Method and device for controlling an air drying unit of an air supply system for the primary and secondary air supply of a vehicle, in particular a rail vehicle

An auxiliary air and air-drying technology, which is applied in the direction of air treatment devices, vehicle subunit functions, chemical instruments and methods, etc., can solve the problems of refilling lag, lag, consumption, etc., and achieve the effect of quickly putting into use and shortening the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

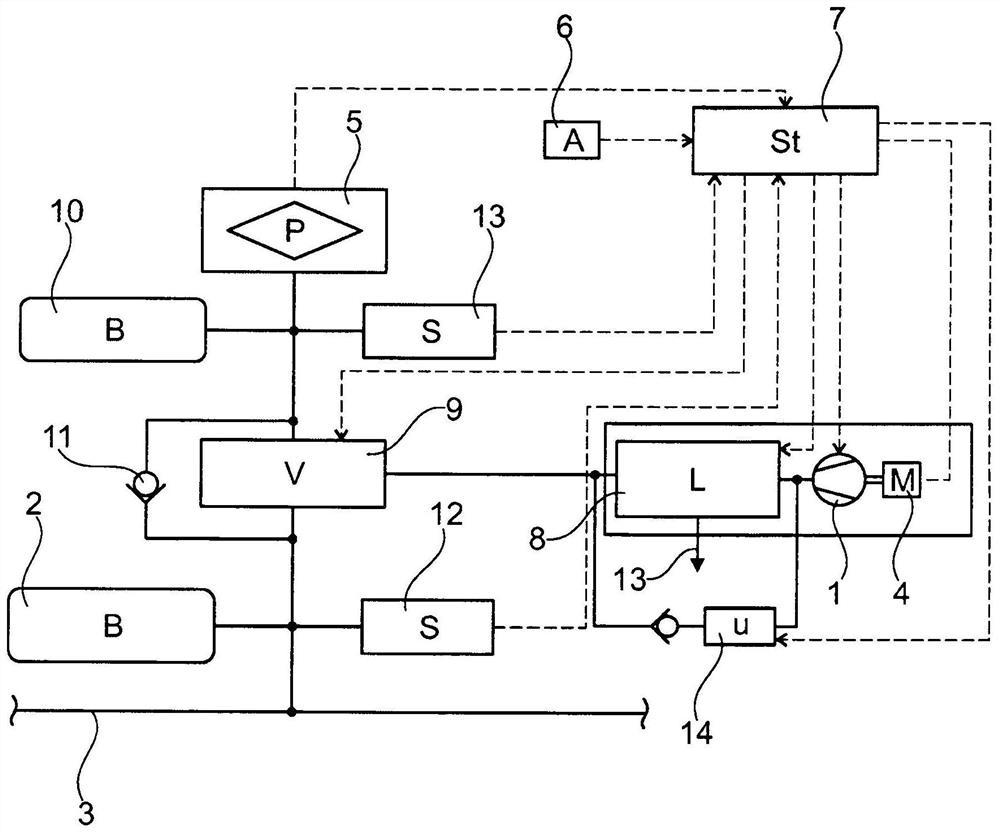

[0024] according to figure 1 , in the area of the main and auxiliary air supply of the electric rail vehicle (not further shown) a compressor 1 is arranged to generate a main air storage tank 2 for filling and a main air storage tank line 3 connected thereto of compressed air. The compressor 1 is driven by an electric motor 4 . During normal operation of the rail vehicle, the electrical energy for driving the electric motor 4 is harvested via the pantograph 5 via the overhead conductor connection. The on-board battery 6 provided on the vehicle is used for additional electrical energy supply. The electrical energy supply by means of the pantograph 5 and the on-board battery 6 is controlled via the electronic control unit 7 (dotted line), which in particular also contains an integrated converter to vary the voltage and frequency for driving the electric motor 4, which In this case, it is designed as a three-phase AC motor.

[0025] For retracting and extending the pantogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com