Patents

Literature

55 results about "Operational readiness" patented technology

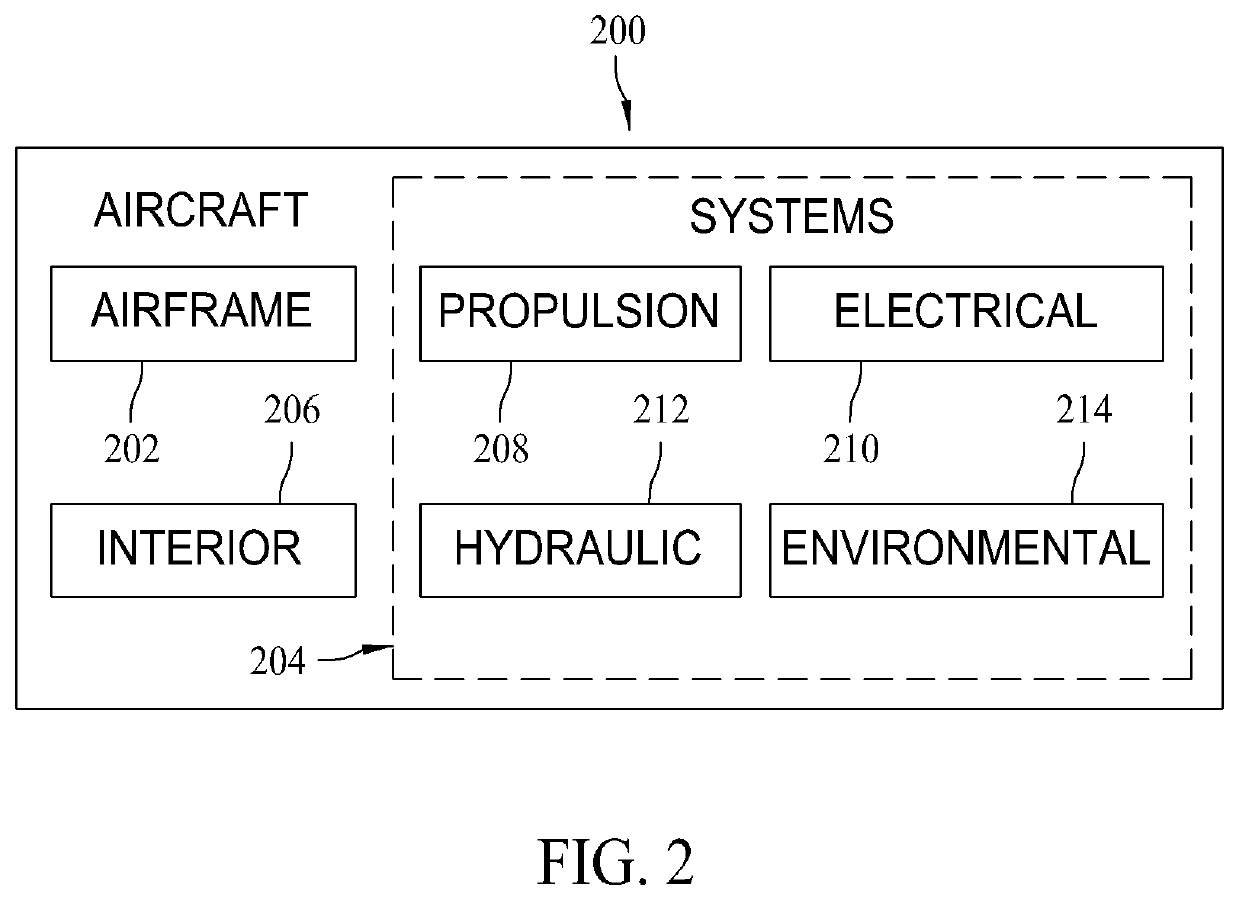

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Operational readiness typically begins as a planning function early in the project lifecycle, and continues through to when the project becomes operational. Completion of operational readiness activities will usually be progressive and may also be staged along with project delivery as work packages, or sub-elements of work packages, are completed.

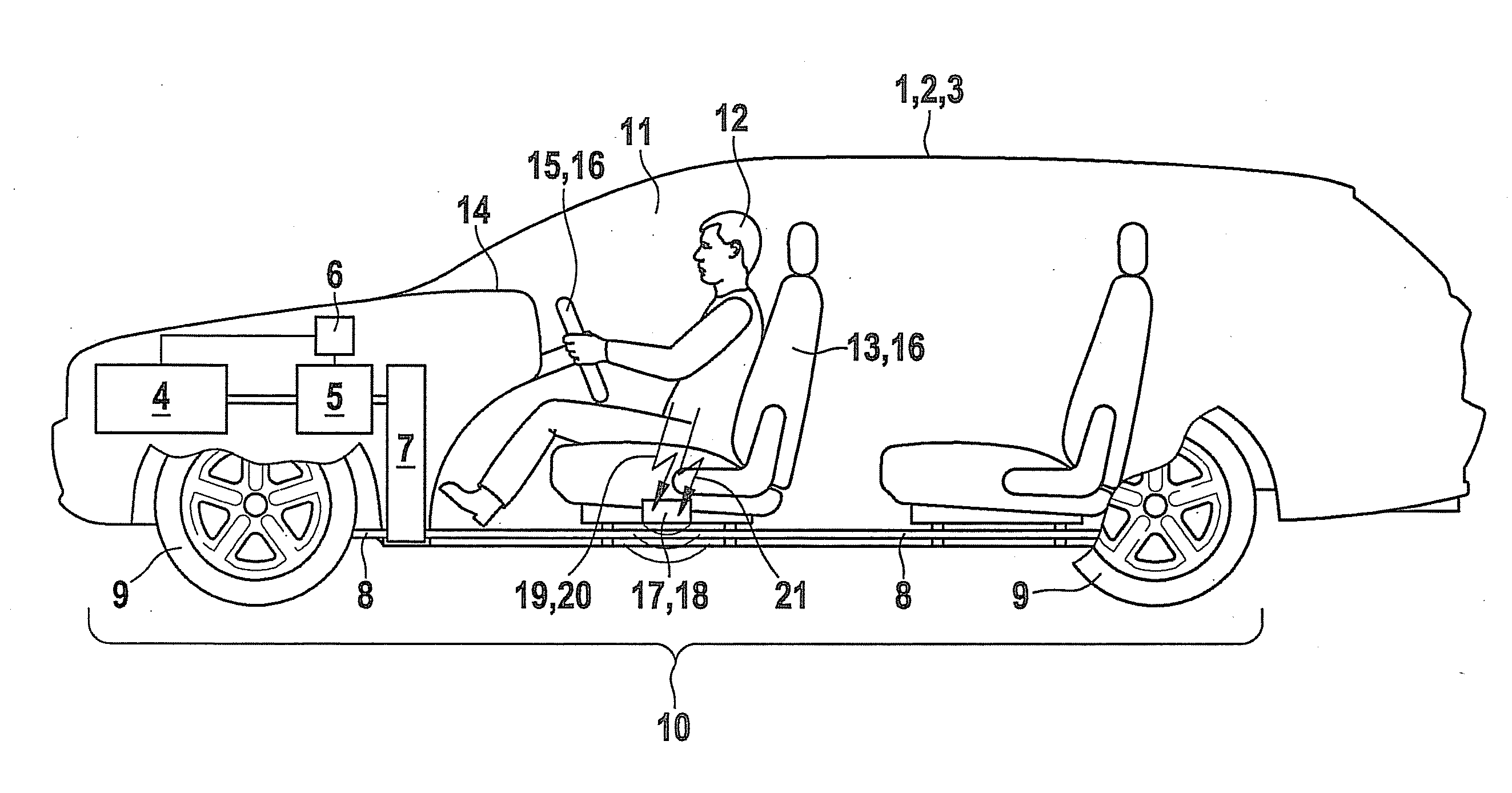

Tactile driver feedback regarding the operational readiness of a vehicle

InactiveUS20110187521A1Increase rangeLot of attentionVehicle seatsRailway vehiclesDriver/operatorHaptic sensation

A method is described for generating a tactile driver feedback regarding the operational readiness of a vehicle, in particular a hybrid vehicle, the feedback being generated as a function of the state of a drive train of the vehicle.

Owner:ROBERT BOSCH GMBH

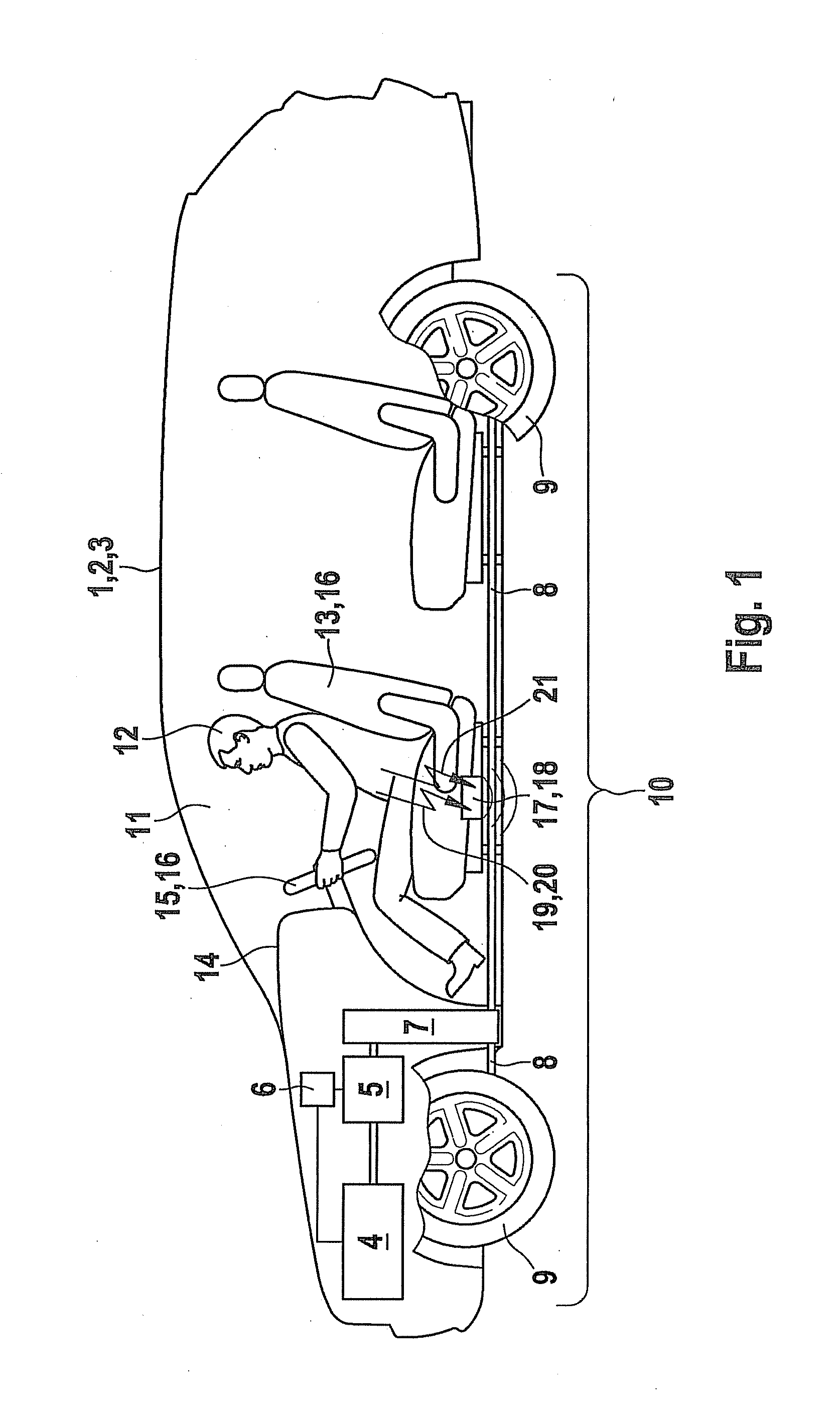

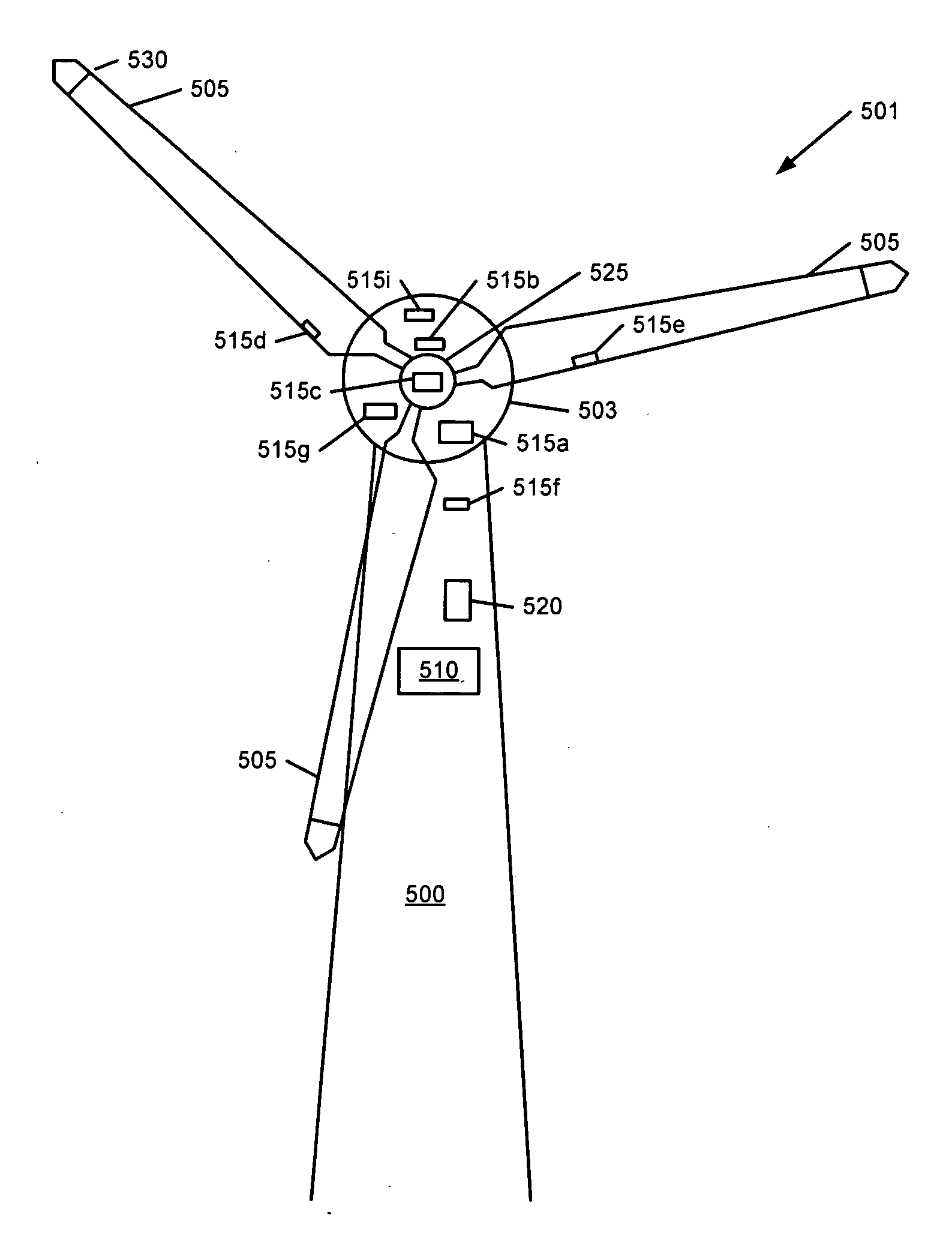

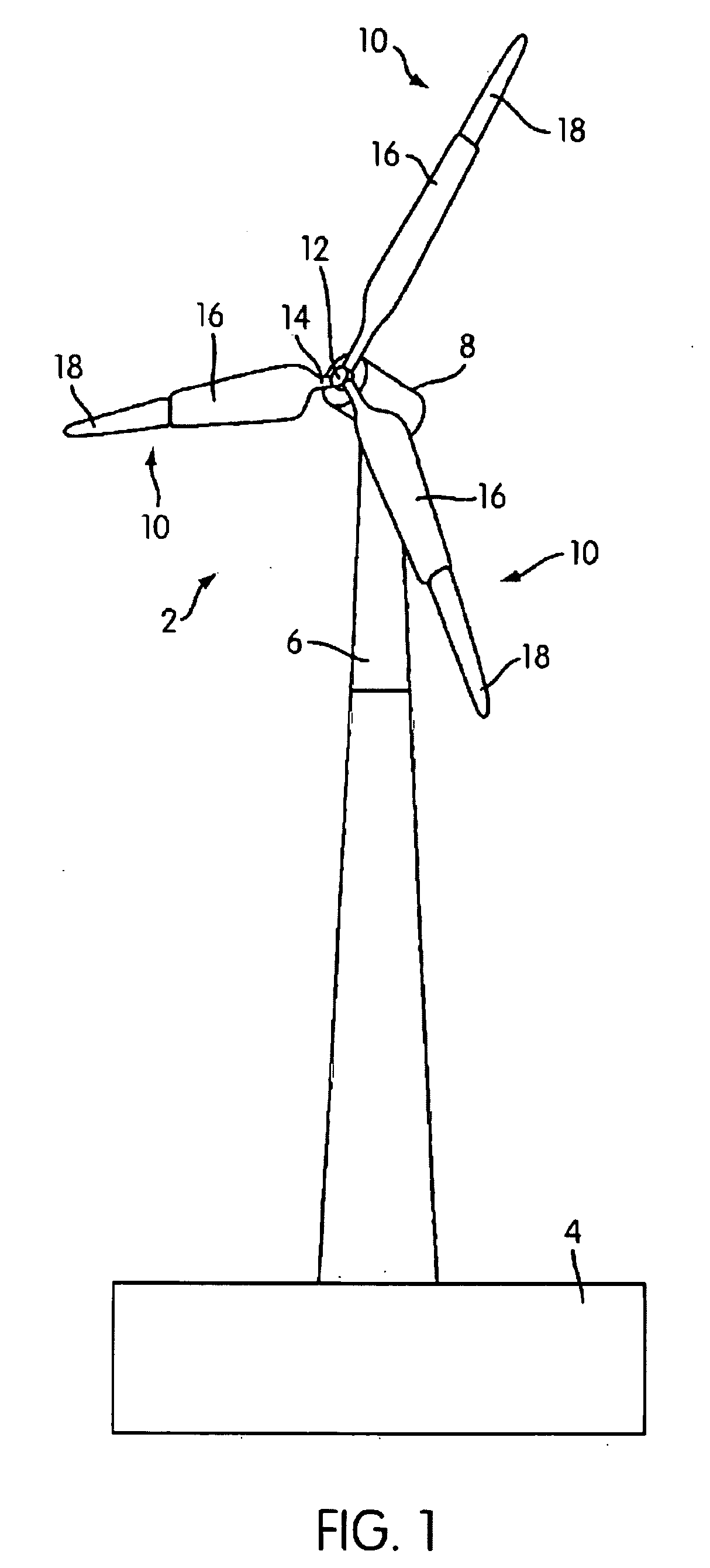

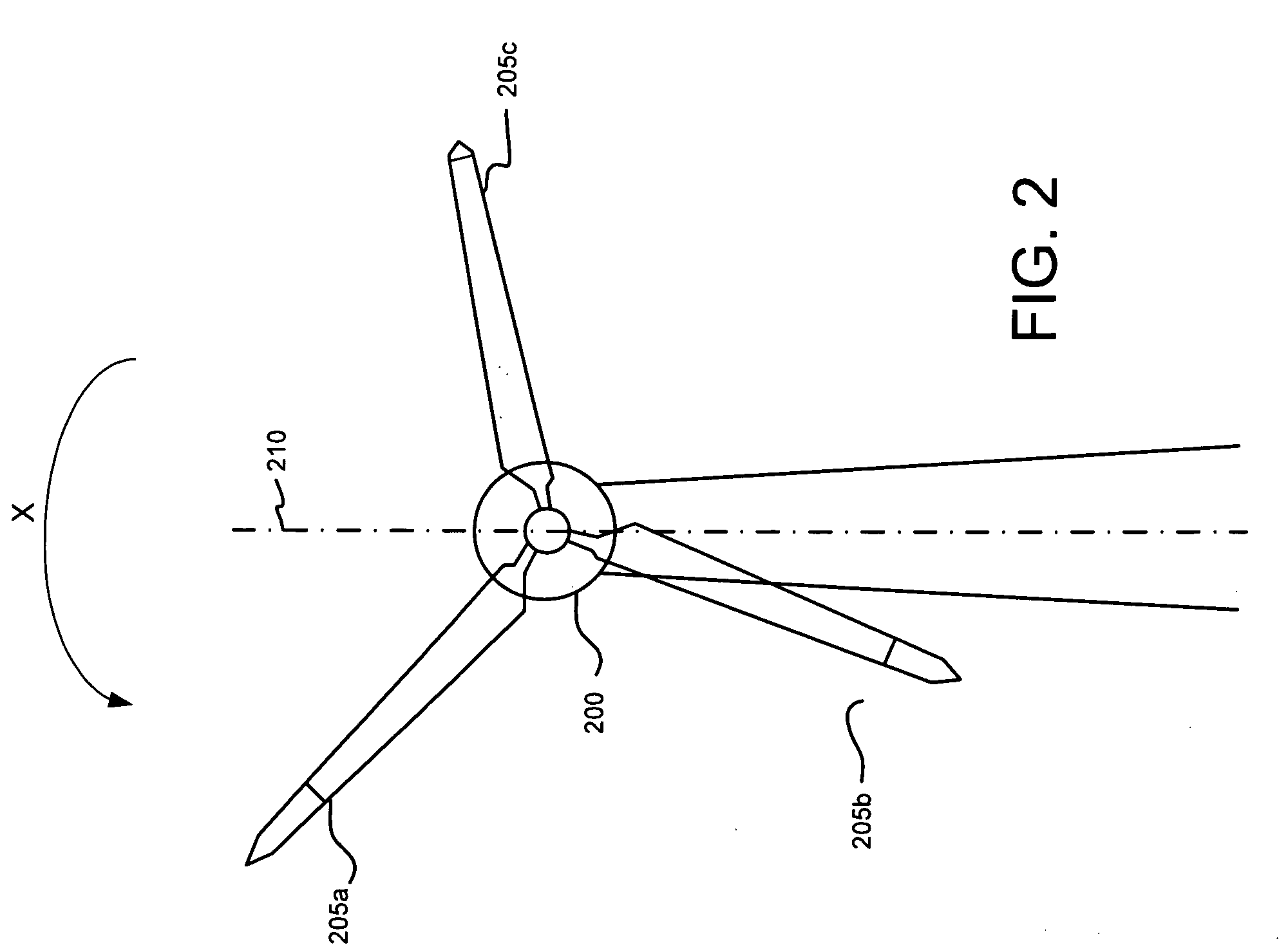

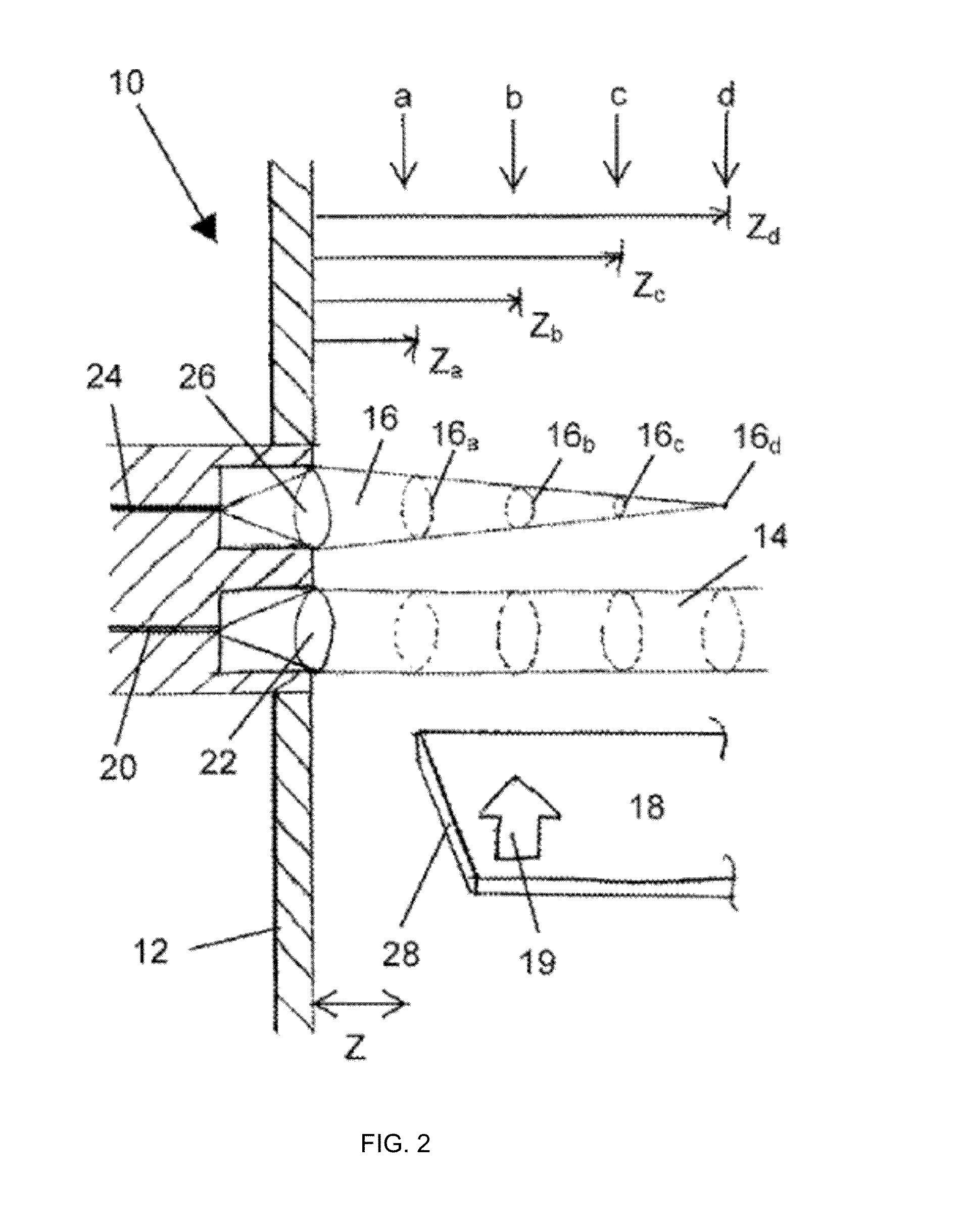

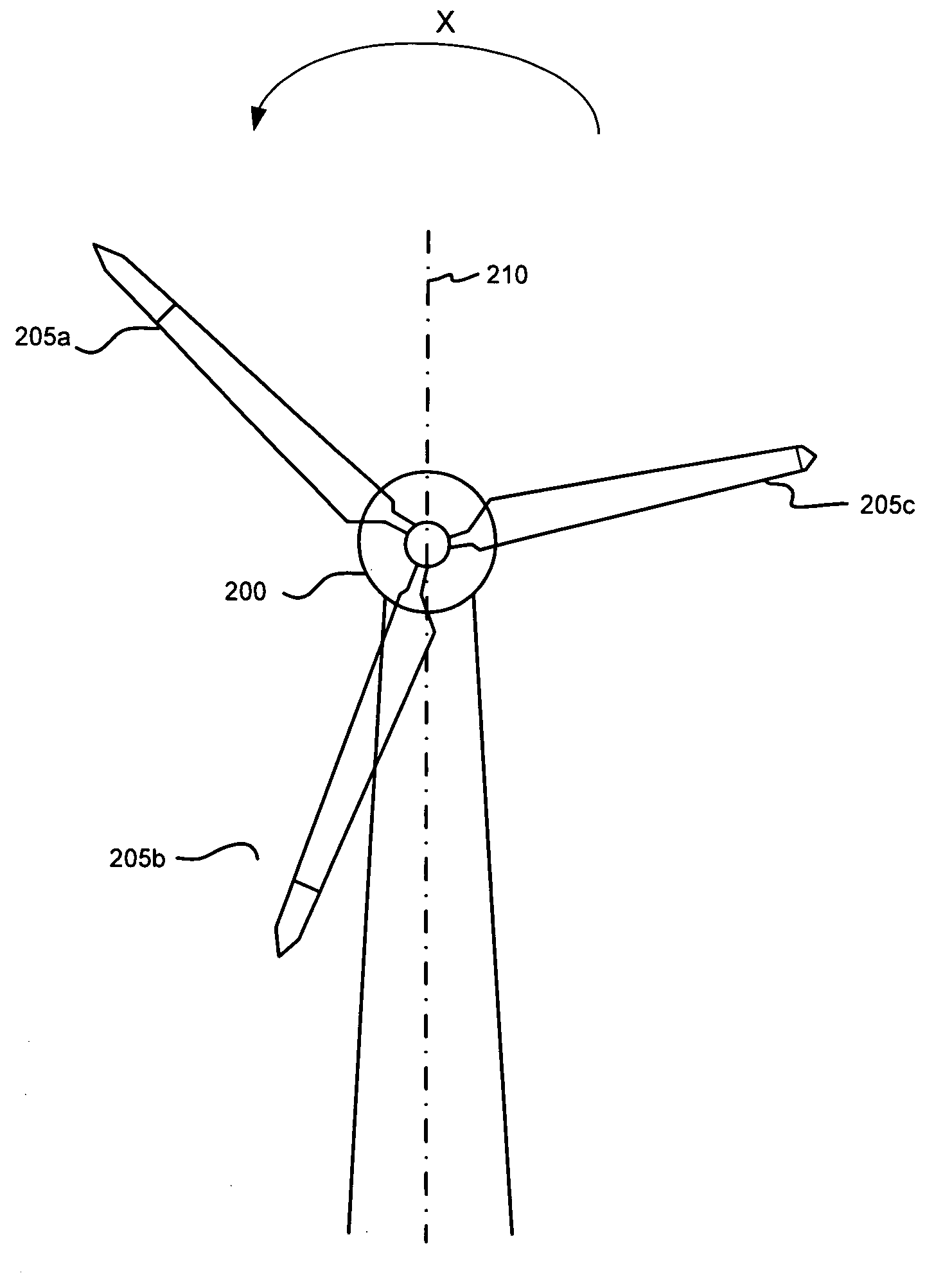

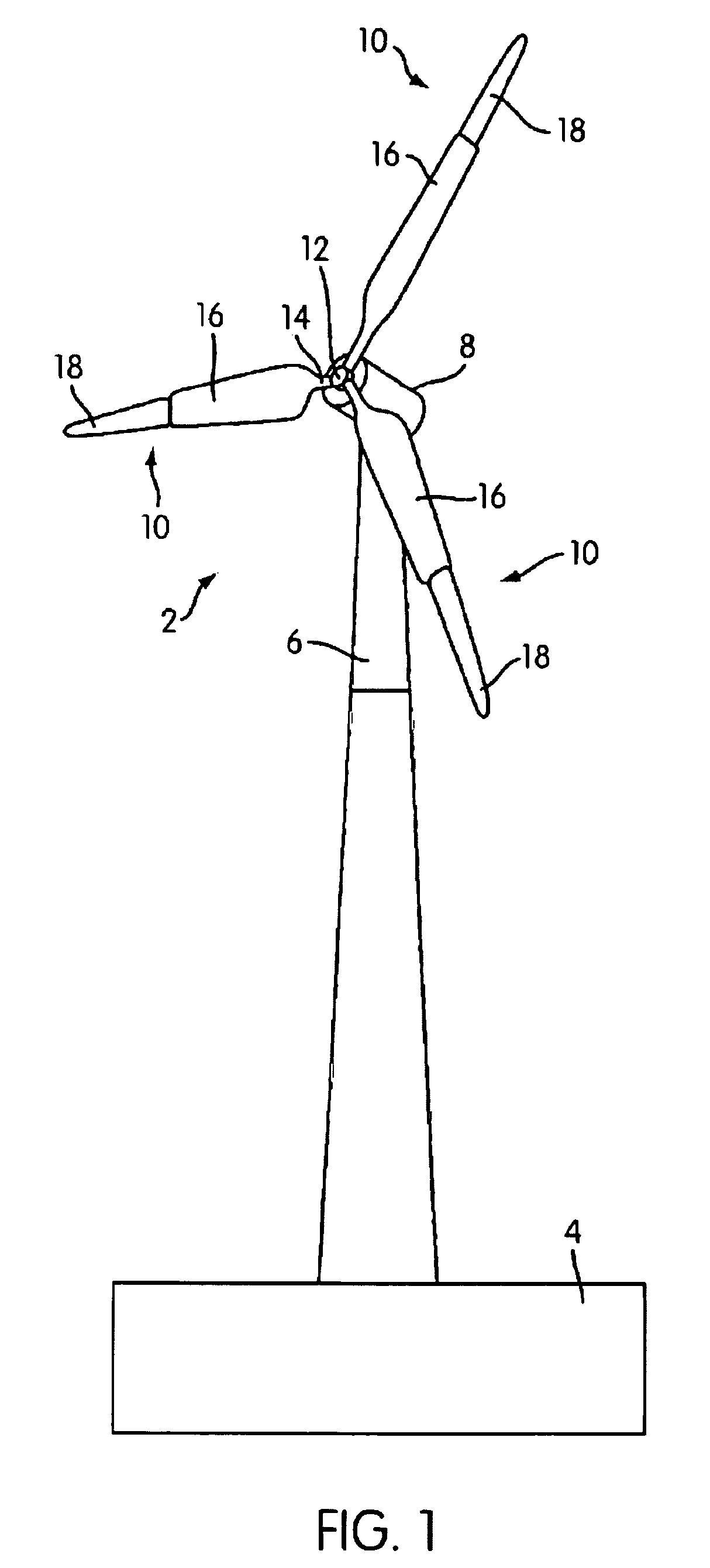

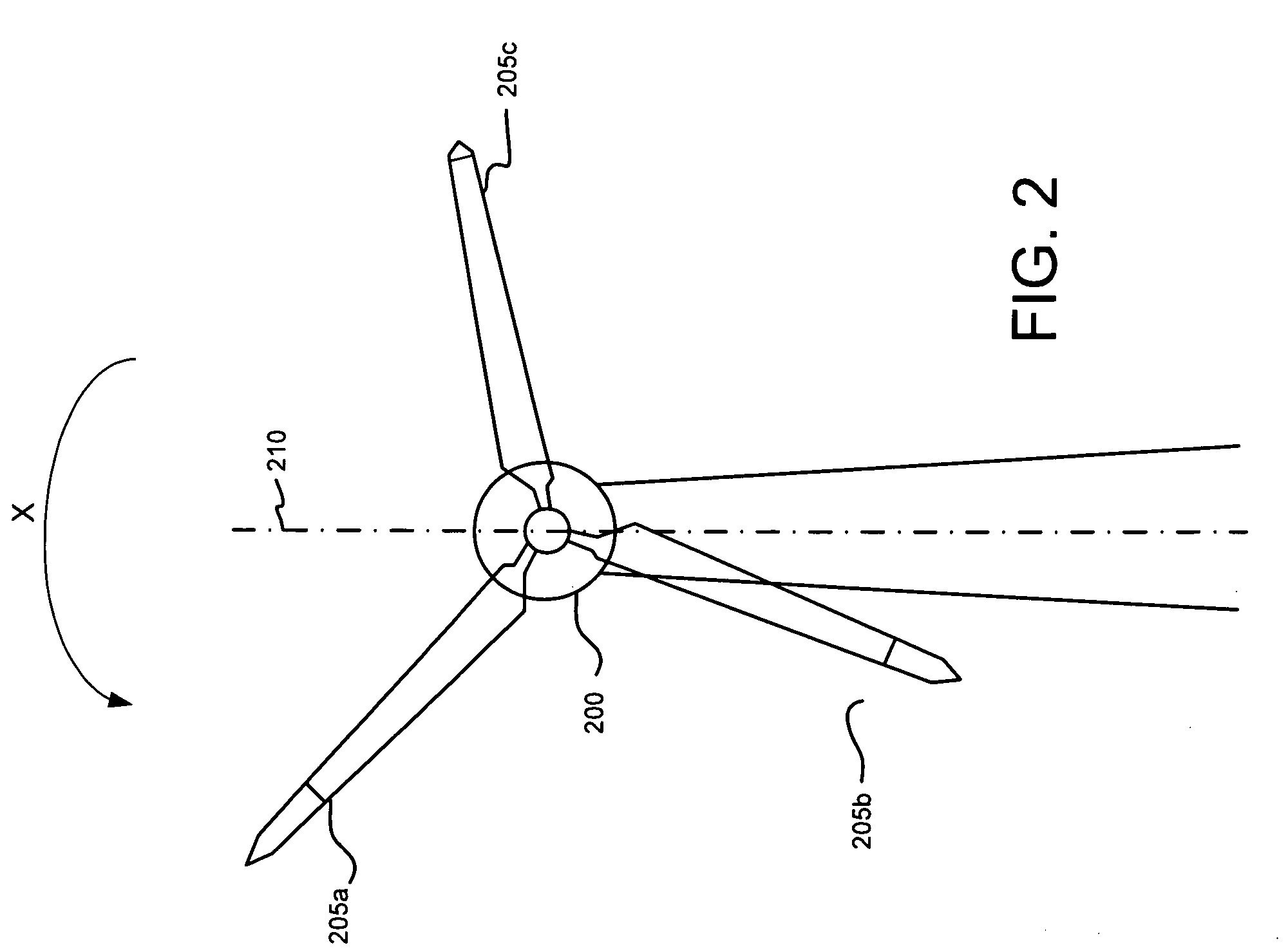

Control Modes for Extendable Rotor Blades

InactiveUS20100158687A1Maximize incomeReduce paymentPropellersRotary propellersAccelerometerEngineering

A wind turbine may be controlled in a variety of manners to optimize operating parameters. In one arrangement, for example, the length or the pitch of a wind turbine rotor blade may be adjusted to avoid harmonic resonance frequencies. In another example, the length of a rotor blade may be modified to reduce noise or to optimize profits or both. The controls may be based on data from various types of sensors including accelerometers, sound meters, strain gauges and the like. Actuation of extendable rotor blades can rotate wind turbine rotors without wind or generator pulsing affording multiple advantages. A battery test control may also be used to determine the operational readiness of a battery useful for a variety of purposes in a turbine.

