Equivalent circuit for activation of an electric vacuum pump in case of control unit failure

A technology of electric vacuum pump and backup circuit, which is applied in the direction of brakes, brake safety systems, brake transmissions, etc., and can solve problems such as troubles and discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

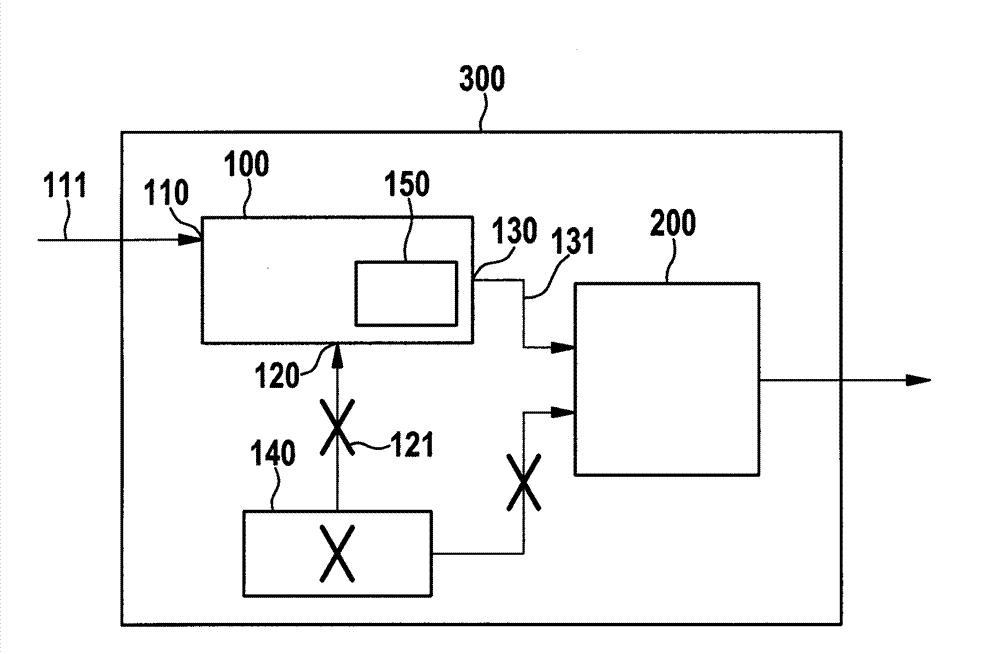

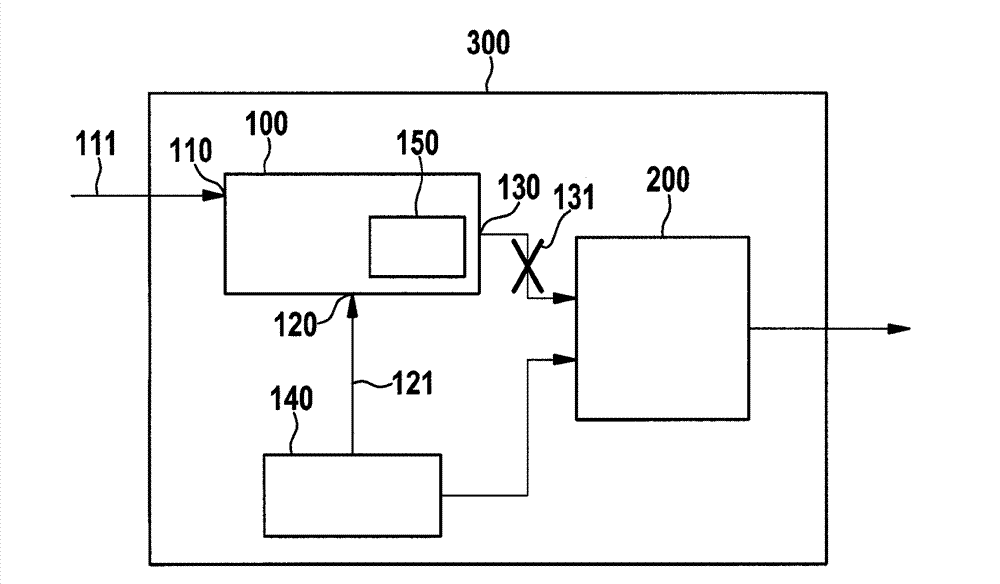

[0028] figure 1 A functional diagram of the backup circuit 100 according to the invention is shown when the main control device 140 is functionally ready.

[0029] The backup circuit 100 for activating the electric vacuum pump 200 in the braking force amplification device 300 has a first signal input terminal 110 for inputting a brake operation signal 111 and a reference signal 121 for inputting a main control device 140 of the electric vacuum pump. The second signal input terminal 120 . Among them, for example, an ESP controller can be used as the main control device 140 . Furthermore, the standby circuit has a signal output 130 for triggering the electric vacuum pump 200 . First signal input 110 and signal output 130 are connected to each other in such a way that a signal 131 for activating electric vacuum pump 200 is output at signal output 130 when a signal 111 representing a brake operation is input to first signal input 110 . The second signal input 120 and the signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com