A method for drying gases and a device applied thereby

A drying and equipment technology, applied in the field of dry gas, which can solve the problems of inability to be dried and low regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

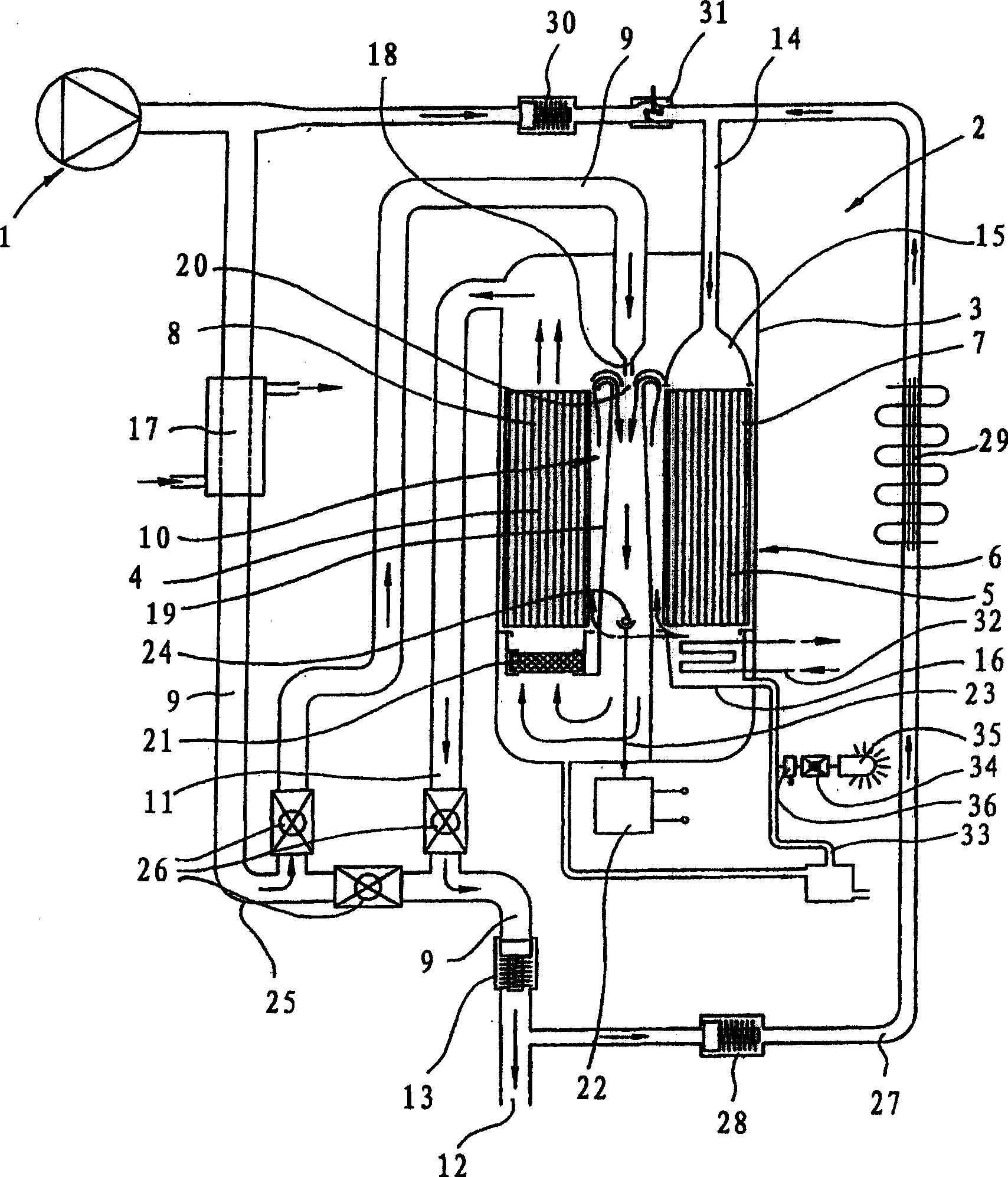

[0013] As shown in the figure, the plant for drying the gas is connected to a compressor 1 and consists essentially of a dryer 2 of the type described in BE 1,005,764 and which comprises a drying zone 4 and a regeneration zone 5 The pressure vessel 3 , and the rotating body 6 constituted by circular drying elements 7 in which adsorption and / or absorption media 8 are arranged alternately through drying zones 4 and regeneration zones 5 .

[0014] Furthermore, the dryer 2 comprises a main duct 9 connecting the dryer 2 to the outlet of the compressor 1 and which opens in a mixing device 10 whose outlet is connected to the inlet of the above-mentioned drying zone 4, And in this case, the main pipeline is integrally integrated in the pressure vessel 3 ; the outlet pipe 11 connects the outlet of the drying zone 4 to the consumer network 12 , whereby the outlet pipe 11 and the consumer network 12 are separated by a check valve 13 and a second conduit 14 connecting the outlet of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com