Owner:FRONTIER WIND LLC

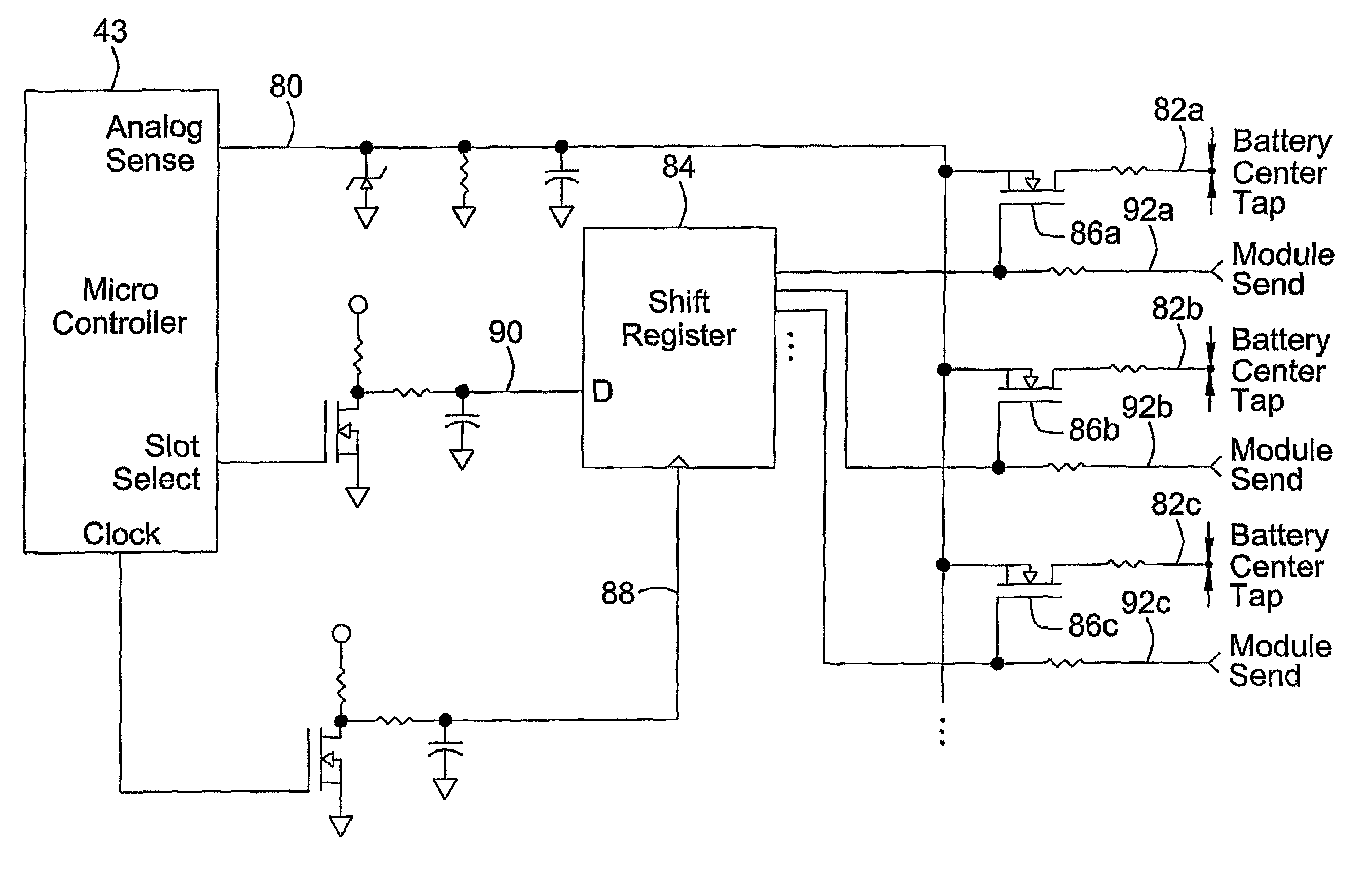

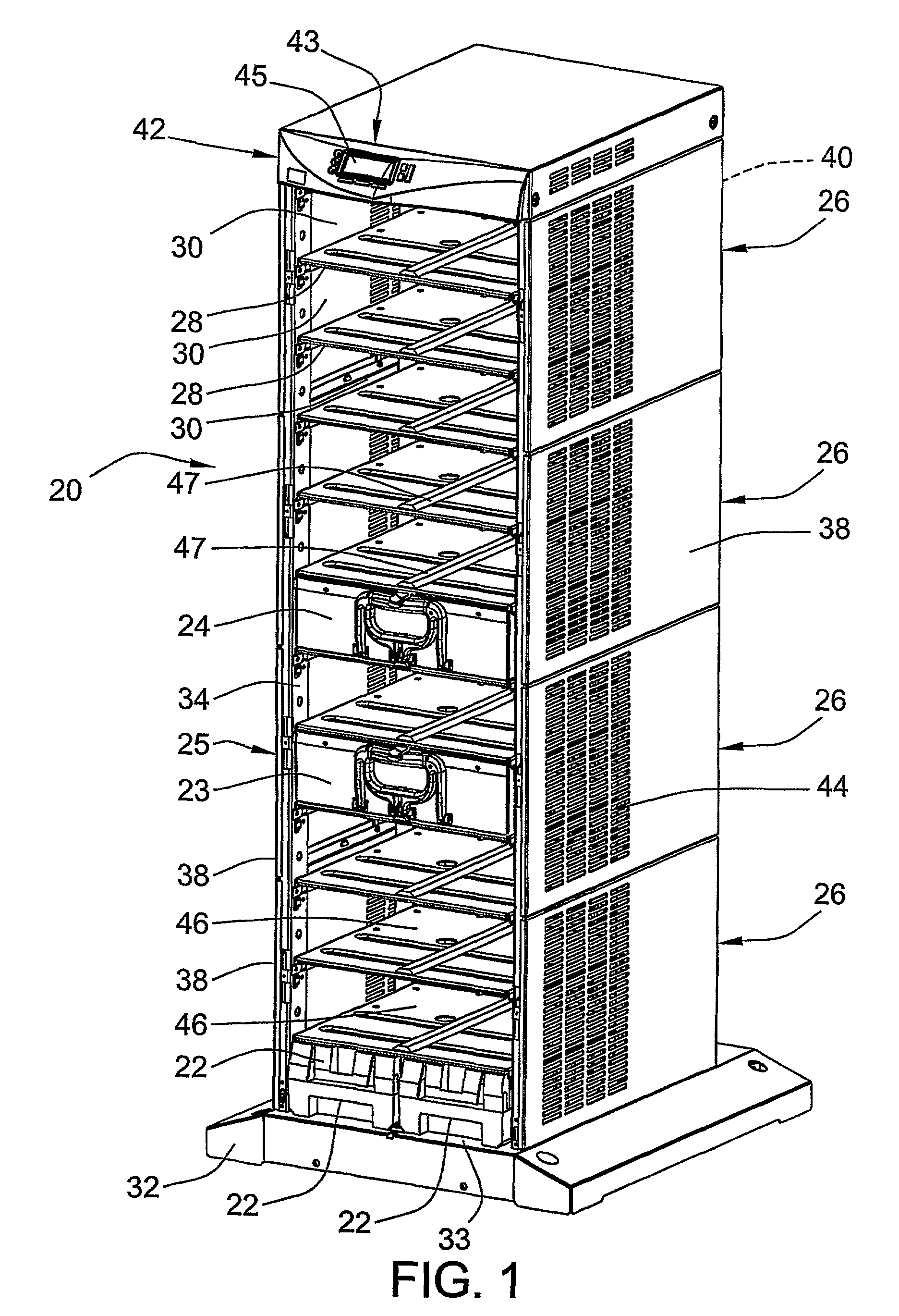

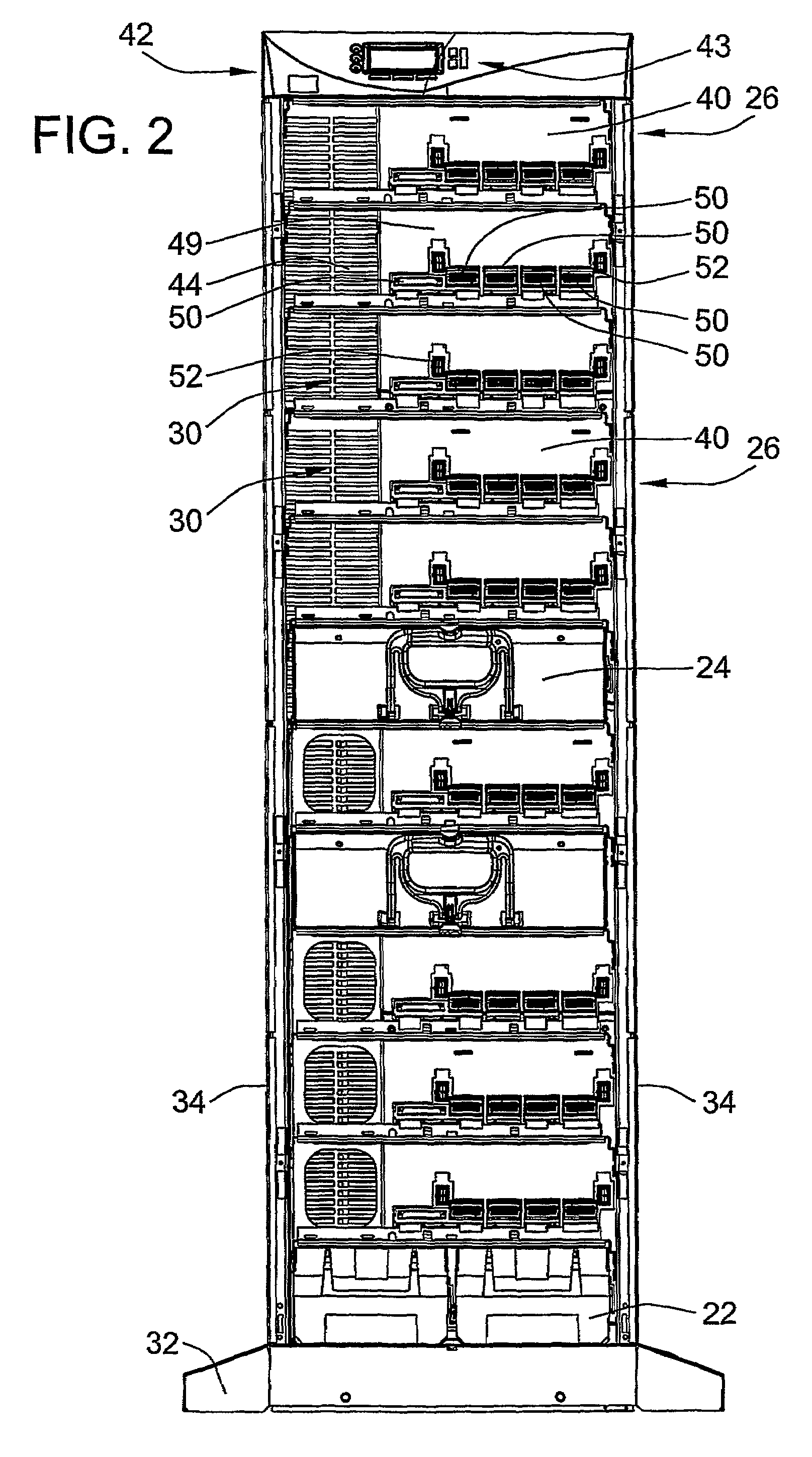

System for detecting defective battery packs

InactiveUS7132833B2Maximum flexibilityCurrent conducting connectionsMaterial analysis by electric/magnetic meansOperational readinessUninterruptible power supply

An electrical cabinet for an uninterruptibe power supply (UPS) system includes universal slots that can receive power modules, battery packs, or chargers. The back plane of the slot has connector terminals for battery packs and power modules. The cabinet can be easily reconfigured as desired by changing the number of power modules chargers or battery packs installed. Circuitry is provided that indicates the capacity and operational readiness of the cabinet. This circuitry monitors the battery packs in each slot, and isolates any detected fault to a particular pack.

Owner:POWERWARE

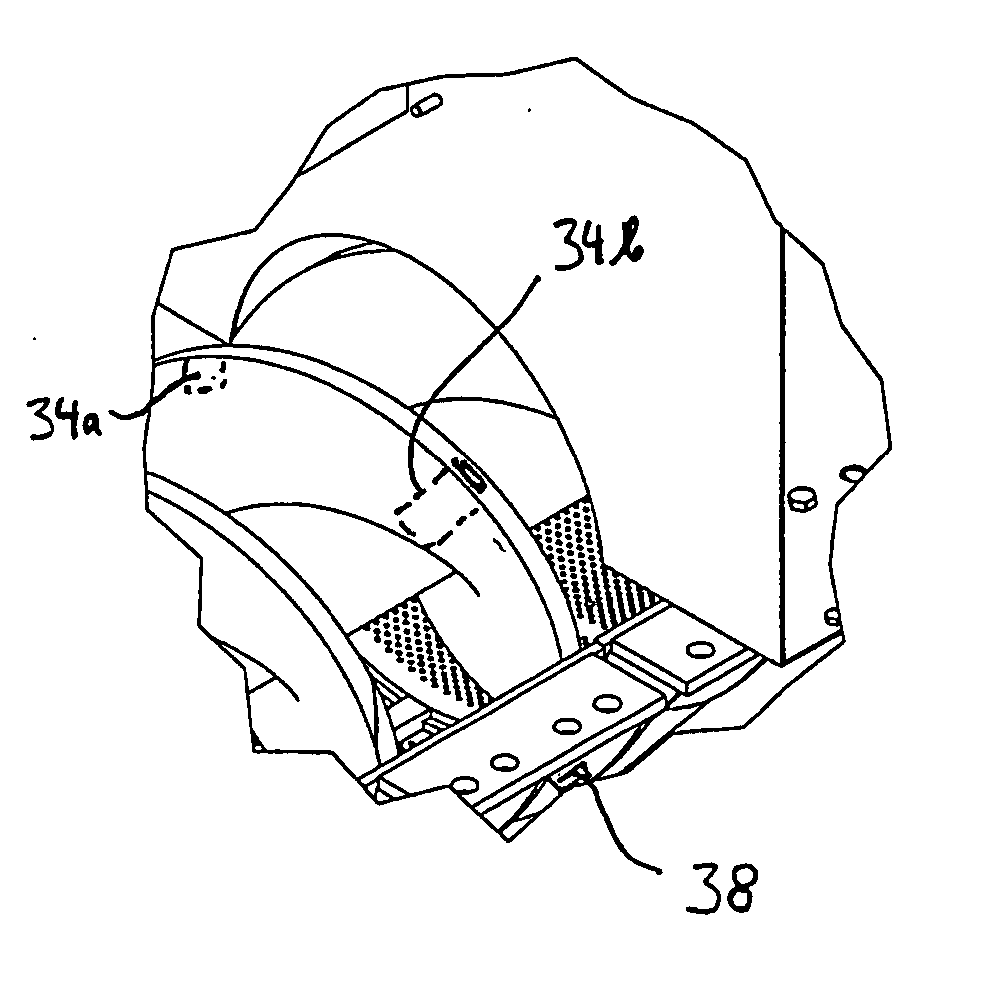

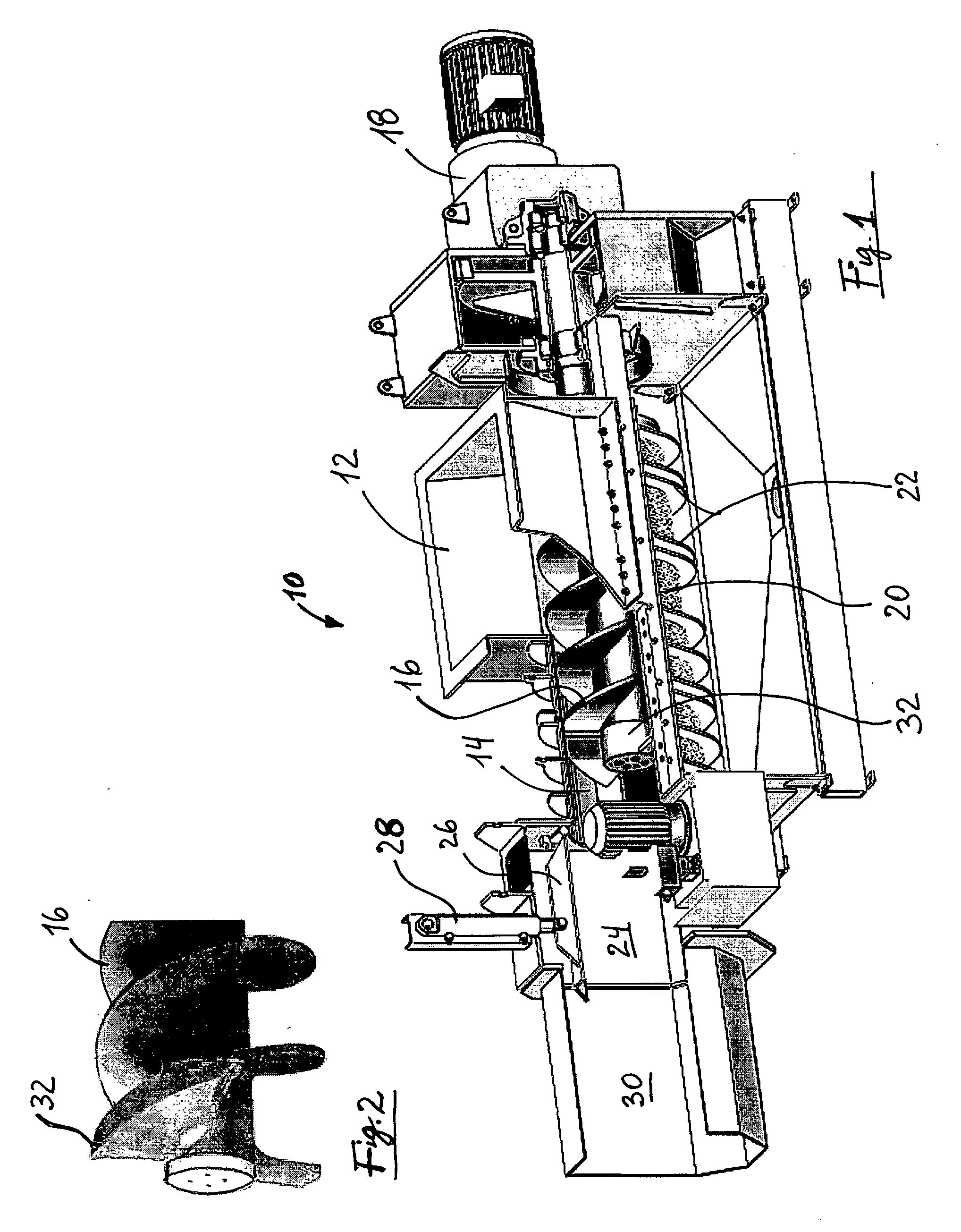

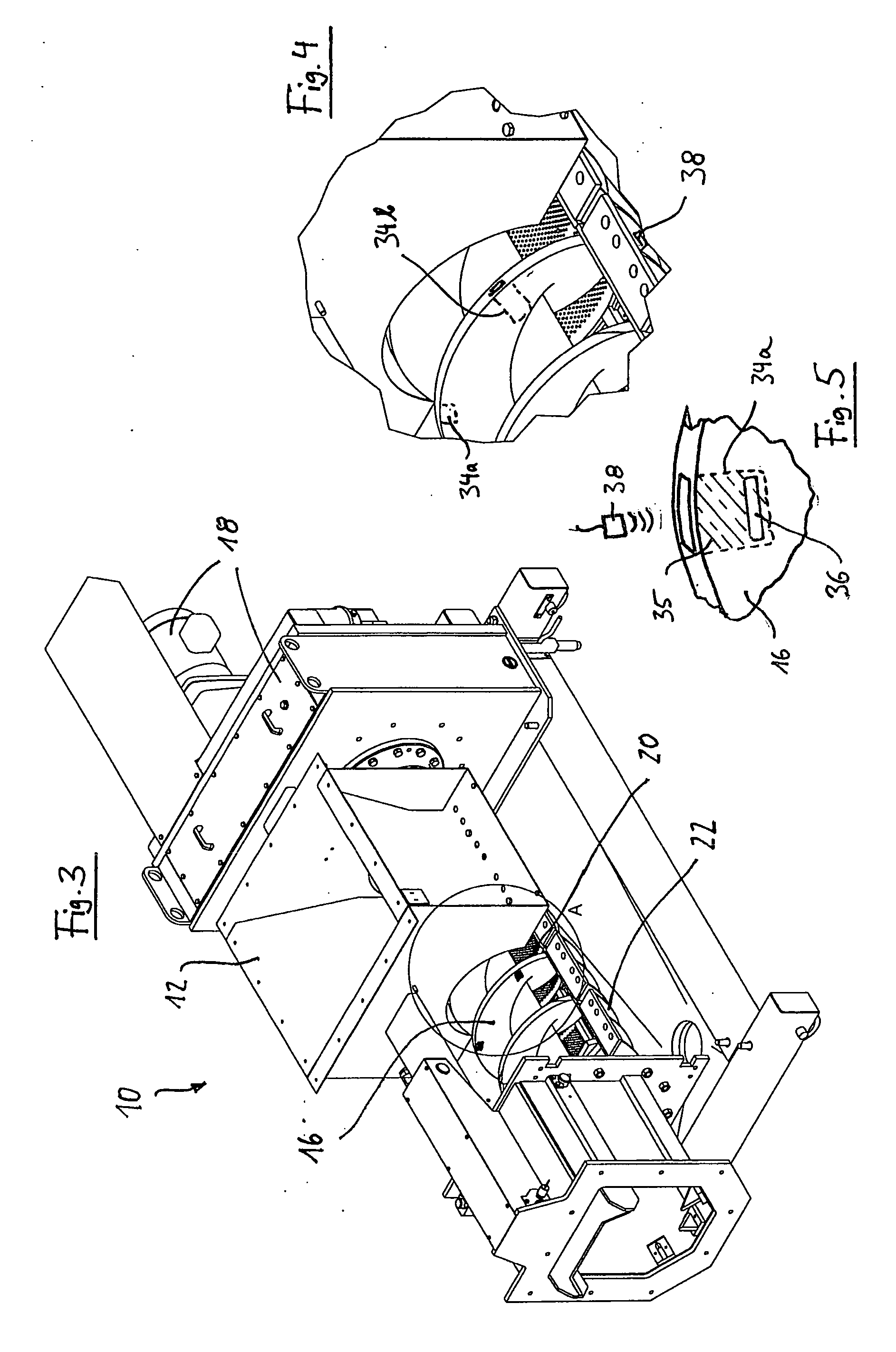

Wear detection by transponder destruction

InactiveUS20060226984A1Improve wear resistanceParticular wear-resistance or hardnessMeasurement devicesControl devices for conveyorsMachine partsMechanical wear

The invention relates to a system and a method for the detection of the wear state of machine parts which are subject to mechanical wear, by means of an electronic transmitting / receiving device (38) and at least one transponder device (36), which is embedded in the machine part (16) and sends back an acknowledgement signal in response to a transmitted signal which is transmitted by the transmitting / receiving device (38), in which case the reaching of a predetermined wear value can be indicated by the destruction of the transponder device (36) and by the lack of the acknowledgement signal associated with this. The invention is based on the discovery that the arrangement of a transponder device at a specific position which is a measure of a predetermined wear state means that the operational readiness of the transponder device, on the one hand, is indicated in advance by its signal return, and the reaching of the predetermined wear value is indicated by its destruction.

Owner:MERI ENTSORGUNGSTECHN FUR DIE PAPIERIND

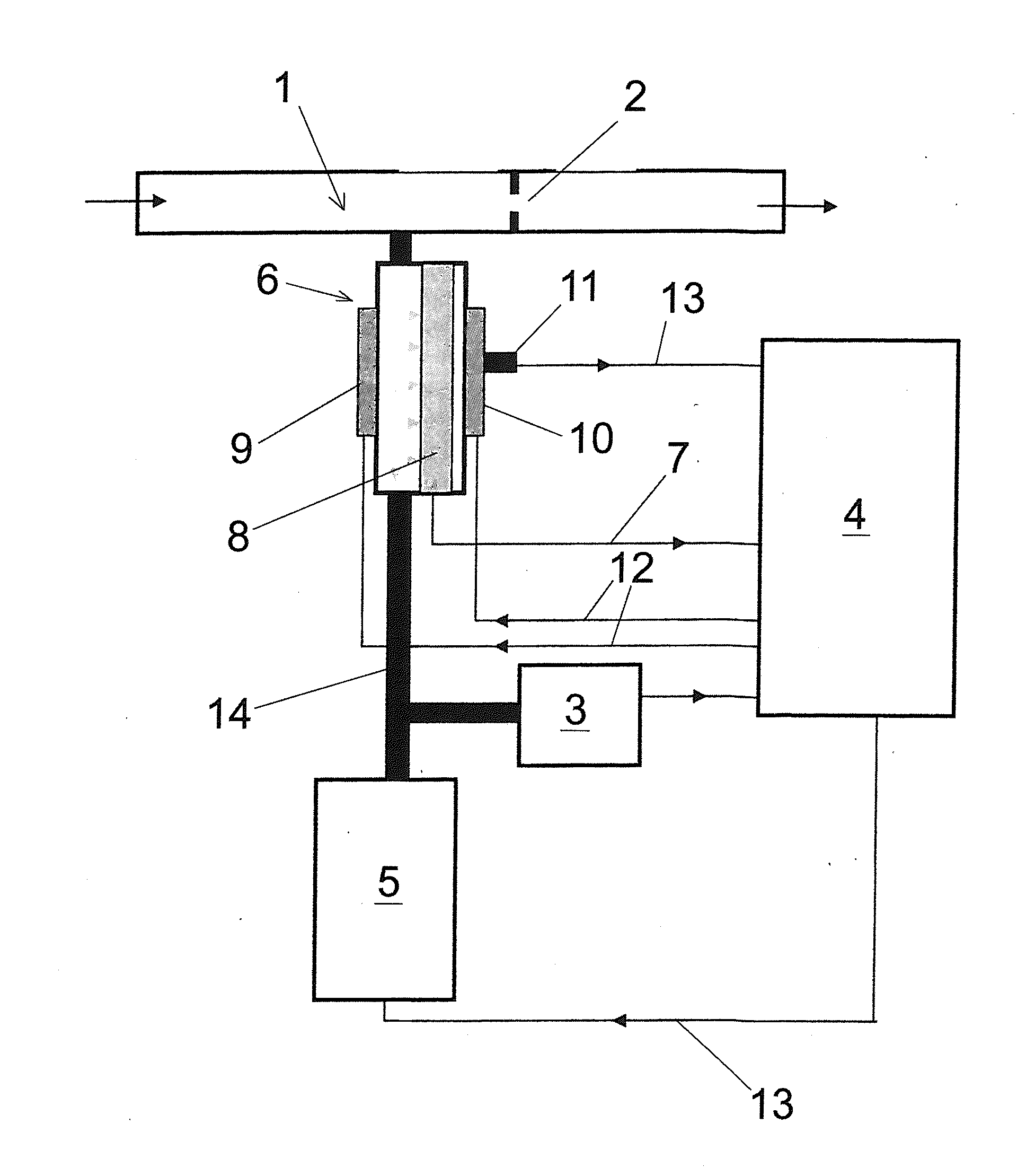

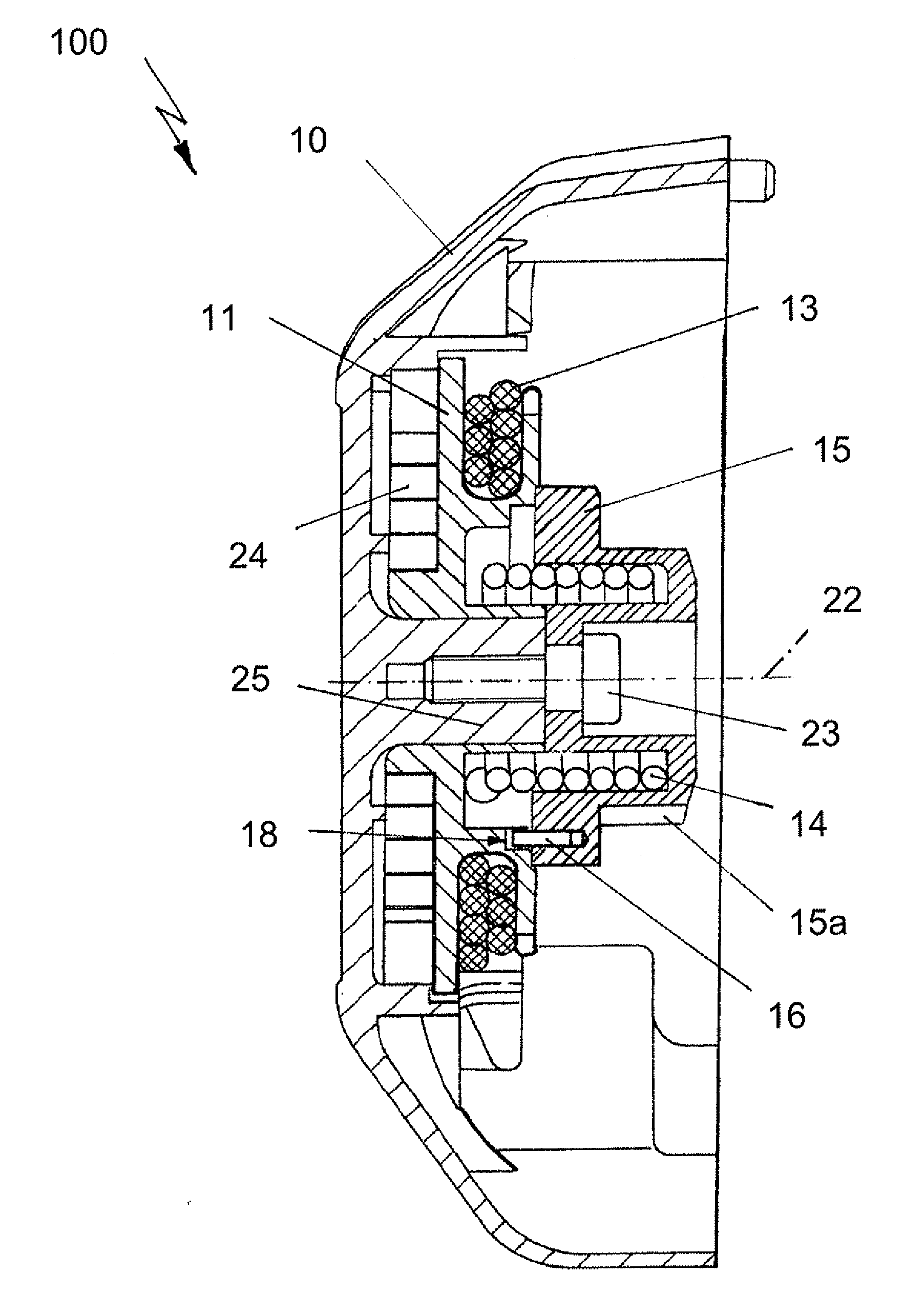

Alcohol-measuring device with fast operational readiness

ActiveUS20140061043A1Fast operational readinessStrong flow abilityImmobilised enzymesBioreactor/fermenter combinationsElectricityEngineering

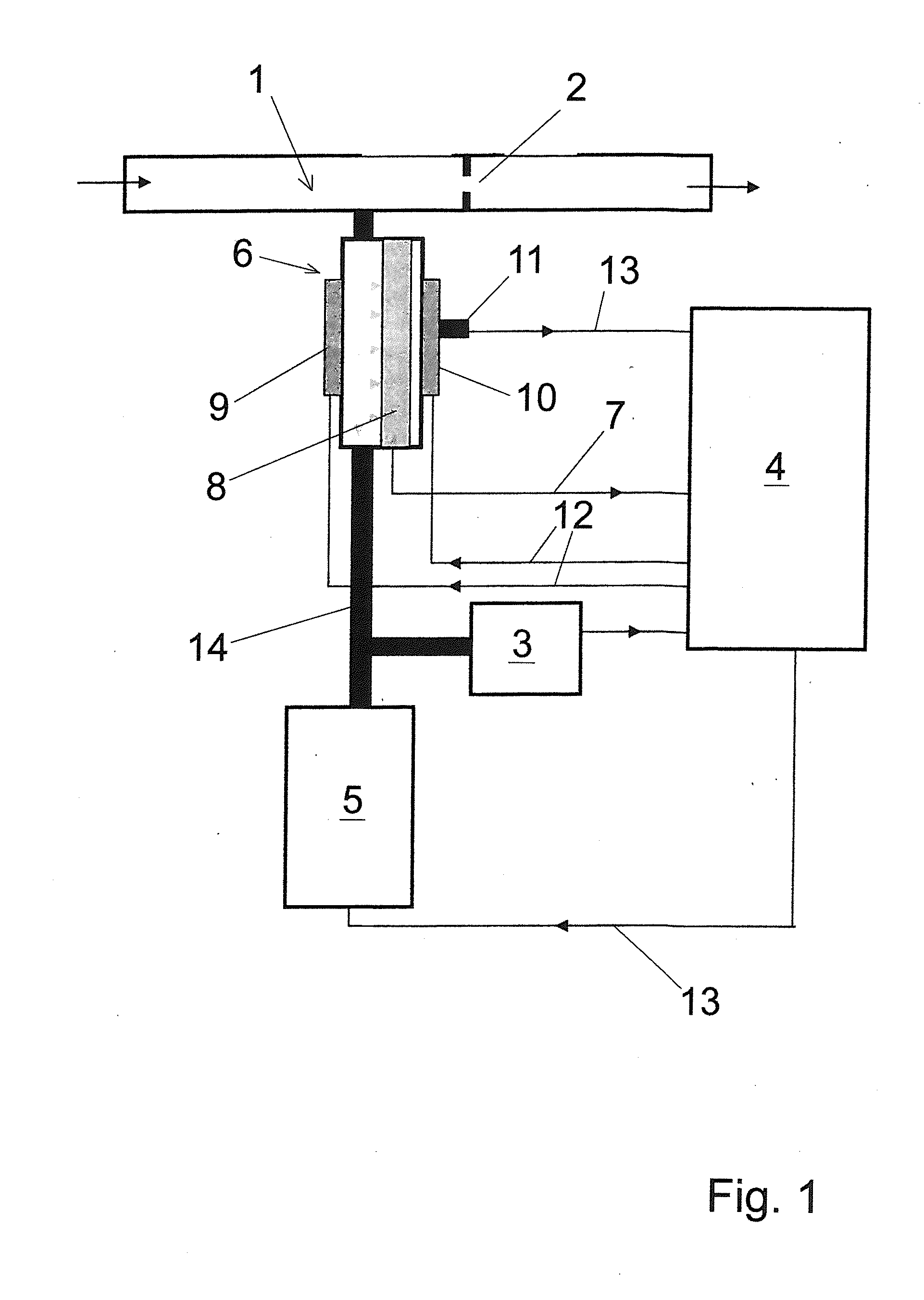

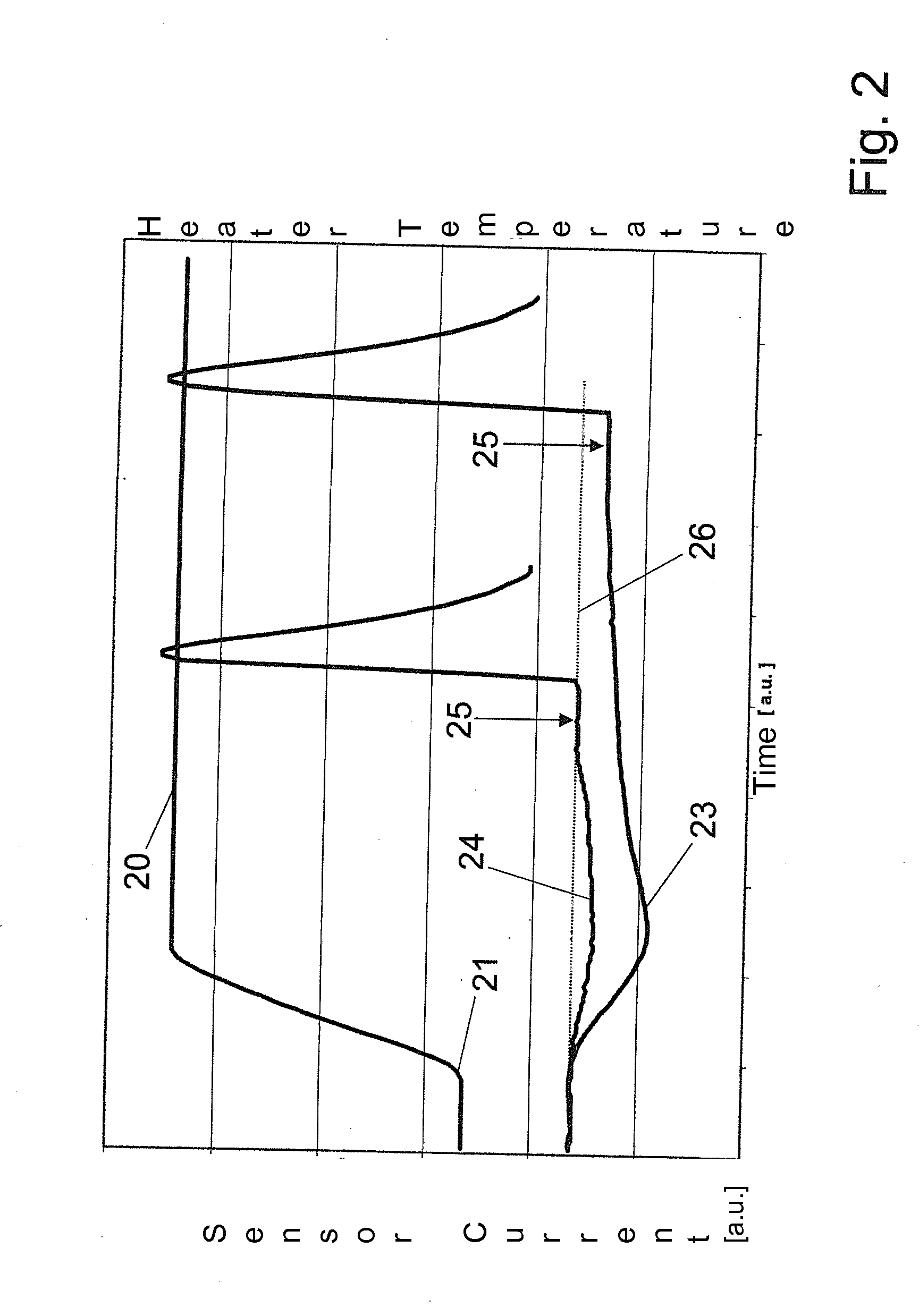

An alcohol-measuring device includes a mouthpiece (1), designed to enable a test subject to release breathing air into the mouthpiece, an electrochemical sensor (6), in fluidic connection with the mouthpiece (1) to measure alcohol in the breathing air of the test subject and a control unit. The sensor (6) has at least two heating elements (9, 10), one heating element arranged on the front side and one heating element arranged on the rear side of the sensor (6). The control unit (4) is electrically connected to the heating elements to supply electrical energy for the heating elements. The control unit (4) is set up to heat the heating elements each to a desired temperature. The control unit (4) is also electrically connected to the sensor (6) in order to determine the value of the alcohol concentration in the breathing air of the test subject.

