Electro-adsorption desalting system, regeneration system and corresponding method

A regeneration system and electro-adsorption technology, applied in the field of water treatment, can solve the problems of low treatment efficiency, achieve high water production rate, flexible regeneration mode, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

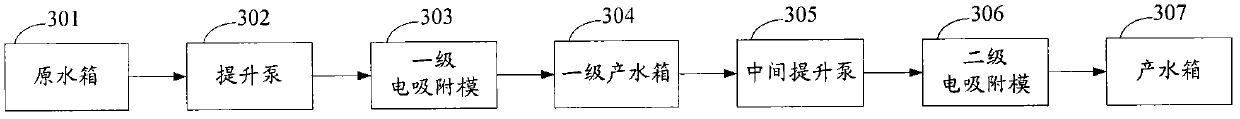

[0021] Embodiment 1. This embodiment provides an electro-adsorption desalination system, taking two-stage series electro-adsorption modules as an example, see image 3 As shown, it includes: raw water tank 301, lift pump 302, primary electro-adsorption module 303 (namely first-stage electro-adsorption module), primary water production tank 304 (namely intermediate production water tank), intermediate lift pump 305, secondary The first-stage electrosorption module 306 (that is, the last-stage electrosorption module) and the produced water tank 307 .

[0022] Wherein, the first-stage water production tank 304 is used for temporarily storing the water after the electro-adsorption treatment by the first-stage electrosorption module 303 . The intermediate lift pump 305 is used to lift the water temporarily stored in the primary water production tank 304 to the secondary electrosorption module 306 .

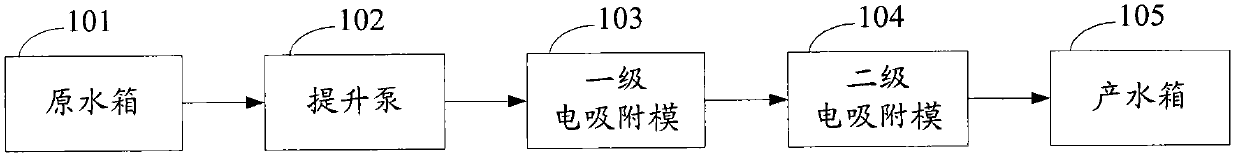

[0023] Depend on figure 1 and image 3 It can be seen from the comparison that ...

Embodiment 2

[0025] Embodiment 2. This embodiment provides an electro-adsorption desalination method. Taking the two-stage series electro-adsorption module as an example, the system provided in the above-mentioned embodiment 1 is used for implementation. See Figure 4 shown, including the following steps:

[0026] S401. The lift pump lifts the raw water in the raw water tank to the first-level electro-adsorption module, and the first-level electro-adsorption module performs electro-adsorption desalination treatment.

[0027] S402. The primary electro-adsorption module discharges the treated water to the intermediate water tank for temporary storage.

[0028] S403. The intermediate lift pump lifts the temporarily stored water in the intermediate product water tank to the secondary electro-adsorption module, and the secondary electro-adsorption module continues the electro-adsorption desalination treatment.

[0029] S404. The secondary electro-adsorption module discharges the treated water ...

Embodiment 3

[0030] Embodiment 3. This embodiment provides an electro-adsorption module regeneration system, taking two-stage series electro-adsorption modules as an example, see Figure 5 shown, including:

[0031] The raw water tank 501, lifting pump 502, secondary electro-adsorption module 503 (the last-stage electro-adsorption module), intermediate water tank 504, intermediate lifting pump 505, and primary-level electro-adsorption module 506 (the first-stage electro-adsorption module) are connected in series in sequence And sewage tank 507.

[0032] Wherein, the reclaimed water tank 504 is used for temporarily storing reclaimed water regenerated by the secondary electrosorption module 503 . The intermediate lift pump 505 is used to lift the reclaimed water temporarily stored in the reclaimed water tank 504 to the primary electrosorption module 506 .

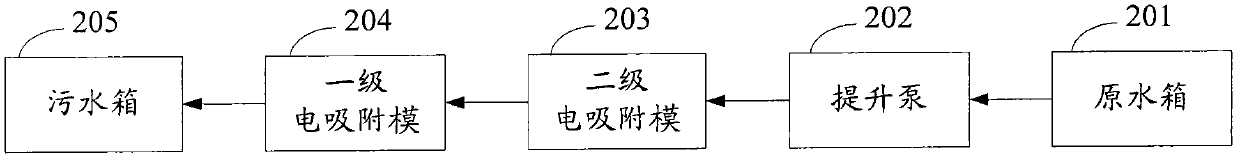

[0033] Depend on figure 2 and Figure 5 It can be seen from the comparison that the existing process uses two-stage electro-adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com