Dehydrogenase electrode and preparation method thereof

A dehydrogenase and electrode technology, which is applied in the field of biosensors to achieve the effects of reducing activity loss, realizing process optimization control, and improving the hydrophilicity of electrode surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

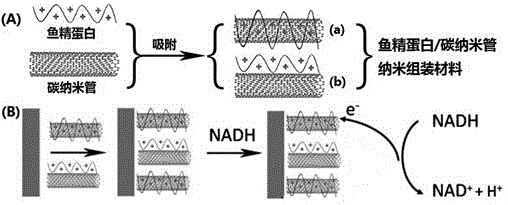

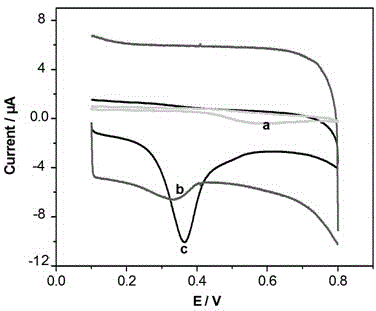

[0030] Take the reduced coenzyme Ⅰ (NADH) in the test buffer solution of this electrode as an example (for the principle of electrode response, see figure 1 ). Its measurement steps are as follows:

[0031] a. The modified electrode prepared by drop-coating the carbon nanotube / protamine composite material on the surface of the base electrode was used as the working electrode, the Ag / AgCl (3M KCl) electrode was used as the reference electrode, and the foil electrode was used as the counter electrode. (CHI 760D) electrochemical workstation for determination. The modified electrode, Ag / AgCl (3M KCl), foil electrode and CHI 760D electrochemical workstation are connected. Insert the working electrode directly into the measuring cell filled with buffer solution, and record the initial cyclic voltammetry curve.

[0032] Electrode preparation process: Take 20mg of protamine, add it into 5mL ultrapure water, prepare 4mg / mL protamine aqueous solution, and place it for later use. 5 m...

Embodiment 2

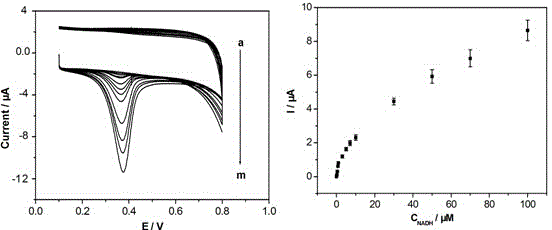

[0036] First, the buffer solution was taken to configure two spiked samples, the concentrations were 10 -6 and 10 -7 , measure oxidation peak current according to embodiment 1, according to peak current value, contrast standard working curve (such as image 3 ) to calculate the corresponding concentration.

Embodiment 3

[0038] Test the content of ethanol in the buffer solution with a dehydrogenase electrode (for the principle of electrode response, see Figure 4 ). Its measurement steps are as follows:

[0039] a. The alcohol dehydrogenase electrode was used as the working electrode, the Ag / AgCl (3M KCl) electrode was used as the reference electrode, and the foil electrode was used as the counter electrode, and Shanghai Chenhua (CHI 760D) electrochemical workstation was used for determination. The enzyme electrode, Ag / AgCl (3M KCl), foil electrode and CHI 760D electrochemical workstation are connected. Insert the dehydrogenase electrode directly into the measuring cell filled with buffer solution, record the initial cyclic voltammetry curve, add ethanol of known concentration into the measuring cell, and an oxidation peak appears on the cyclic voltammetric curve (such as Figure 5 ), draw a standard curve according to the oxidation peak current size and ethanol concentration after adding et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com