Owner:DRAGER SAFETY

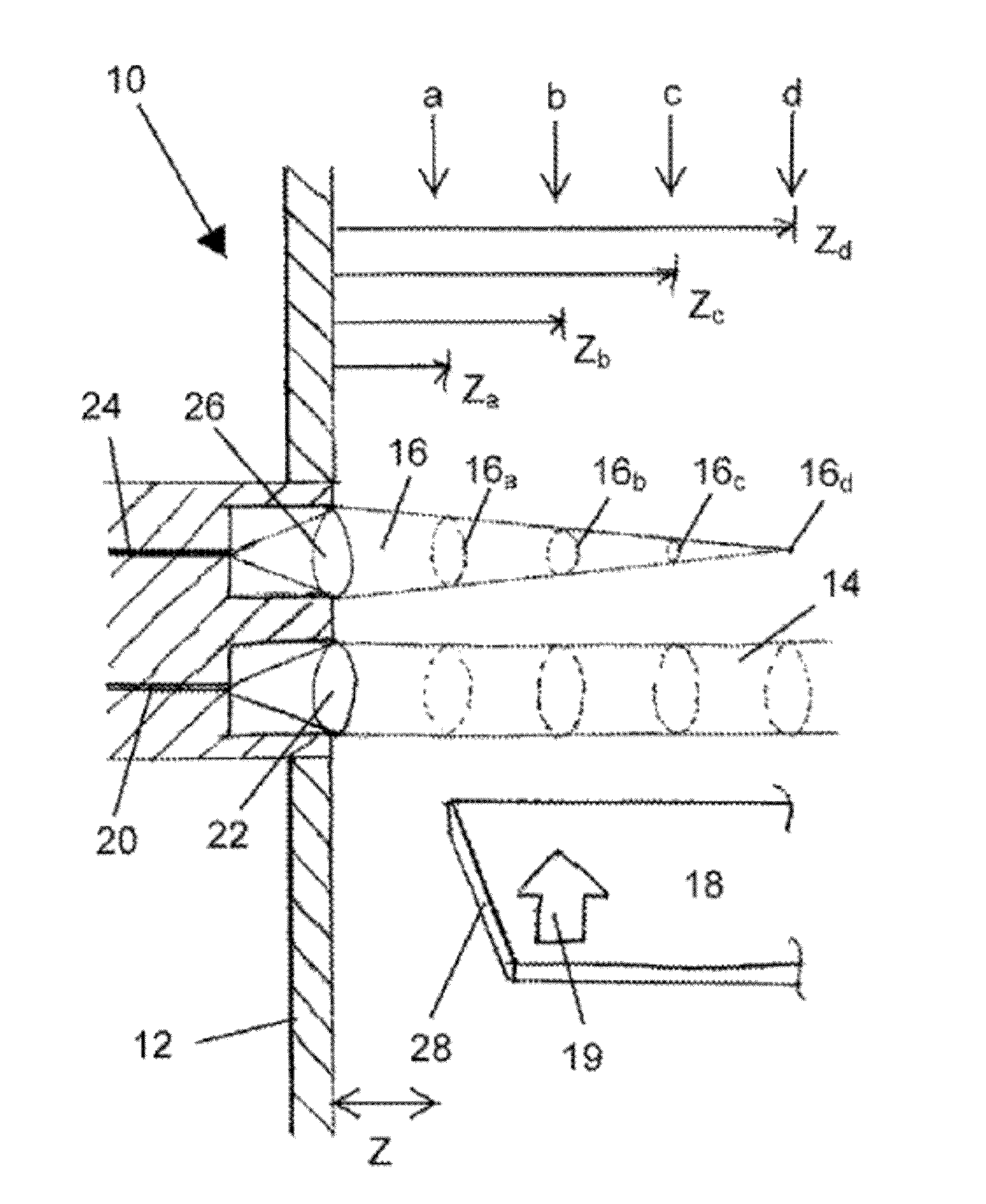

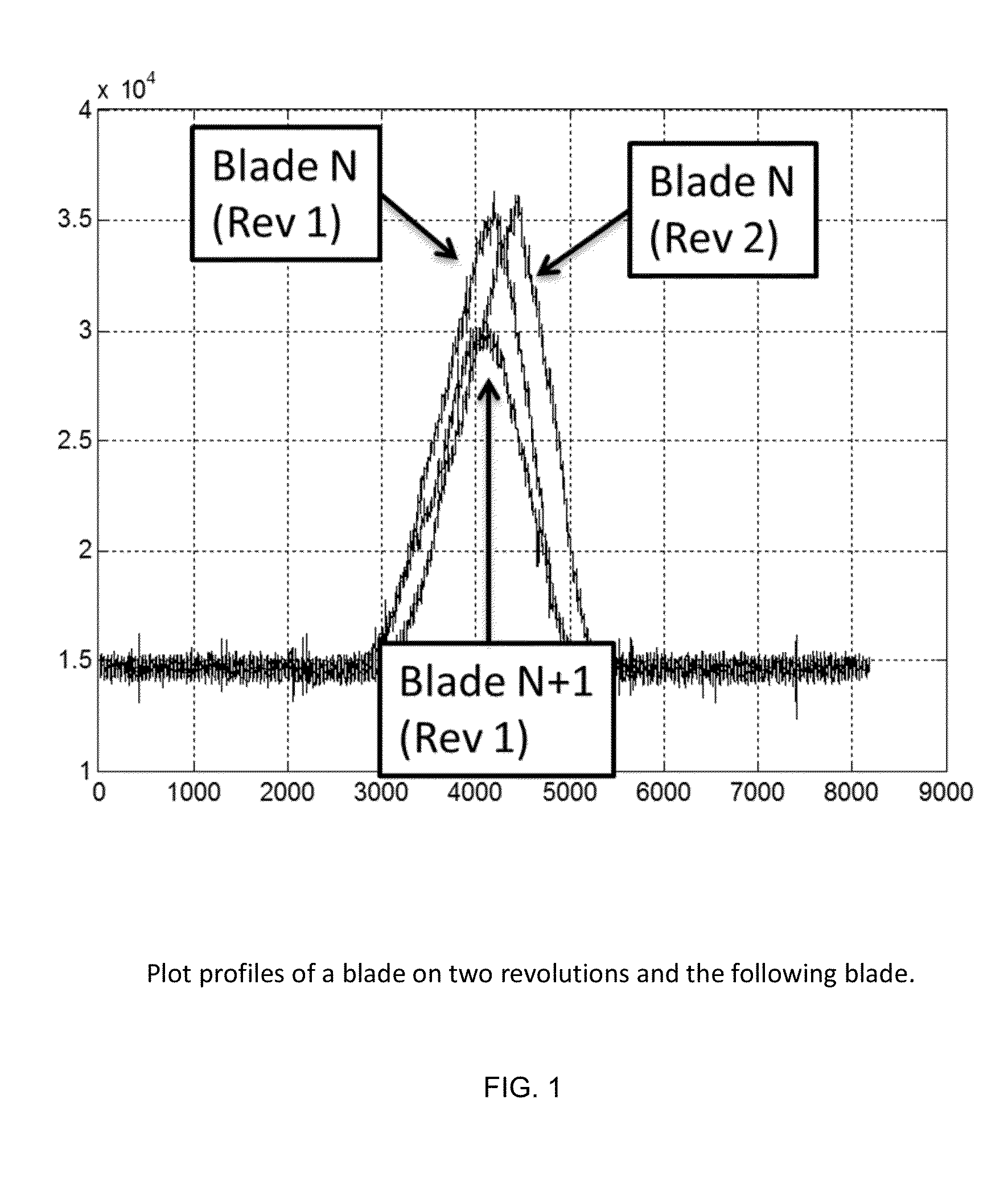

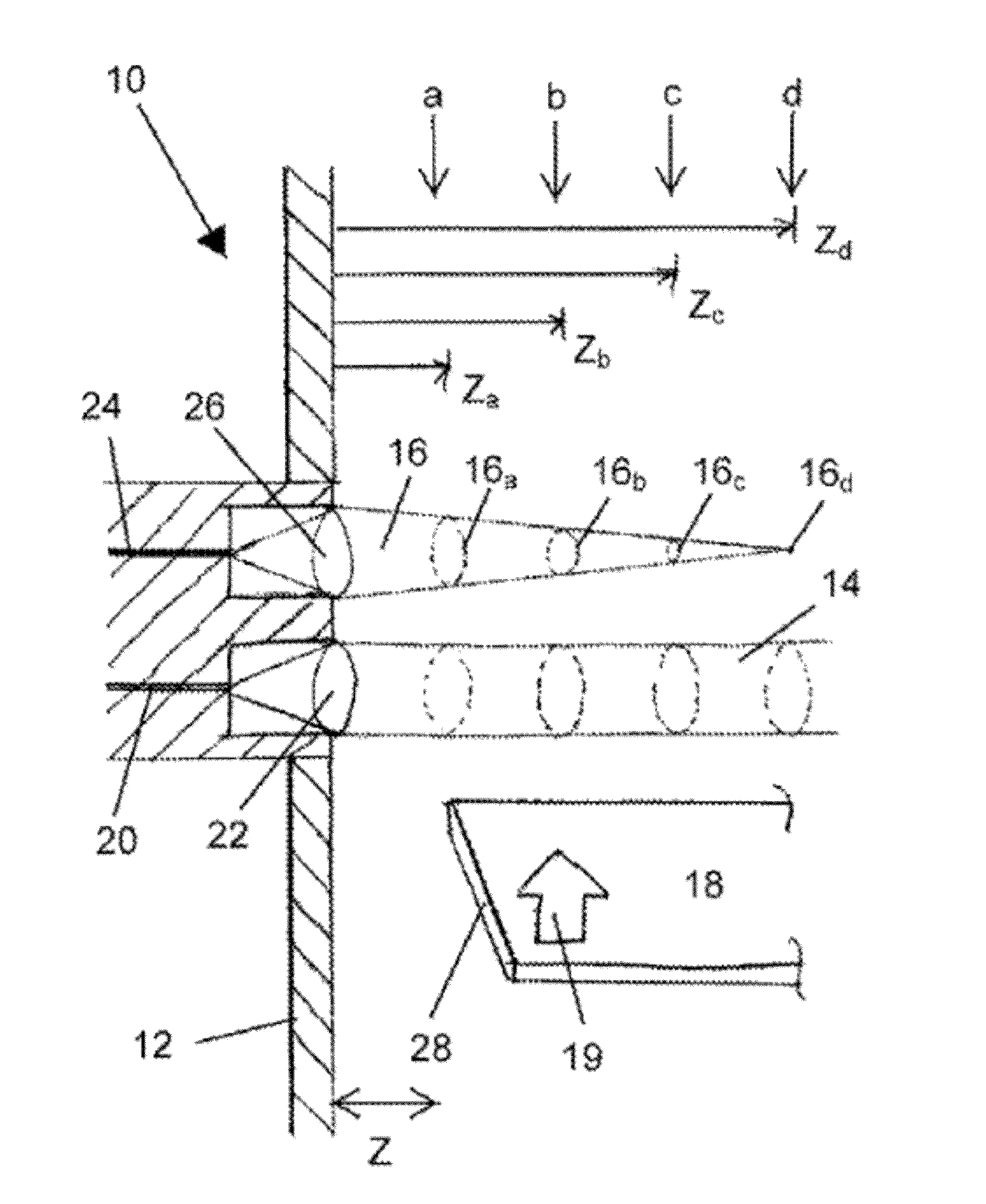

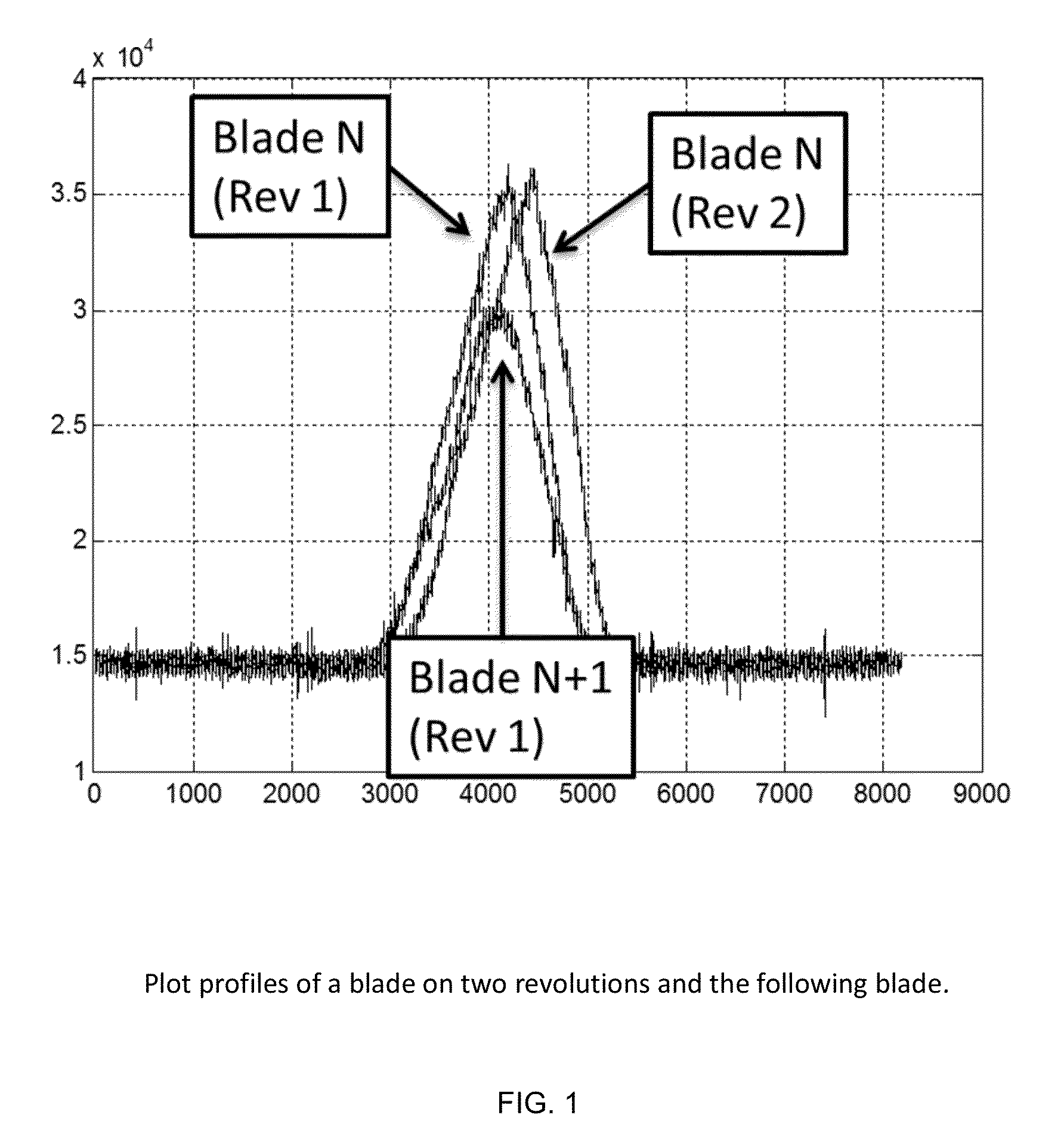

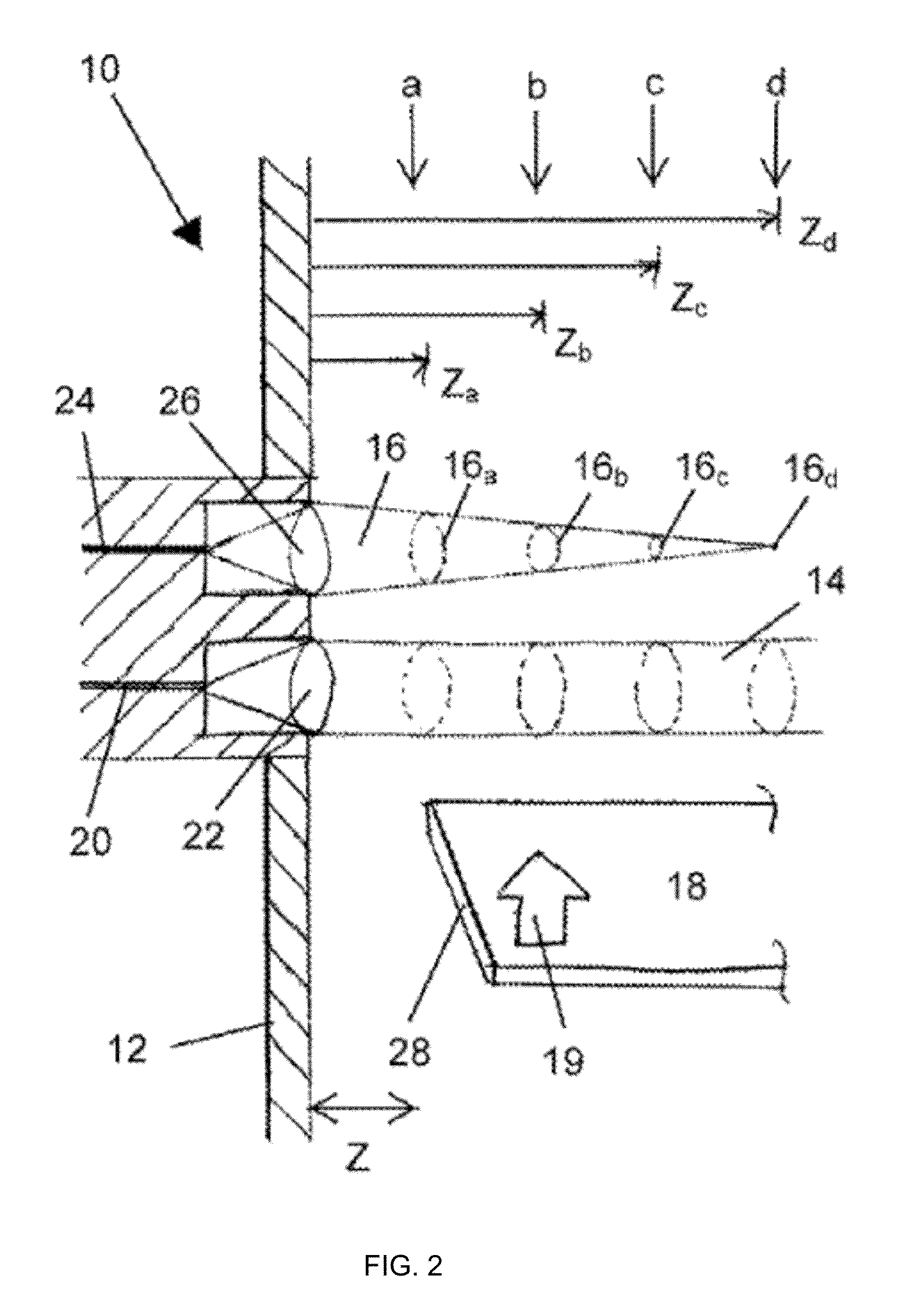

Method for Detecting Foreign Object Damage in Turbomachinery

ActiveUS20130006541A1Low costRemoval costPlug gaugesEngine fuctionsForeign object damageOperational costs

The present invention relates to systems and methods for real-time health monitoring of engines to monitor turbomachinery blades during engine operation and report anomalous behavior and shape of the blades if it occurs, such as damage by FOD. The system comprises sensor(s) for obtaining a blade reflection profile from a blade passing by the sensor(s) during a revolution of the rotor in combination with a processor for performing timing calculations and / or fingerprint comparisons with reference data to identify a change in blade fingerprint relative to the reference data, which may indicate blade damage. Such systems can reduce operational costs, enhance safety and improve operational readiness by facilitating condition-based maintenance of engine rotors as opposed to schedule-based solutions. The invention can prevent the needless loss of life and assets caused by undetected minor levels of blade damage that may lead to unexpected catastrophic failure of an engine.

Owner:PRIME PHOTONICS LC

Control modes for extendable rotor blades

InactiveUS8128361B2Reduce noiseVibration minimizationPropellersWind motor controlAccelerometerEngineering

A wind turbine may be controlled in a variety of manners to optimize operating parameters. In one arrangement, for example, the length or the pitch of a wind turbine rotor blade may be adjusted to avoid harmonic resonance frequencies. In another example, the length of a rotor blade may be modified to reduce noise or to optimize profits or both. The controls may be based on data from various types of sensors including accelerometers, sound meters, strain gauges and the like. Actuation of extendable rotor blades can rotate wind turbine rotors without wind or generator pulsing affording multiple advantages. A battery test control may also be used to determine the operational readiness of a battery useful for a variety of purposes in a turbine.

Owner:FRONTIER WIND LLC

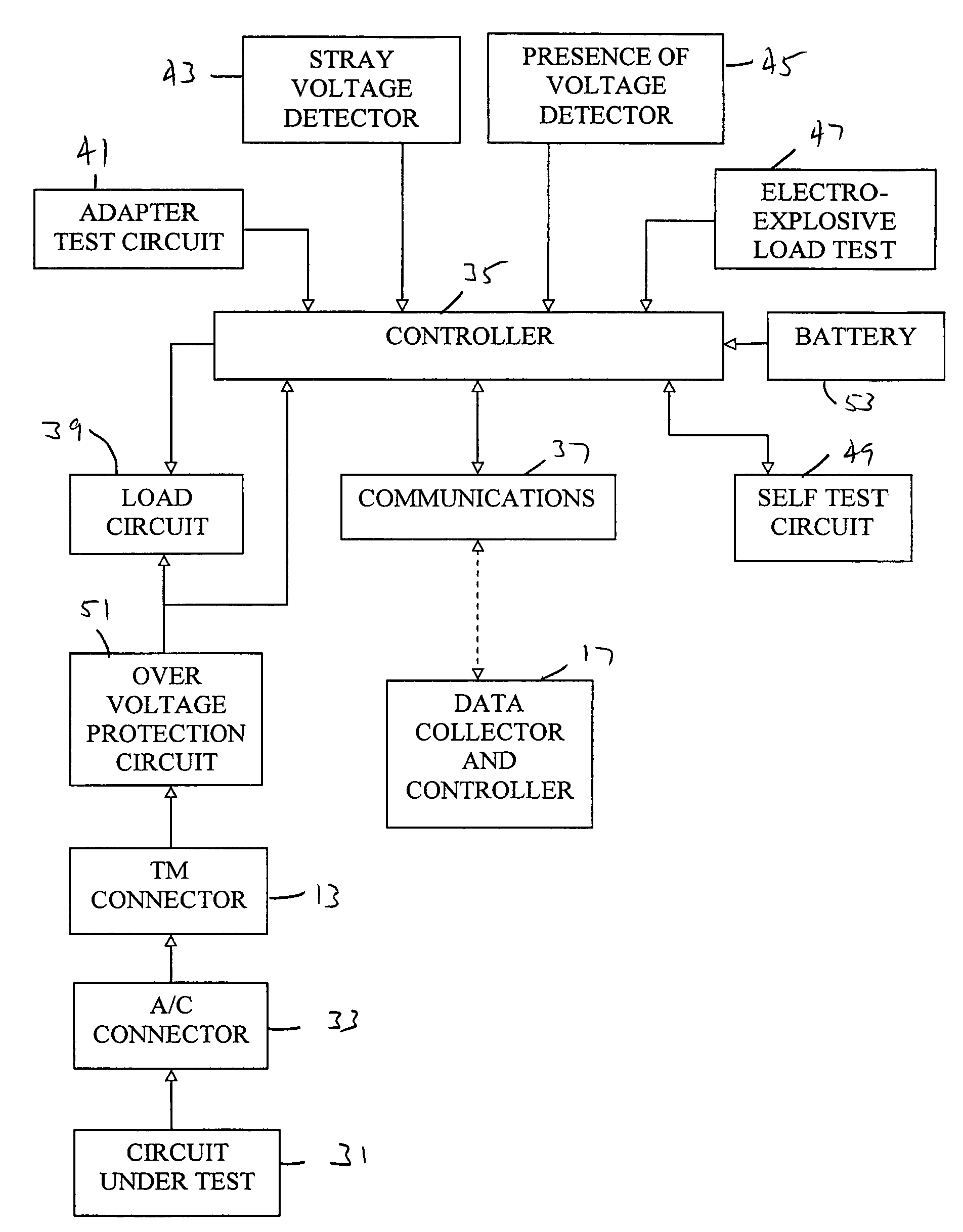

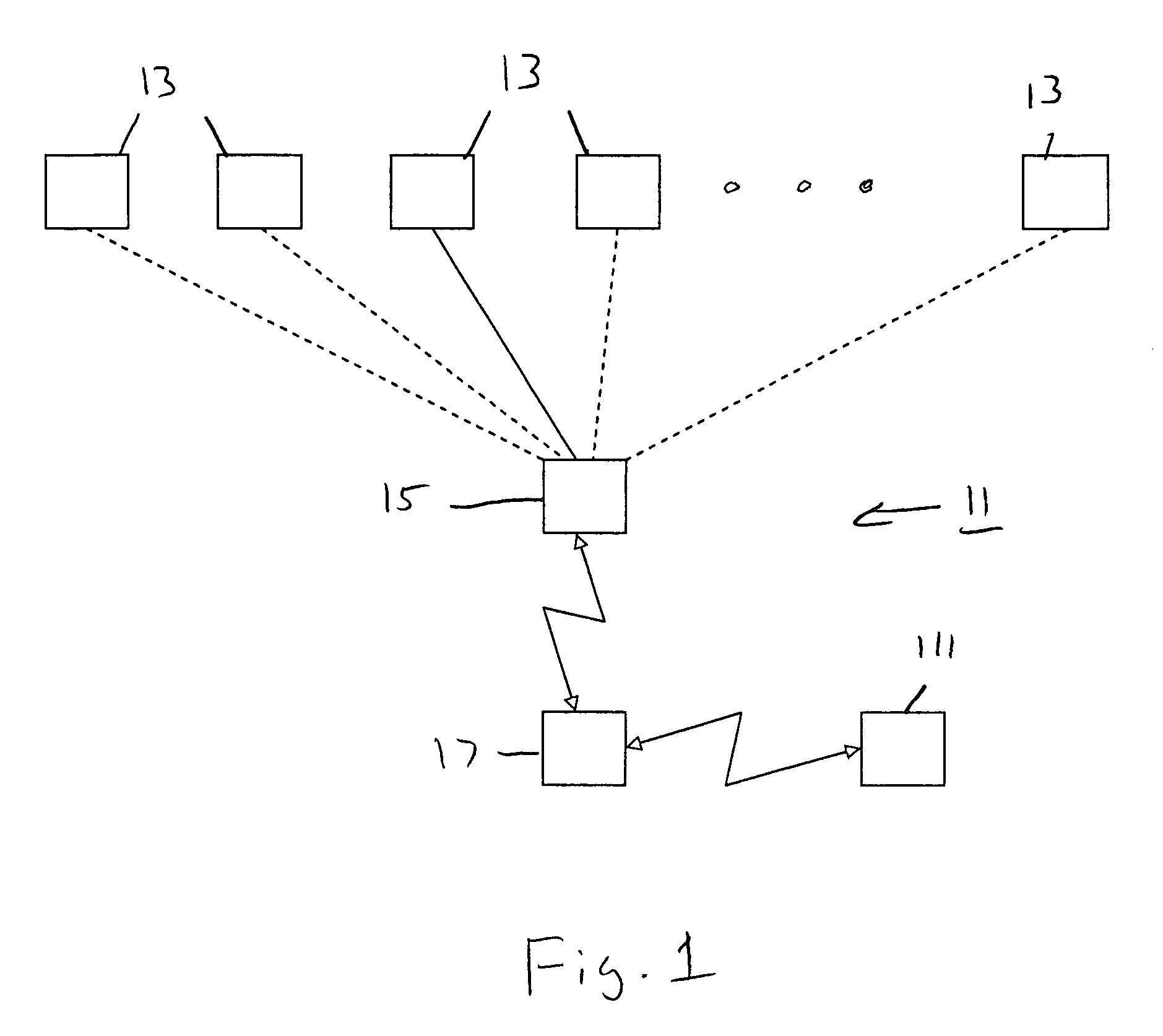

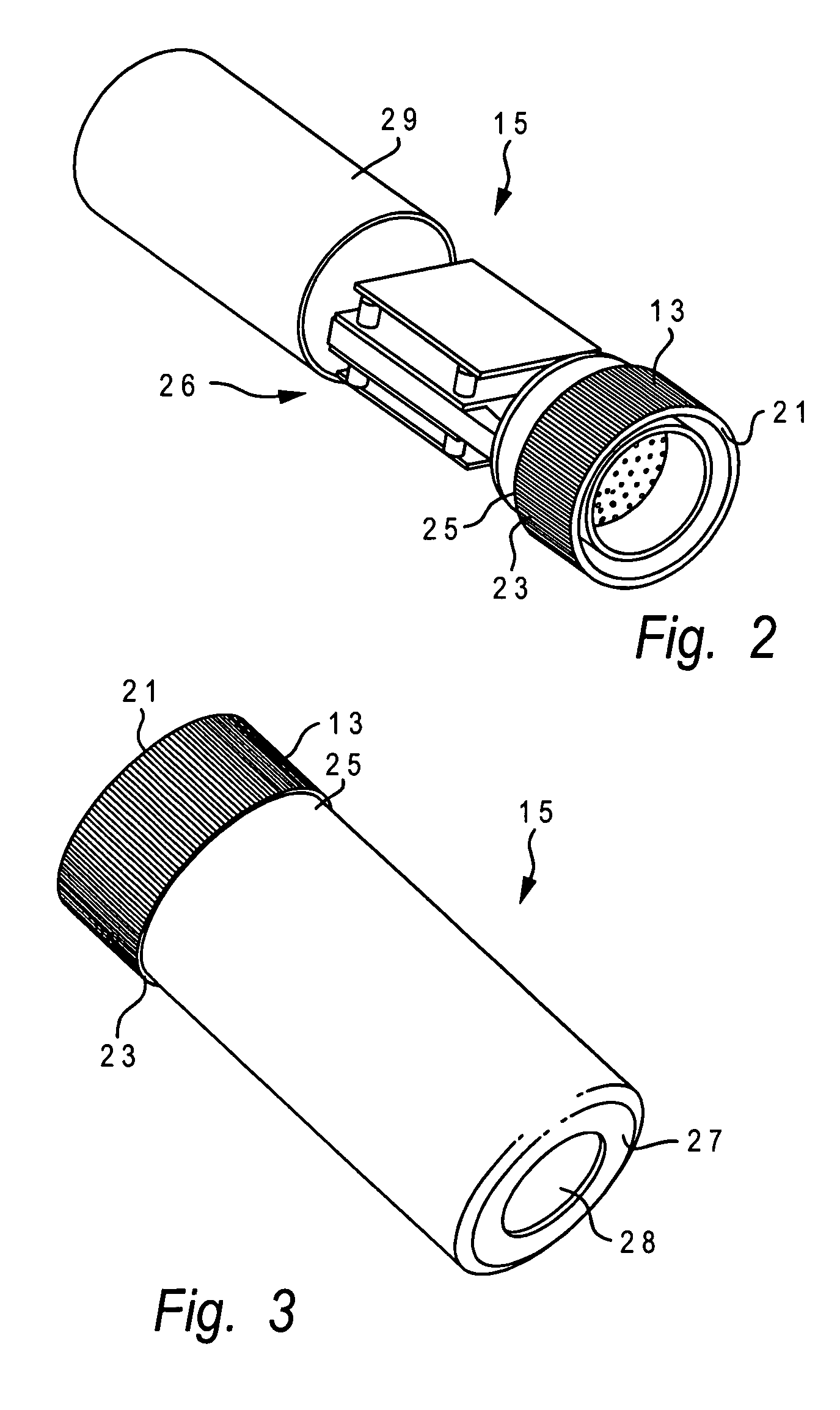

Wireless method and apparatus for testing armament circuits

ActiveUS7613963B1Low equipment requirementsReduce weightAircraft componentsDirection controllersTelecommunications linkData acquisition

The testing apparatus of the present invention provides a self-contained test module that connects to the weapons firing circuit on the weapons platform. This test module communicates with a data collector and controller that is carried by a technician or operator. The communication link between the test module and the data collector and controller is wireless so that the technician can move about without interference from the cable. The test module, which contains a digital voltage detector, is more accurate than prior analog voltage detectors. The test module connects to different connectors, allowing for a reduction of equipment needed in the testing apparatus and providing a significant savings in weight. The data collector and controller stores test data of a particular circuit over a period of time and performs analysis on that test data to identify upcoming or potential problems so that repair can be made before operational readiness is compromised by a circuit failure.

Owner:WILLIAMSRDM

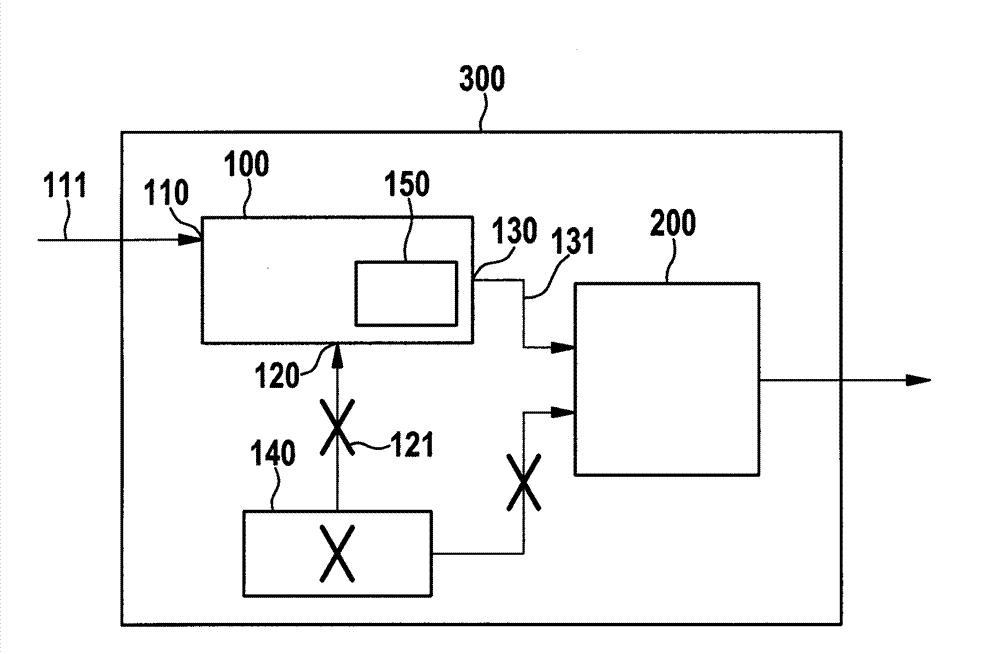

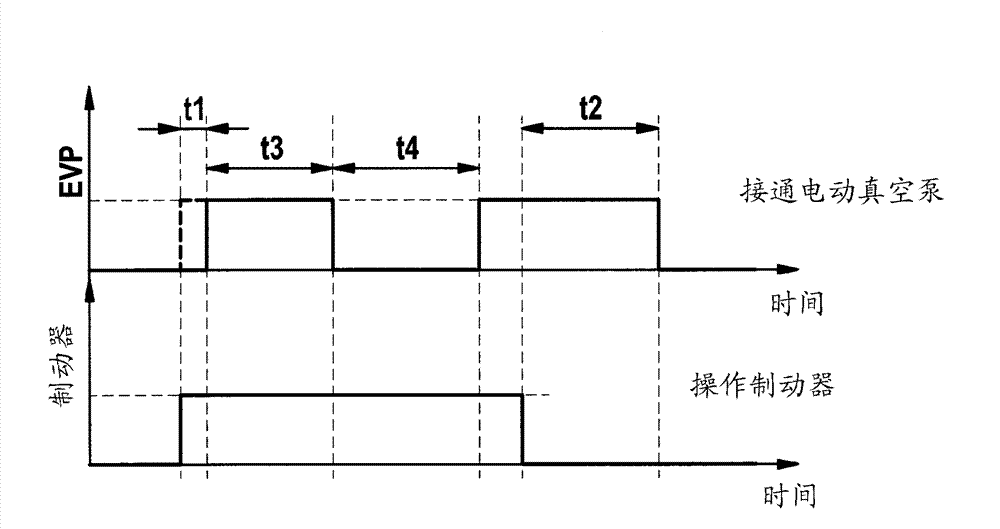

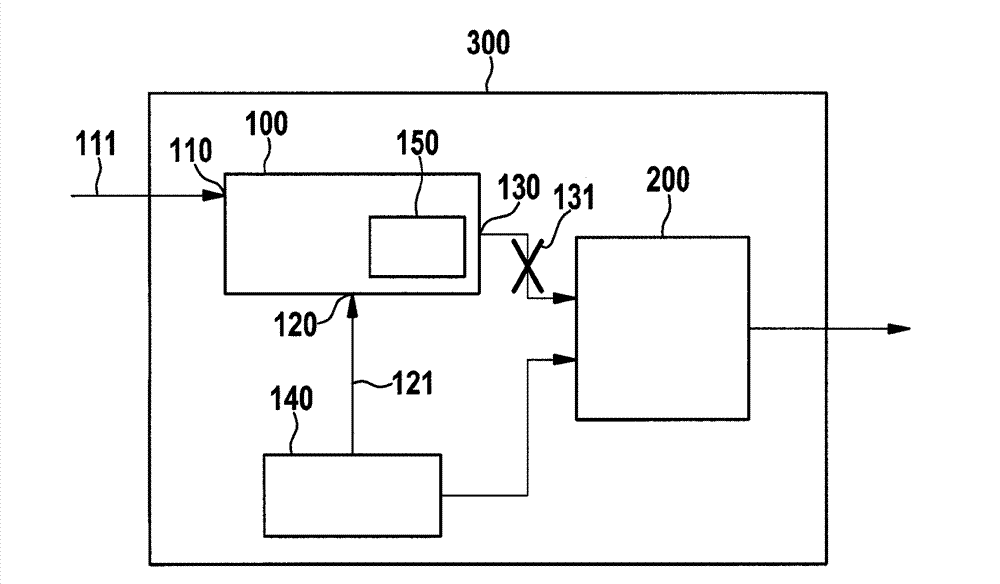

Equivalent circuit for activation of an electric vacuum pump in case of control unit failure

ActiveCN102815290AEnough vacuumIncrease braking powerBraking action transmissionPump/compressor arrangementsOperational readinessVacuum pump

The present invention relates to a brake booster system in motor vehicles. It is an equivalent circuit (100) for activation of an electric vacuum pump (200) is proposed in a booster unit (300) comprising a first signal input (110) for supplying a signal representative of a brake actuation signal (111), a second signal input (120) for feeding a reference signal (121) from an ESP control unit (140) and a signal output (130) for driving the electric vacuum pump (200), wherein the first signal input (110) and the signal output (130) are so interconnected with each other, that upon receipt of one of a brake actuation signal representative (111) at the first signal input (110) is an electric vacuum pump (200) is an activating signal (131) is outputted to the signal output (130), wherein the second signal input (120) to the signal output (130) connected so that an output of an activating electrical vacuum pump signal (131) is suppressed in the signal output (130), providing the operational readiness of the ESP control device (140) representing reference signal (121) applied to the second signal input.

