Normal-temperature low-dew-point runner dehumidification unit

A dehumidification and low dew point technology with a rotary wheel, which is applied in household heating, lighting and heating equipment, space heating and ventilation, etc. It can solve the problems of less adjustability of residual pressure, increased cooling consumption of middle and surface cooling, and easy leakage of airflow and other problems, to achieve the effect of more adjustable residual pressure, low leakage treatment and stable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the present invention, the present invention will be described in detail below in conjunction with the preferred embodiments of the present invention given in the accompanying drawings.

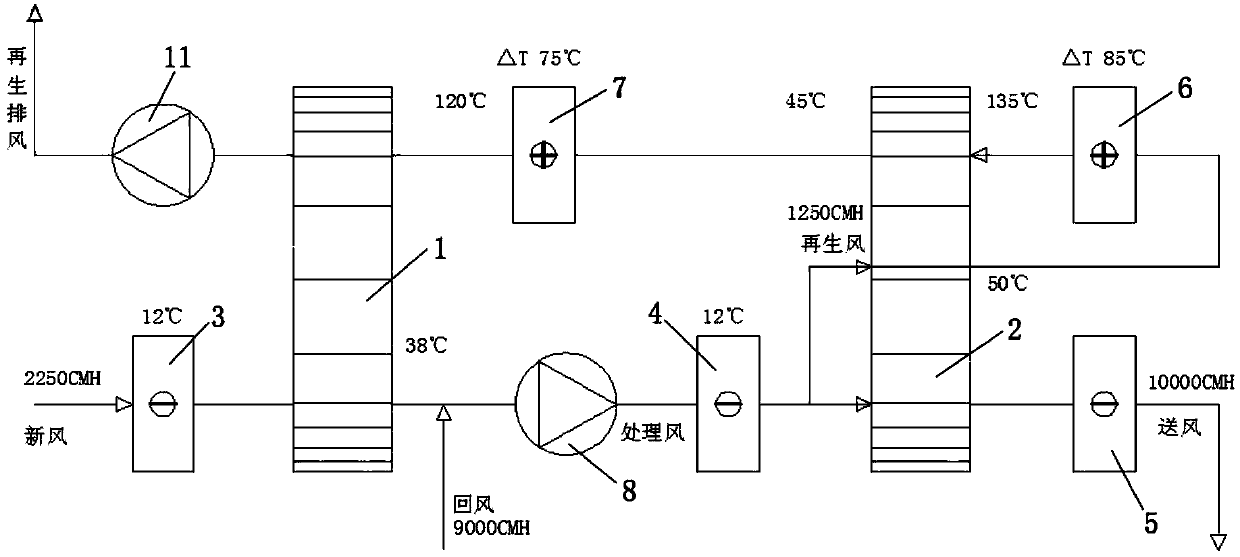

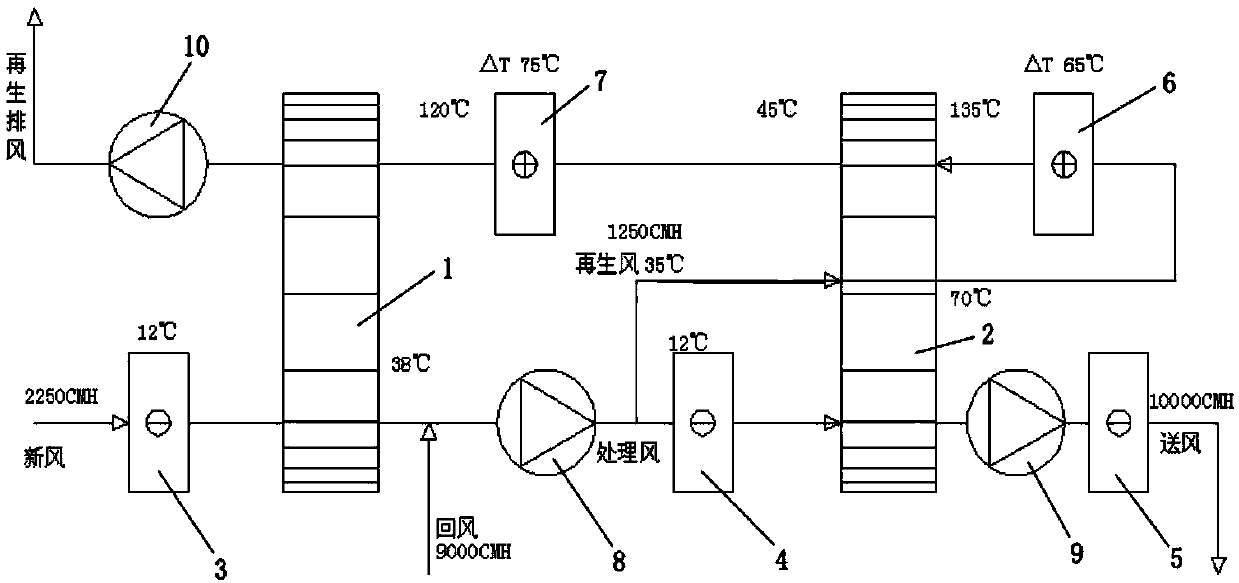

[0019] like figure 2 As shown, the normal temperature low dew point rotary dehumidification unit of the embodiment of the present invention includes a primary rotary heat exchanger 1, a secondary rotary heat exchanger 2, a front surface cooler 3, an intermediate surface cooler 4, and a rear surface cooler. 5, the primary regeneration heater 6 and the secondary regeneration heater 7, the primary rotary heat exchanger 1 is set separately for the primary treatment moisture absorption zone and the primary regeneration desorption zone, and the secondary rotary heat exchanger 2 is set separately Secondary treatment moisture absorption zone, secondary regeneration desorption zone and secondary regeneration cooling zone. As an example, the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com