Patents

Literature

78results about "Tungsten compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

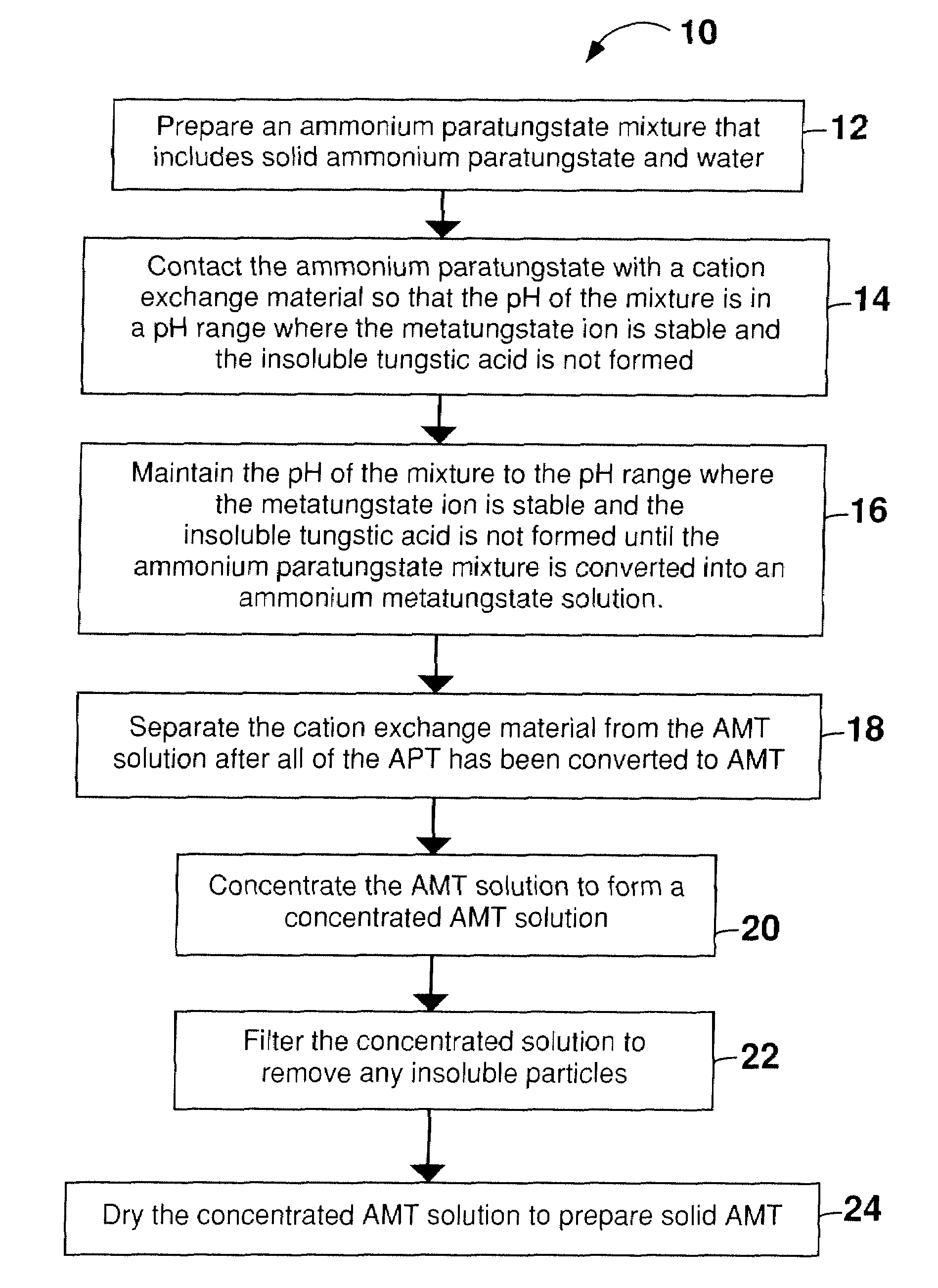

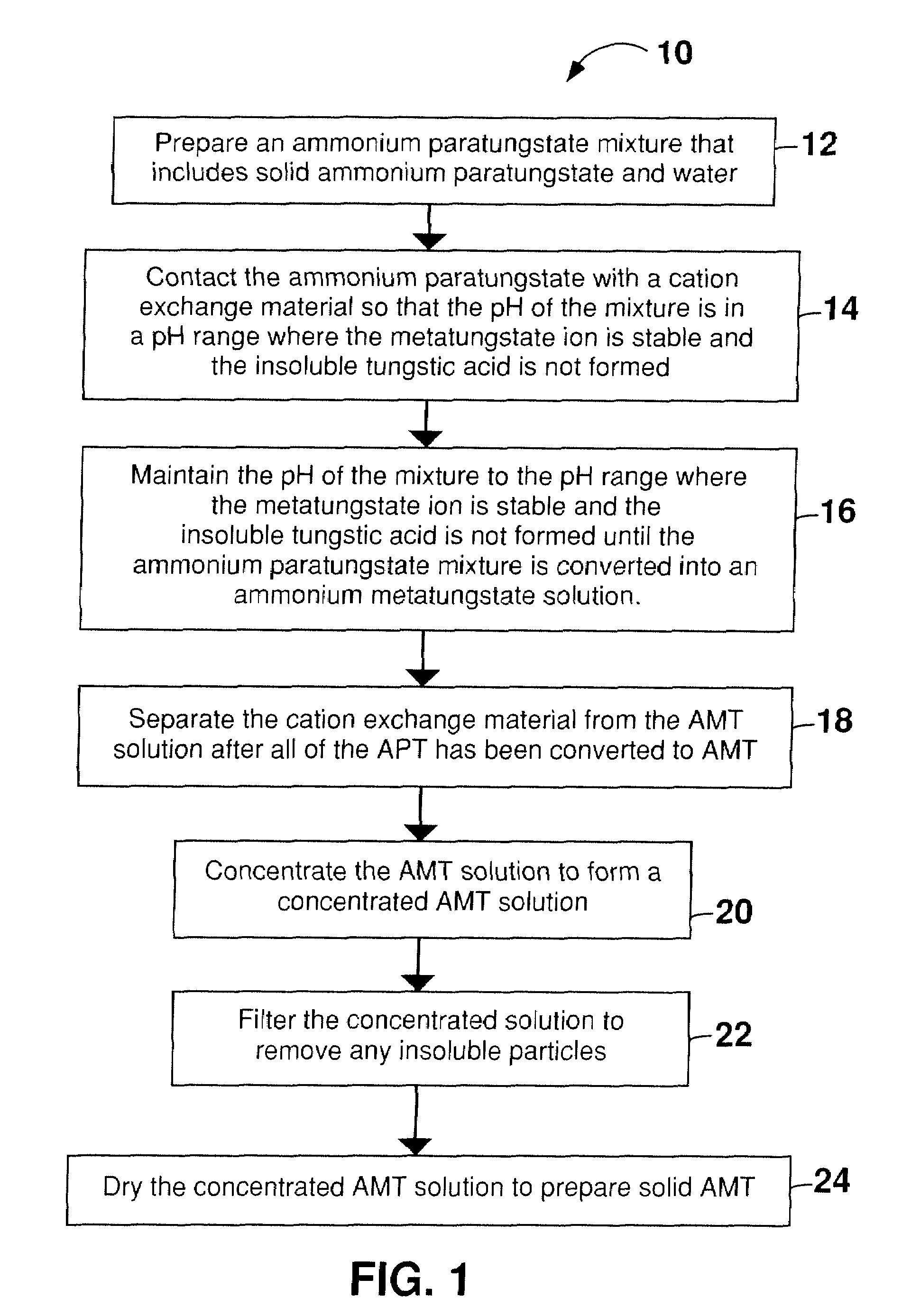

Method for making ammonium metatungstate

InactiveUS20100040532A1Oxygen/ozone/oxide/hydroxideOther chemical processesAmmonium paratungstatePh range

