S-shaped regenerative chamber type regenerative burner nozzle

A regenerator, regenerative technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of difficult maintenance, large volume, complex burner structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

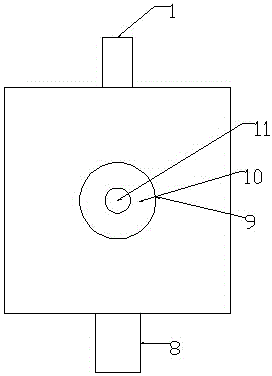

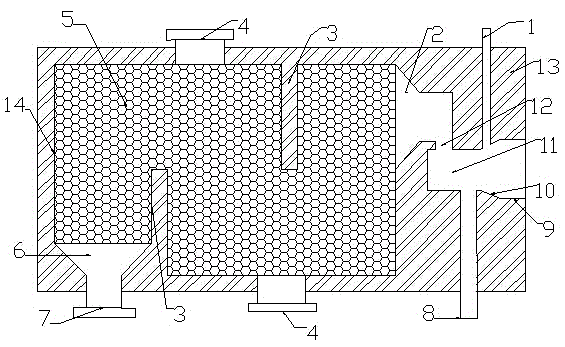

[0009] The regenerative burner adopts integral casting and is divided into a burner body 13 and a regenerator 14 . Such as figure 1 and figure 2 As shown, the burner body 13 is divided into an injection section 9 , a combustion section 10 and a mixing section 11 . The injection section 9 adopts a cylindrical shape, and the combustion section 10 adopts a fan shape, and is connected with the guide burner 1, which is helpful for the dispersion of the mixed gas and enhances the combustion effect. The mixing section 11 adopts a cylindrical shape and connects the air passage 12 and the fuel pipe 8 , and the other side of the air passage 12 adopts a fan-shaped end 2 . The fuel pipe 8 can form any angle with the central axis of the burner. The regenerator 14 is in the shape of a quadrangular prism, and partition plates 3 are arranged alternately up and down to separate the regenerator into an S-shape. The number of partition plates 3 is 1 to 5. If the number is too large, the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com