Owner:ROBERT BOSCH GMBH

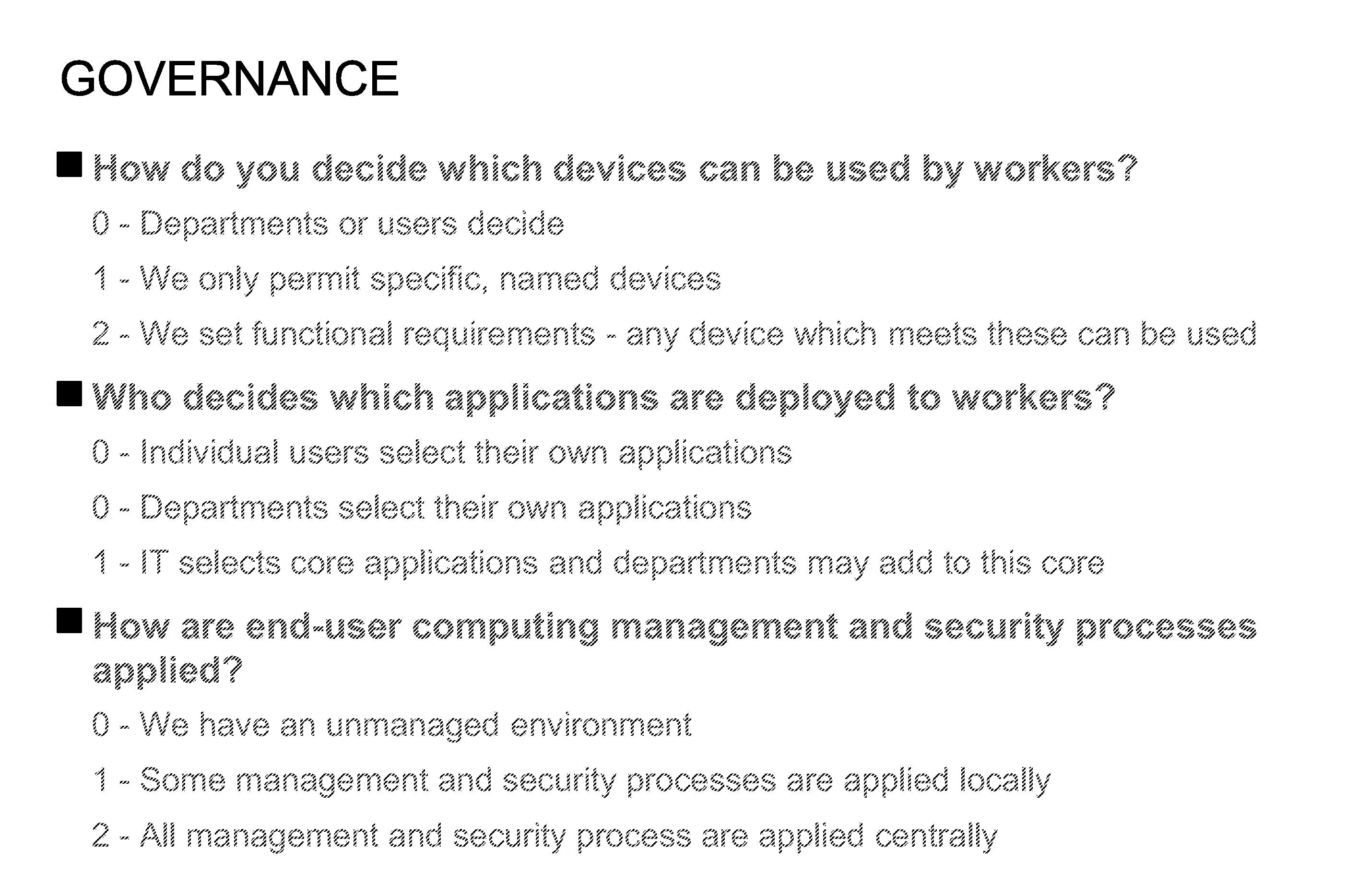

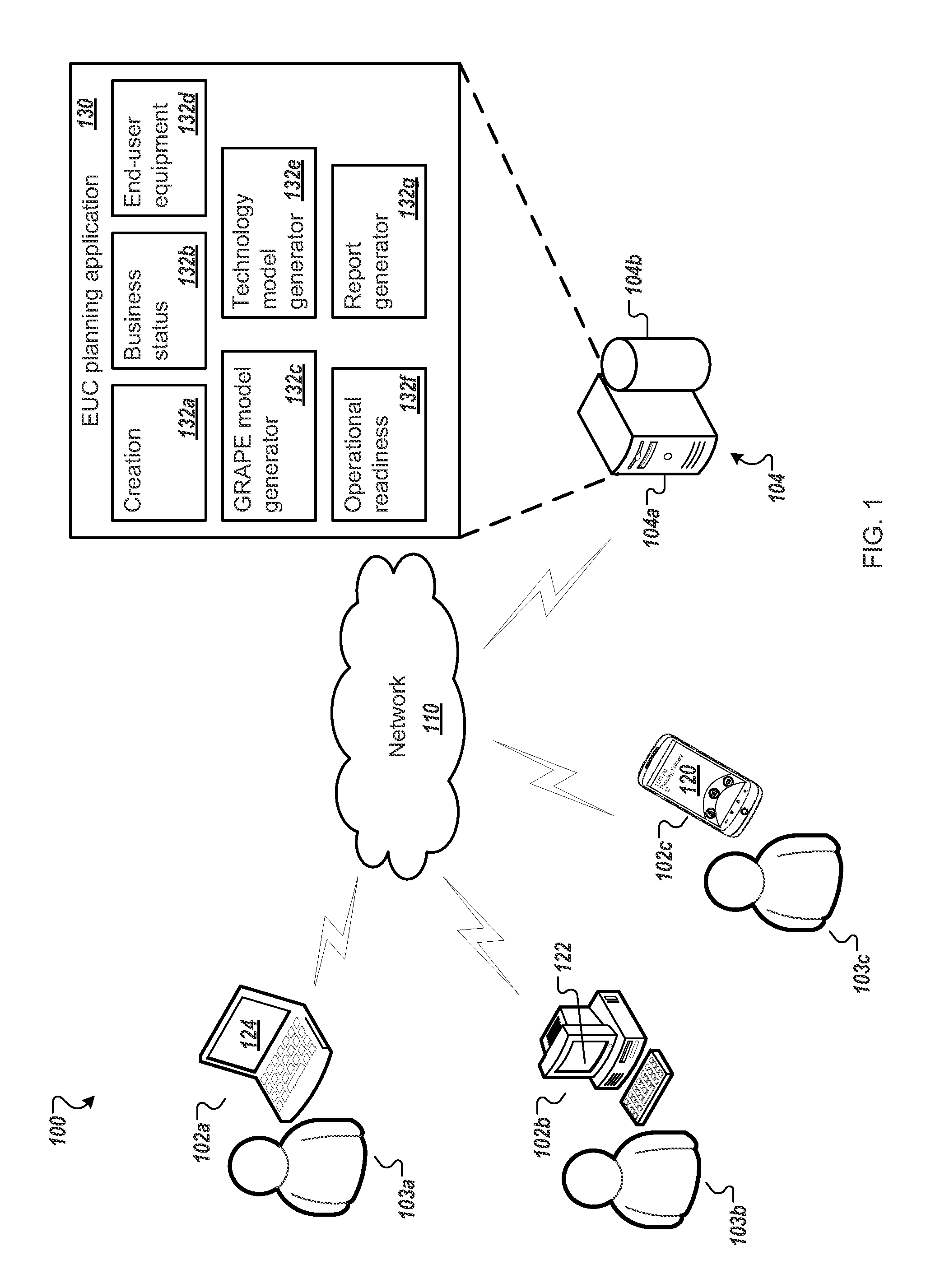

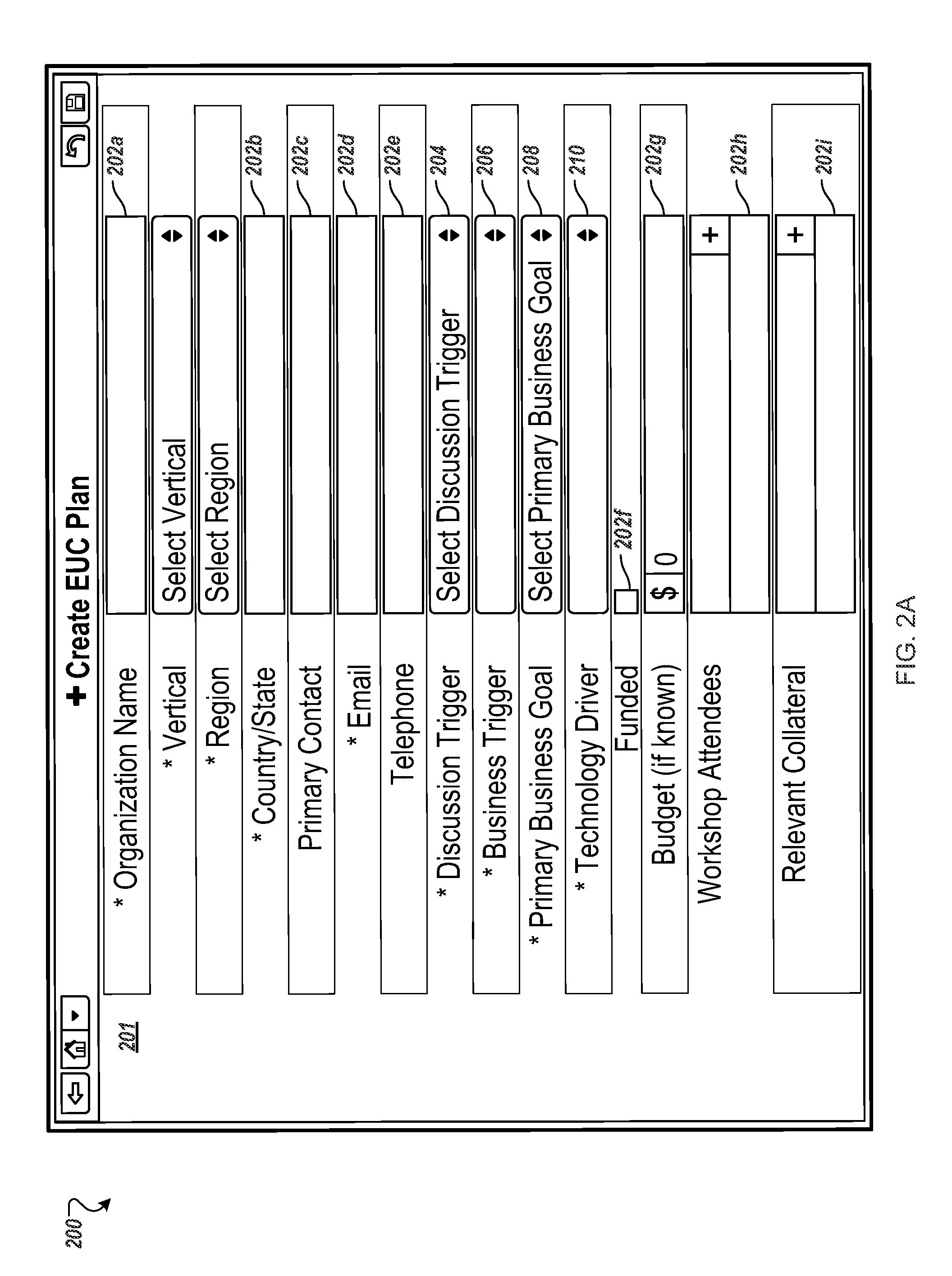

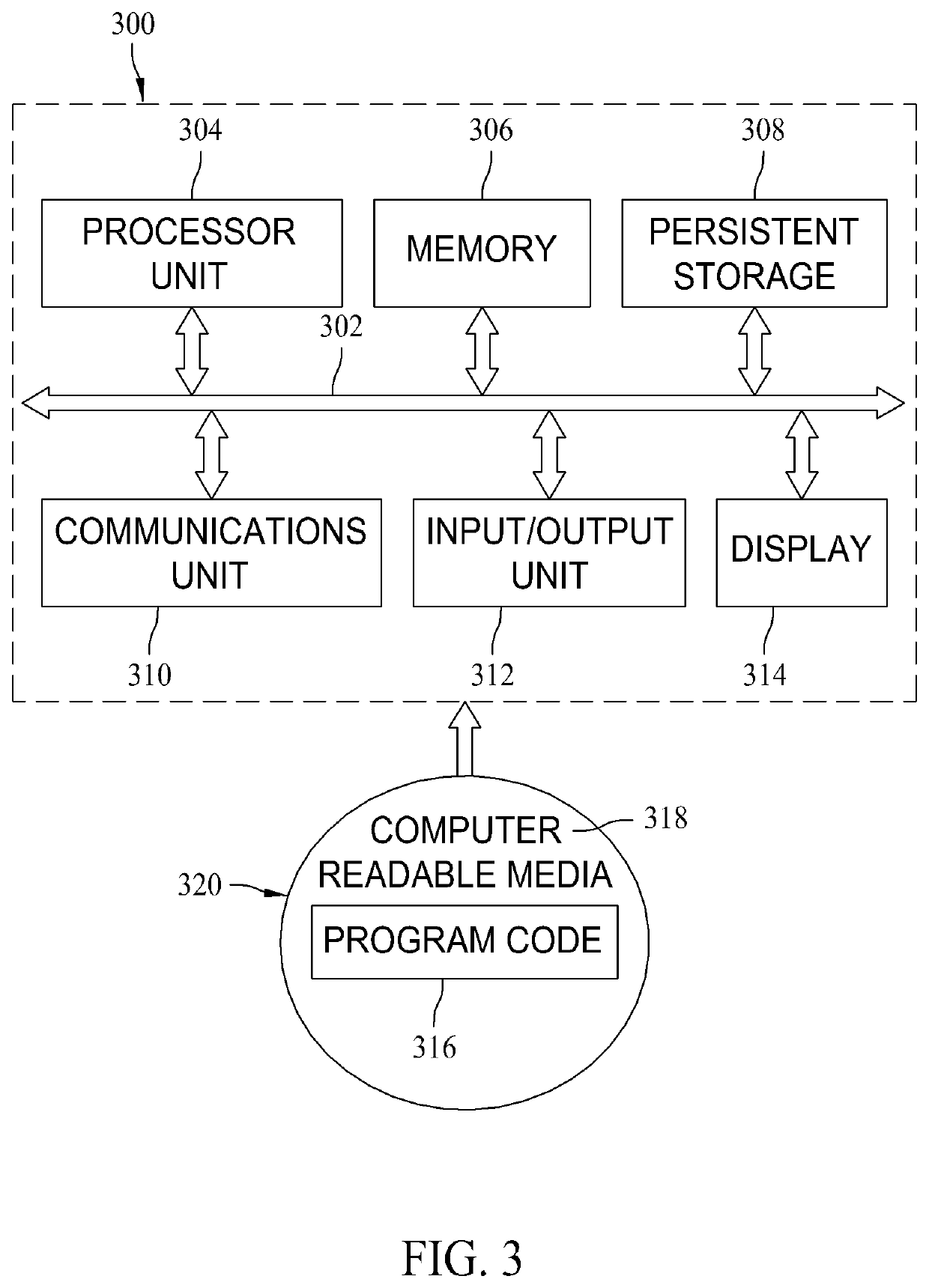

Strategic planning process for end user computing

Systems and methods are described for obtaining a first governance score that is a measure of federation for a platform, a first risk score that is a measure of risk tolerance for the platform, a first audit score that is a measure of record keeping ability for the platform, a first productivity score that is a measure of workforce productivity for the platform, and a first elasticity score that is a measure of change tolerance for the platform. The method further obtains operational readiness scores that are measures of processes used to manage the platform within an organization, adjusts the first scores based on the operational readiness scores, calculates respective corresponding second scores pertaining to the organization, calculates a respective assessment for each of the adjusted first scores based on a comparison of the adjusted first score with the corresponding second score, and provides a summary of the assessments.

Owner:VMWARE INC

Method for detecting foreign object damage in turbomachinery

ActiveUS9046000B2Removal costEliminates of numberPlug gaugesEngine fuctionsForeign matterForeign object damage

The present invention relates to systems and methods for real-time health monitoring of engines to monitor turbomachinery blades during engine operation and report anomalous behavior and shape of the blades if it occurs, such as damage by FOD. The system includes sensor(s) for obtaining a blade reflection profile from a blade passing by the sensor(s) during a revolution of the rotor in combination with a processor for performing timing calculations and / or fingerprint comparisons with reference data to identify a change in blade fingerprint relative to the reference data, which may indicate blade damage. Such systems can reduce operational costs, enhance safety and improve operational readiness by facilitating condition-based maintenance of engine rotors as opposed to schedule-based solutions. The invention can prevent the needless loss of life and assets caused by undetected minor levels of blade damage that may lead to unexpected catastrophic failure of an engine.

Owner:PRIME PHOTONICS LC

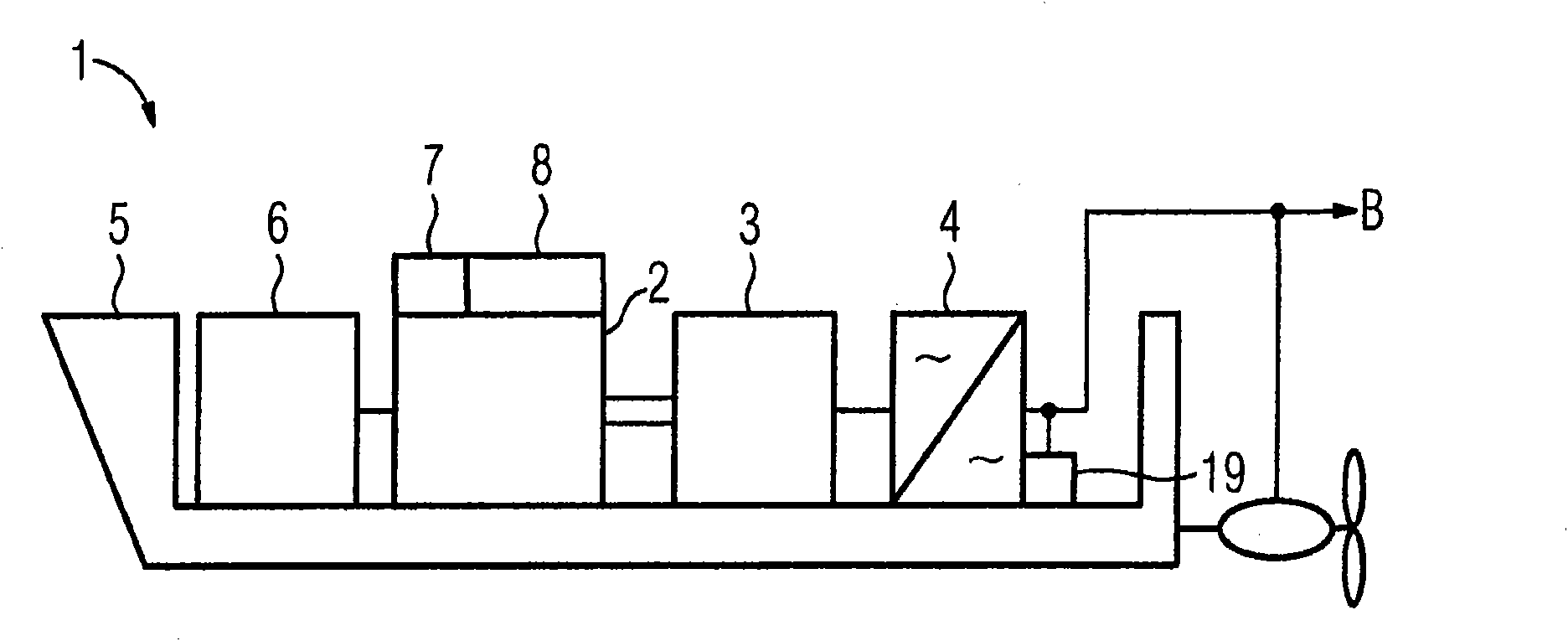

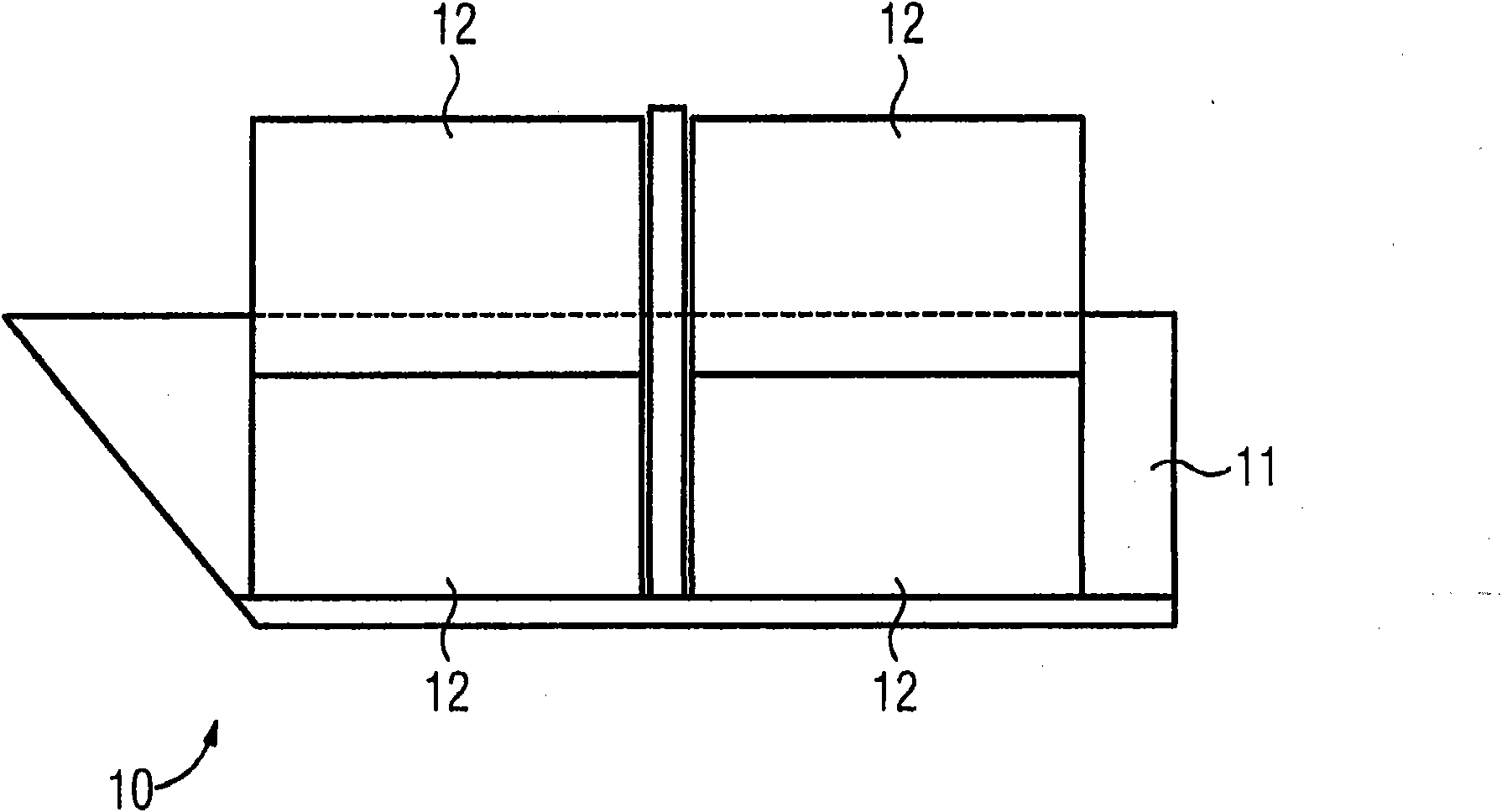

Buoyant harbor power supply

InactiveCN101842566AEasy to useEasy to moveInternal combustion piston enginesEnergy based wastewater treatmentReadiness findingExternal energy

The invention relates to supplying ships in a harbor with external energy in order to prevent the formation of soot and CO2. For this purpose it is already known to supply ships with power from the wharfage. One problem in such a power supply provided from the wharf is that differences in the harbor's water level must be balanced for the power supply of a ship in the harbor. Furthermore, the operational readiness of such a power supply on land may be adversely affected, such as in the case of high water. In order to solve said problem, the invention proposes a buoyant harbor power supply (1), e.g. the components of the harbor power supply are disposed on or in a buoyant device, particularly a barge (11).

Owner:SIEMENS AG

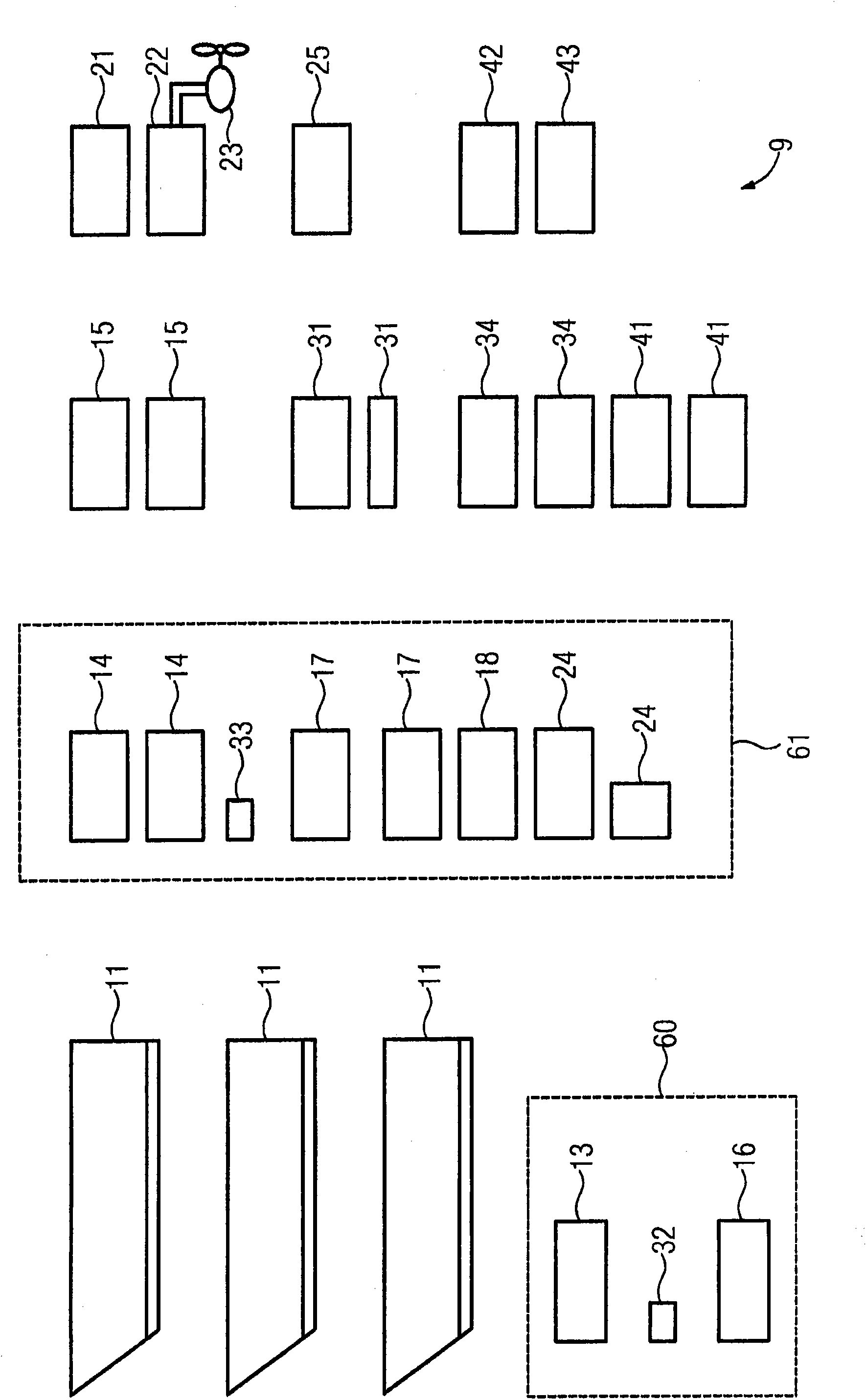

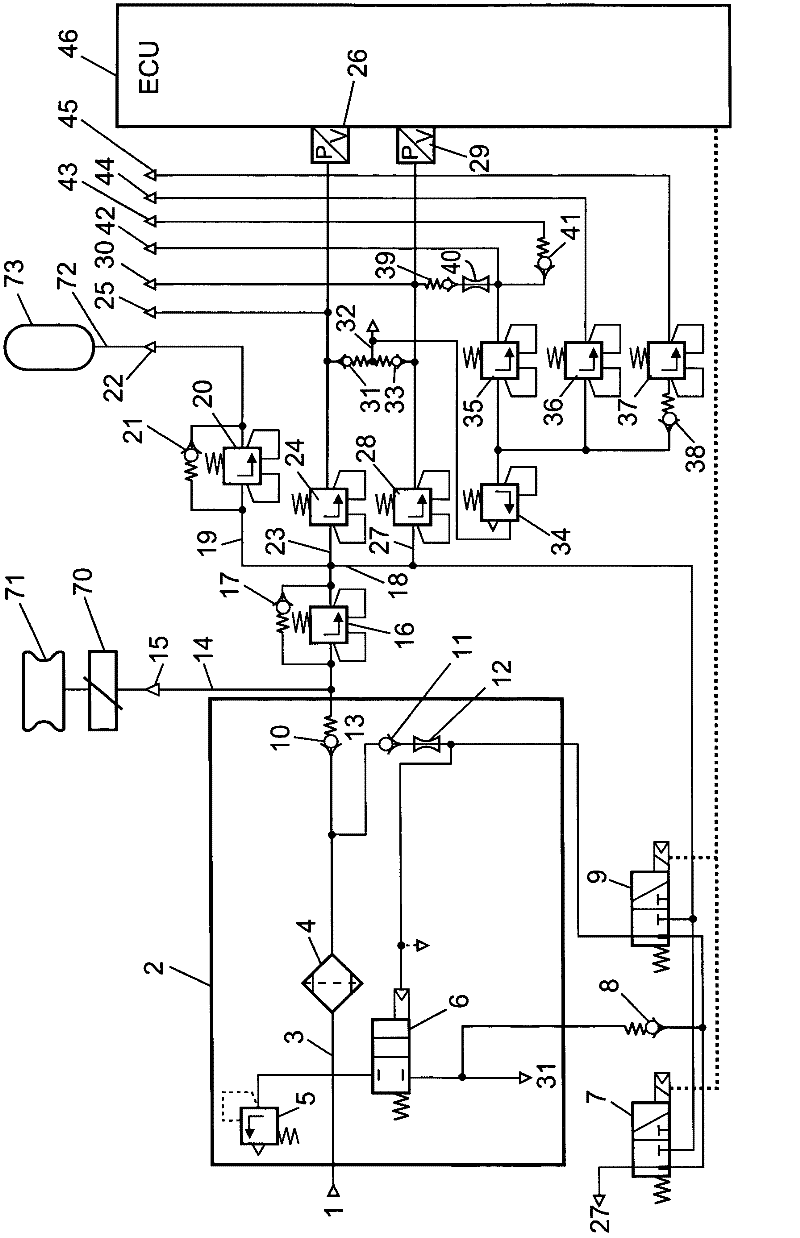

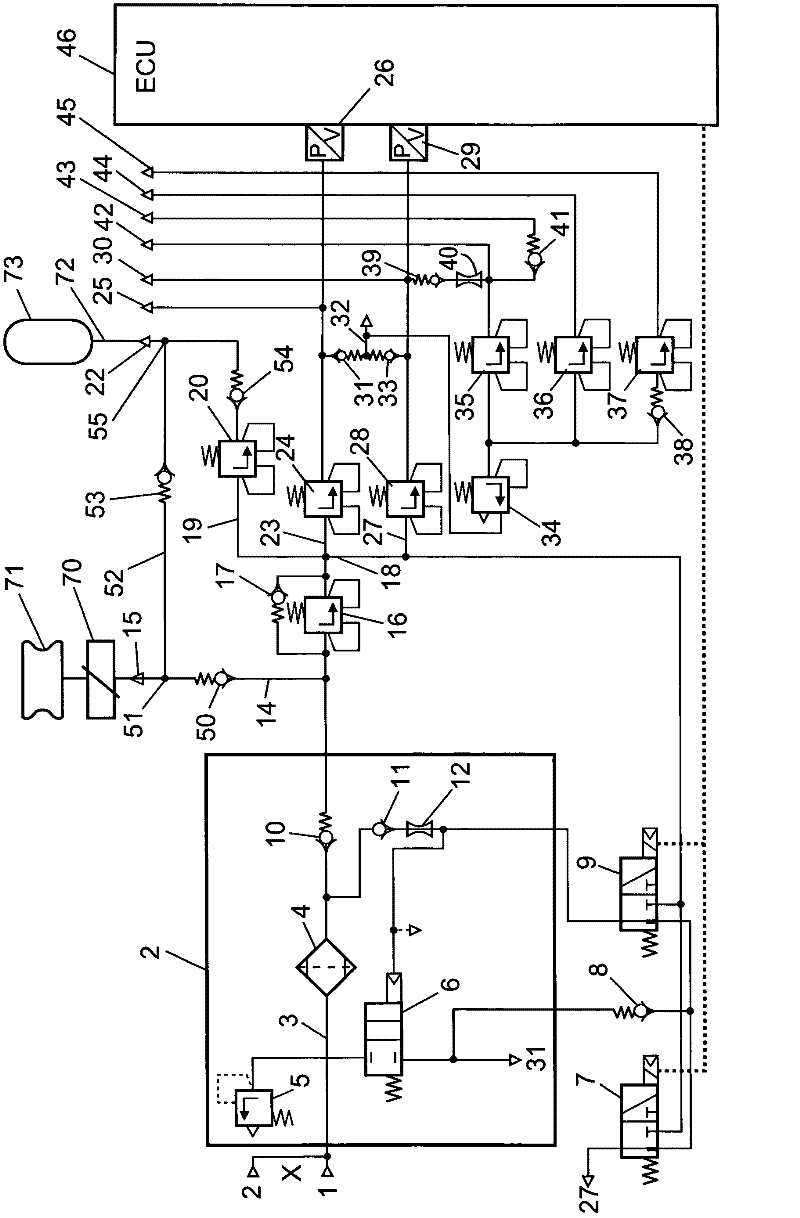

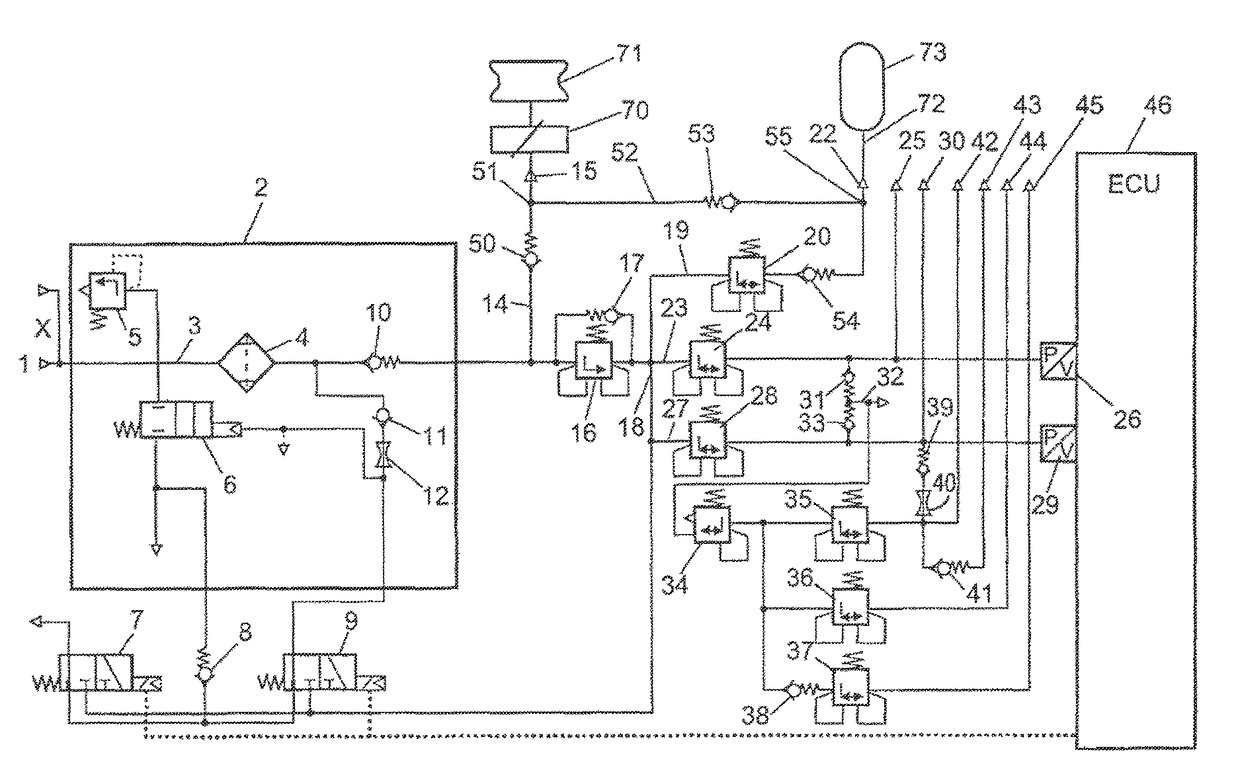

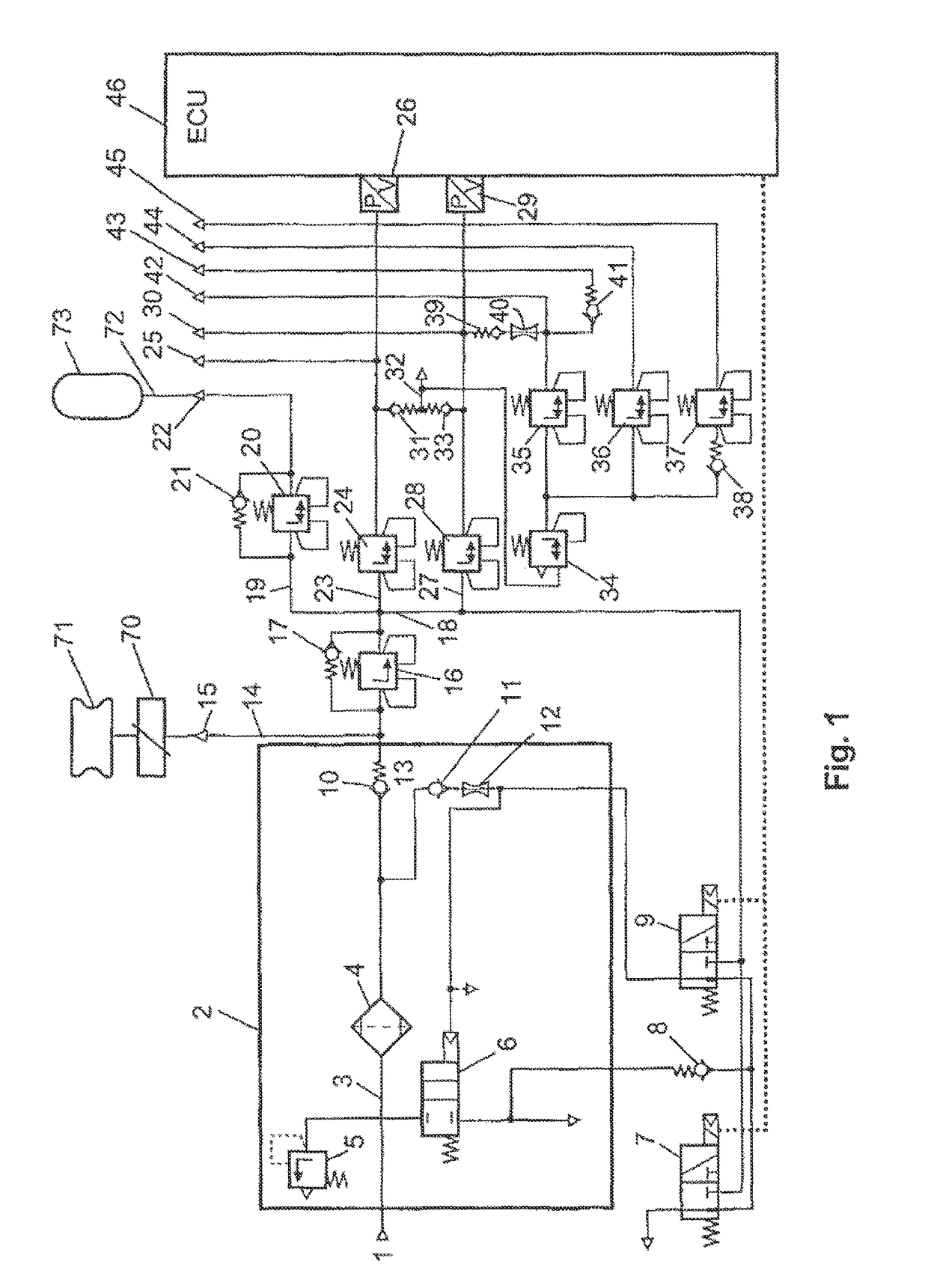

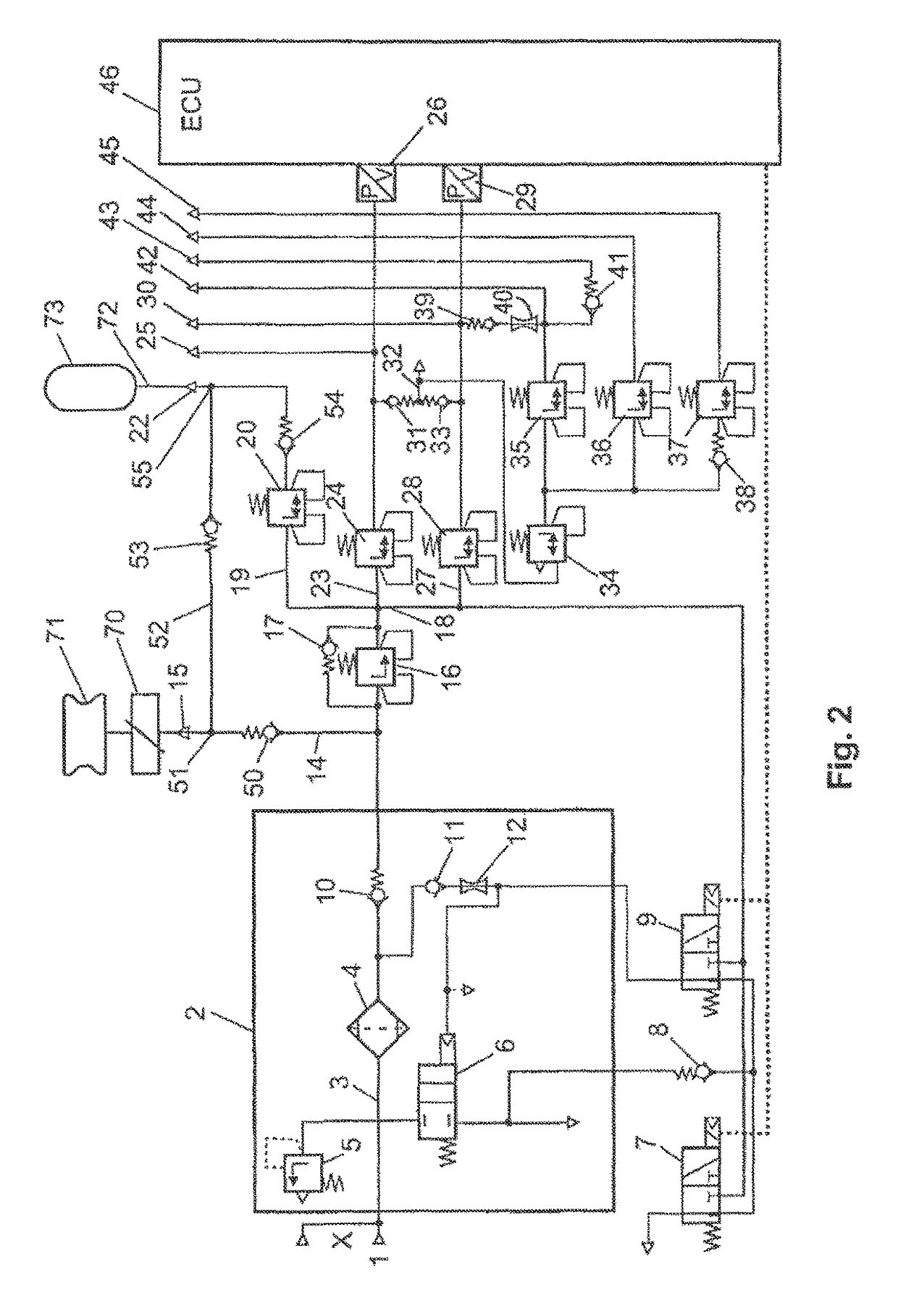

Compressed air supply system for a compressed air consumer circuit, in particular for an air spring system

The invention relates to a compressed air supply system for a first compressed air consumer circuit (70, 71), particularly for an air spring system for a vehicle. The compressed air supply system comprises a first compressed air line (14) leading to the first compressed air consumer circuit and a distribution line (18) leading to further consumer circuits (25, 30, 42, 43, 44, 45). A priority valve arrangement (16) is disposed between the first compressed air line (14) leading to the compressed air consumer circuit and the distribution line (18) leading to the further consumer circuits (25, 30, 42, 43, 44, 45), wherein the first compressed air line (14) comprises no safety valve. The first compressed air consumer circuit (70, 71) can therefore be filled at a higher priority, and achieve operational readiness quickly. Air spring processes, for example, such as lifting or raising activities, can be performed very quickly with priority.