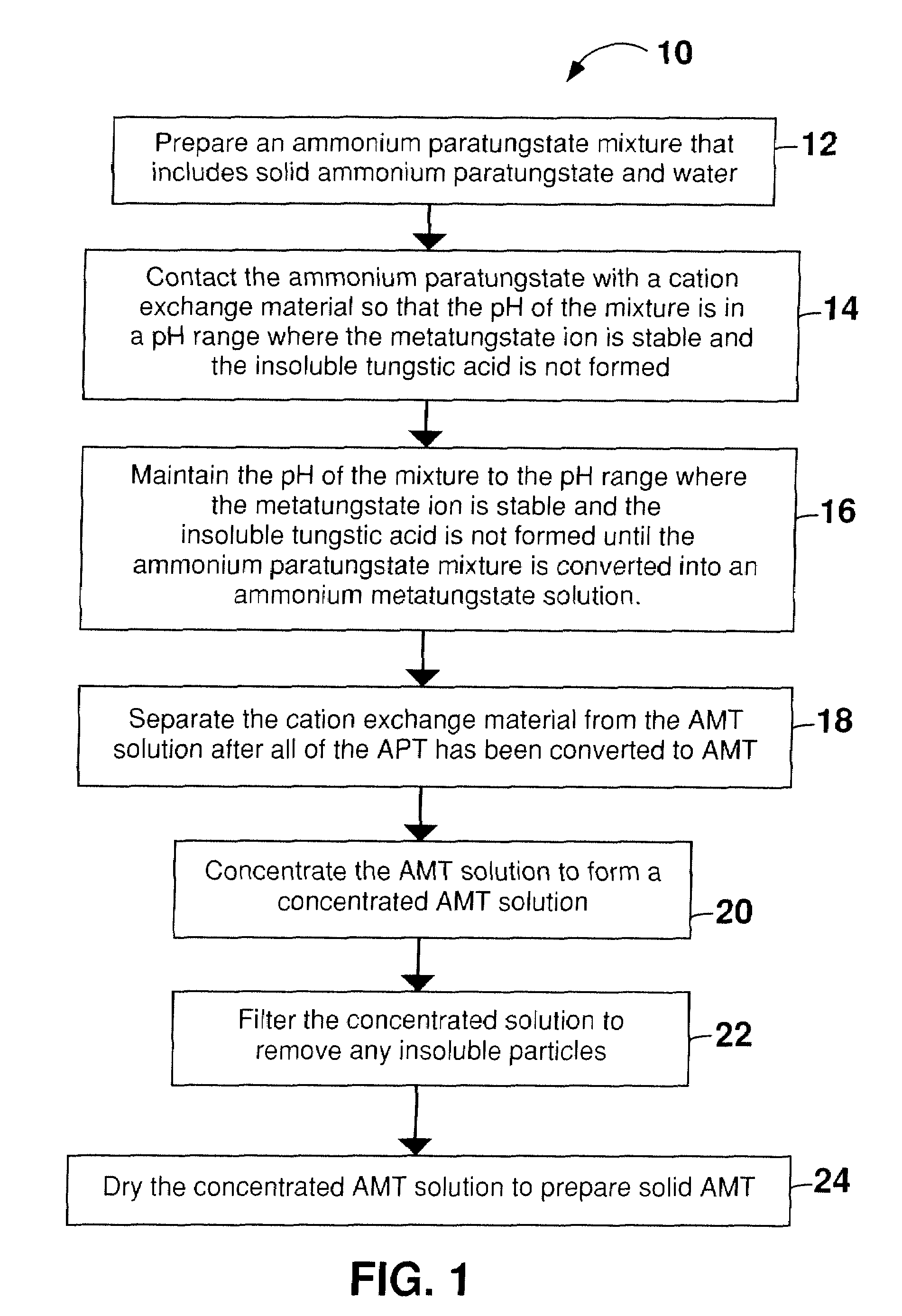

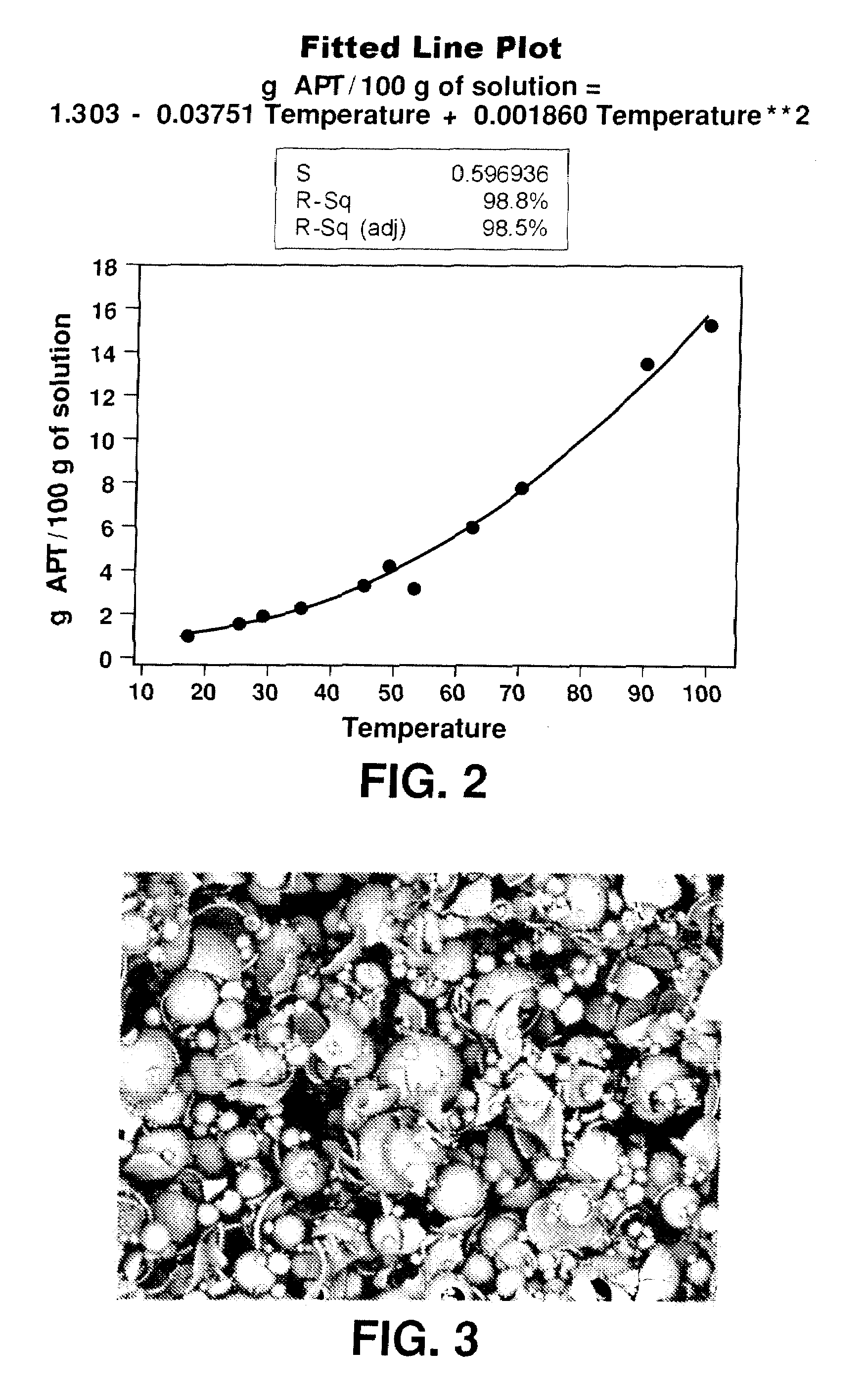

A method for producing ammonium metatungstate from ammonium paratungstate includes preparing an ammonium paratungstate mixture including solid ammonium paratungstate and water. The mixture is contacted with a cation exchange material to lower a pH of the mixture to a pH range wherein metatungstate ion is stable and an insoluble tungstic acid is not formed. The pH of the mixture may be maintained in the pH range until the ammonium paratungstate mixture is converted into an ammonium metatungstate solution.

