High-temperature air combustion intensifying device and method applicable to low heating value mixed garbage

A high-temperature air, low calorific value technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of low incineration power generation efficiency, insufficient combustion, high proportion of coal mixed, etc., to achieve long-term stable operation promotion, long residence time, Enhance the effect of waste incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

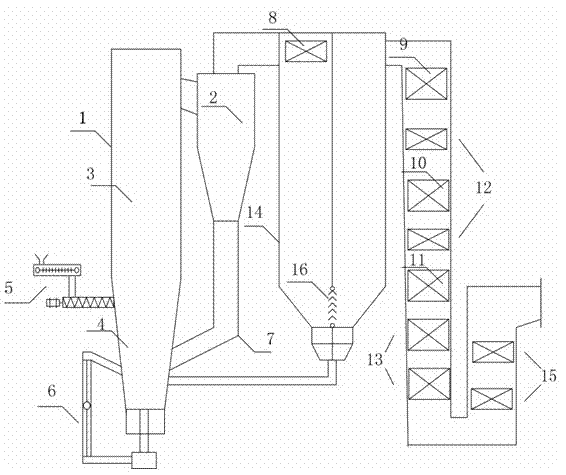

[0016] Such as figure 1 As shown, the high-temperature air enhanced combustion device suitable for mixed waste with low calorific value includes furnace 1, cyclone separator 2, furnace dilute-phase zone 3, furnace dense-phase zone 4, garbage feeding port 5, water-cooled cold slag sorting and recycling Feeding device 6, feeder 7, high temperature air preheater 8, high temperature superheater 9, medium temperature superheater 10, low temperature superheater 11, primary and secondary air air preheater 12, economizer 13, U-shaped burner Chamber 14, low-temperature air preheater 15, impact separator 16 and U-shaped tail flue; the upper part of the furnace 1 is the furnace dilute-phase zone 3, the lower part of the furnace 1 is the furnace dense-phase zone 4, and the upper part of the front side of the U-shaped ember chamber 14 A high-temperature air preheater 8 is provided, an impact separator 16 is provided at the bottom of the U-shaped ember chamber 14, and a high-temperature sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com