A low-temperature continuous regeneration device and process method for waste rubber

A regeneration device and waste rubber technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of general desulfurization effect, low production efficiency, complicated process, etc., and achieve the effect of improving the decoupling effect, increasing production efficiency, and strengthening the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

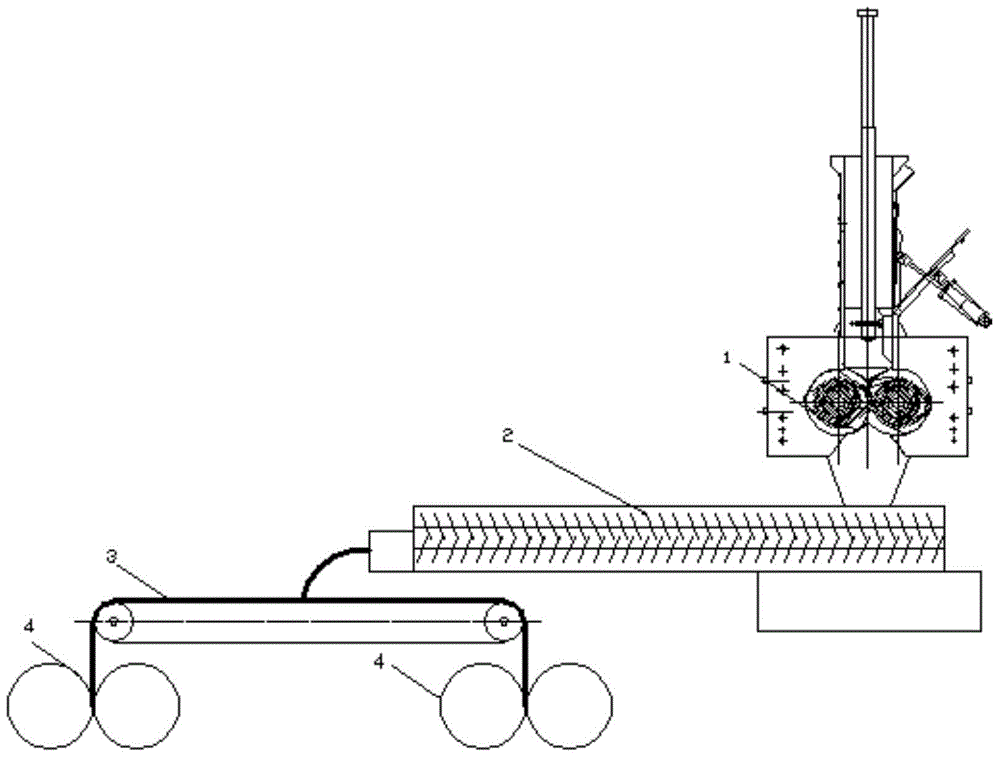

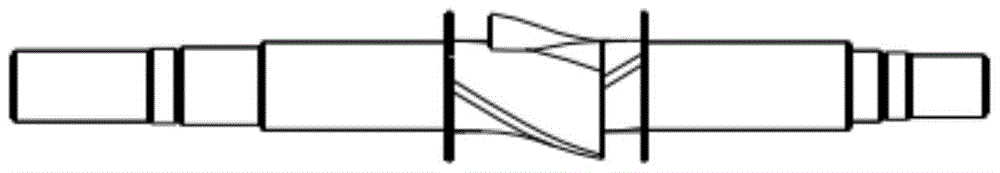

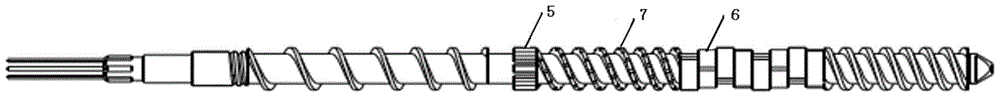

[0026] Such as Figure 1-3 As shown, the present invention comprises internal mixer 1, twin-screw extruder 2 and open mill 4 connected in sequence, the outlet of internal mixer 1 links to each other with the feed inlet of twin-screw extruder 2, twin-screw extruder The discharge port of the extruder 2 is equipped with a conveyor belt 3 for conveying rubber, and an open mill 4 is provided at the end of the conveyor belt 3. 6. The intermeshing device of the slotted thread 7 can have different combinations and numbers on the twin-screw, and the specific combination can be designed according to actual needs, as long as the effect of mechanical coupling can be satisfied; the conveyor belt Two-way transmission and motor control, each equipped with an open mill at the end of the conveyor belt; the length-to-diameter ratio of the twin-screw is 25-30; In the design, the rotor of the internal mixer can adopt the shear type or internal mixing type rotor with two ribs, four ribs or six ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com