Owner:KENNAMETAL INC

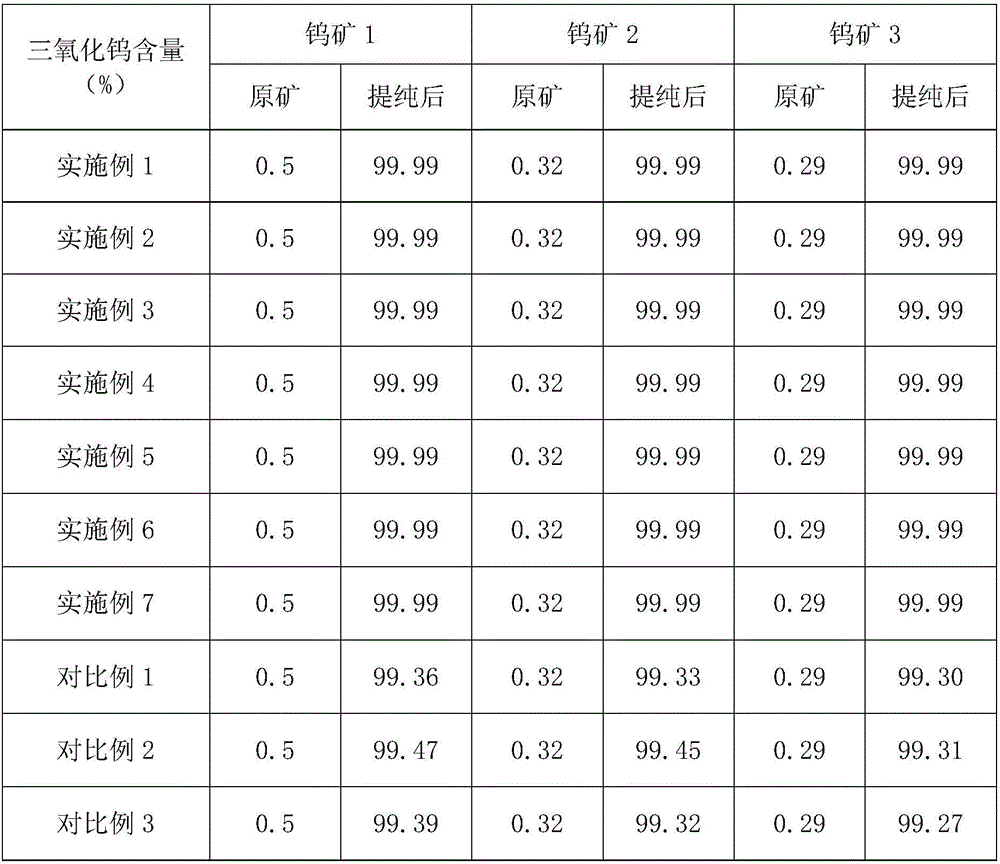

Method of producing tungsten product from crude sodium tungstate solution

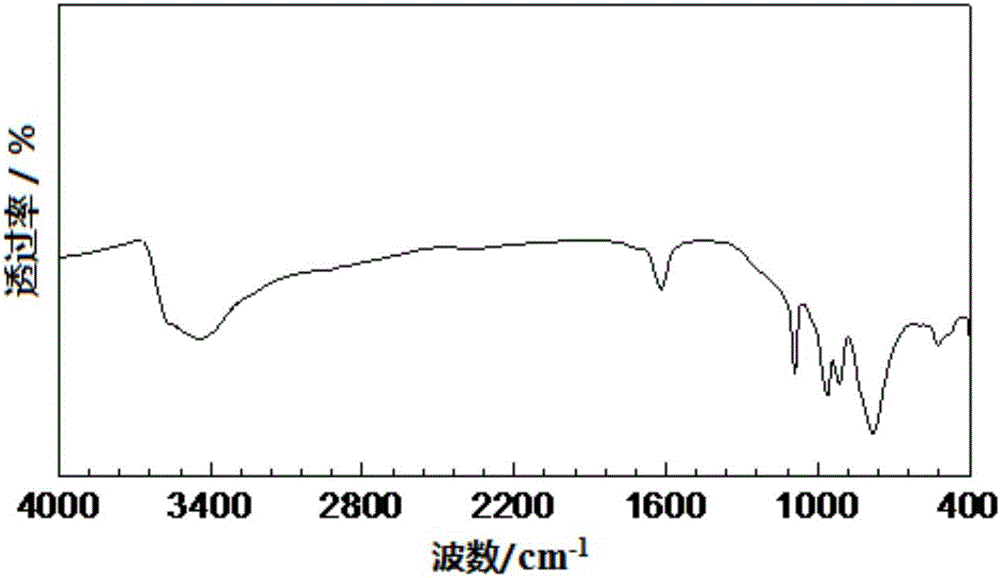

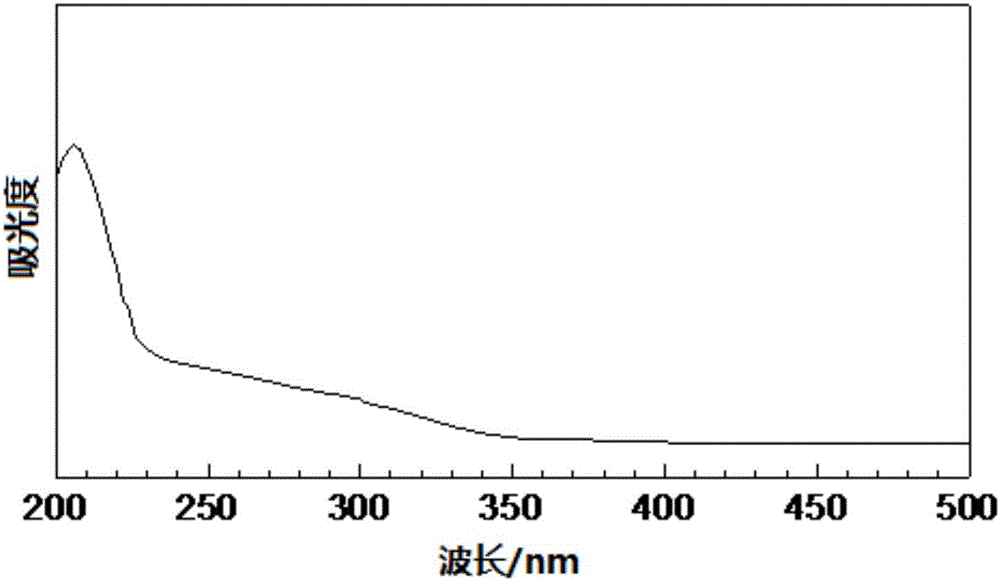

ActiveCN108516588AReduce environmental costsAvoid emissionsTungsten compounds preparationTungsten oxides/hydroxidesUltrasonic spray pyrolysisSodium tungstate

The invention relates to a method of producing a tungsten product from a crude sodium tungstate solution. The method includes steps of: adding a proper amount of acid to the crude sodium tungstate solution to generate precipitate, and filtering the solution to obtain crude tungstic acid and a filtrate; recycling tungsten from the filtrate through a weak-alkaline anion exchange resin or with an extraction agent; extracting the crude tungstic acid with H2O2, and heating a peroxytungstic acid solution or feeding SO2 to prepare tungstic acid; repeating the step for several times until preparing pure tungstic acid; preparing WO3 or tungsten powder from the pure tungstic acid; dissolving the tungstic acid in H2O2 solution to obtain the peroxytungstic acid solution; and performing ultrasonic spray pyrolysis to obtain tungsten oxide powder or tungsten powder. The method has great separation effect, is simple and controllable in operation process, and is easy to promote and apply in industry.

Owner:CENT SOUTH UNIV

Preparation method of phosphotungstic acid

ActiveCN106277060ANo pollutionSimple processPhysical/chemical process catalystsTungsten compounds preparationRaffinatePollution

The invention belongs to the technical field of heteropolyacid preparation, and particularly relates to a preparation method of phosphotungstic acid. The method includes the steps of making white tungstic acid or artificial scheelite as the raw material react with a phosphorous compound and an inorganic acid water solution, conducting extraction through an alcohol extraction agent, directly conducting reverse extraction on a load phase through water to obtain a phosphotungstic acid water solution, and conducting evaporative crystallization or spray drying to obtain phosphotungstic acid crystals. An organic phase obtained after reverse extraction directly returns to the extraction step, and the organic phase regeneration process is not needed; raffinate can be repeatedly used after consumption acid is supplemented. The method is short in technological process, low in manufacturing cost, high in product yield, environmentally friendly and free of pollution and can be used for large-scale industrial production, and a mother solution can be recycled.

