Method for recovering gasoline from mixed gas containing gasoline

A technology of mixed gas and gasoline, applied in the field of recovering gasoline from mixed gas containing gasoline vapor by adsorption method, can solve the problems of reduced tail gas recovery efficiency, hidden dangers, failure to meet environmental protection emission standards, etc. The effect of improving efficiency and full regeneration is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

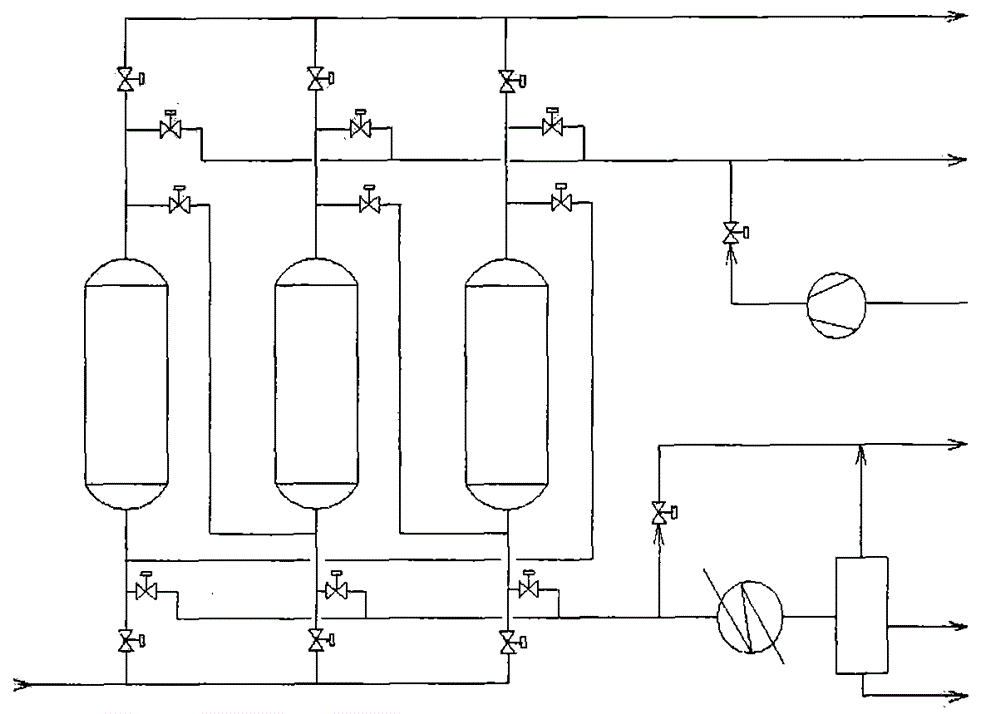

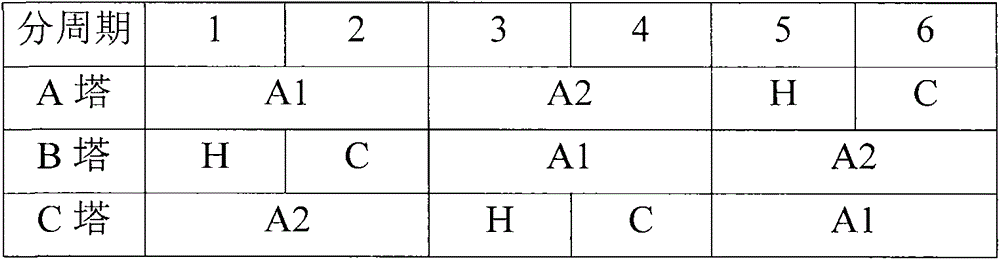

[0012] The device of the method embodiment of the method for recovering gasoline vapor in the mixed gas by adsorption method consists of three adsorption towers filled with active carbon adsorbent and 18 program-controlled valves, an electric heating steam generator (or steam boiler), a water cooling A device (or an air cooler), a water-oil separator, a blower and corresponding pipelines are connected.

[0013] When the system is running, the computer controls the switch of each program-controlled valve according to the program (according to the timing sequence in Table 1). In the following, the operation of the device will be described with the first step and the second step in the sequence of Table 2. The air mixture containing gasoline vapor extracted from the suction pipe of the refueling gun of the gas station and the outlet of the gasoline storage tank with a pressure of 0.11MPa (absolute pressure) and a temperature of 5°C enters the adsorption unit in the adsorption ste...

Embodiment 2

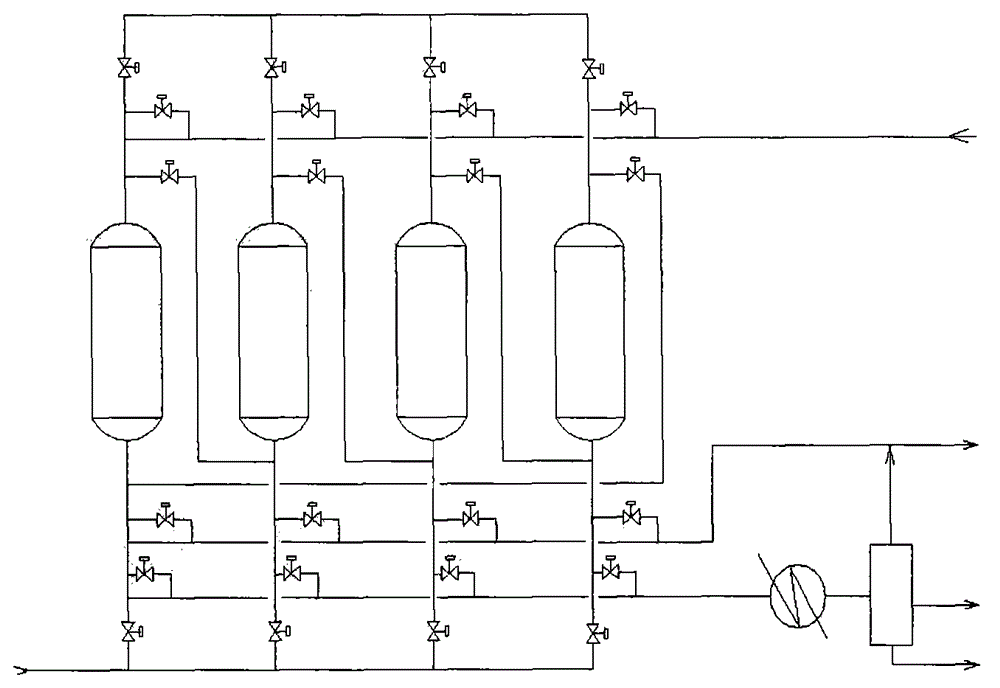

[0017] The device of the method embodiment 2 of the method embodiment 2 of the gasoline vapor in the mixed gas reclaimed by adsorption method is composed of four adsorption towers and 24 program-controlled valves filled with activated carbon adsorbent, a set of PLC control system, an electrothermal steam generator (or steam Boiler), a water cooler (or air cooler), an oil-water separator and corresponding pipelines.

[0018] When the system is running, the PLC control system controls the switch of each program-controlled valve according to the program (according to the sequence in Table 2). In the following, the operation of the device will be described with 1 sub-period and 2 sub-period in the time sequence of Table 2. The air mixture containing gasoline vapor extracted by the fan from the suction pipe of the refueling gun of the gas station and the outlet of the gasoline storage tank with a pressure of 0.13MPa (absolute pressure) and a temperature of 35°C enters the adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com