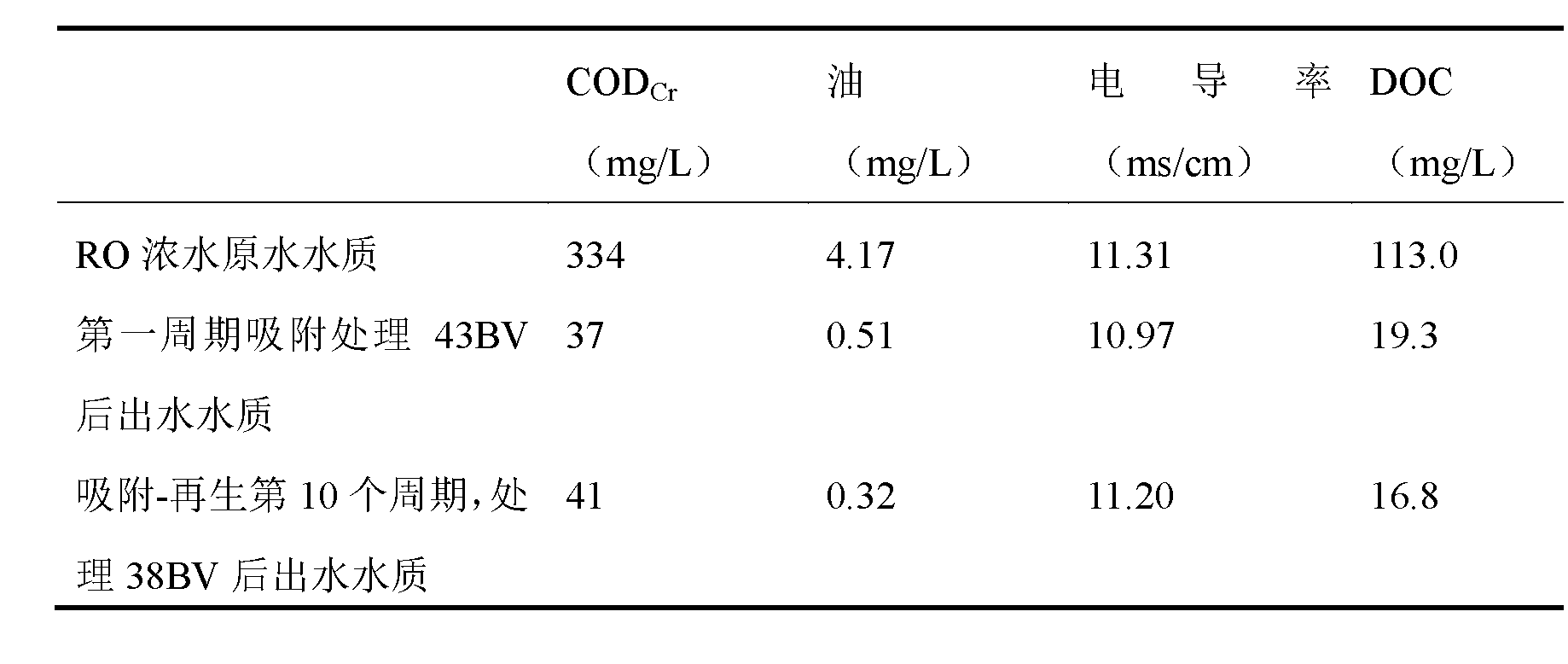

[0022] Table 2 Water quality changes before and after RO concentrated water treatment

[0023]

[0024] Activated carbon is used as an adsorbent to treat RO concentrated water in the oil refining industry. The operating condition is that the HRT is 20 minutes. The first cycle can stably treat 43 BV of RO concentrated water. The COD of the effluent is 37 mg / L, which meets the emission of COD≤50mg / L index. The saturated activated carbon is regenerated by electrochemical method, the voltage is 19 V, the current is 2.53-3.17 A, and the HRT is 6 h. After 10 cycles of adsorption-regeneration, the regeneration efficiency is above 88.4%. The experimental results show that COD, DOC, oil and other indicators in RO c...

Embodiment 2

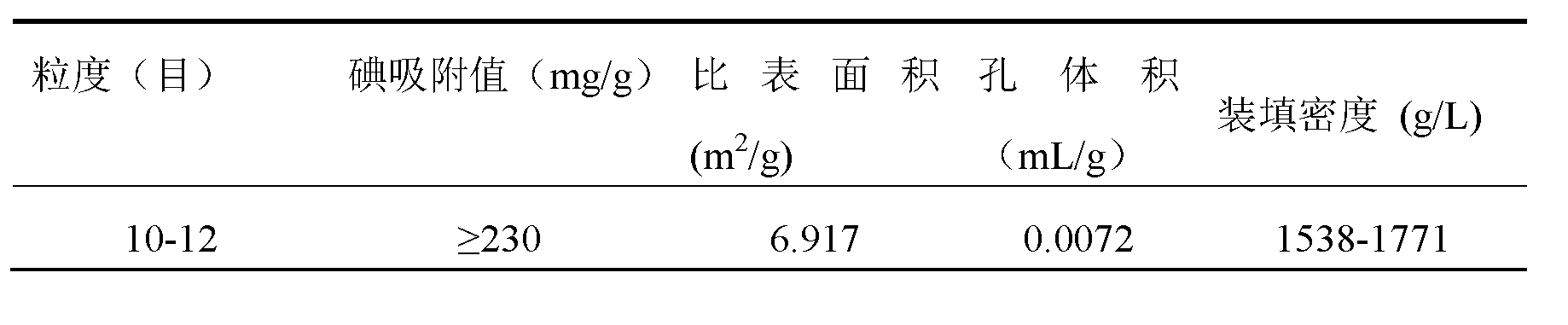

[0026] Process treatment of RO concentrated water in the petrochemical industry. The adsorbent in the adsorption tower is modified fly ash, and its performance parameters are shown in Table 3:

[0027] Table 3 Performance parameters of modified fly ash

[0028]

[0029] Table 4 Water quality changes before and after RO concentrated water treatment

[0030]

[0031] Using modified fly ash as an adsorbent to treat RO concentrated water in the petrochemical industry, the operating condition is HRT of 60 min, the first cycle can stably treat 23 BV of RO concentrated water, the effluent COD is 48 mg / L, and COD≤50 mg / L emission index. The saturated modified fly ash is regenerated by electrochemical method, the voltage is 38 V, the current is 5.53-6.21 A, and the HRT is 2 h. After 10 cycles of adsorption-regeneration, the regeneration efficiency is above 73.9%. The experimental results show that after the modified fly ash adsorption-electrochemical regeneration process, the ...

Embodiment 3

[0033] Process treatment of RO concentrated water in the steel industry. The adsorbent in the adsorption tower is activated carbon fiber felt, and the water quality changes before and after treatment are shown in Table 5:

[0034] Table 5 Water quality changes before and after RO concentrated water treatment

[0035]

[0036] Activated carbon fiber is used as an adsorbent to treat RO concentrated water in the iron and steel industry. The operating condition is HRT of 30 minutes. The first cycle can stably treat RO concentrated water of 58 BV. The COD of the effluent is 37 mg / L, which meets the COD≤50 mg / L emission indicators. After saturation, the electrochemical method is used for regeneration, the voltage is 45 V, the current is 8. 21-9. 51 A, and the HRT is 0.5 h. After 12 cycles of adsorption-regeneration, 52 BV can still be treated up to the standard, and the regeneration efficiency is stable at 89.7% above. The experimental results show that after the activated car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com