Owner:CENT SOUTH UNIV

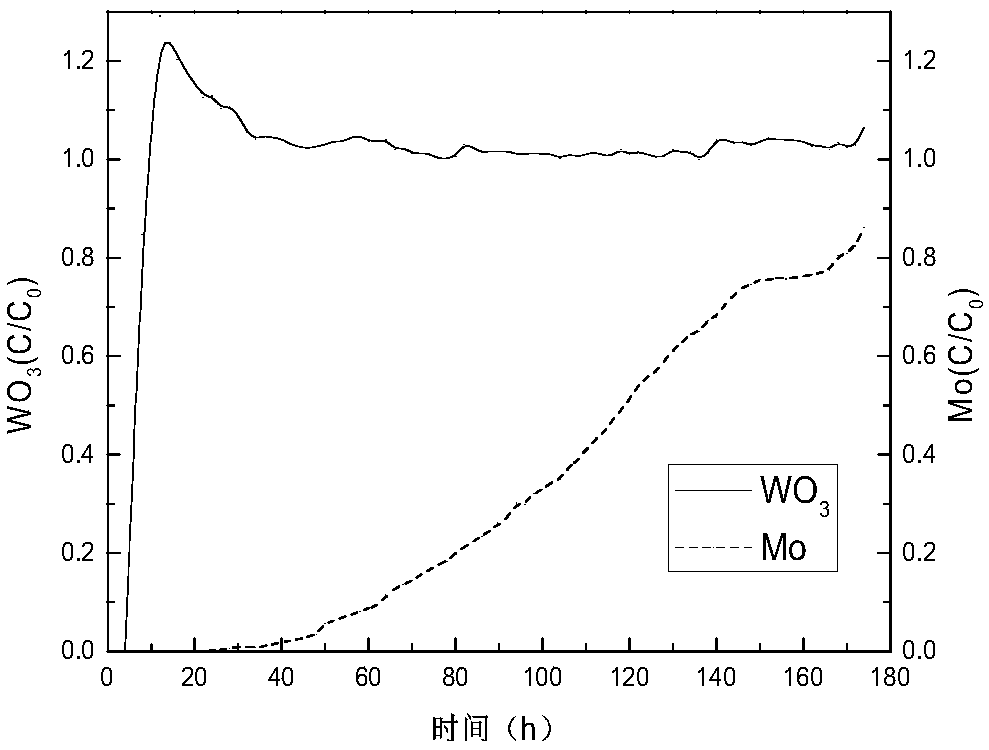

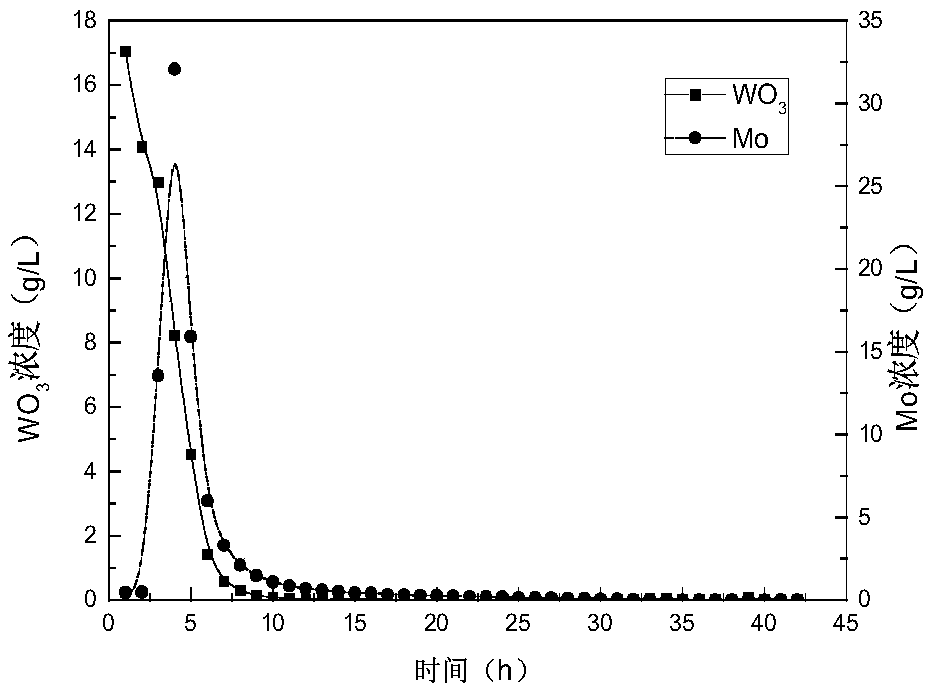

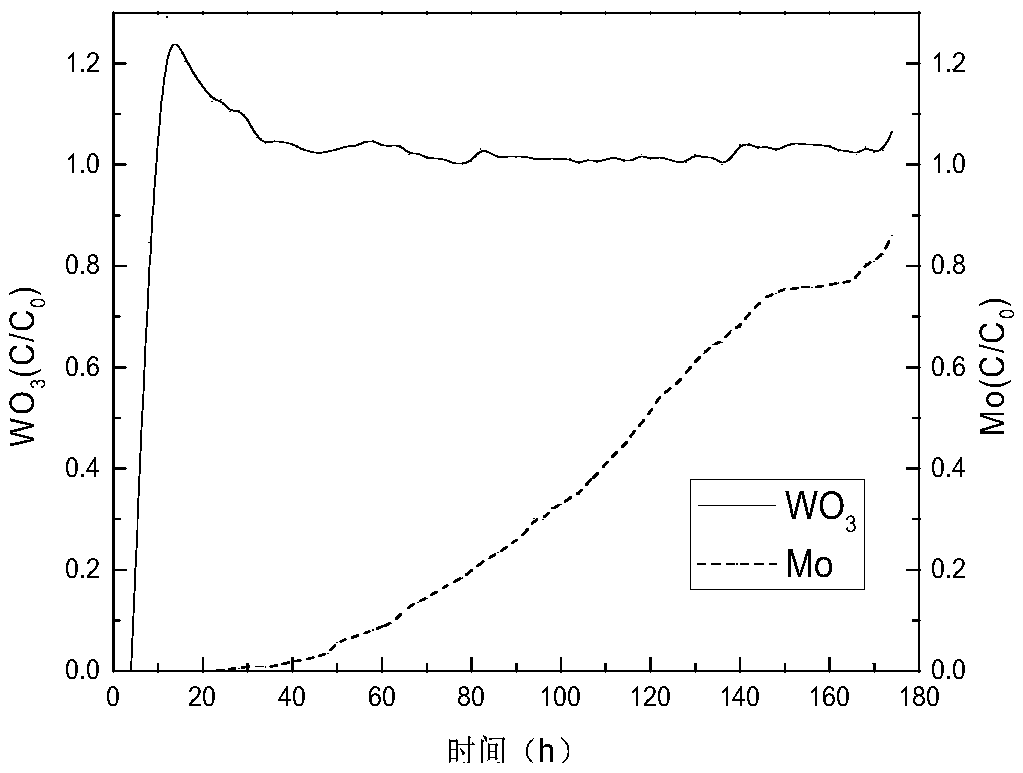

Method for separating molybdenum from tungstate solution through ion exchange

ActiveCN109534403ATransportation safetySafe storageTungsten compounds preparationMolybdateVulcanization

The invention discloses a method for separating molybdenum from a tungstate solution through ion exchange. The method includes the steps that trithiocyanuric acid is added into the molybdenum-containing tungstate solution to carry out vulcanization reaction, so that a tungstate solution containing thiomolybdate is obtained; the tungstate solution containing the thiomolybdate is subjected to ion exchange by adopting weak-base anion-exchange resin so as to adsorb the thiomolybdate, and a tungstate solution is obtained; and the weak-base anion-exchange resin loaded with the thiomolybdate is desorbed by an alkaline desorption solution, so that a molybdate solution is obtained. According to the method, the separating effect of molybdenum in the high-tungsten low-molybdenum solution is good, tungsten loss is little, operation is simple, no hydrogen sulfide is released in the vulcanization process, a hydrogen sulfide recovery facility is not needed, no oxidant is used in the desorption process, molybdenum is easy to recover, the service life of the resin is prolonged, and industrial application is facilitated.