Owner:WABCO GMBH

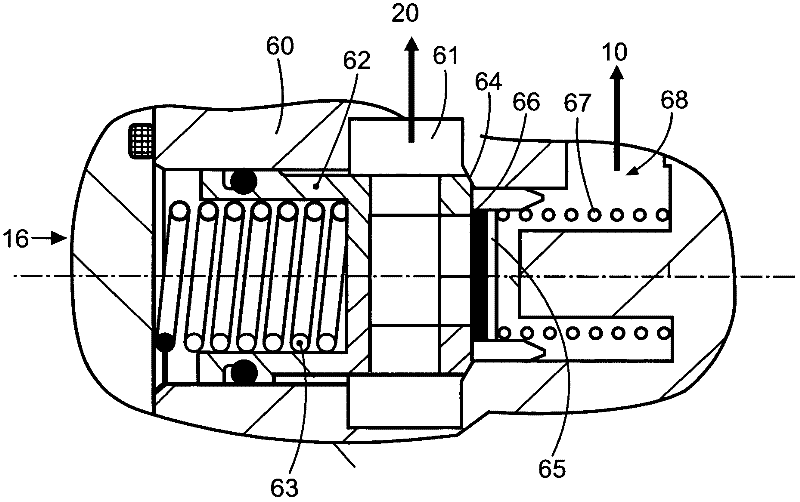

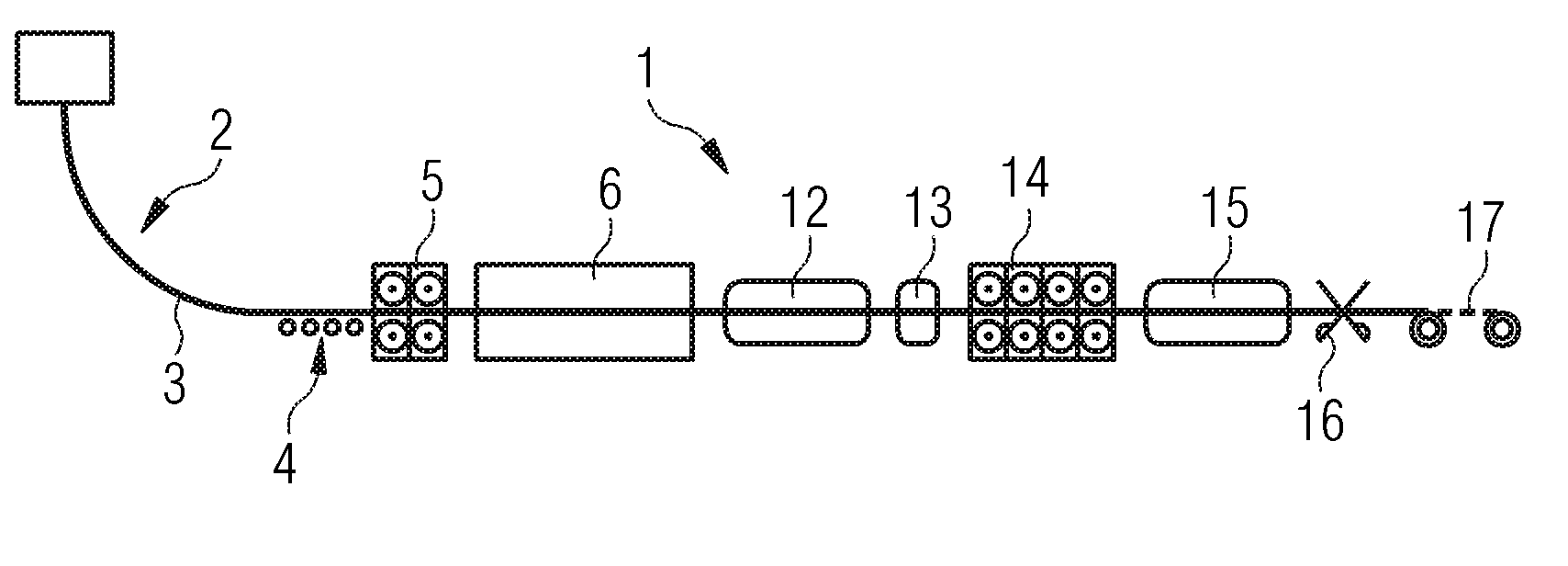

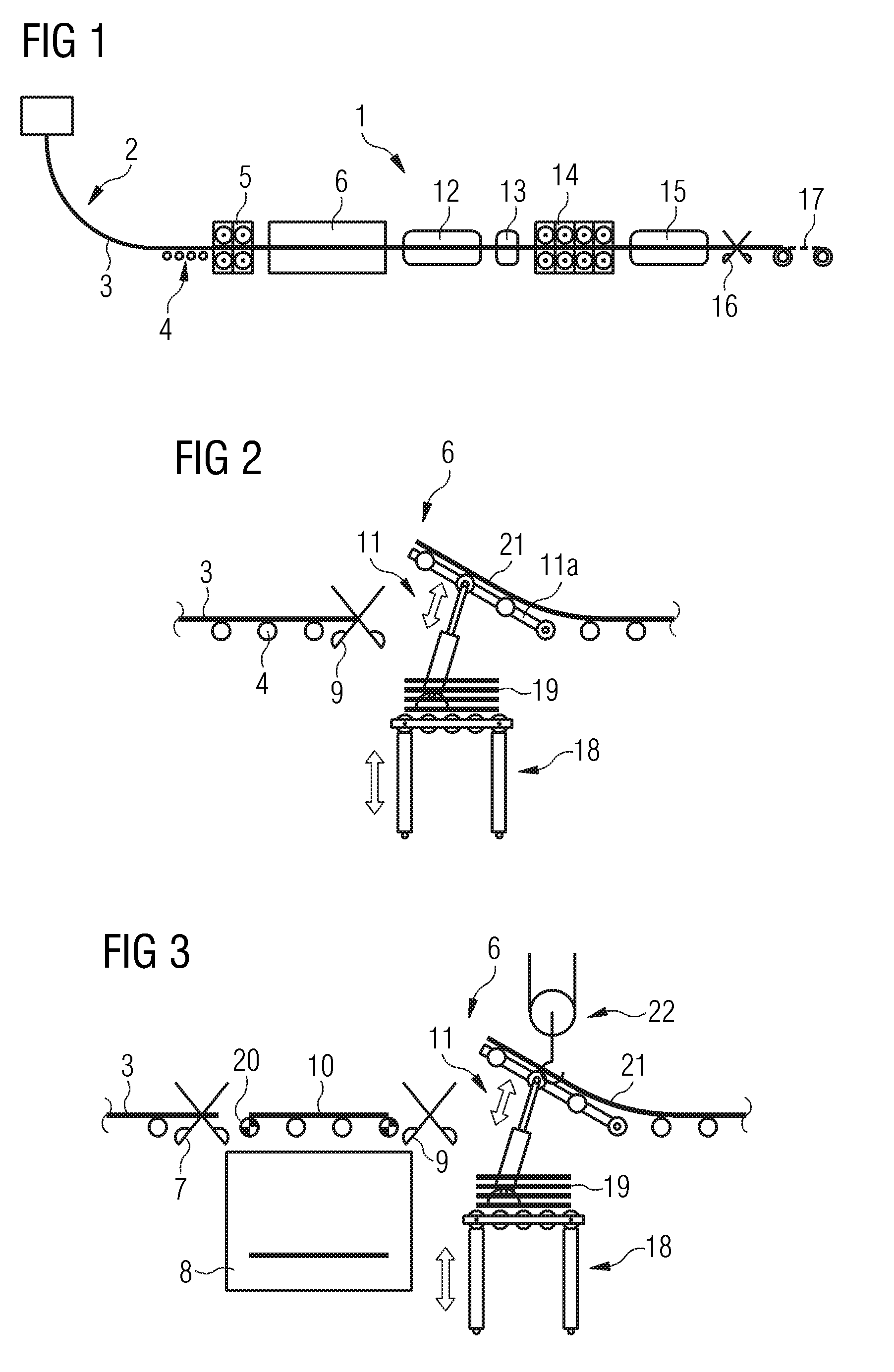

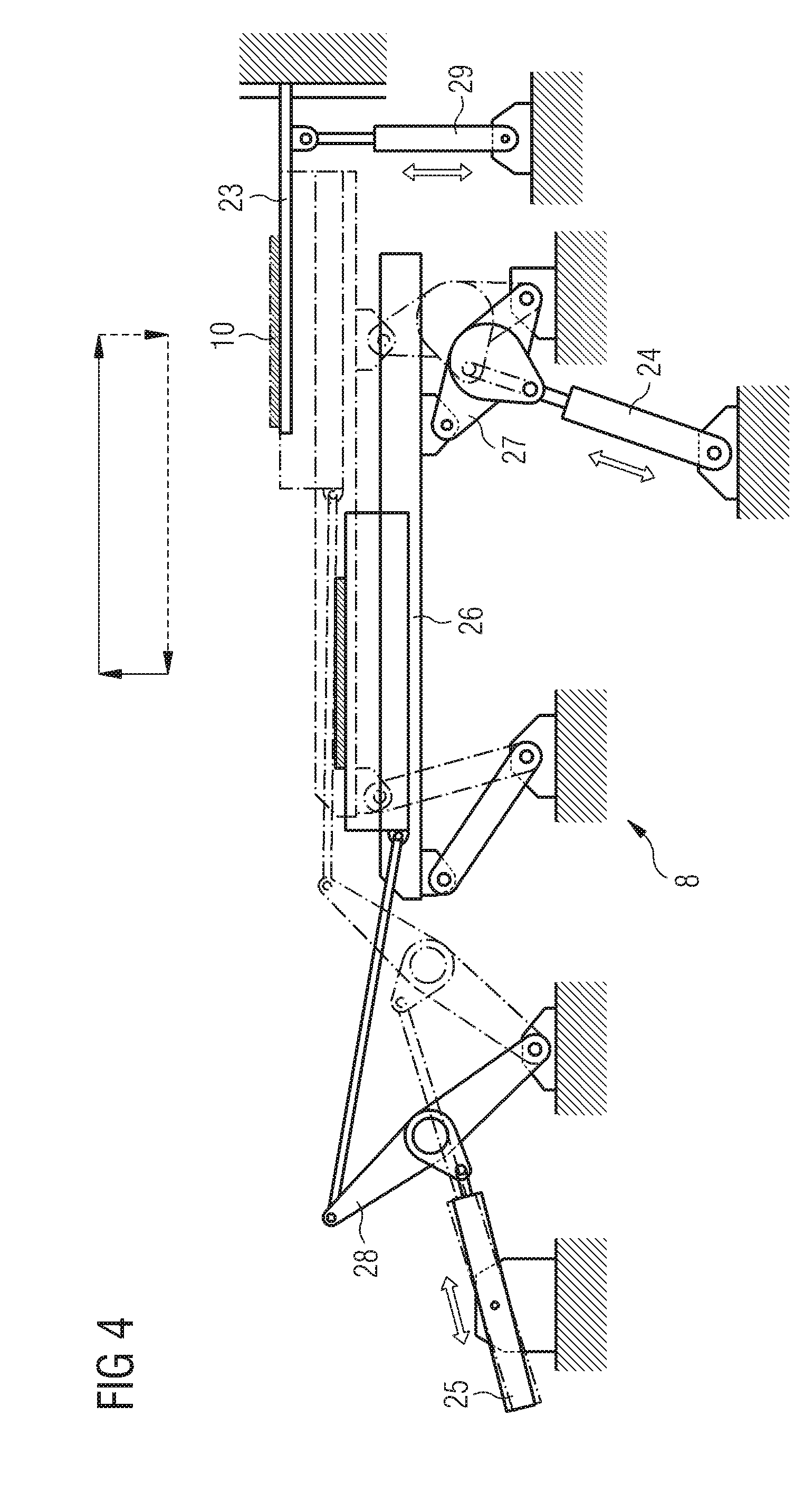

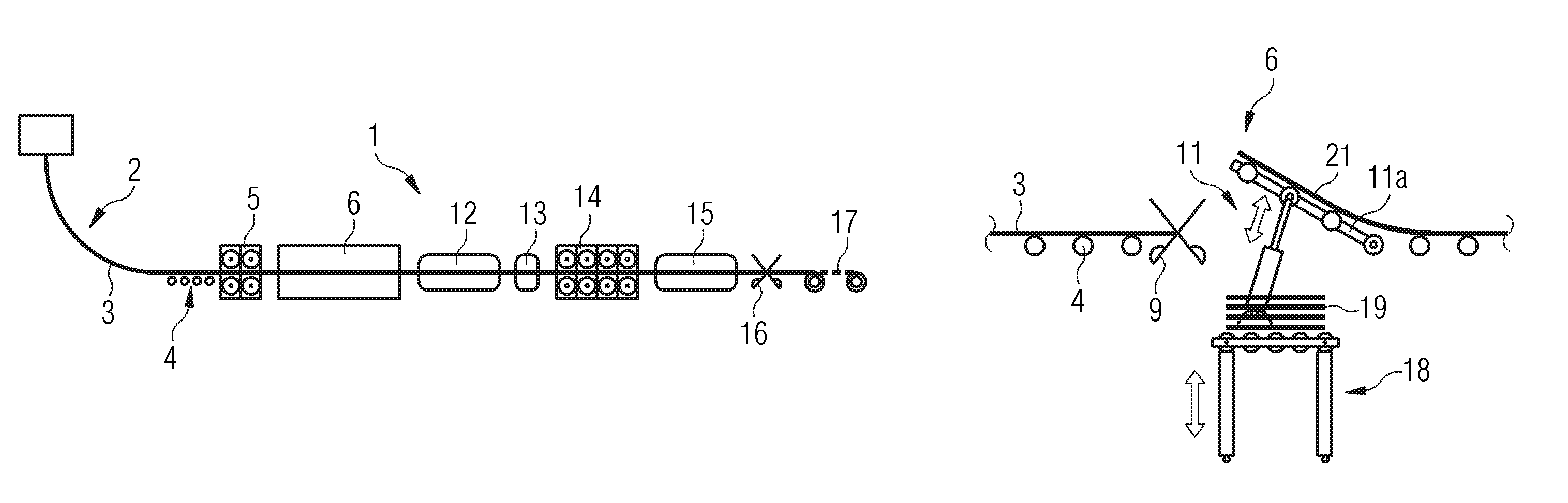

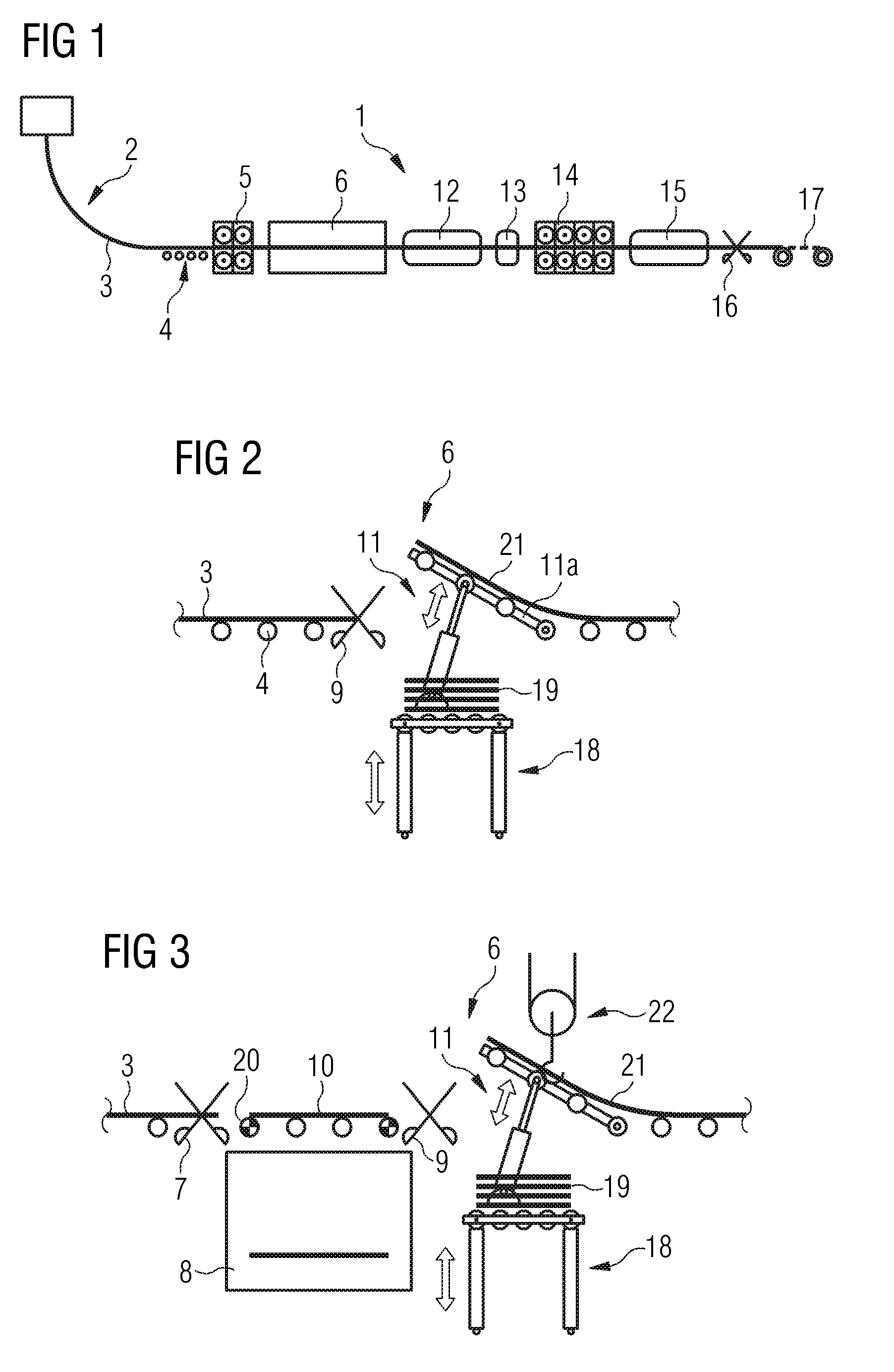

Process and apparatus for a combined casting and rolling installation

ActiveUS20110056649A1Rapid and advantageous mannerEasy to transportMetal rolling arrangementsEngineeringOperational readiness

A method and an apparatus for producing hot-rolled products in a combined casting-rolling installation. A method and a combined casting-rolling installation with which an uninterrupted continuous casting process can be maintained not only when there is a planned interruption to production but also when there is an unplanned interruption to production, occurring for example in a heating zone, a finishing mill train, a cooling zone or a storage device. This method steps are carried out to bridge an interruption in production in the part of the installation that is downstream of the cutting-up and delivering device (6): a) cutting off a strand portion (21) of the continuously produced preliminary material (3) by means of a first shears (9); b) raising the tail part of the strand portion (21) from the roller table (4) by means of a raising device (11); c) breaking up the preliminary material (3) passing the first shears (9) into pieces of scrap (19) by means of the first shears (9)into pieces of scrap (19) by means of the first shears (9), delivering the pieces of scrap (19) and removing the strand portion (21) unit the operational readiness of the combined casting-rolling installation is restored.

Owner:PRIMETALS TECH AUSTRIA GMBH

Compressed air supply system for a compressed air consumer circuit

InactiveUS9783019B2Easy to controlFunction increaseServomotor componentsServomotorsAir springOperational readiness

In a compressed air supply system for a first compressed air consumer circuit such as an air spring system of a vehicle, a first compressed air line leads to the first compressed air consumer circuit and a distribution line leads to further consumer circuits. A priority valve arrangement is disposed between the first compressed air line, wherein the first compressed air line comprises no safety valve. The first compressed air consumer circuit can therefore be filled at a higher priority, and achieve operational readiness quickly in air spring processes such as lifting or raising activities.

Owner:WABCO GMBH

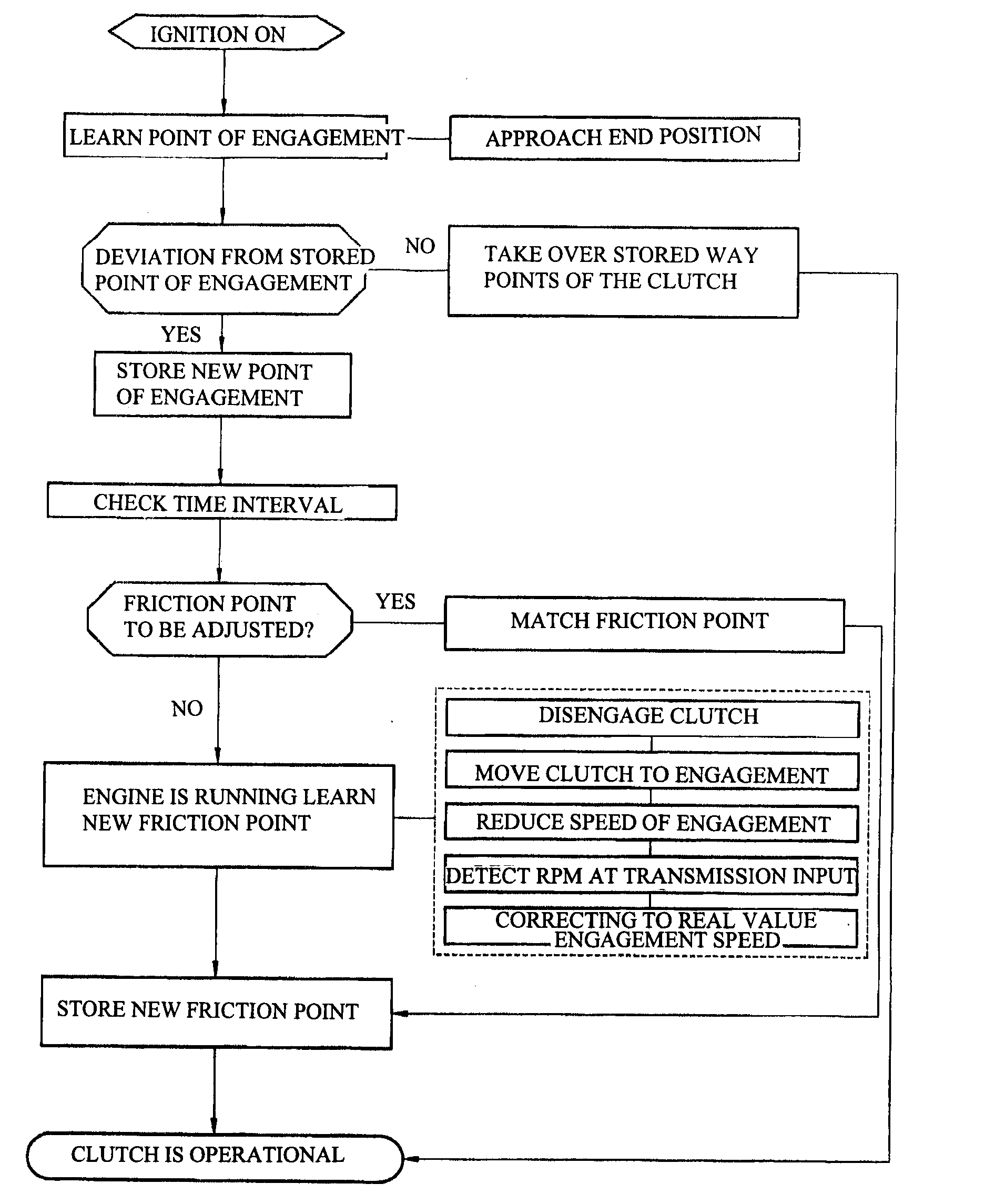

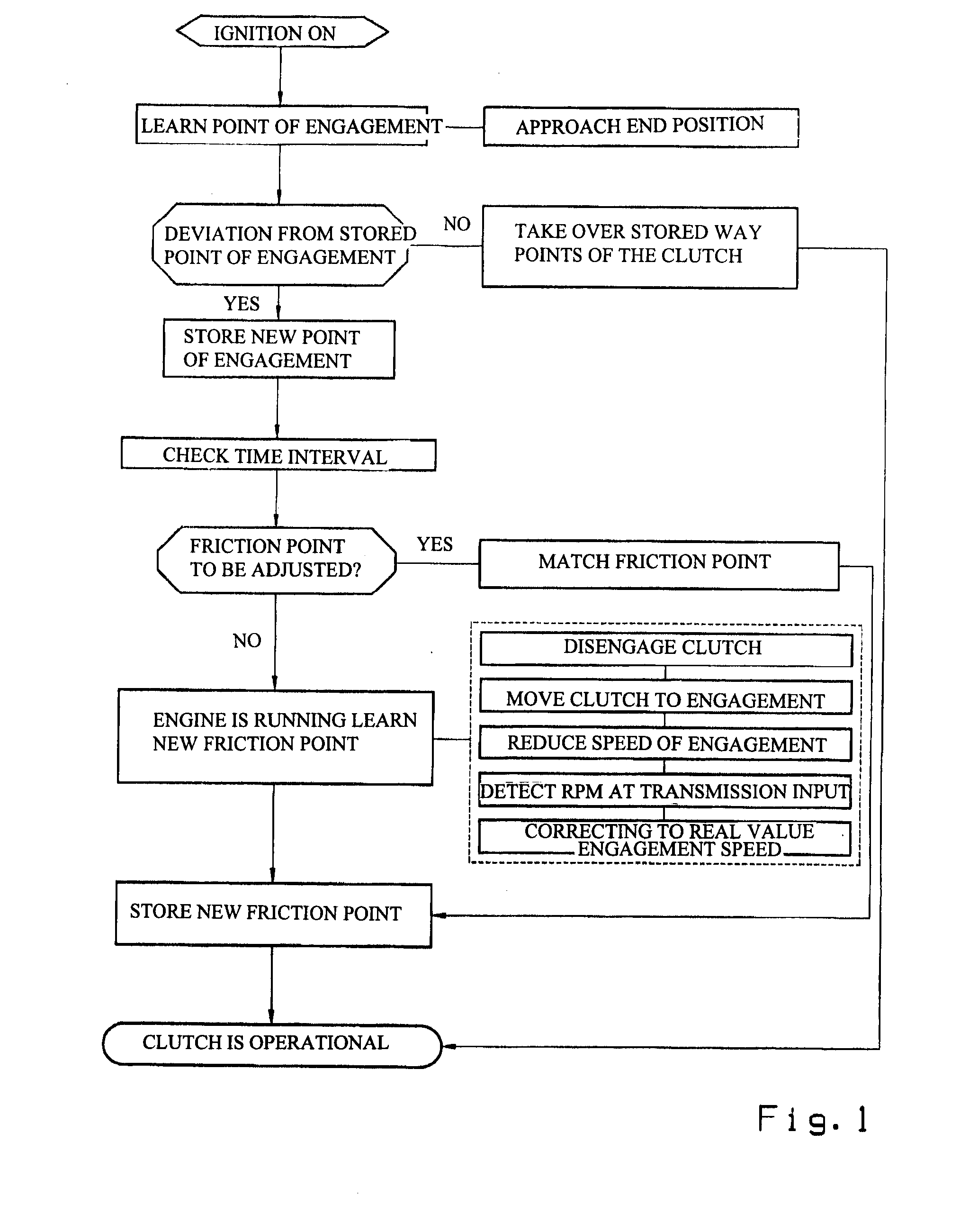

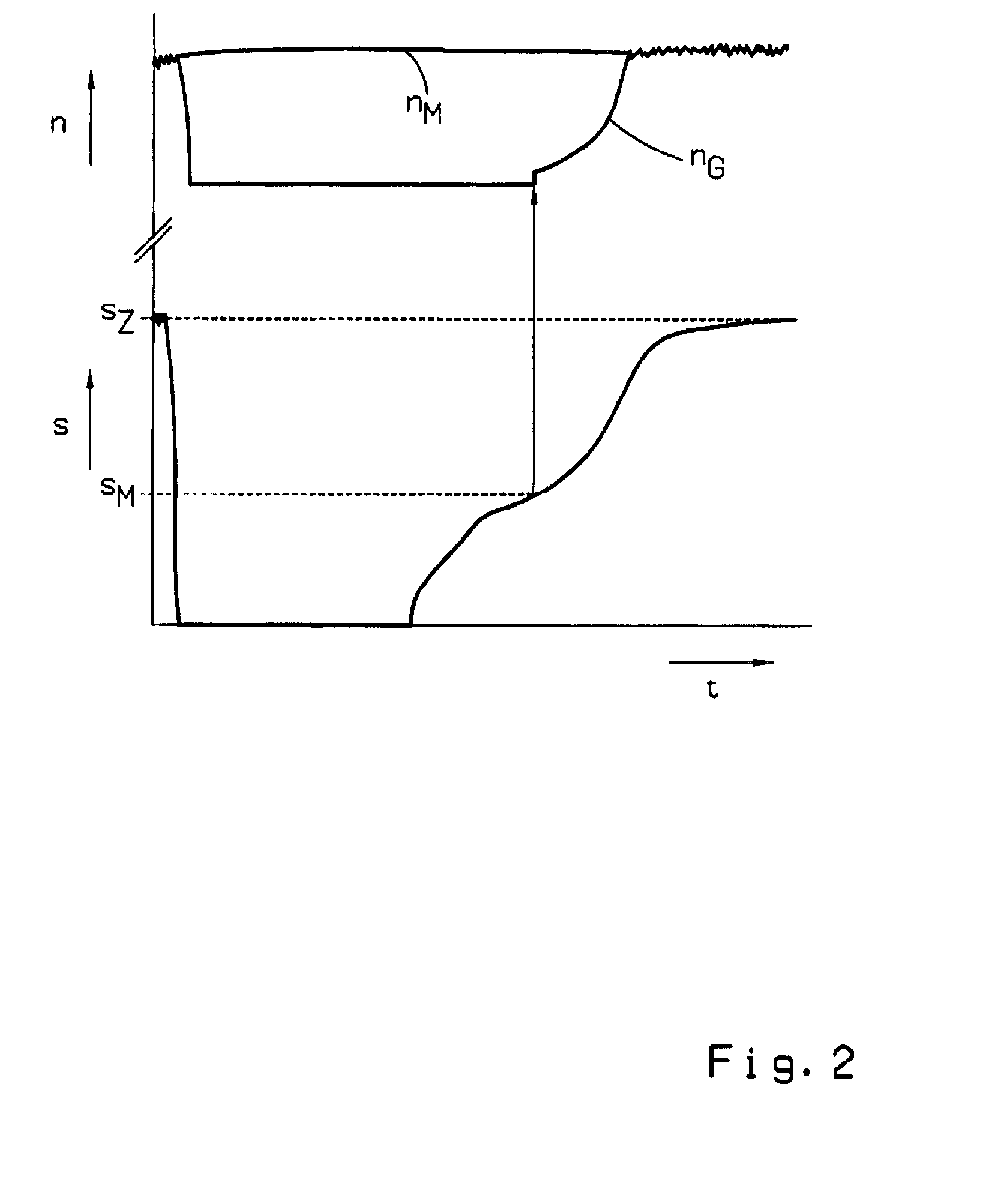

Method and device for controlling a clutch

InactiveUS20100204010A1Short timeKeep for a long timeFluid couplingsDigital data processing detailsMobile vehicleEngineering

A method and a device for controlling a clutch, for example an automatic friction clutch forming part of a drive train of a motor vehicle, for a torque transfer between an engine and a transmission, with the clutch having significant clutch way points assigned to it. For achieving the operational readiness of the clutch over the shortest possible time period, whereby an accurate clutch adjustment is still guaranteed, a clutch way point coordinate system is monitored by checking the point of engagement of the clutch, established through a learning process and having at least a relevant clutch way point for the starting procedure. In case of any recognized change(s), the clutch way point is suitably corrected or otherwise used as is.

Owner:ZF FRIEDRICHSHAFEN AG

Process and apparatus for a combined casting and rolling installation

Owner:PRIMETALS TECH AUSTRIA GMBH

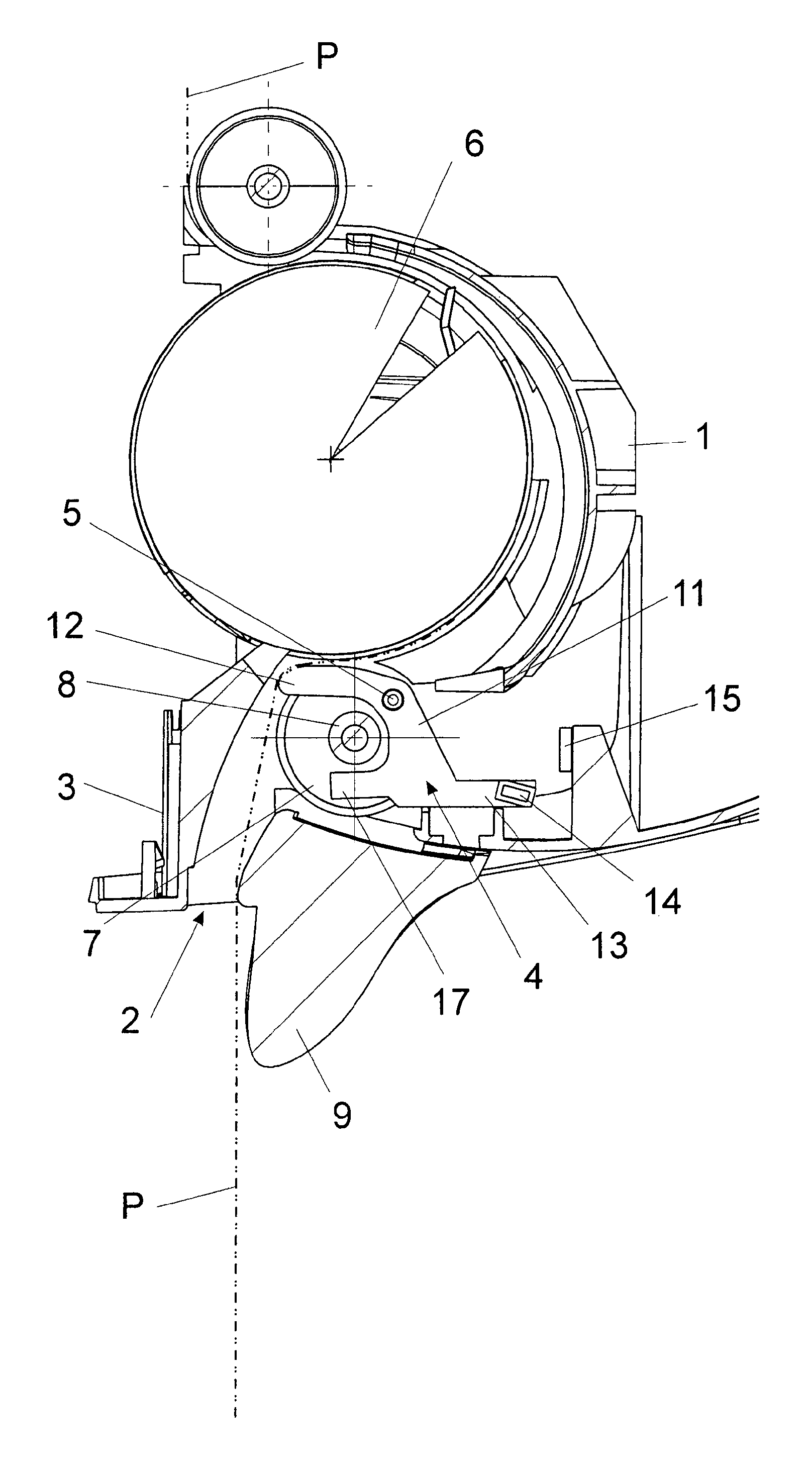

Method of dispensing paper sheet by sheet from a stock and a paper dispenser

A method and a dispenser dispense a sheet of paper through a bottom outlet gap from a stock. A sensor activates, upon detection of a person, an electric drive which delivers a portion of paper from the outlet gap so that the sheet of paper can be torn off by hand. When the delivered sheet of paper is torn off, a switch is actuated. Actuation of the switch puts the dispenser in an operational readiness for delivery of another portion of paper.

