Process for desulphurizing methane through Fe-Cl mixed solution

A mixed solution and biogas technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of incomplete absorption of lye, non-renewable absorbing liquid, low efficiency of lye wet desulfurization, etc. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

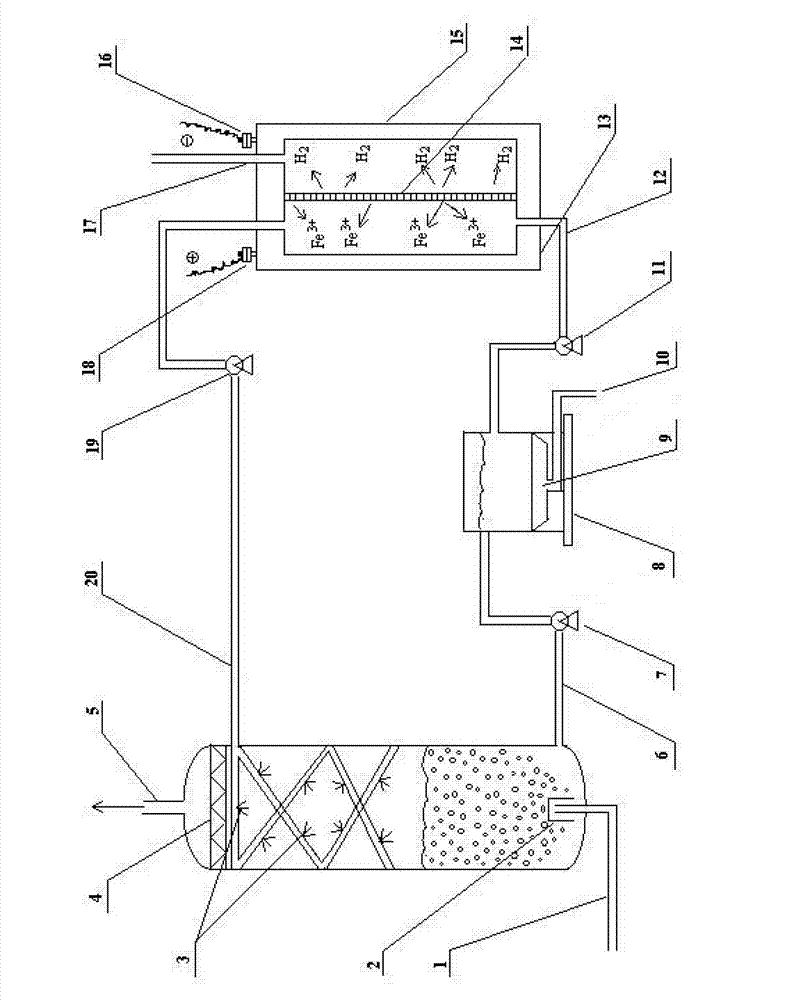

[0025] According to the structure shown in Figure 1, this embodiment is a device for absorbing hydrogen sulfide in biogas in the desulfurization tower: there are biogas inlet pipe 1, rotating bubble cup 2, atomizing nozzle 3, demister 4, biogas outlet pipe 5, absorption Tail liquid conduit 6, water pump 7 for absorbing tail liquid entering the sedimentation tank, and regeneration absorption liquid conduit 20; sedimentation tank 8, sulfur mud tank 9, sulfur mud conduit 10, water pump 11 for absorbing tail liquid entering the electrolyzer, and absorption tail liquid conduit 12 , the tail liquid absorption conduit 6 is connected to the sedimentation tank 8; the bucket center of the sulfur sludge tank 9 is connected to the sulfur sludge conduit 10. The regenerated absorption liquid conduit 20 is connected to the top of the desulfurization tower and the atomizing nozzle installed on the inner wall of the tower; the demister 4 is above the atomizing nozzle on the top of the tower and...

Embodiment 2

[0031]According to the flowchart structure diagram shown in accompanying drawing 1, the same biogas in embodiment 1 was subjected to treatment test.

[0032] The Fe—Cl mixed solution is used as the absorption liquid, and the Fe in the mixed solution 3+ and Fe 2+ The concentration is 1.2mol / L, where Fe 2+ The proportion of Fe element in the absorption liquid system is 10%, and the concentration range of HCl is 4.0mol / L; when the volume of the absorption liquid in the desulfurization tower reaches 1 / 3 of the internal volume of the desulfurization tower, open the atomization nozzle and the biogas inlet valve , let the rotating bubbling cup bubble with a bubble diameter of 0.2~2.0 mm, the rotation speed of the rotating bubbling cup is about 5000rpm, and the residence time of the biogas in the tower is about 5 minutes; the temperature range of the absorption liquid: 80 ℃; the absorption liquid and Biogas formation countercurrent contact;

[0033] (2) The biogas after the desulfu...

Embodiment 3

[0037] According to the flow chart shown in Figure 1, the treatment test was carried out relative to the biogas with higher sulfur content in Example 1.

[0038] The Fe—Cl mixed solution is used as the absorption liquid, and the Fe in the mixed solution 3+ and Fe 2+ The concentration is 1.5mol / L, where Fe 2+ The proportion of Fe element in the absorption liquid system is 15%, and the concentration range of HCl is 5.0mol / L; when the volume of the absorption liquid in the desulfurization tower reaches 1 / 2 of the internal volume of the desulfurization tower, open the atomization nozzle and the biogas inlet valve , let the rotating bubbling cup bubble with a bubble diameter of 0.2~2.0 mm, the rotation speed of the rotating bubbling cup is about 6000rpm, and the residence time of the biogas in the tower is about 6 minutes; the temperature range of the absorption liquid: 70 ℃; the absorption liquid and Biogas formation countercurrent contact;

[0039] (2) The biogas after the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com