Owner:CENT SOUTH UNIV

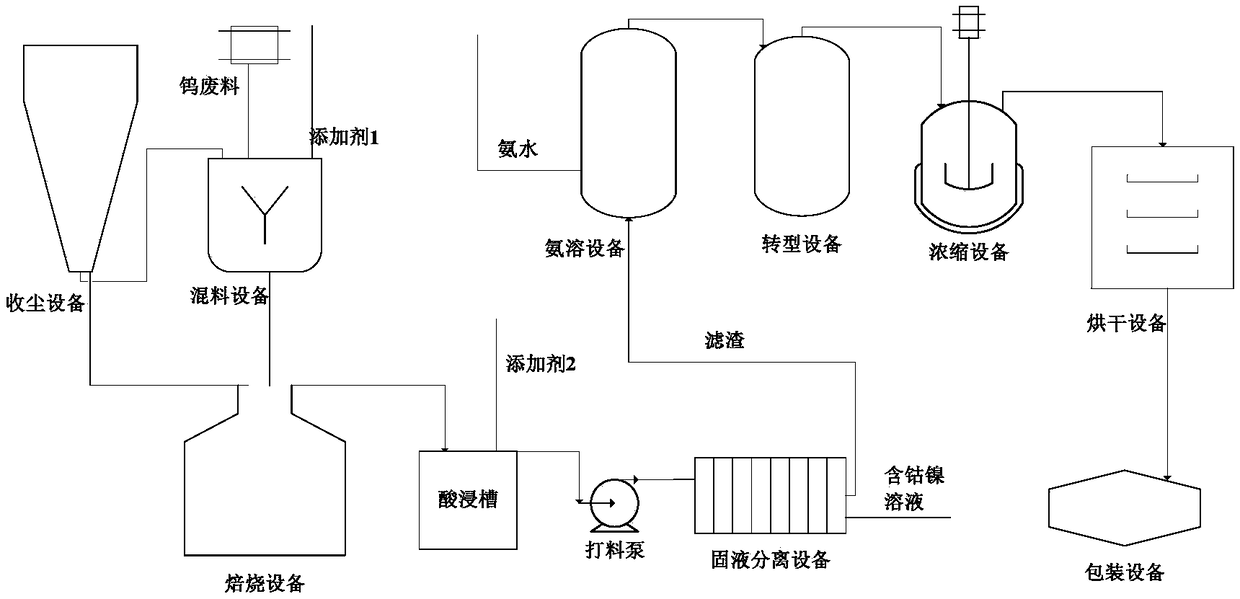

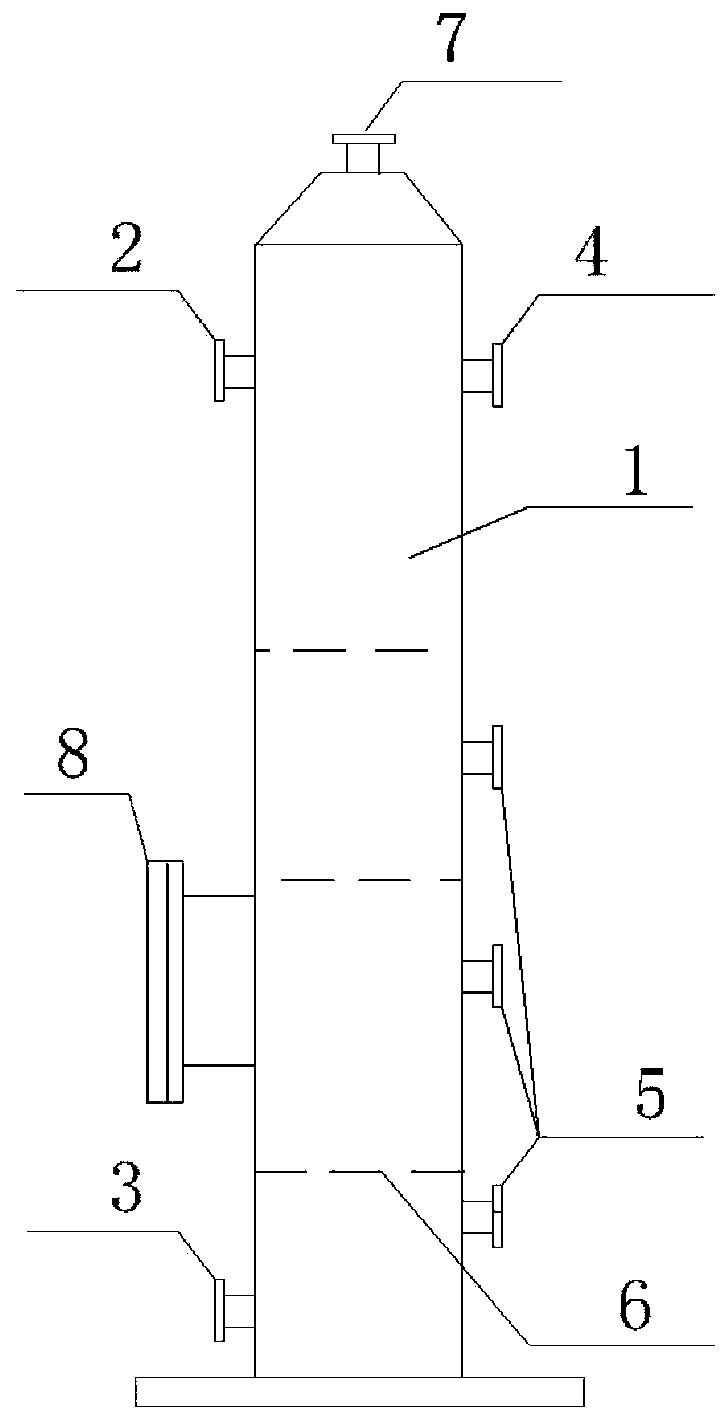

Method for producing ammonium metatungstate by wolfram-containing waste and device thereof

ActiveCN108751259ACobalt content is unlimitedEfficient use ofTungsten compounds preparationTungstateSlag

The invention relates to a method for producing ammonium metatungstate by a wolfram-containing waste and a device thereof. The method comprises the following steps: mixing the wolfram-containing wasteand an additive 1 to obtain a mixture; roasting the mixture, to obtain a roasted material; adding an additive 2 into the roasted material and reacting, to obtain a solid-liquid mixture; filtering thesolid-liquid mixture to obtain a filter residue and filtrate, adding the filter residue into ammonia water, performing extraction or ion exchange on an obtained ammonium tungstate solution, and evaporating and crystallizing an obtained ammonium metatungstate solution, to obtain the ammonium metatungstate. The method for producing the ammonium metatungstate by the wolfram-containing waste is suitable for recovering treatment of multiple wolfram-containing wastes, such as a floor material, a dust collecting material, a grinding material and a waste material generated in a hard alloy productionprocess, and a floor material, a dust collecting material and a waste material generated in production processes of wolfram carbide powder and tungsten powder; general material mixing devices and roasting devices are used, clotted slag is avoided, a tungsten recovery rate is high, and the method has great popularization significance.

Owner:XIAMEN TUNGSTEN +1

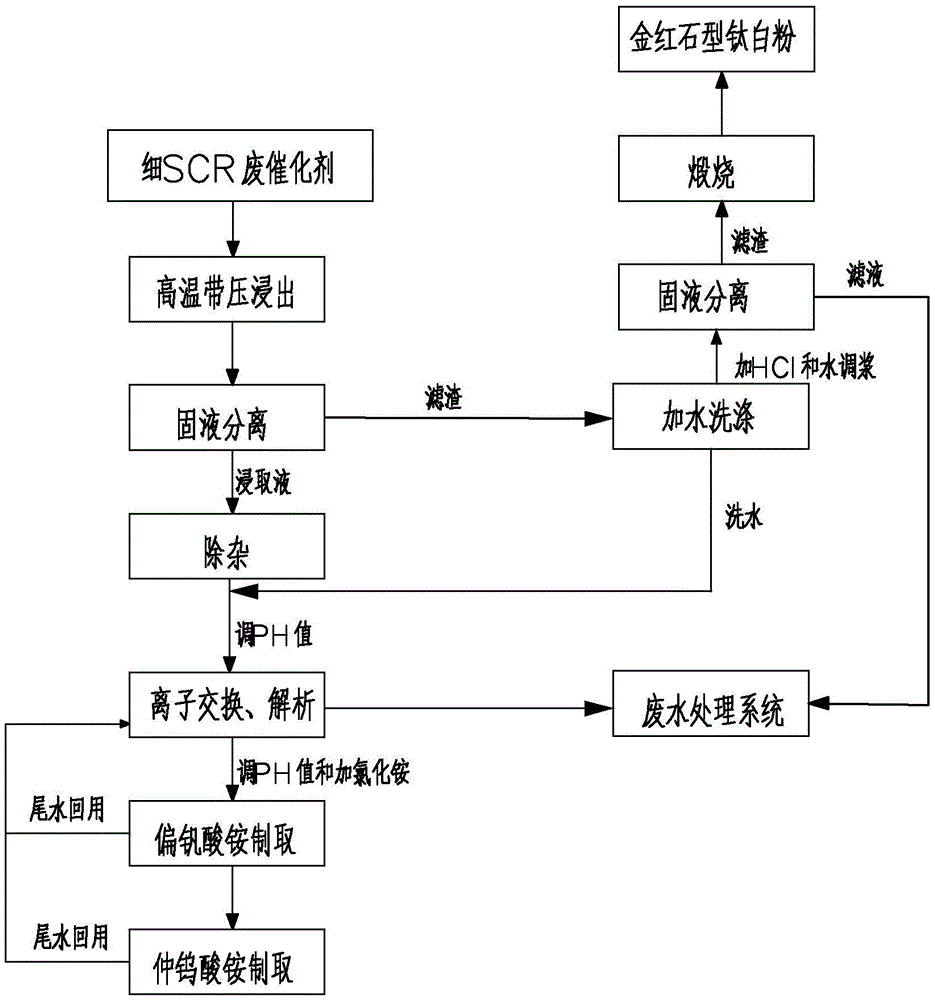

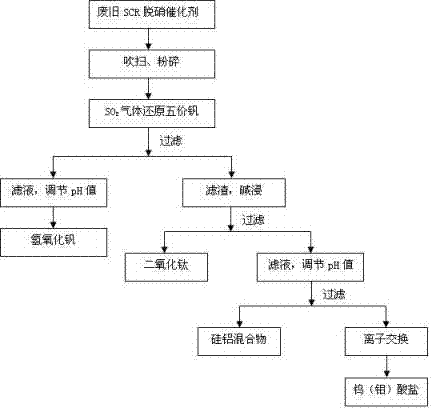

Process for reclaiming honeycomb SCR waste catalyst

ActiveCN105621483AFairly technologically advancedQuite practicalTungsten compounds preparationVanadium compounds preparationAmmonium paratungstateIon exchange

Owner:TIANCHANG GAOPENG EXPERIMENT EQUIP

Method of preparing phosphotungstic acid from sodium tungstate as raw material

ActiveCN106335928APhase separation effect is goodSimple processTungsten compounds preparationAlcoholSodium tungstate

The invention belongs to the technical field of heteropolyacid preparation, and particularly relates to a preparing method of sodium tungstate. Industrial sodium tungstate crystal is used as the raw material, an alcohol extraction agent is used for extracting to obtain a phosphotungstic acid water solution, phosphotungstic acid crystal can be obtained through evaporative crystallization or spray drying, organic phase and raffinate obtained after reverse extraction can be returned and used directly, and the process of organic phase regeneration is avoided. The method is short in process flow, low in manufacturing cost, high in product yield, environmentally friendly and capable of achieving large-scale industrial production.