Owner:HAGLEITNER HANS GEORG

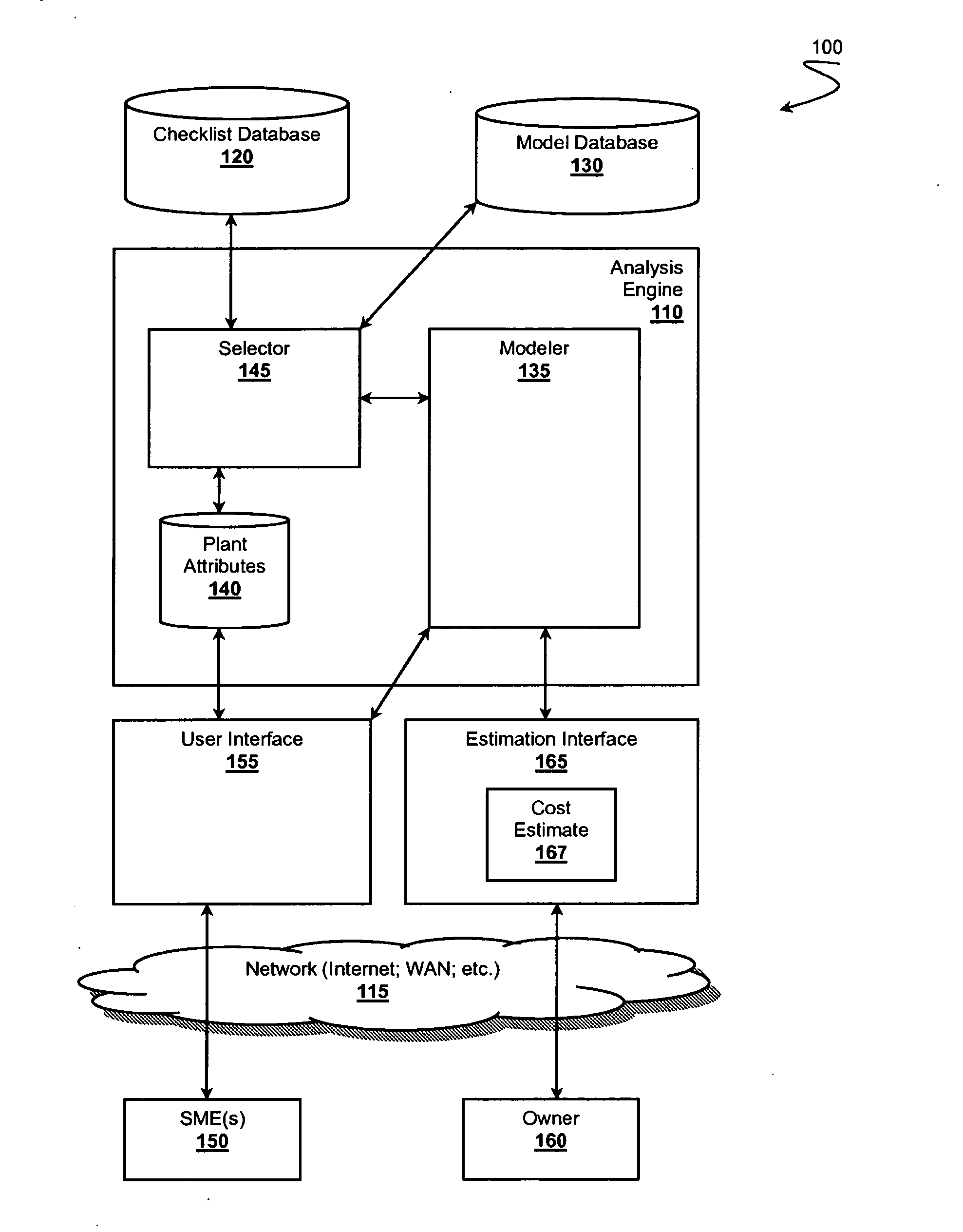

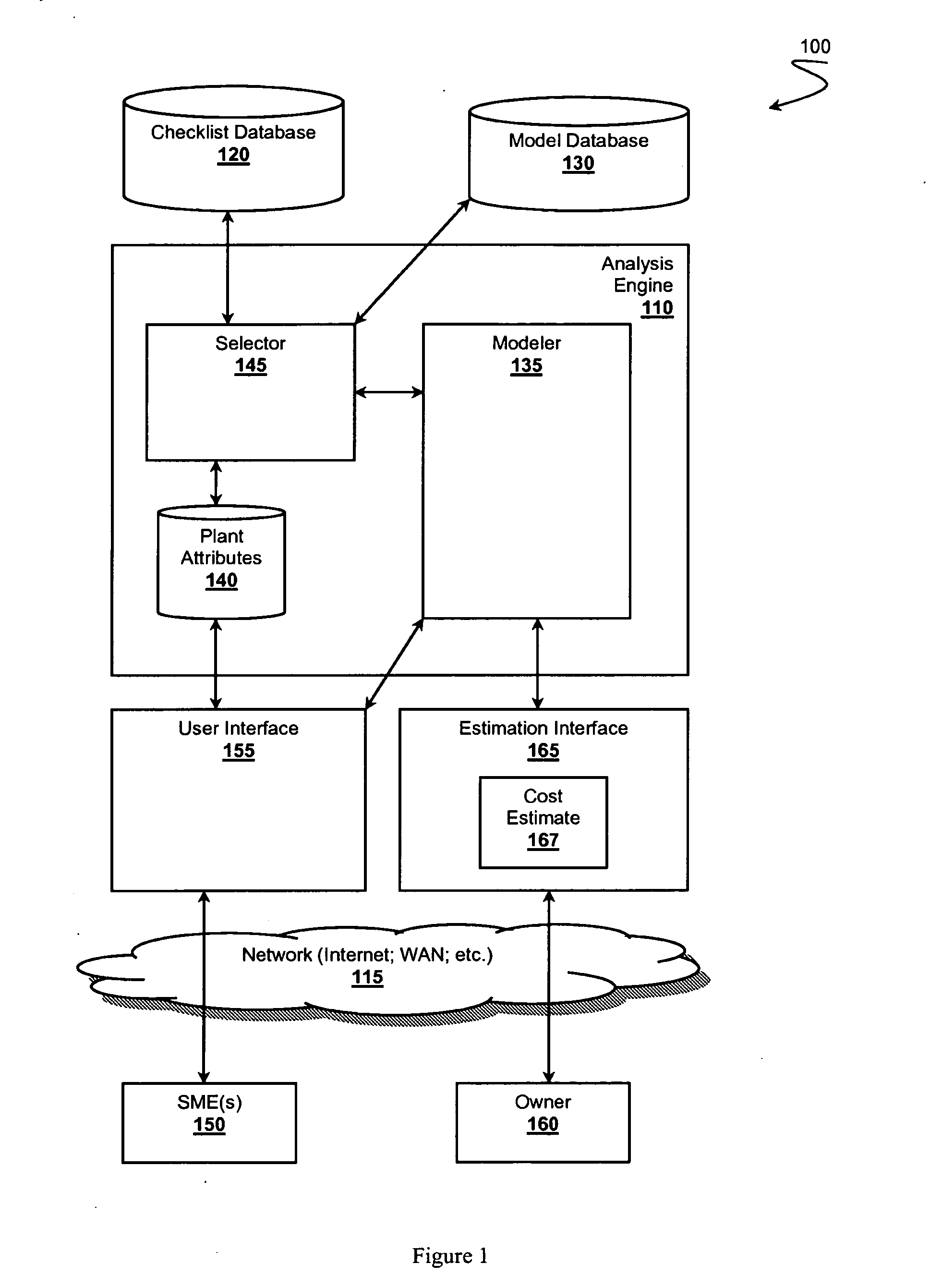

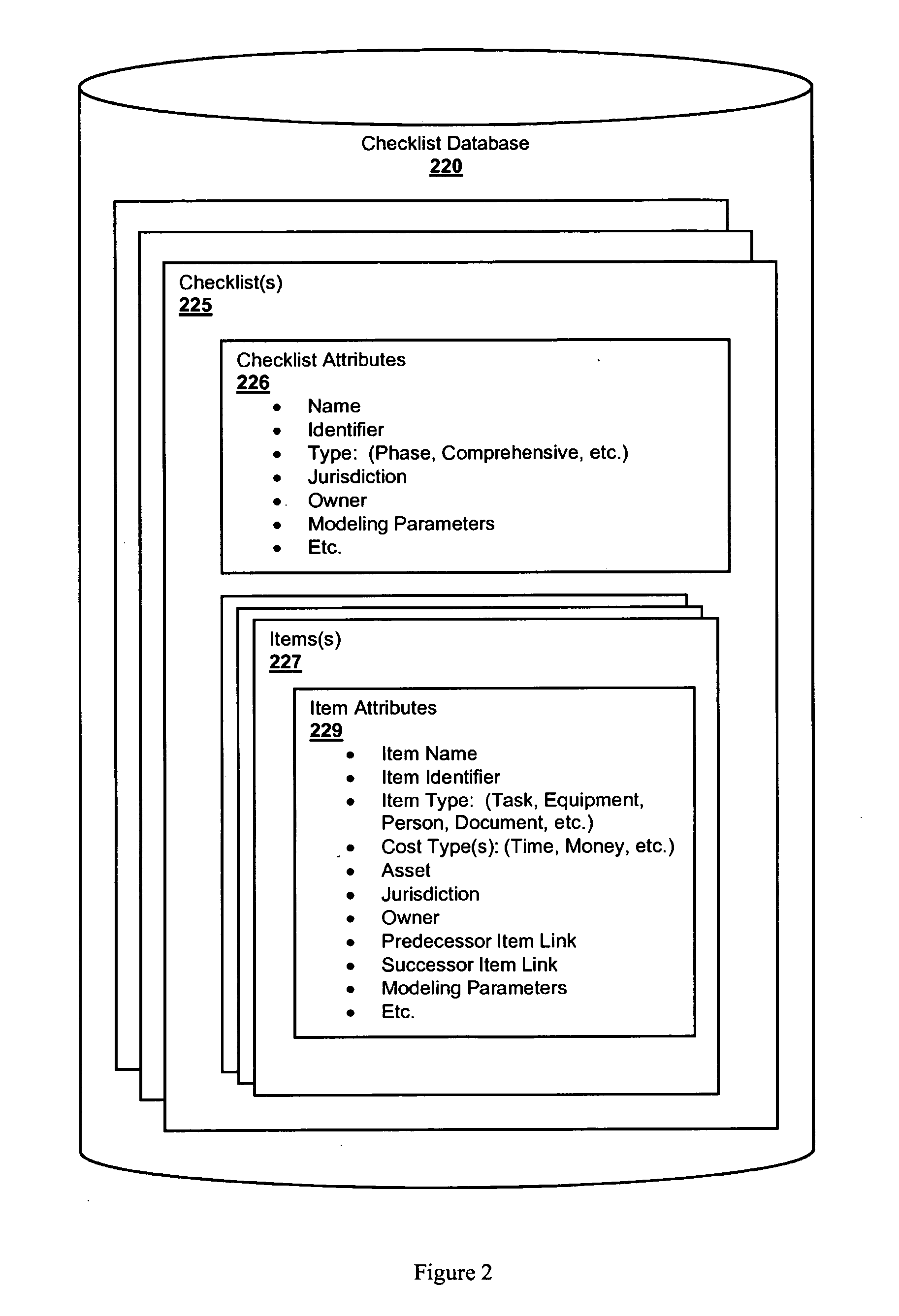

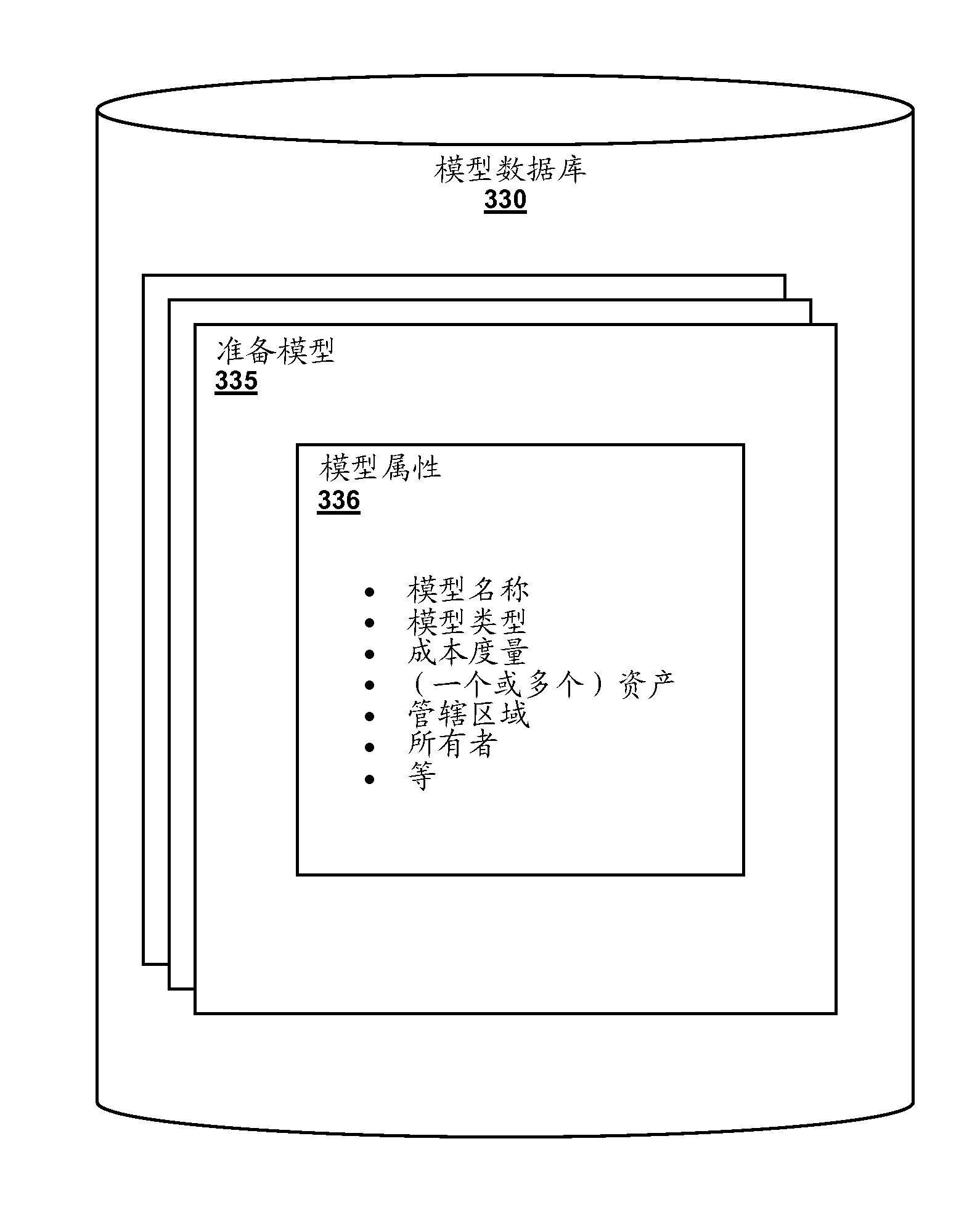

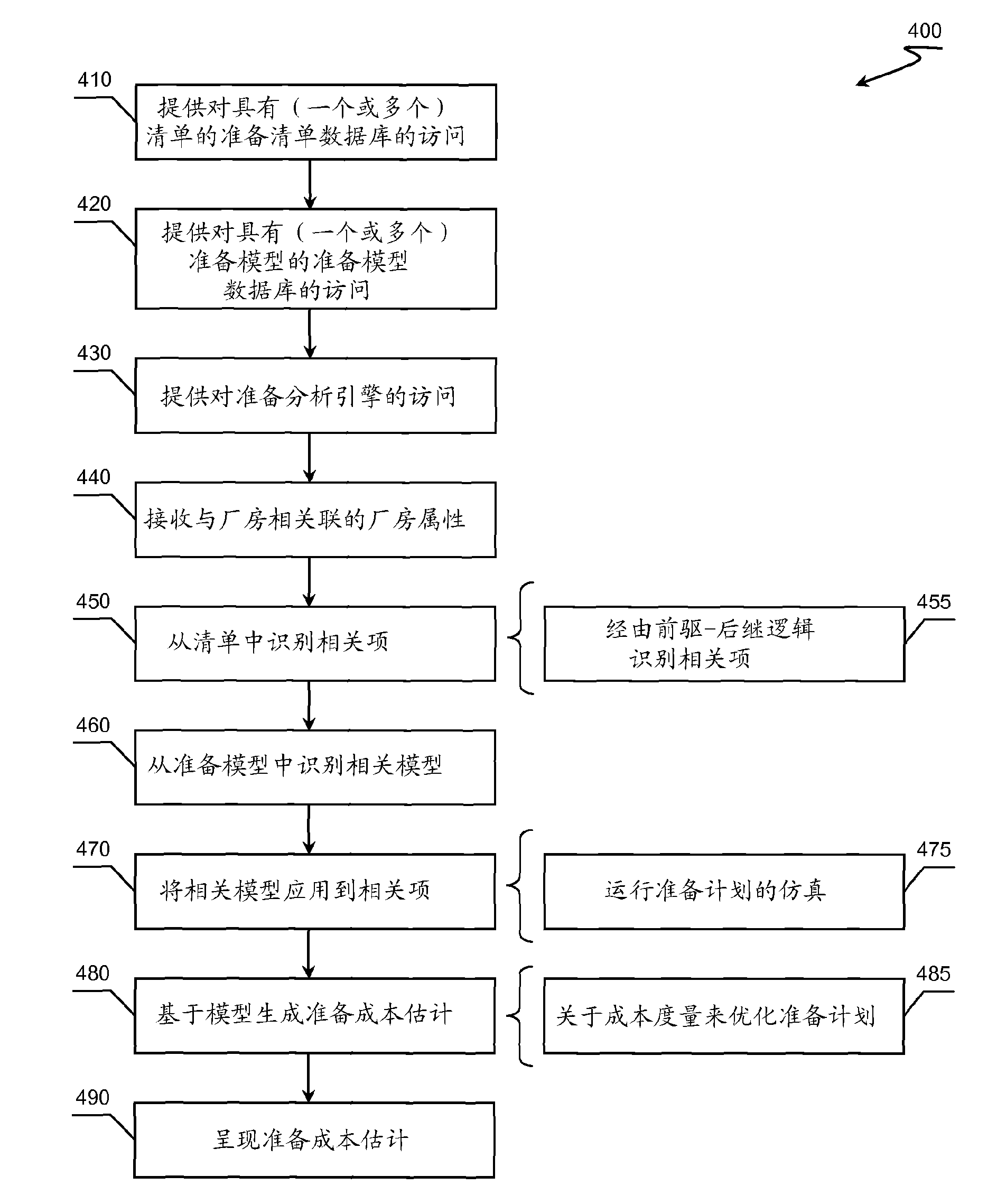

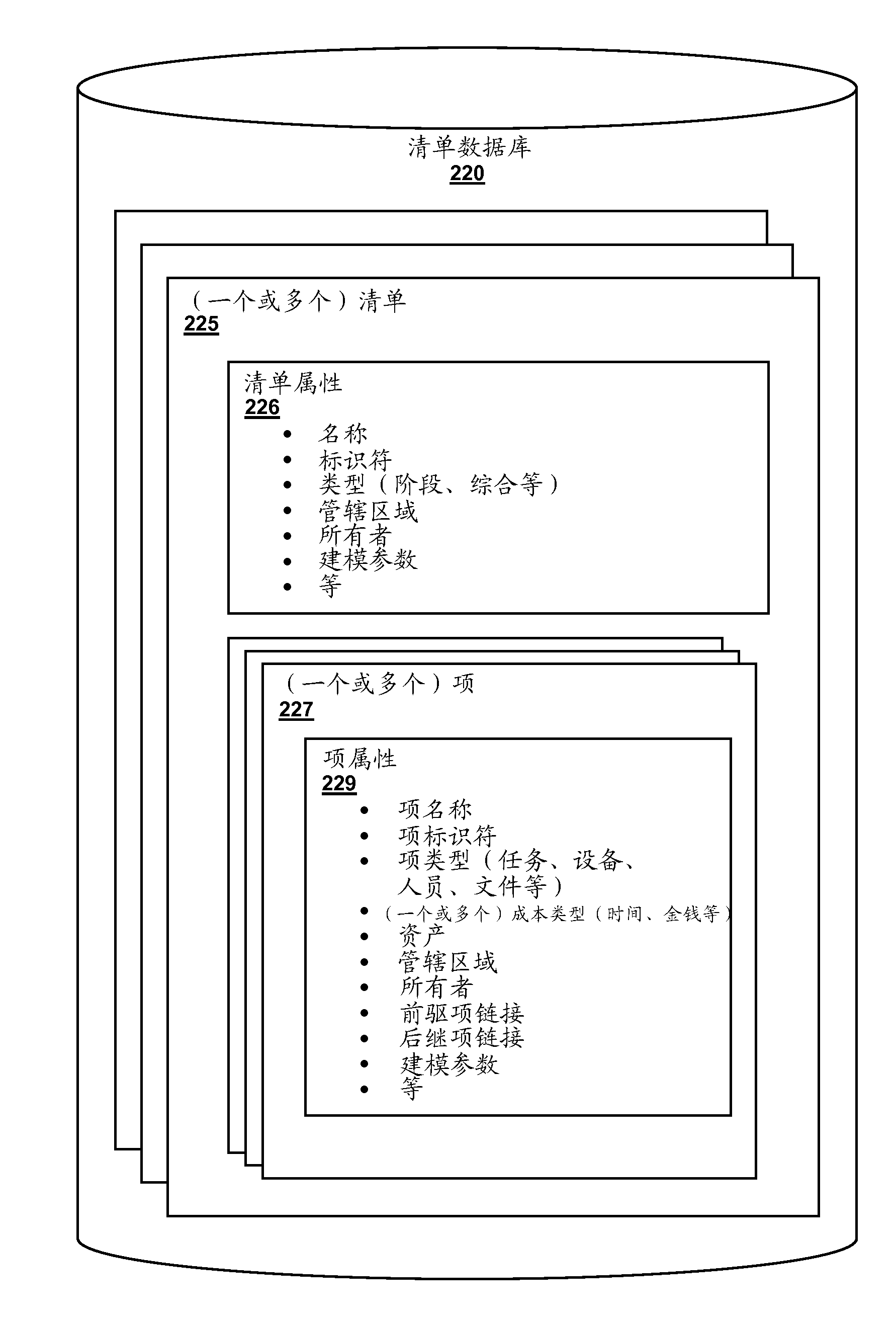

Systems for estimating new industrial plant operational readiness costs

InactiveUS20130191093A1Operational readinessOperating costTechnology managementDesign optimisation/simulationProgram planningOperational readiness

Systems and methods of estimating a plant owner readiness are presented. When a plant owner is preparing for a phase deliverable of a plant construction project (e.g., ownership or operating of the plant), the readiness of the owner can be determined. Furthermore, the cost of achieving readiness can be estimated based on attributes of the plant under construction and based previous plant construction project checklists or readiness models. Contemplated systems can also recommend a readiness plan along with a likelihood of plan success.

Owner:FLUOR TECH CORP

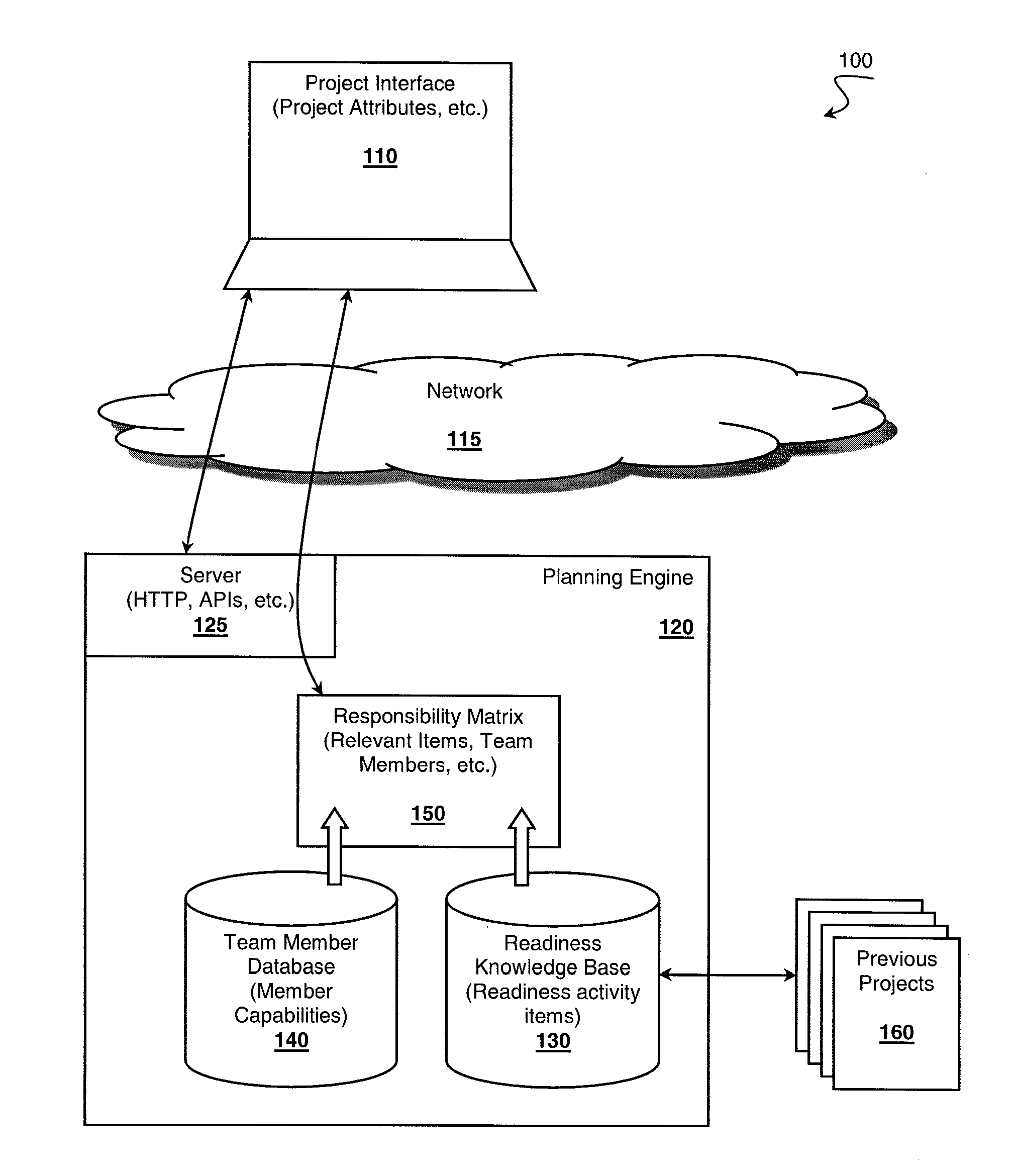

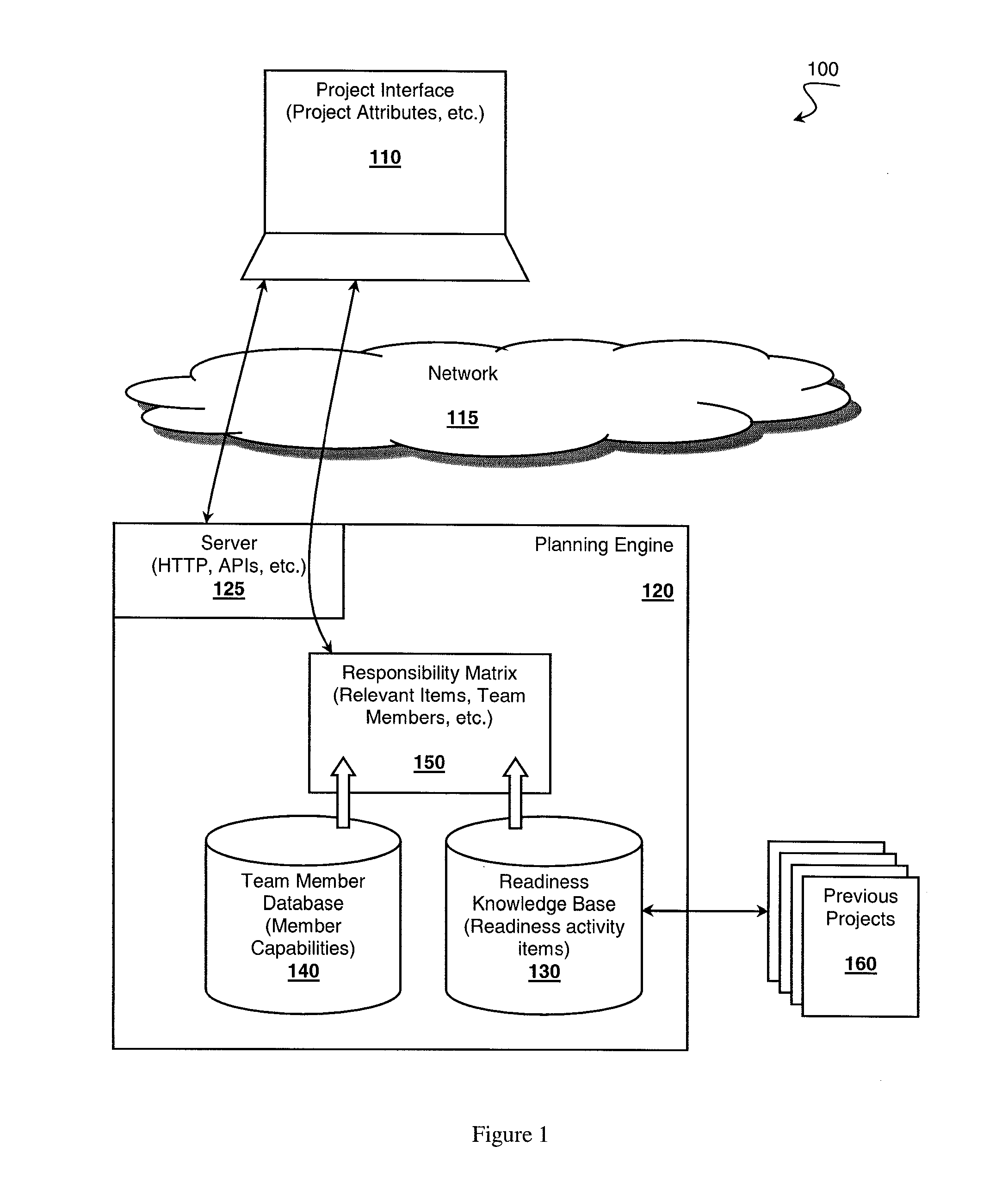

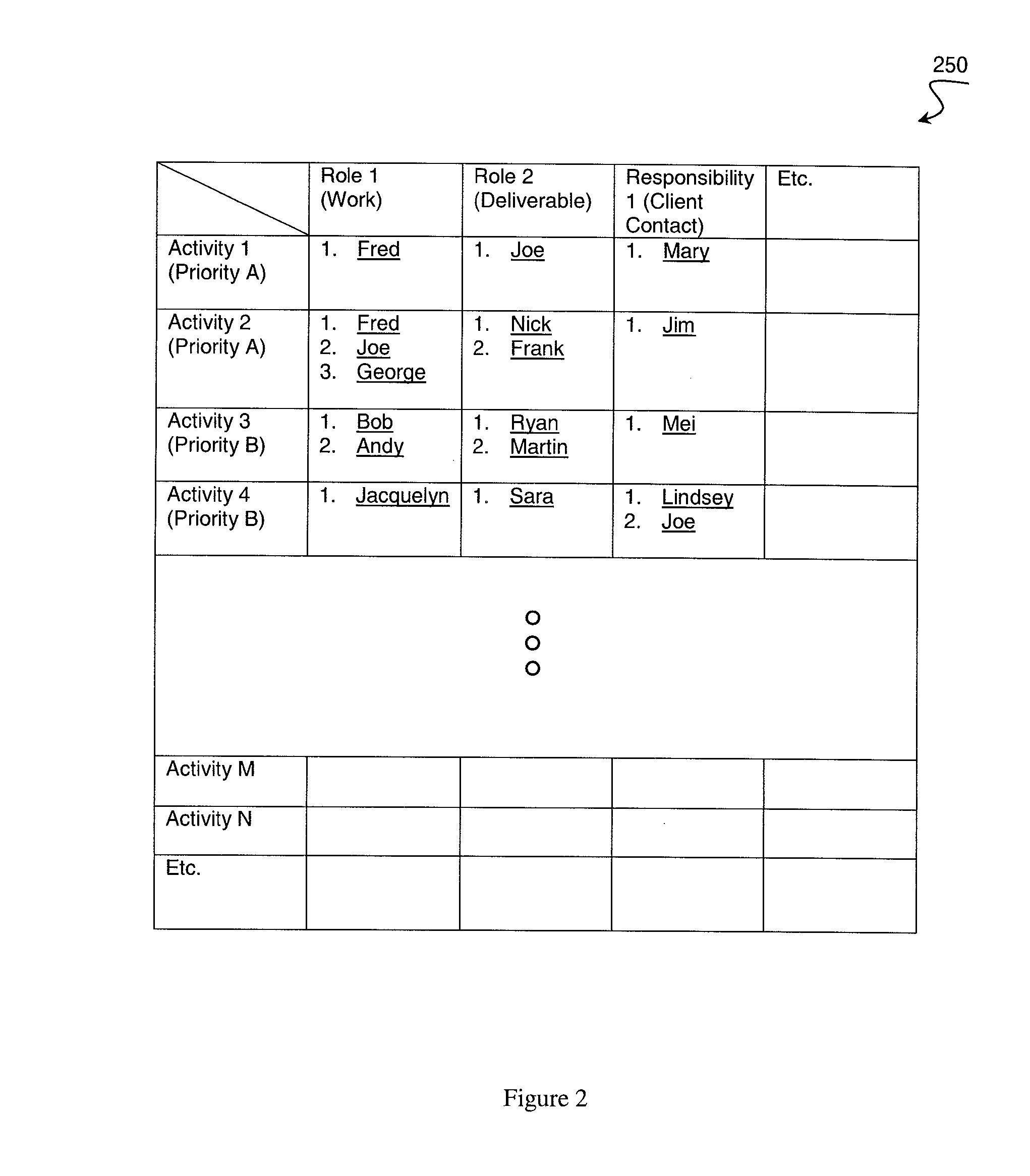

Alignment of operational readiness activities

An operational readiness alignment system is presented. A planning engine leverages readiness activities previous projects to determine which readiness activities are relevant to a current project. The planning engine can further correlate readiness activities with available team members to derive a responsibility matrix representing a recommendation on which team members should be assigned to which readiness activity roles or responsibilities. One can use the contemplated system to derive one or more readiness measures.

Owner:FLUOR TECH CORP

Step analysis process steps within a fleet performance optimization tool

ActiveUS20190354939A1Easy to replaceData processing applicationsRegistering/indicating working of vehiclesData setRanking

A computer-based method for determining an effect of operational readiness for a vehicle in a fleet of vehicles based on a component replacement simulation is described. The method includes querying, using a fleet performance optimization tool, a maintenance data database. The method also includes analyzing the data set using a power law process to predict a next component removal for each vehicle based on hours of operation for each vehicle. The method also includes determining an effect of operational readiness for the selected vehicle based on the simulation. The method further includes ranking each vehicle in the fleet of vehicles based on the operational readiness of each vehicle. The method also includes displaying, based on the ranking, the operational readiness of each vehicle on the user interface to facilitate actual replacement of at least one component on at least one of the vehicles.

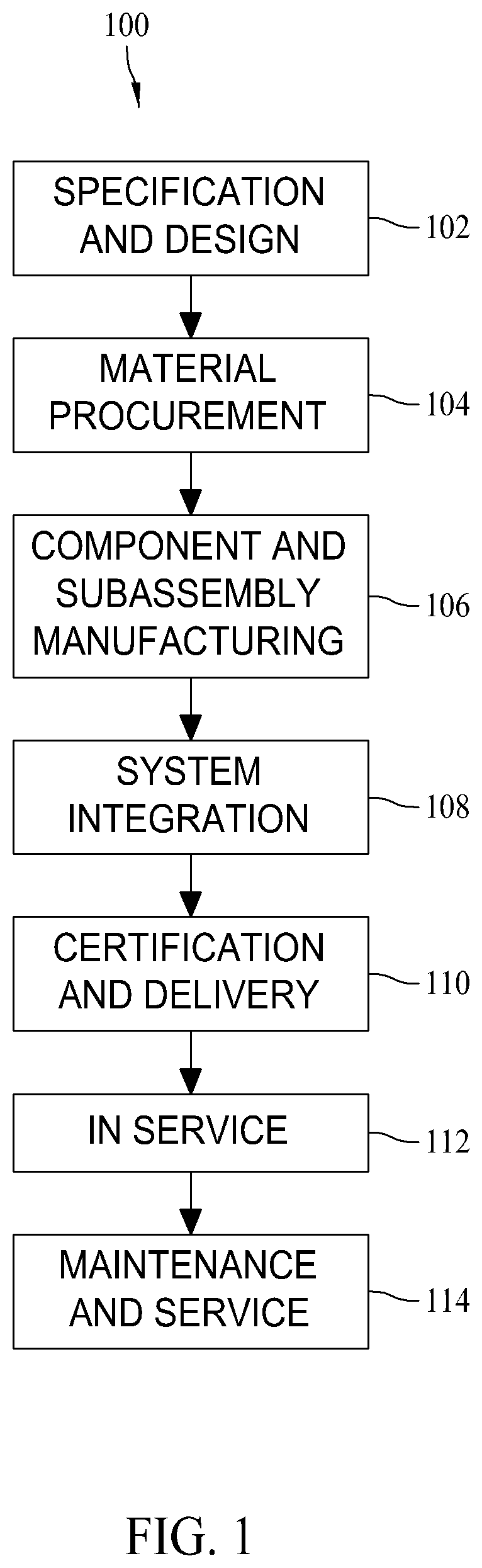

Owner:THE BOEING CO

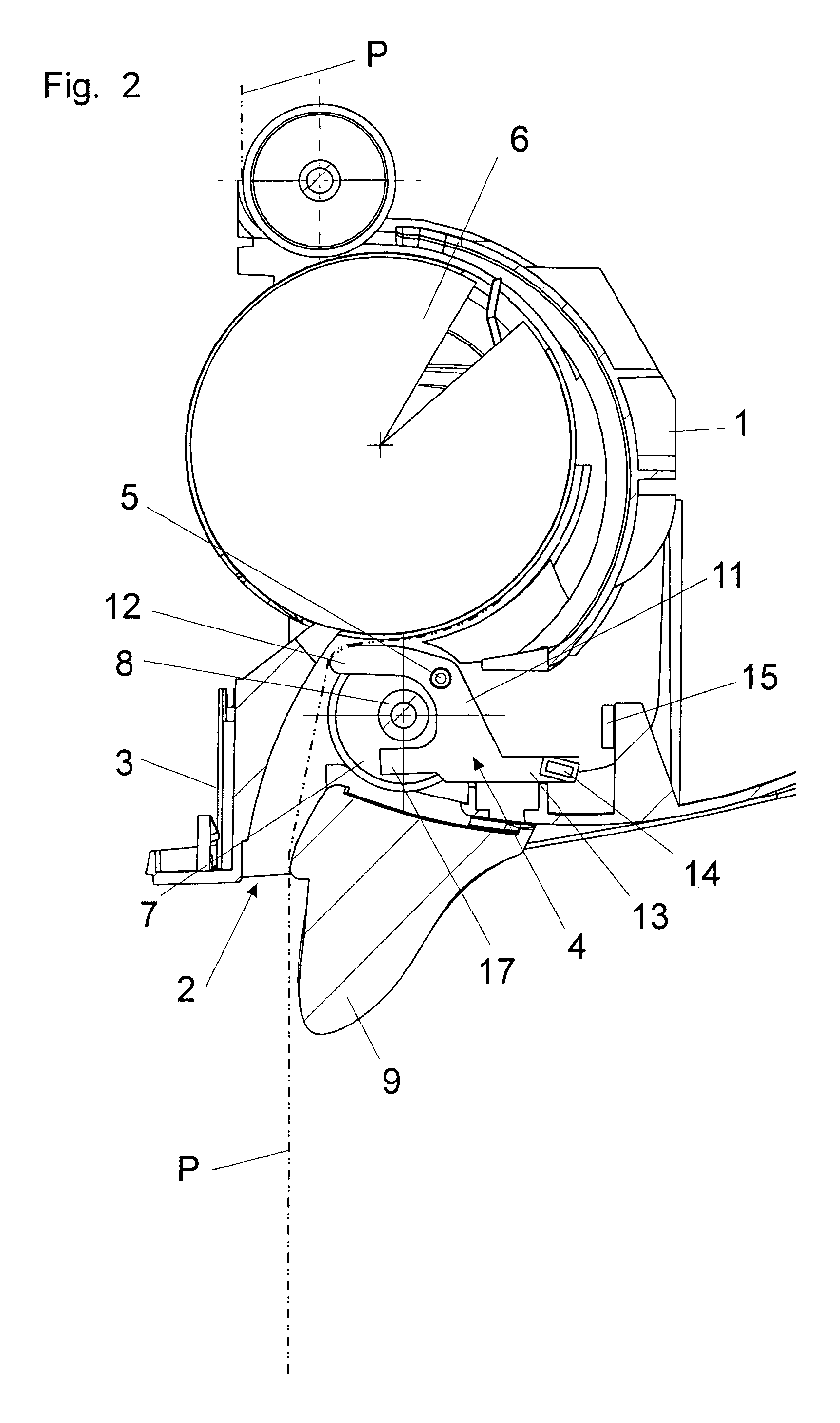

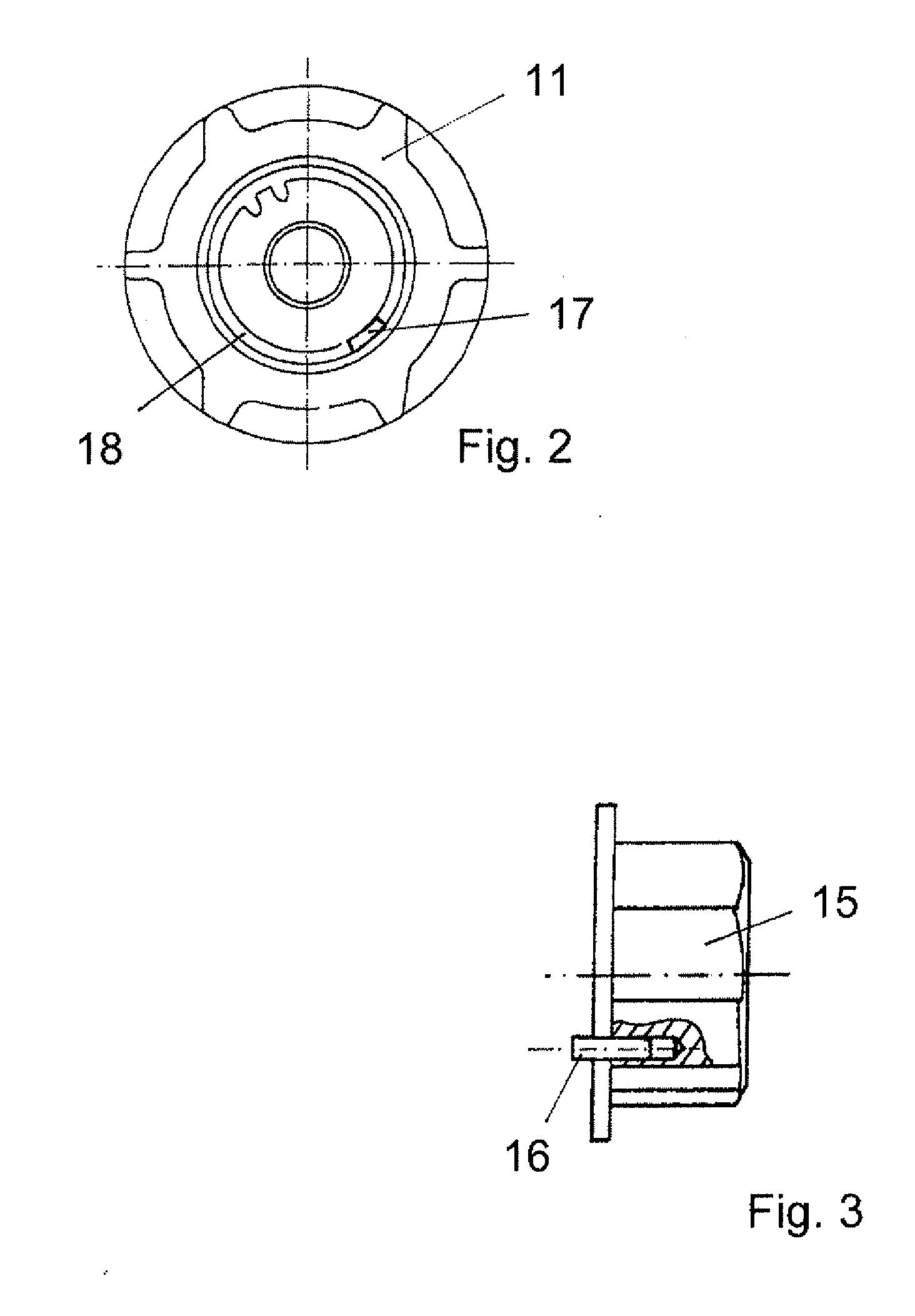

Starting device for an internal combustion engine

InactiveUS20120132170A1Reduce intensityResistant to twistingPower operated startersMuscle operated startersExternal combustion engineEngineering

A starting device for an internal combustion engine includes a pulley mounted rotatably in a housing which can be set in rotation by a tension means to produce a drive torque for a motor shaft by a starter handle and which is connected to an engaging member by a damping spring. The drive torque is transmitted to the motor shaft to start the internal combustion engine, whereby under torsion of the damping spring, a twisting of the pulley against the engaging member is rendered possible until a stop element impacts against a counter-stop to delimit the twisting, which enables a high operational readiness of the starting device. In the case of a defect of the damping spring, the stop element and / or the counter-stop is formed from a material which has a higher strength than the material of the engaging member and / or the material of the pulley.