Owner:CENT SOUTH UNIV

Process for Recovering Molybdate or Tungstate from Aqueous Solutions

InactiveUS20090274598A1Reduce consumptionReduce the ratioWater treatment parameter controlSolvent extractionMolybdateTungstate

Process for recovering molybdate or tungstate from an aqueous solution, in which molybdate or tungstate is bound to a water-insoluble, cationized inorganic carrier material from the aqueous solution at a pH in the range from 2 to 6, the laden carrier material is separated off and the bound molybdate or tungstate is liberated once again into aqueous solution at a pH in the range from 6 to 14. The process is suitable for recovering molybdate or tungstate in the delignification of pulp with hydrogen peroxide in the presence of molybdate or tungstate as catalyst. The recovered molybdate or tungstate can be recycled to the delignification.

Owner:EVONIK DEGUSSA GMBH

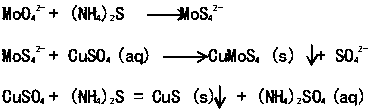

Method for preparing ammonium paratungstate by utilizing low-grade scheelite concentrate

InactiveCN109437308ARelieve pressurePromote decompositionTungsten compounds preparationChemical industryAmmonium paratungstate

The invention discloses a method for preparing ammonium paratungstate by utilizing a low-grade scheelite concentrate, and relates to the technical field of metallurgy chemical industry. The method comprises the following steps of adding a sodium hydroxide solution into the low-grade scheelite concentrate, mechanically grinding, then adopting far-infrared radiation heating for carrying out alkali autoclave treatment, filter pressing the obtained ore pulp through a filter press, and water washing to obtain a sodium tungstate solution; concentrating and crystallizing the sodium tungstate solutionto obtain a sodium tungstate crystal; dissolving the sodium tungstate crystal into water to prepare sodium tungstate pre-fluid for ion exchange; adopting strong-base anion exchange resin for carryingout ion exchange adsorption on the sodium tungstate solution, flushing, and desorbing tungsten by using mixed liquor of ammonium chloride and ammonium hydroxide; adding (NH4)2S into the desorbed solution, vulcanizing, adding a CuSO4 solution for removing molybdenum, filtering, concentrating, crystallizing, and drying to obtain the ammonium paratungstate. The leaching efficiency of scheelite is high, impurity components such as trace metal cation in the solution can be effectively removed, the molybdenum removal rate is high, and the purity of the obtained ammonium paratungstate is high.

Owner:江西五矿高安有色金属有限公司

Recovery method of waste SCR denitration catalyst

ActiveCN110817944AGood removal effectImprove permeabilityAlkaline earth titanatesTungsten compounds preparationPtru catalystTungstate

The invention belongs to the field of non-ferrous metal recovery, and particularly relates to a recovery method of a waste SCR denitration catalyst. The recovery method comprises the steps of pretreatment, TiO2 separation, extraction and purification, titanium recovery, vanadium recovery, tungsten / molybdenum recovery and the like. The recovery method is capable of recycling a several precious recovery products such as V2O5, ammonium tungstate / ammonium molybdate and BaTiO3 from the waste SCR denitration catalyst. The invention provides an effective technical scheme, and efficient resource utilization of the waste SCR denitration catalyst can be realized.

Owner:北京华电光大环境股份有限公司

Method for purifying phosphotungstic acid crystal

ActiveCN106082343ANo pollutionSimple processPolycrystalline material growthTungsten compounds preparationHigh concentrationHeteropoly acid

The invention belongs to the technical field of preparation of heteropoly acids and particularly relates to a method for purifying phosphotungstic acid crystal. Industrially acquired phosphotungstic acids typically comprise a high amount of impurities such as phosphorus, sulfur, molybdenum, sodium and calcium, and the invention is intended to purify the phosphotungstic acids with high impurity content. The method of the invention includes: dissolving industrial phosphotungstic acid with high impurity content in water, extracting with an alcohol extracting agent, back-extracting directly with distilled water to obtain high-concentration phosphotungstic acid solution, wherein the alcohol extracting agent can be returned and extracted directly after back-extraction and raffinate can also be returned directly to the dissolved phosphotungstic acid crystal for reuse; if comprising molybdenum, the obtained high-concentration phosphotungstic acid solution needs to be subjected to extraction, molybdenum removal and evaporative crystallization to prepare high-purity phosphotungstic acid crystal, and if not comprising molybdenum, the high-concentration phosphotungstic acid solution can be subjected directly to evaporative crystallization to obtain high-purity phosphotungstic acid crystal. The method of the invention has short process flow, low manufacture cost and high product yield, is environment-friendly and is suitable for large-scale industrial production.

Owner:CENT SOUTH UNIV

Method for preparing phosphotungstic acid crystals from tungstenic mixed phosphoric and sulfuric acid solution

The invention discloses a method for preparing phosphotungstic acid crystals from tungstenic mixed phosphoric and sulfuric acid solution. The method includes the following steps: firstly, regulating the concentration of sulfuric acid in the tungstenic mixed phosphoric and sulfuric acid solution; adding an organic alcohol extraction agent for extraction to obtain a loaded organic phase; subjecting the obtained loaded organic phase to reverse extraction with distilled water to obtain reverse extract liquid; subjecting the reverse extract liquid to heating and evaporative crystallization to obtain the phosphotungstic acid crystals. The method is simple in process, short in process flow, low in preparation cost, free of pollution to the environment and easy for large-scale industrial production.

Owner:CENT SOUTH UNIV

Method for making ammonium metatungstate

InactiveUS7794686B2Oxygen/ozone/oxide/hydroxideOther chemical processesAmmonium paratungstateAmmonium metatungstate

A method for producing ammonium metatungstate from ammonium paratungstate includes preparing an ammonium paratungstate mixture including solid ammonium paratungstate and water. The mixture is contacted with a cation exchange material to lower a pH of the mixture to a pH range wherein metatungstate ion is stable and an insoluble tungstic acid is not formed. The pH of the mixture may be maintained in the pH range until the ammonium paratungstate mixture is converted into an ammonium metatungstate solution.

Owner:KENNAMETAL INC

Method of recycling component substances in a waste SCR denitration catalyst

InactiveCN107416904AEfficient separationHigh purityTungsten compounds preparationTitanium dioxideTungstateIon-exchange resin

The invention discloses a method of recycling component substances in a waste SCR denitration catalyst. The method includes the following steps: 1) performing pretreatment to remove impurities on the surface of the waste SCR denitration catalyst and crushing the catalyst; 2) adding the crushed catalyst to a sulfuric acid solution to reduce vanadium (V) with SO2 gas, filtering and separating the solution, and regulating the pH value of the filtrate to precipitate vanadium hydroxide; 3) adding an alkali solution to filter residues to dissolve tungsten (molybdenum) trioxide, silicon dioxide and aluminum oxide, and filtering and separating the solution to obtain TiO2 and an alkaline filtrate; 4) regulating the pH value of the alkaline filtrate to precipitate silicon and aluminum, filtering and separating the filtrate, and adsorbing tungsten (molybdenum) ions from the filtrate by ion exchange resin; 5) eluting the tungsten (molybdenum) ions from the resin to obtain tungstate (molybdate). The method achieves high-effective separation of the component substances in a SCR denitration catalyst, reaches more than 96% in recycling rate and more than 98% in purity. The method is low in energy consumption and cost and has wide industrial application prospect.

Owner:北京清树科技发展有限公司

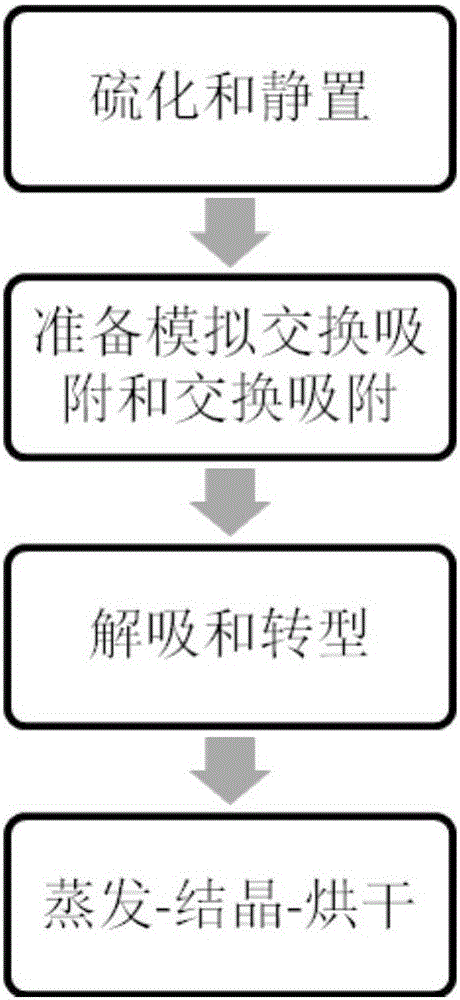

High efficiency purification method of ammonium tungstate solution with high Mo content by using special resin

InactiveCN105967238AReduce cleaning processSimple processTungsten compounds preparationPurification methodsTungstate

The invention belongs to the field of metallurgy of rare metals, and concretely relates to a high efficiency purification method of an ammonium tungstate solution with high Mo content by using special resin. The invention discloses the high efficiency purification method of the ammonium tungstate solution with high Mo content by using special resin, and disadvantages of low efficiency in the production method of 0 grade APT, complex processes, and high cost. The method comprises the following steps: a. the solution is sulfurated and permitted to stand; b. simulated exchange adsorption and exchange adsorption are prepared; c. desorption and transition are carried out; d. evaporation-crystallization-drying are carried out. The special resin WDA918 is used for high efficiency purification of the ammonium tungstate solution with high Mo content, and the link for removing impurities by copper salts is reduced; compared with the classic purification method of the ammonium tungstate solution with high Mo content including combination of selective precipitation and ion exchange, the links for removing Mo, P, As, Si and other impurities by adding copper sulphate or copper sulphide or copper oxide; the technology is simplified, production cost is reduced, and the recovery rate of WO3 is improved.

Owner:XINYANG HUARUI MOLYBRENUM NEW MATERIALS CO LTD

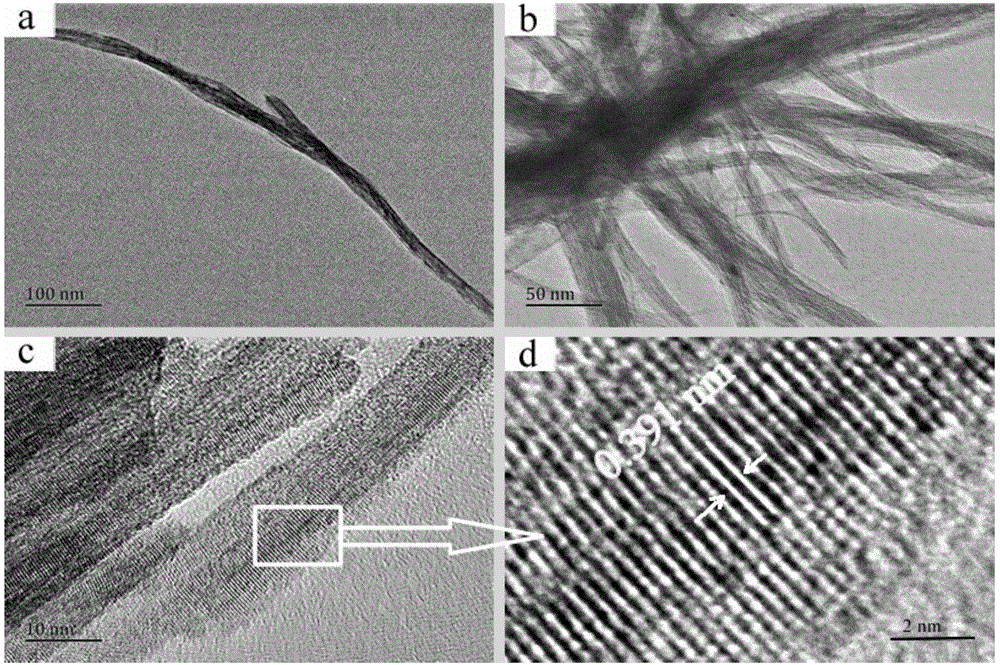

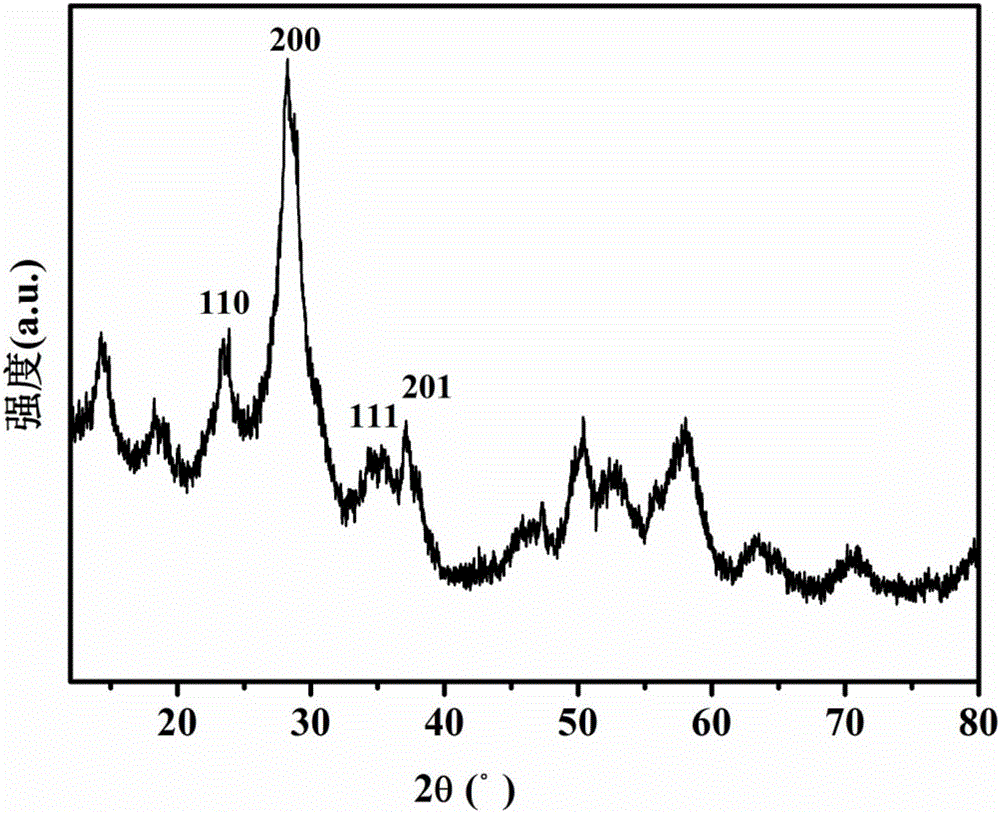

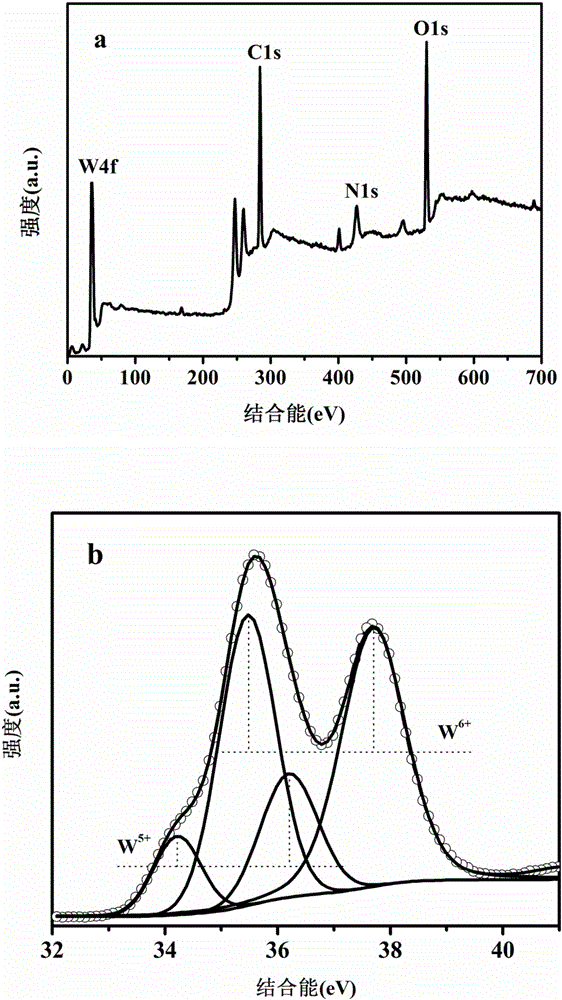

Preparation method and application of ultra-fine WO3 nanowire

InactiveCN106390991AEfficient degradationStrong quantum confinement effectMaterial nanotechnologyTungsten compounds preparationNanowireEmulsion

The invention provides a preparation method of an ultra-fine WO3 nanowire. The ultra-fine WO3 nanowire is prepared by virtue of a modified solvothermal method. The method comprises the following steps: weighing 0.05-0.2g of Na2WO4.2H2O and 0.1-0.4g of (NH4)2SO4, dissolving Na2WO4.2H2O and (NH4)2SO4 in 6mL deionized water, adding 2mL of 0.1-0.3mol / L hydrochloric acid solution, and stirring and mixing all ingredients uniformly, thereby obtaining a solution A; taking 5mL of cyclohexane and 0.4g of an organic additive, uniformly mixing cyclohexane with the organic additive so as to obtain a solution B; mixing solution B with the solution A to obtain an emulsion mixture, performing reaction on the emulsion mixture in a high-pressure reaction kettle at a temperature of 150-200 DEG C for 24 hours, and performing extraction, washing and drying, thereby obtaining the ultra-fine WO3 nanowire. The preparation method is low in cost, simple and convenient to operate, realizable based on one step and high in productivity; the prepared ultra-fine WO3 nanowire has relatively high photocatalysis activity and can be used for photocatalytic degradation of organic pollutants.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Process for recovering molybdate or tungstate from aqueous solutions

InactiveUS8277765B2Reduce consumptionReduce the ratioWater treatment parameter controlSolvent extractionMolybdateTungstate

Process for recovering molybdate or tungstate from an aqueous solution, in which molybdate or tungstate is bound to a water-insoluble, cationized inorganic carrier material from the aqueous solution at a pH in the range from 2 to 6, the laden carrier material is separated off and the bound molybdate or tungstate is liberated once again into aqueous solution at a pH in the range from 6 to 14. The process is suitable for recovering molybdate or tungstate in the delignification of pulp with hydrogen peroxide in the presence of molybdate or tungstate as catalyst. The recovered molybdate or tungstate can be recycled to the delignification.