Owner:MAKITA CORP

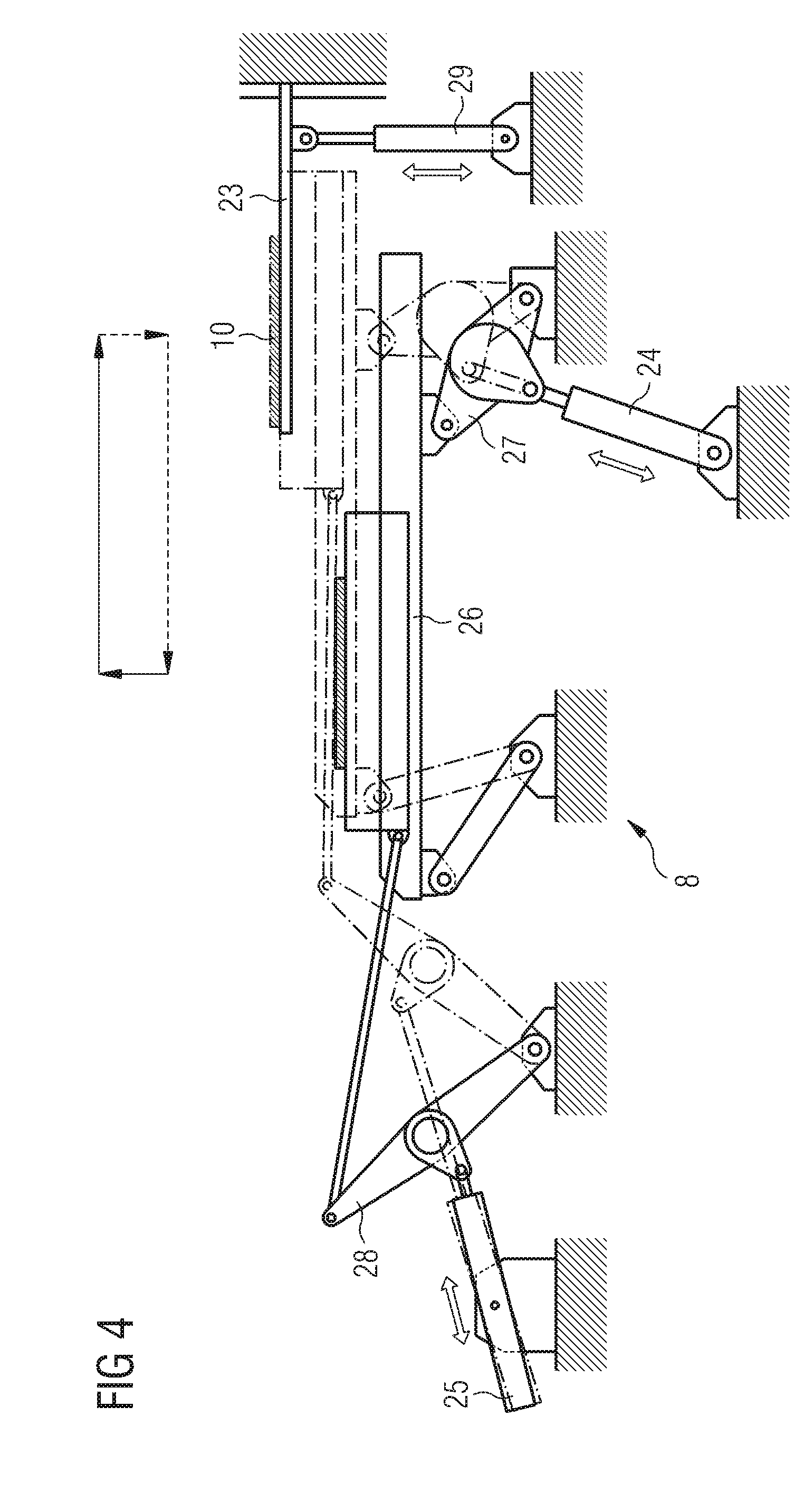

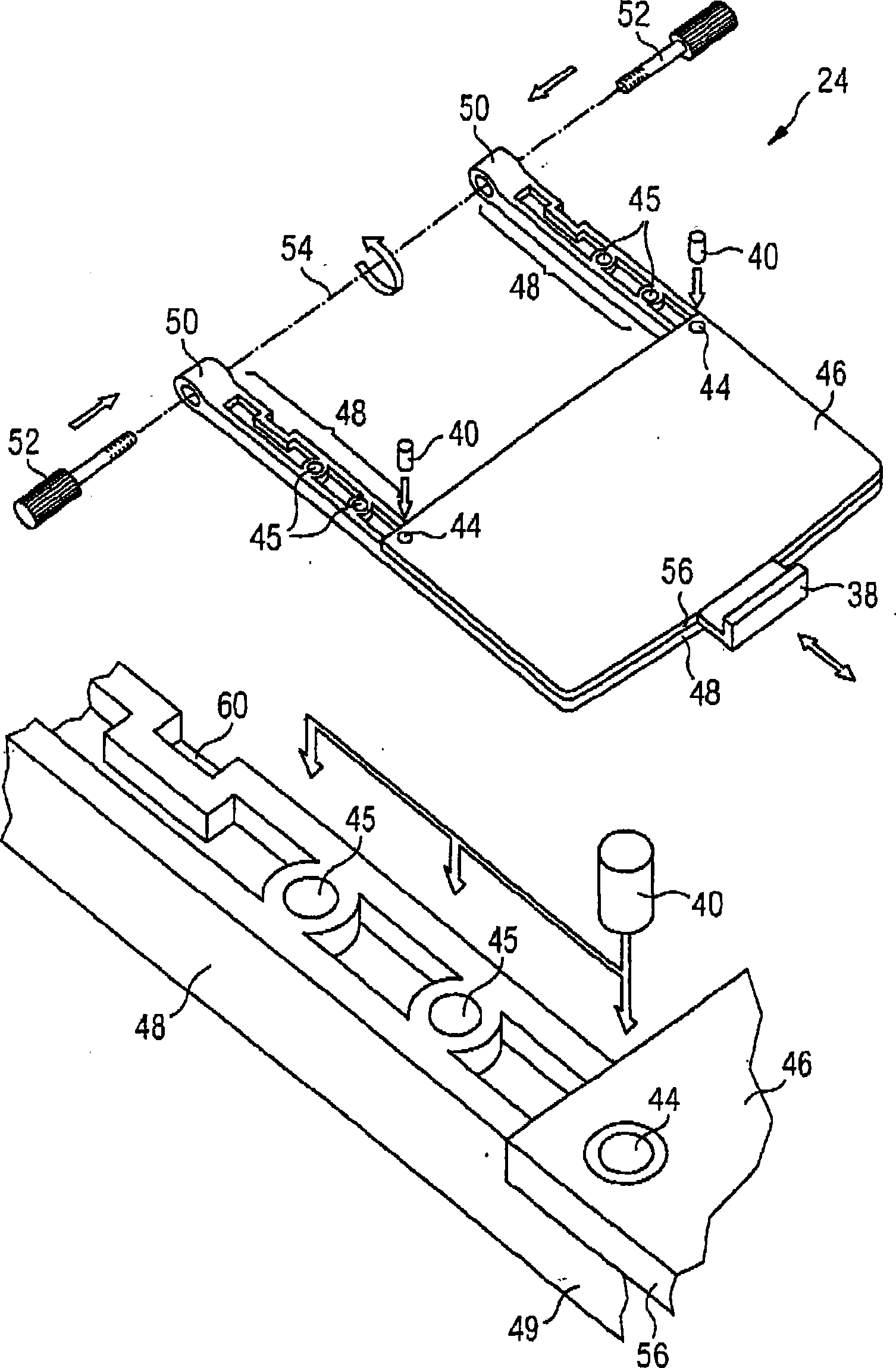

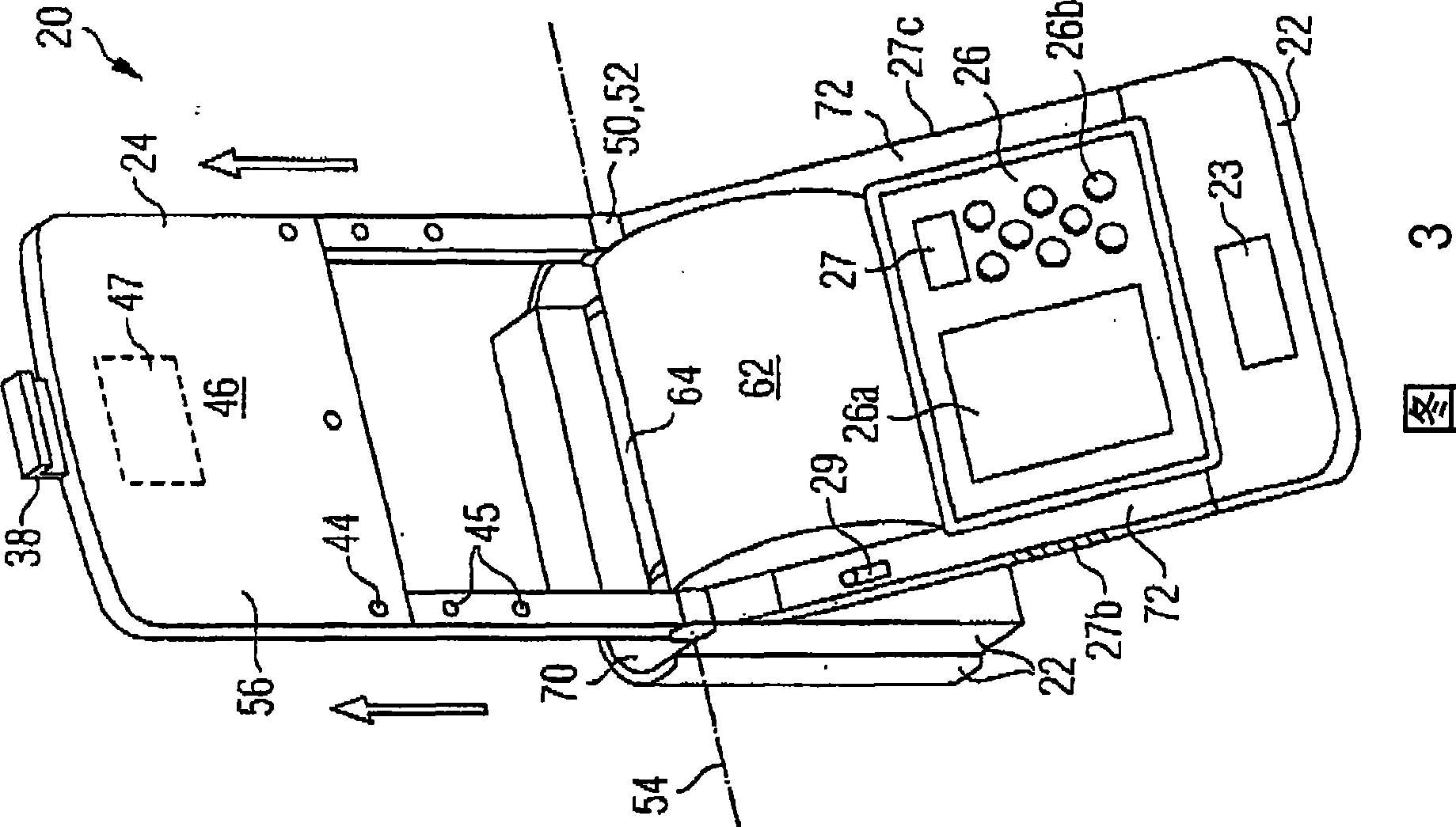

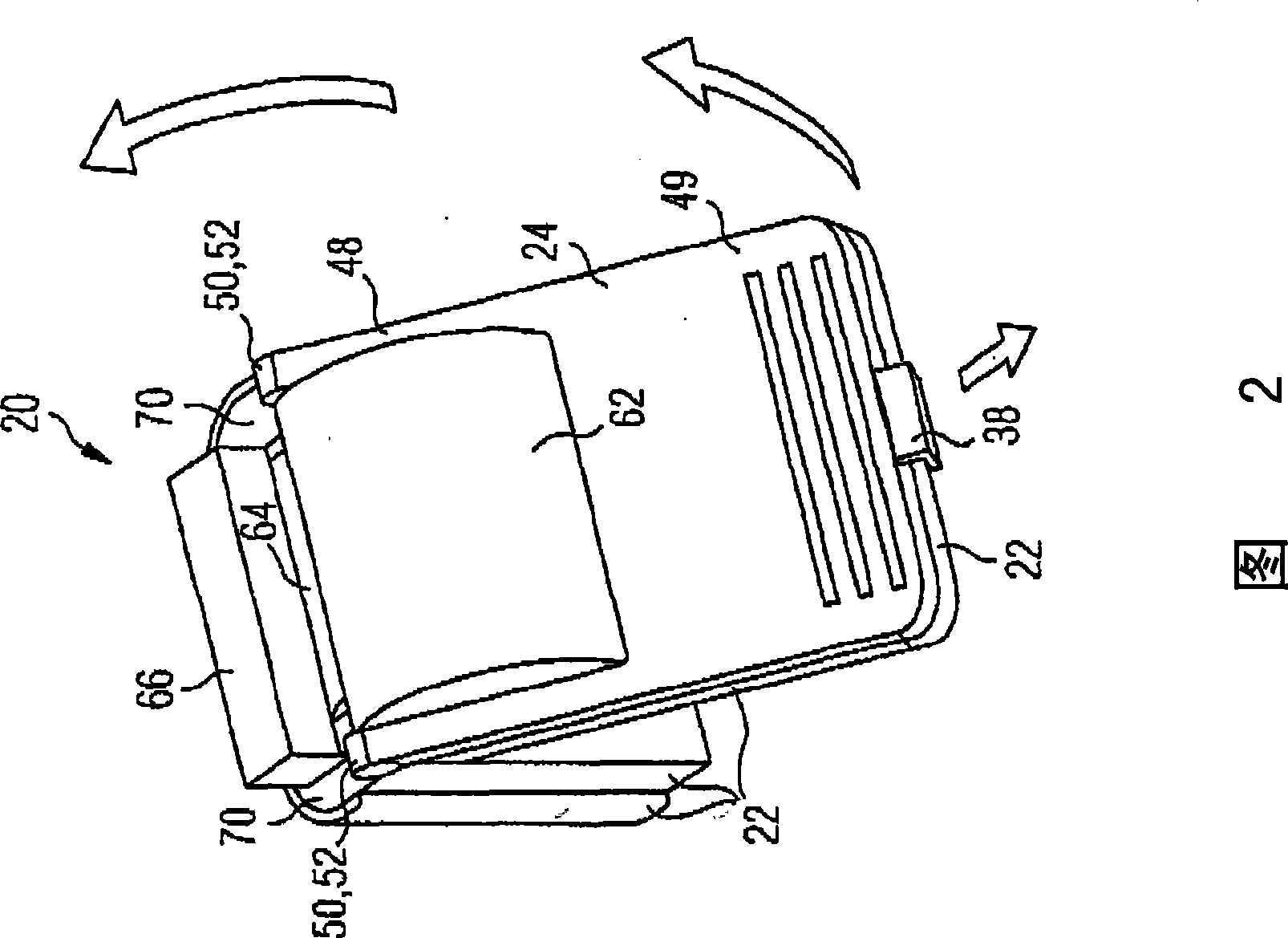

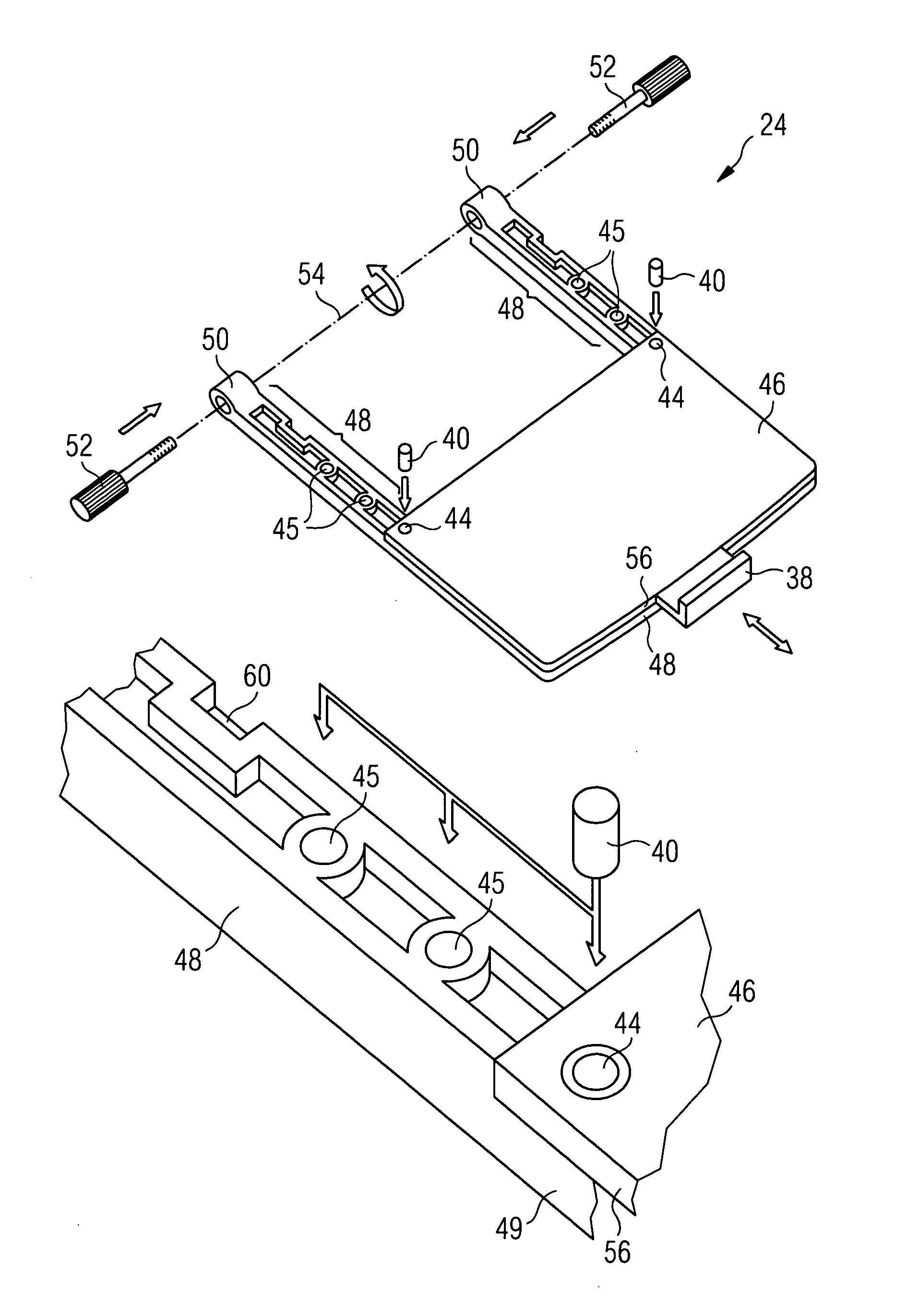

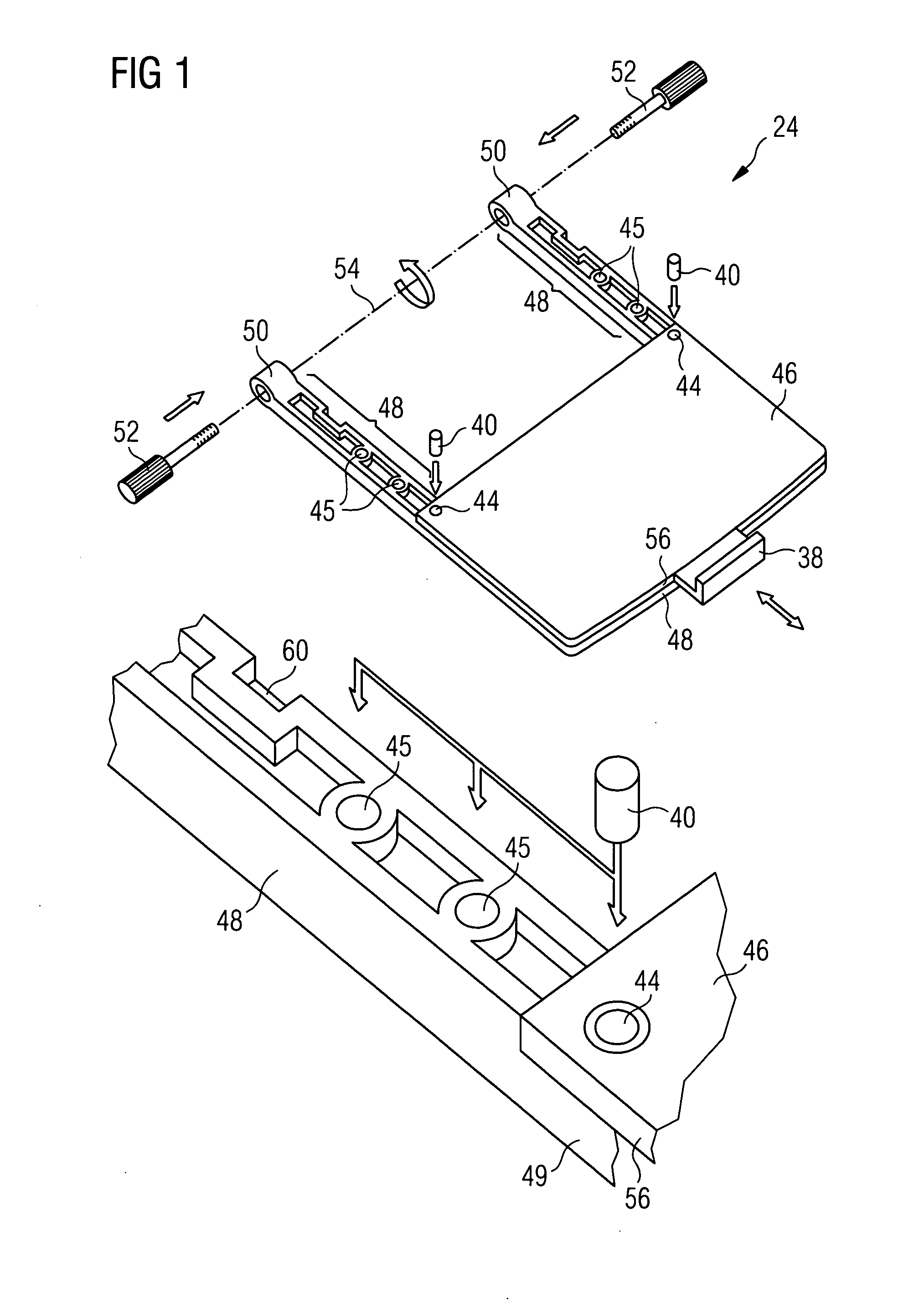

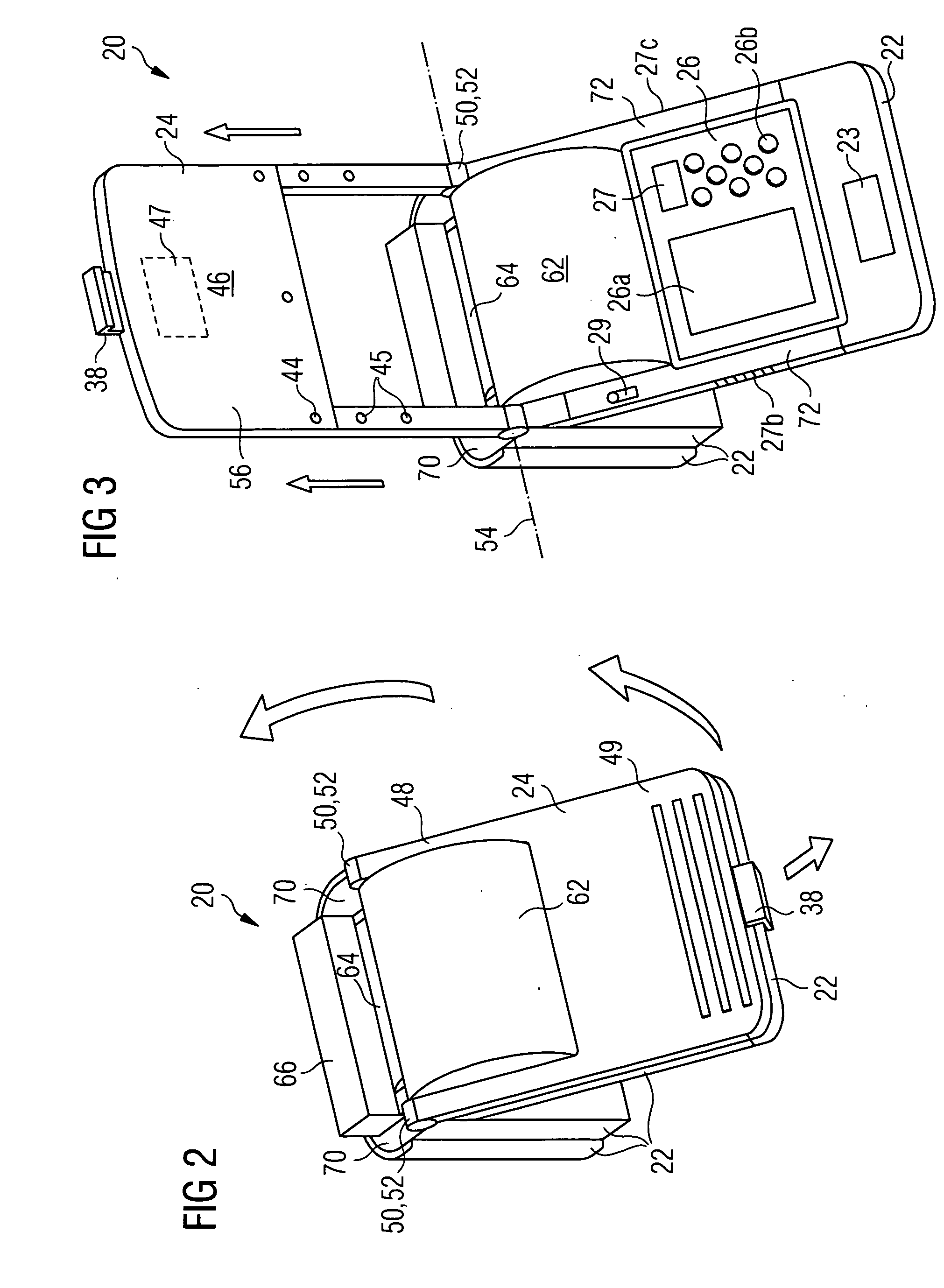

Splicer with rotatable splicing cassette carrier

A splicer (20) comprises a chassis (22) with an opening, in which a splicing unit (10) for splicing optical waveguides (18) is arranged. The splicer can be controlled using a control and display apparatus (26). A splicing cassette carrier (24) is arranged on the chassis (22) such that it can rotate. The splicing cassette carrier is designed such that it can be used both for fixing a splicing cassette but also as a carrying handle for the splicer. The splicer furthermore has a control unit (34) via which the splicer is switched into an active operational state or a stand-by mode, depending on the rotation position (71, 73) of the splicing cassette carrier. If the splicing cassette carrier is open, a light intensity of a background illumination of the display apparatus (26) and a light intensity of an illumination device (63) can be controlled in a variable manner. On account of the reduced power consumption associated therewith, it is possible to extend the operational readiness of the splicer.

Owner:CCS TECH INC

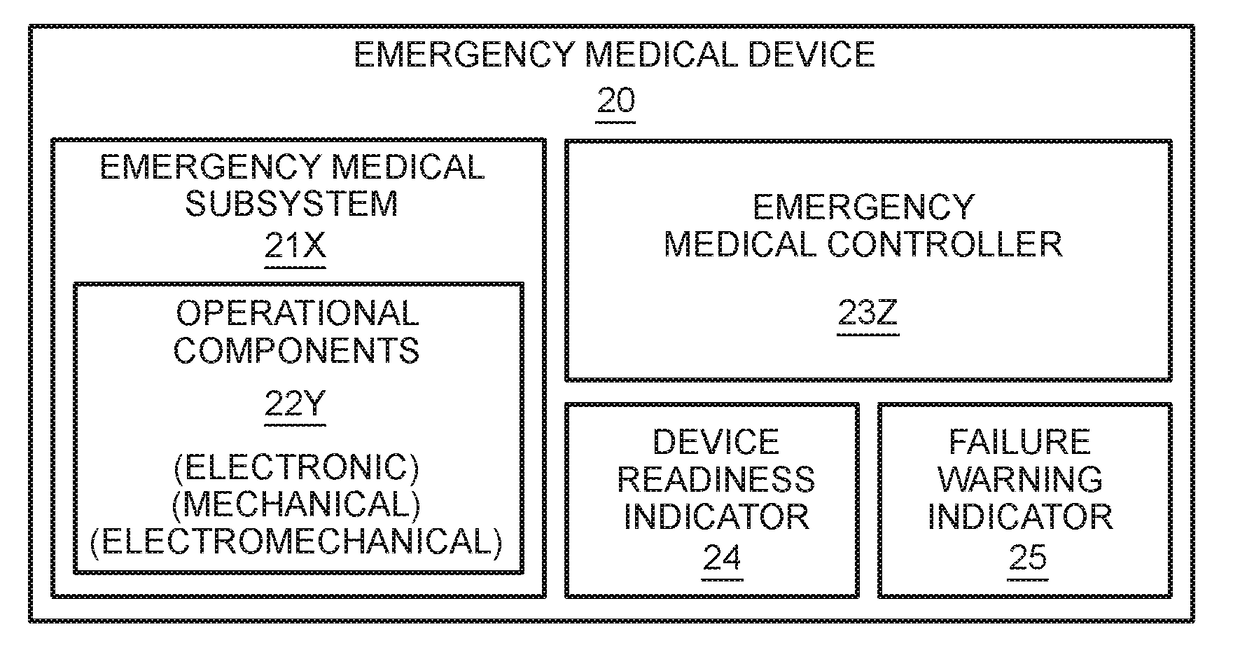

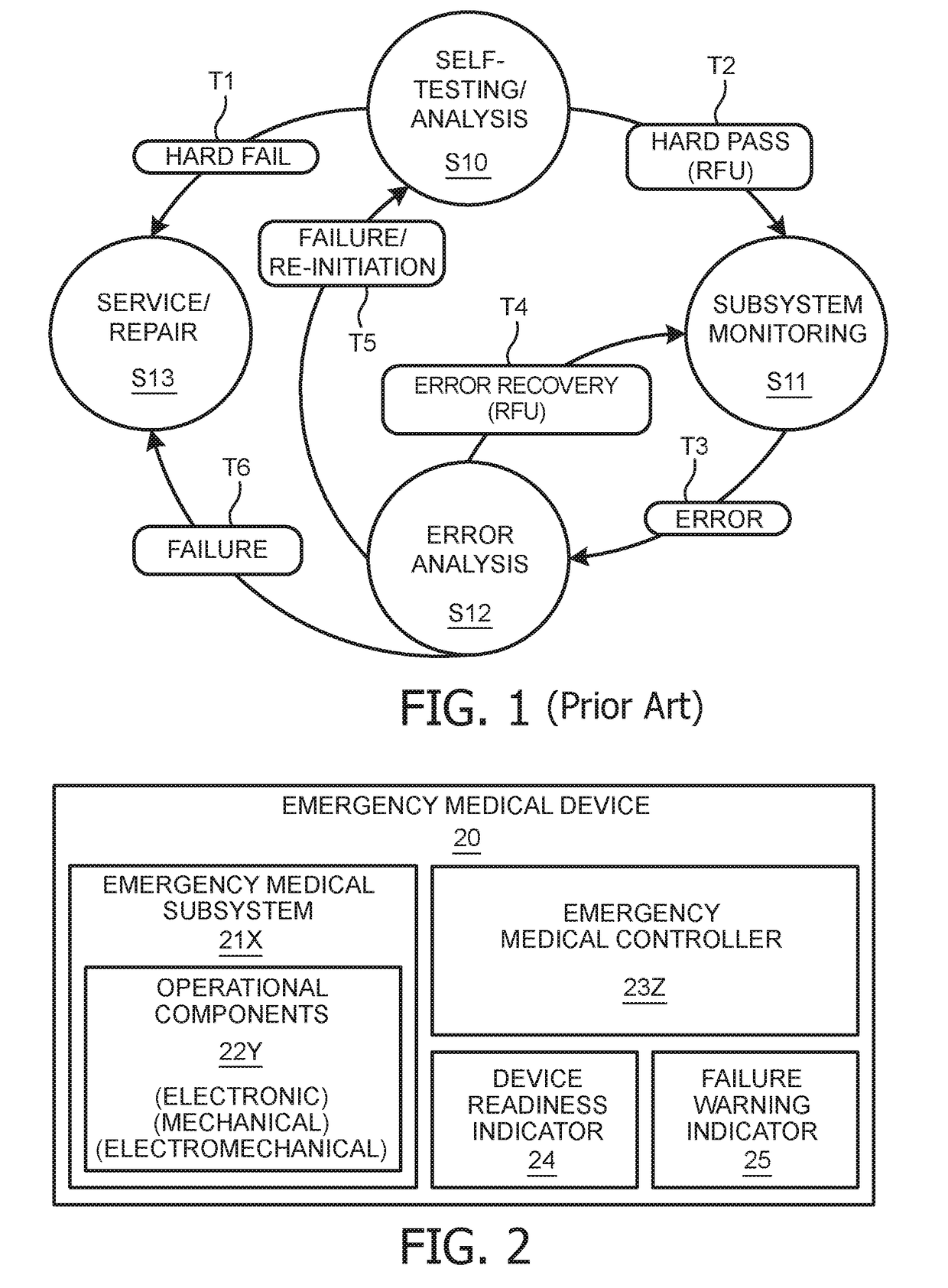

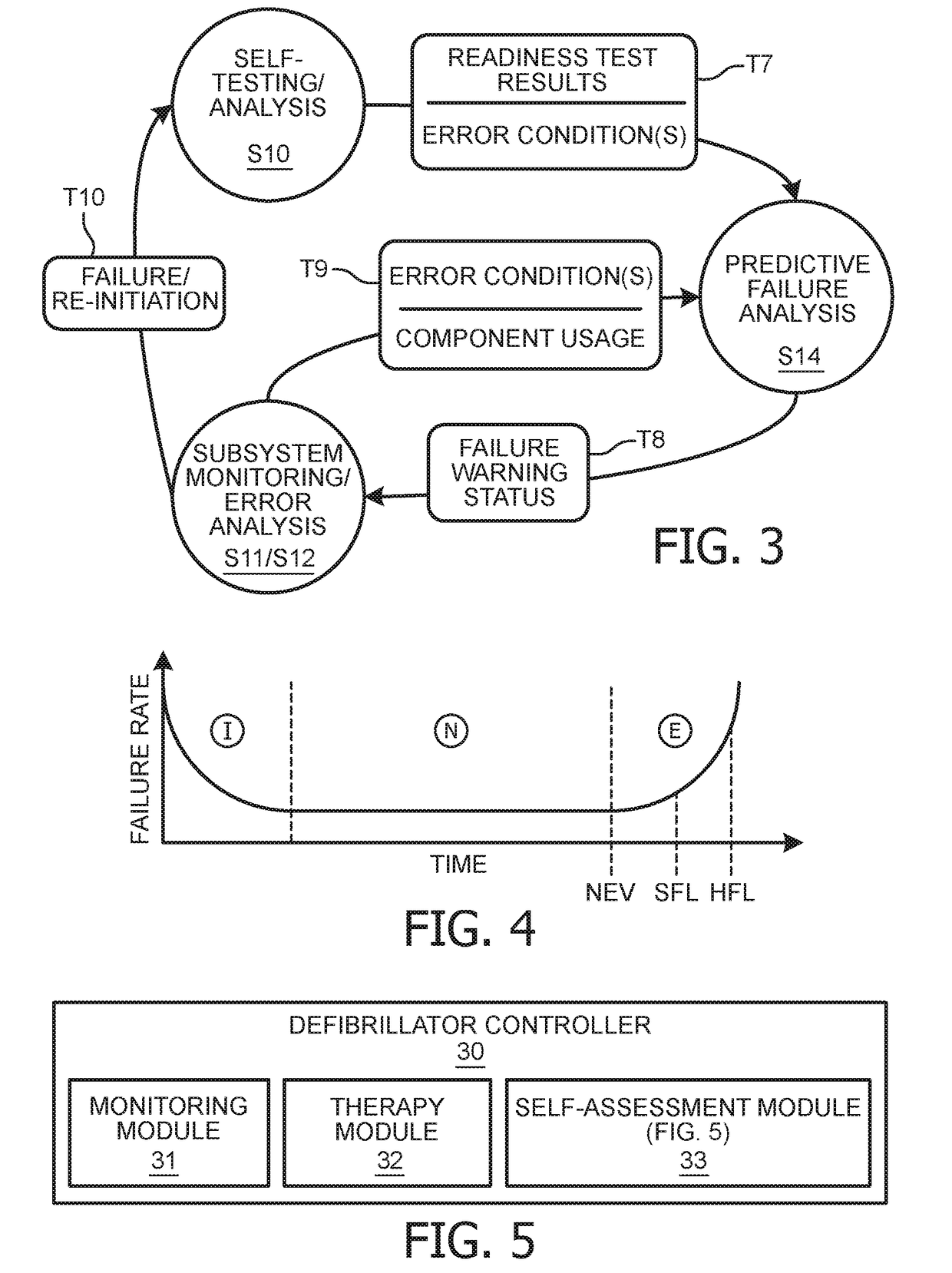

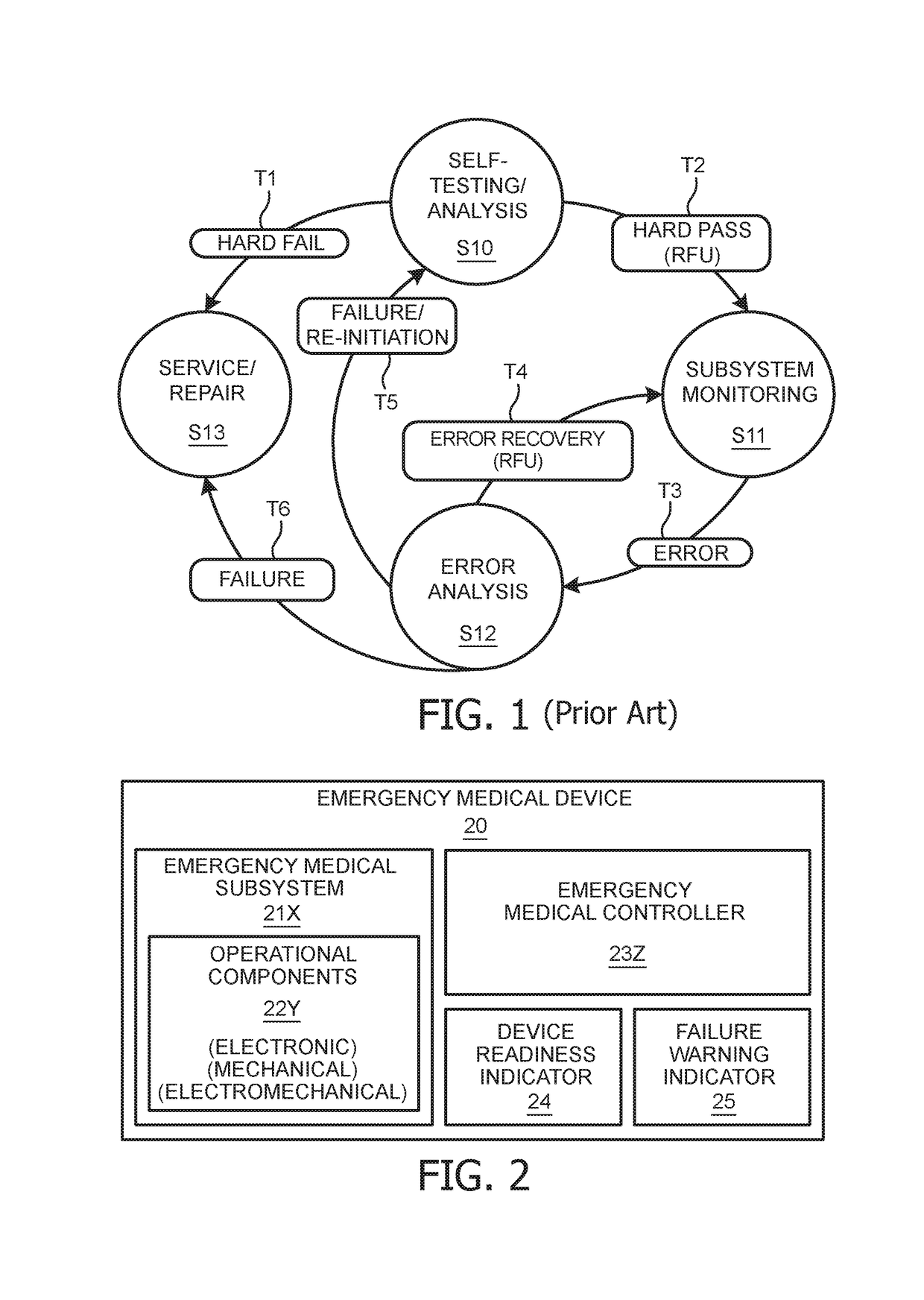

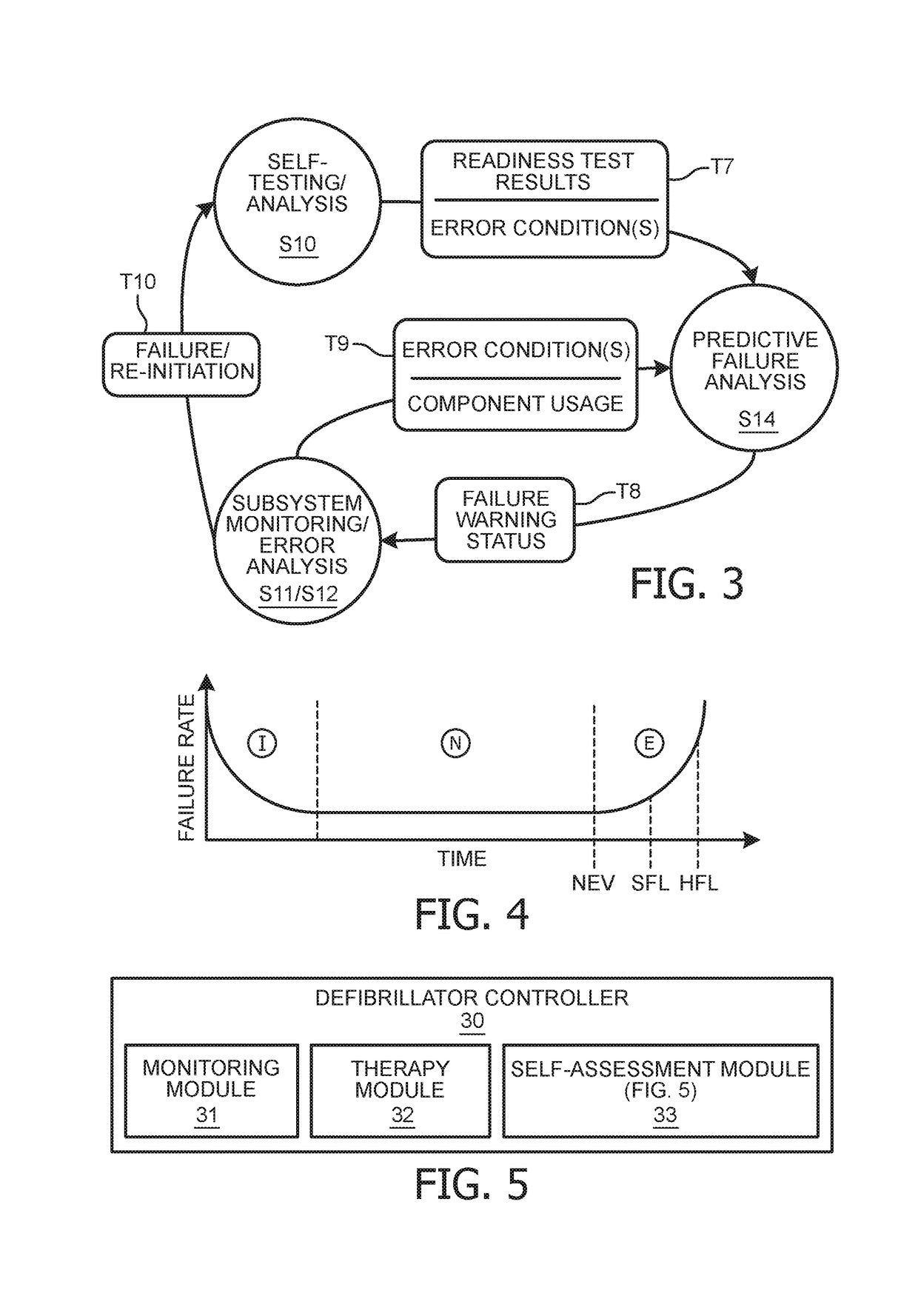

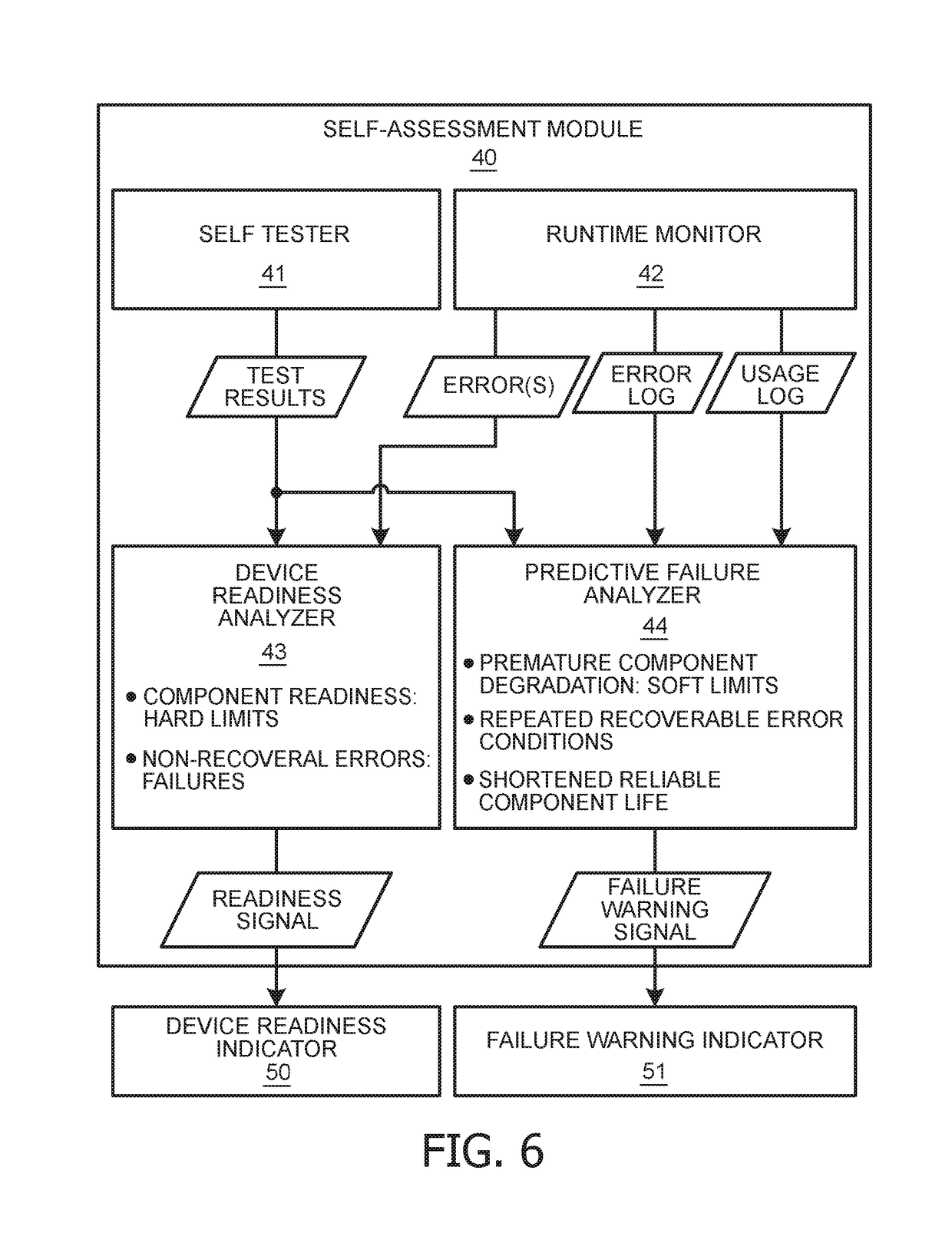

Advanced warning indicator for emergency medical devices

ActiveUS20180001097A1Reduced service lifeMechanical/radiation/invasive therapiesLocal control/monitoringPredictive failure analysisEmergency medical dispatch

An emergency medical device (20) (e.g., an external defibrillator / monitor) employing an emergency medical subsystem (21) for executing an emergency medical procedure (e.g., a monitoring subsystem (21) and a therapy subsystem (21)), and an emergency medical controller (23) for controlling an activation of the emergency medical subsystem (21). The subsystem (21) includes one or more operational components (22). In operation, the controller (23) conditionally actuates a device readiness indicator (24) (e.g., auditory or visual) indicative of an operational readiness of the operational component(s) (22), and conditionally actuates a failure warning indicator (25) (e.g., auditory or visual) indicative of a pending failure of the operational readiness of the operational component(s) (22). The failure warning indicator (25) may be actuated based on a predictive failure analysis of a premature degradation of the operational component(s) (22), a repeated occurrence of error conditions of the operational component(s) (22) (particularly recoverable error conditions), and a shortened reliable life of the operational component(s) (22).

Owner:KONINKLJIJKE PHILIPS NV

Systems for estimating new industrial plant operational readiness costs

InactiveCN103026374ATechnology managementDesign optimisation/simulationProgram planningOperational readiness

Systems and methods of estimating a plant owner readiness are presented. When a plant owner is preparing for a phase deliverable of a plant construction project (e.g., ownership or operating of the plant), the readiness of the owner can be determined. Furthermore, the cost of achieving readiness can be estimated based on attributes of the plant under construction and based previous plant construction project checklists or readiness models. Contemplated systems can also recommend a readiness plan along with a likelihood of plan success.

Owner:FLUOR TECH CORP

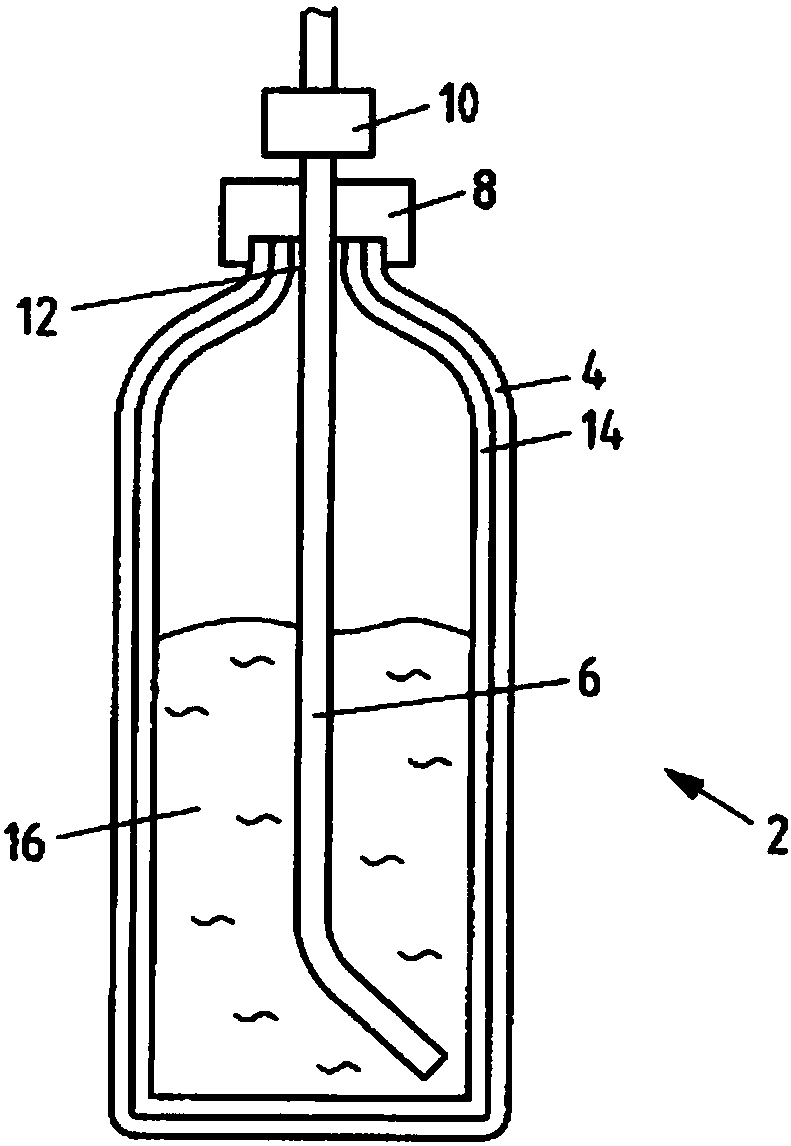

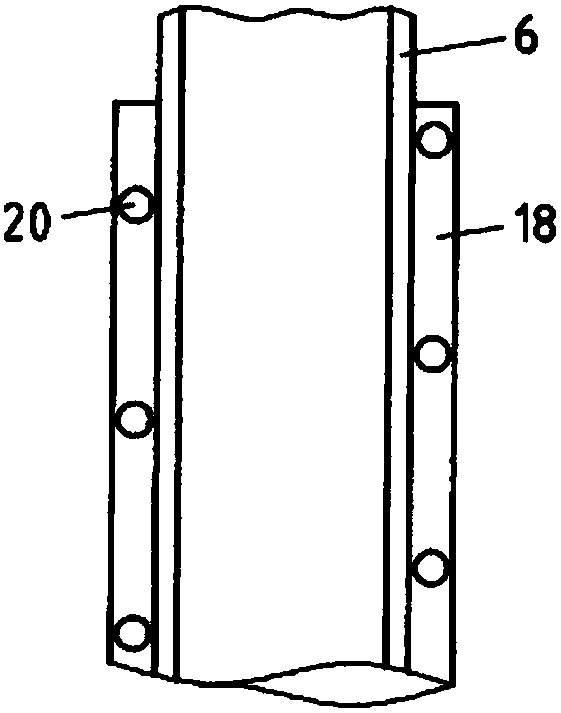

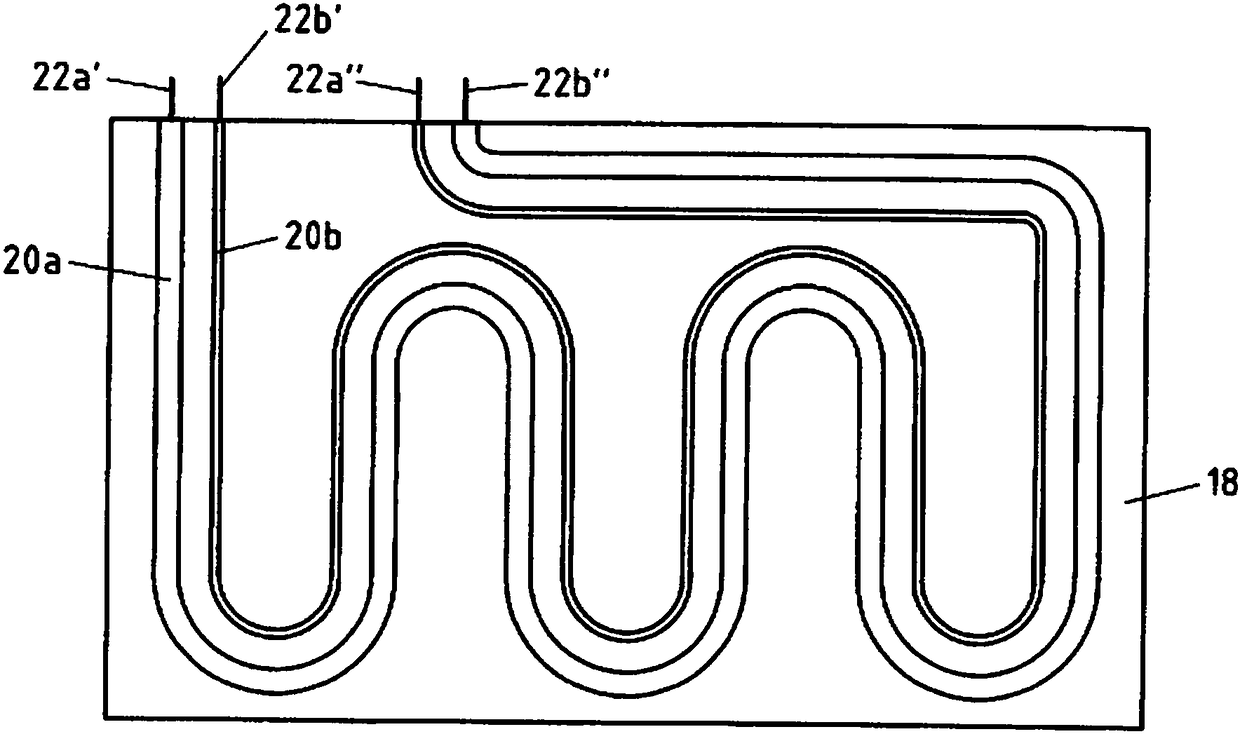

Tubular heating device

PendingCN108348794AIncrease the areaGuaranteed sealing performanceFire rescueOperational readinessBiomedical engineering

The invention relates to a fire fighting system (2). The fire fighting system (2) comprises a pressure-resistant extinguishant container (4), at least one opening in an outer wall of the extinguishantcontainer (4) and a tube (6) disposed in the opening. An increased operational readiness is achieved in that a flat heating means at least partially surrounds the lateral surface of the tube.

Owner:FOGTEC BRANDSCHUTZ GMBH & CO KG

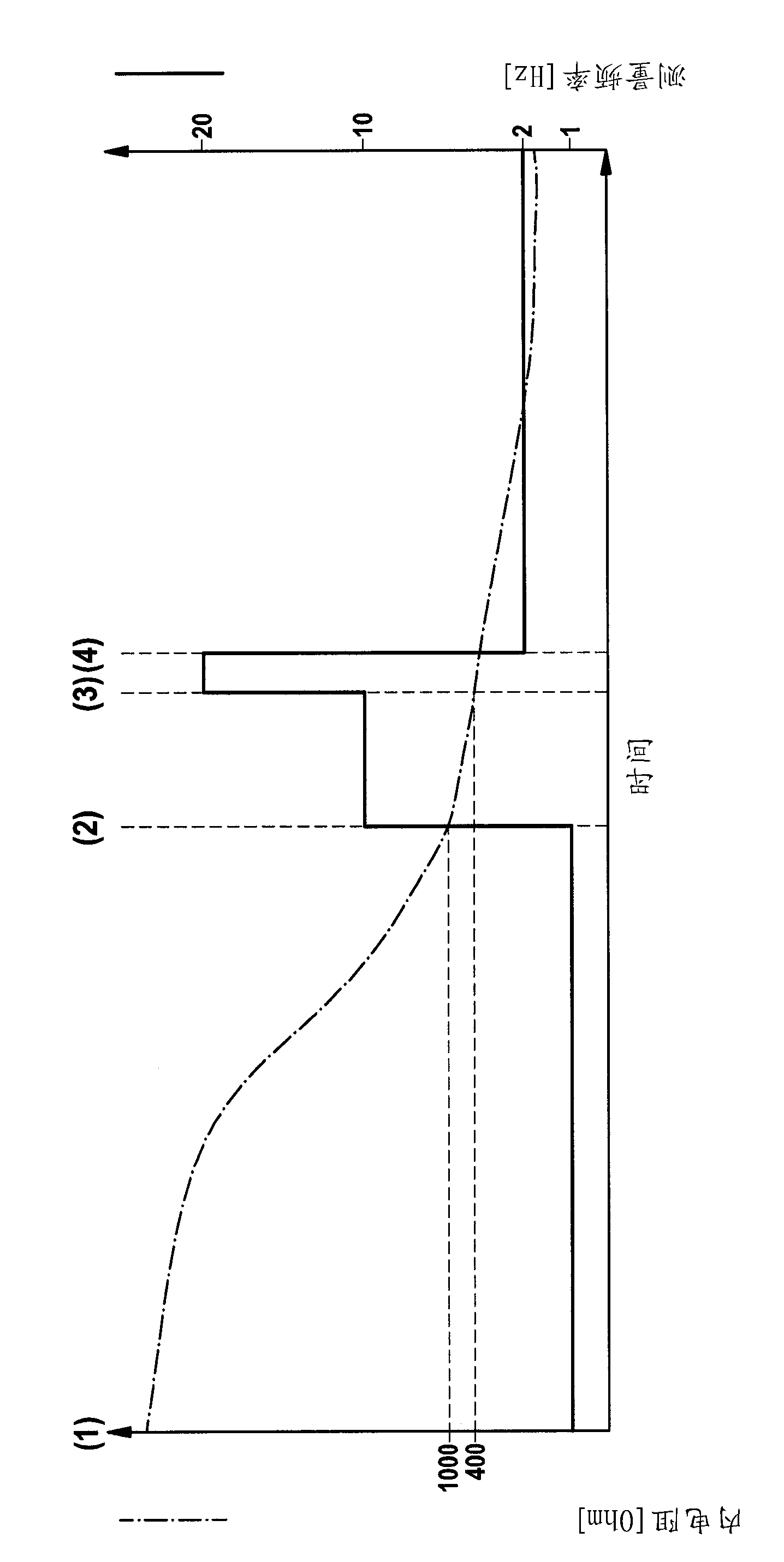

Method for detecting the operational readiness of a jump lambda sensor

ActiveCN103237974AOperational readiness identificationPolarization effects are minimizedElectrical controlInternal combustion piston enginesPower flowInternal resistance

In a method for detecting the operational readiness of a jump lambda sensor associated with an internal combustion engine the internal resistance of the sensor is determined as the criterion for the operational readiness of the sensor. The internal resistance is measured by applying a pulsed current to the sensor, the frequency of the current being selected as a function of the state of the sensor (1, 2, 3, 4).

Owner:ROBERT BOSCH GMBH

Splicer with Splicing Cassette Carrier

InactiveUS20090232457A1Lengthen operational readinessReduce power consumptionCoupling light guidesEffect lightEngineering

A splicer comprises a chassis with an opening in which a splicing unit for splicing of optical waveguides is arranged. The splicer can be controlled via a control and display apparatus. A splicing cassette carrier is arranged rotatably on the chassis. The splicing cassette carrier is designed such that it can be used both for fixing a splicing cassette or else as a carrying handle for the splicer. Furthermore, the splicer has a control unit via which the splicer is switched to an active operating mode or to a standby mode, as a function of the rotation position of the splicing cassette carrier. When the splicing cassette carrier is open, the light intensity of background lighting for the display apparatus and the light intensity of a lighting device can be controlled so they are variable. The reduced power consumption associated with this allows the operational readiness of the splicer to be lengthened.

Owner:CCS TECH INC

Advanced warning indicator for emergency medical devices

ActiveUS10201714B2Reduced service lifeMechanical/radiation/invasive therapiesElectronic circuit testingPredictive failure analysisEmergency medical dispatch

An emergency medical device (20) (e.g., an external defibrillator / monitor) employing an emergency medical subsystem (21) for executing an emergency medical procedure (e.g., a monitoring subsystem (21) and a therapy subsystem (21)), and an emergency medical controller (23) for controlling an activation of the emergency medical subsystem (21). The subsystem (21) includes one or more operational components (22). In operation, the controller (23) conditionally actuates a device readiness indicator (24) (e.g., auditory or visual) indicative of an operational readiness of the operational component(s) (22), and conditionally actuates a failure warning indicator (25) (e.g., auditory or visual) indicative of a pending failure of the operational readiness of the operational component(s) (22). The failure warning indicator (25) may be actuated based on a predictive failure analysis of a premature degradation of the operational component(s) (22), a repeated occurrence of error conditions of the operational component(s) (22) (particularly recoverable error conditions), and a shortened reliable life of the operational component(s) (22).

Owner:KONINKLJIJKE PHILIPS NV

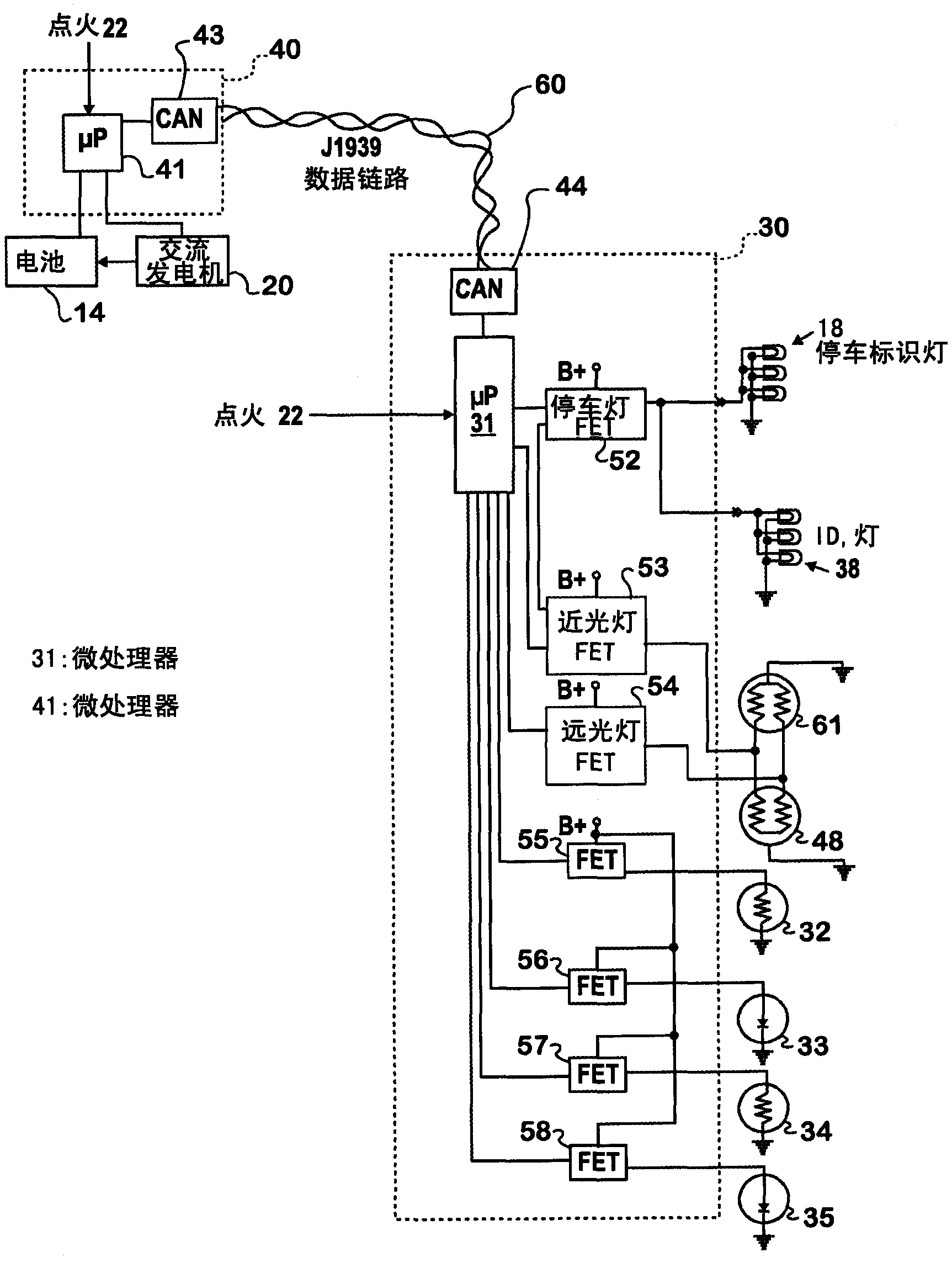

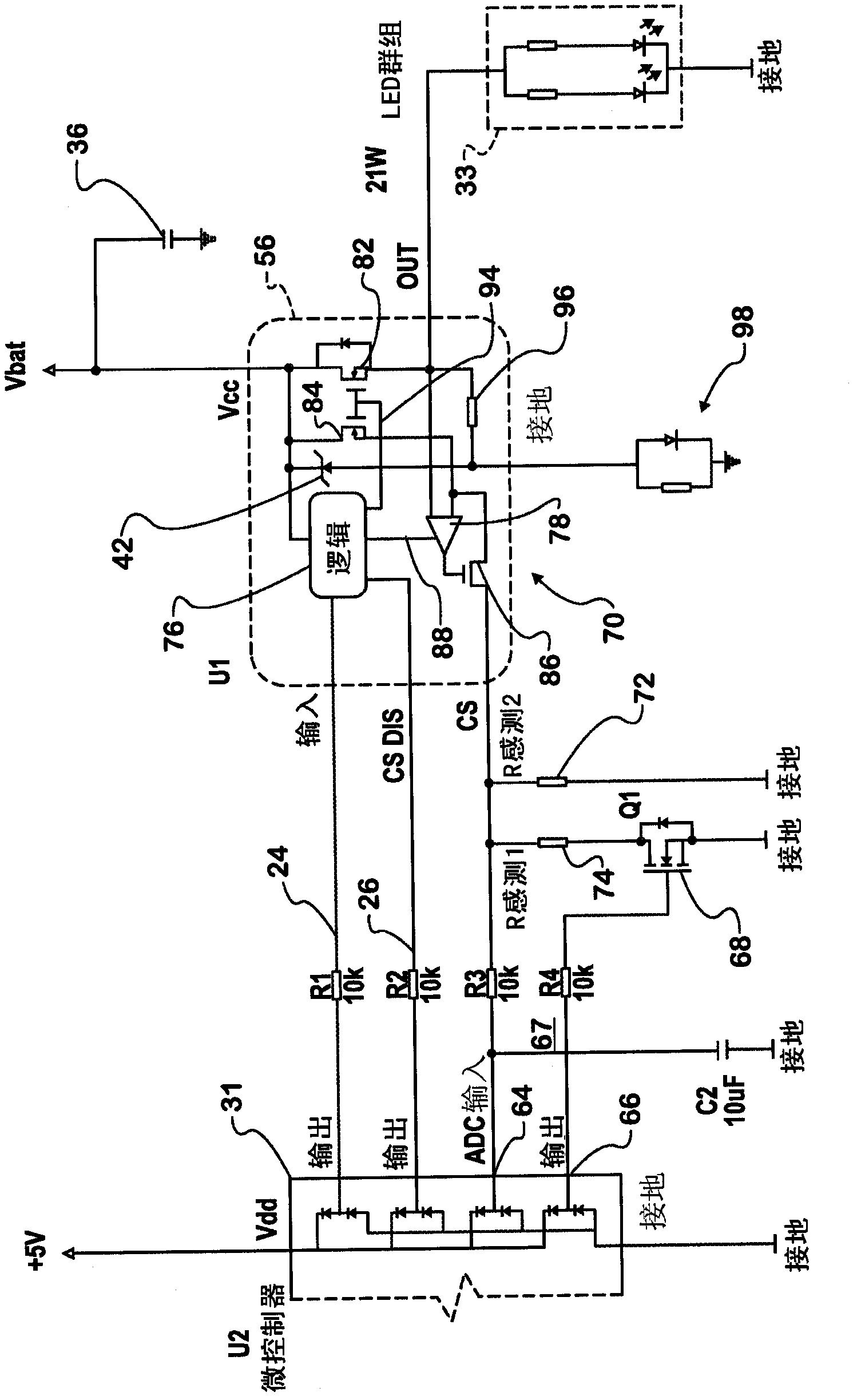

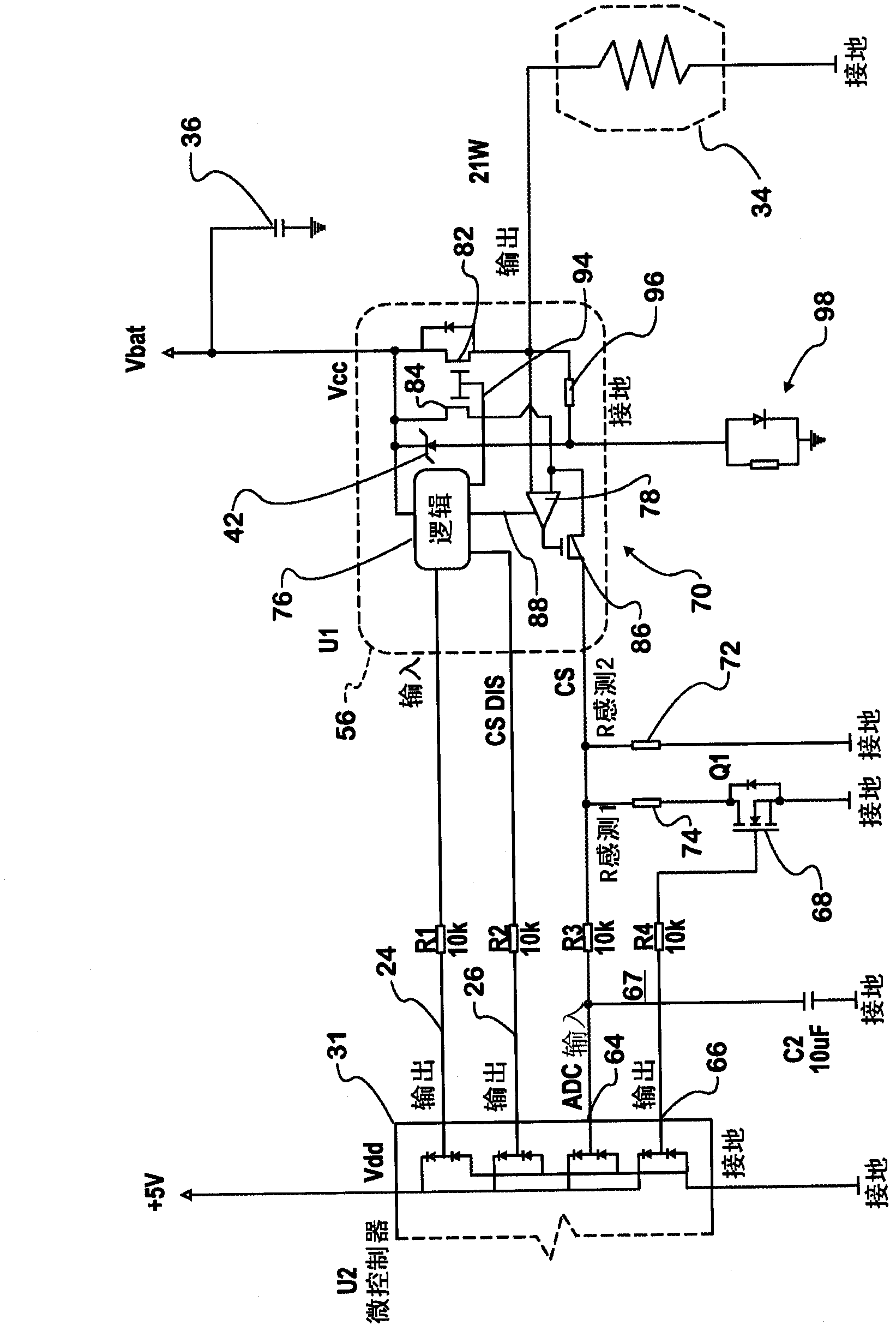

Realtime computer controlled system providing differentiation of incandescent and light emitting diode lamps

InactiveCN103237682AElectrical apparatusAnti-theft devicesComputer control systemOperational readiness

A motor vehicle electrical power system includes a light source powered from an electrical power source. At key on the light source is tested to determine operational readiness and the type of the light source. At key on the switch is cycled to apply a pulse width modulated energization to the light source. A reference copy of the pulse width modulated signal is available. A comparator having first and second inputs provides a comparison of the pulse width modulated signal applied to the light source and reference. Variation in the rate of change of voltage across the light source may be compared with the reference to characterize the light source as a light emitting diode or another type of source, usually an incandescent bulb.

Owner:INT TRUCK INTPROP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com