Owner:EVONIK DEGUSSA GMBH

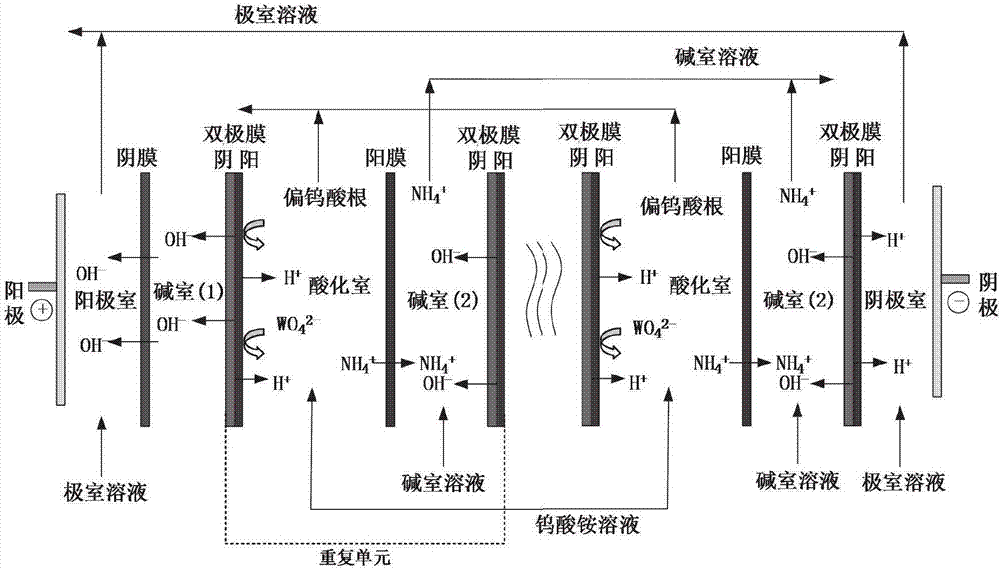

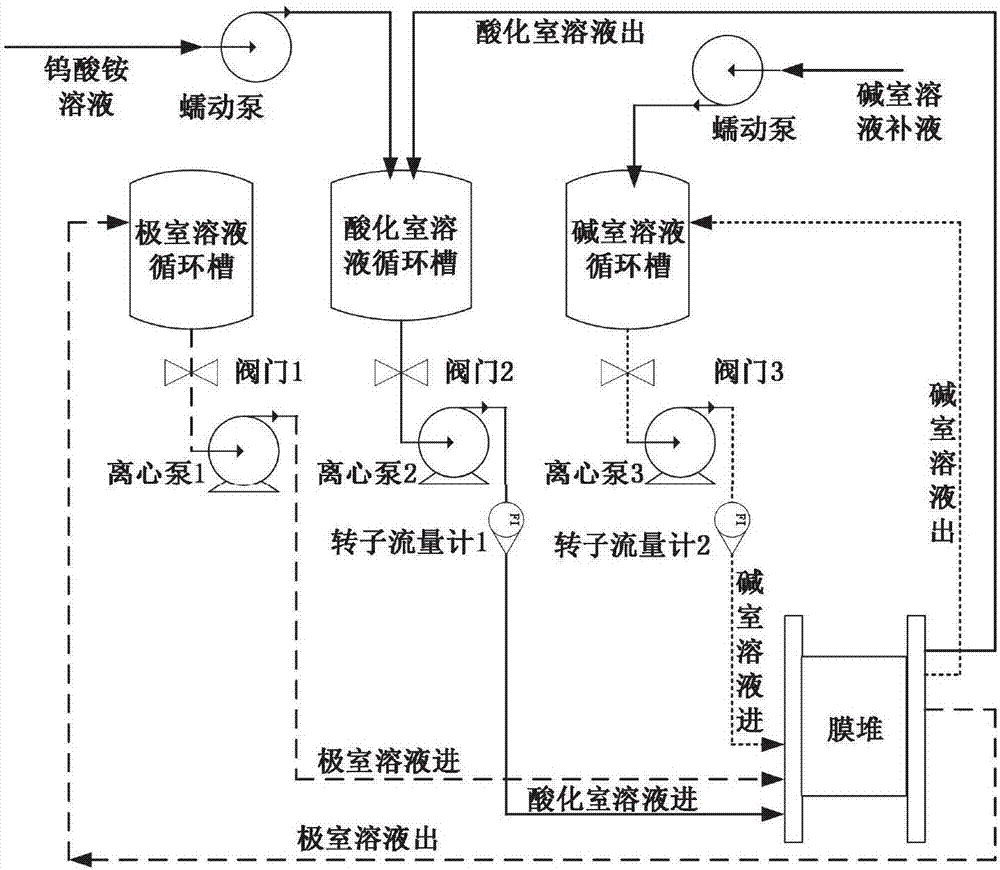

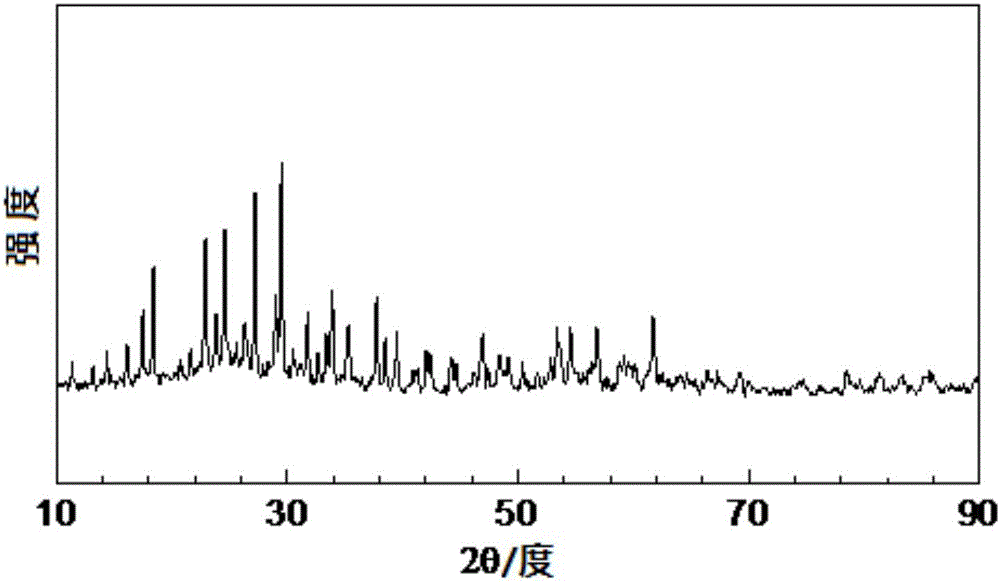

Method of preparing ammonium metatungstate solution based on bipolar membrane electrodialysis

InactiveCN107098391AAchieve discontinuityIncrease production capacityTungsten compounds preparationElectrodialysisTungstateAmmonium metatungstate

The invention discloses a method of preparing an ammonium metatungstate solution based on bipolar membrane electrodialysis. According to the method, the removal of part of ammonium ions in an ammonium tungstate solution serving as a raw material and the reduction of a pH value are realized by adopting a bipolar membrane electrodialysis system with a two-room bipolar membrane electrodialysis membrane stack through bipolar membrane electrodialysis under the action of direct current electric field force; and the ammonium metatungstate solution is obtained in an acidification room of the bipolar membrane electrodialysis system. The method has the beneficial effects that inorganic acids are not consumed; impurity anions are not introduced; and the method has the advantages of short process, high direct recovery rate, low power consumption, environmental protection and easy realization of industrialization.

Owner:CENT SOUTH UNIV

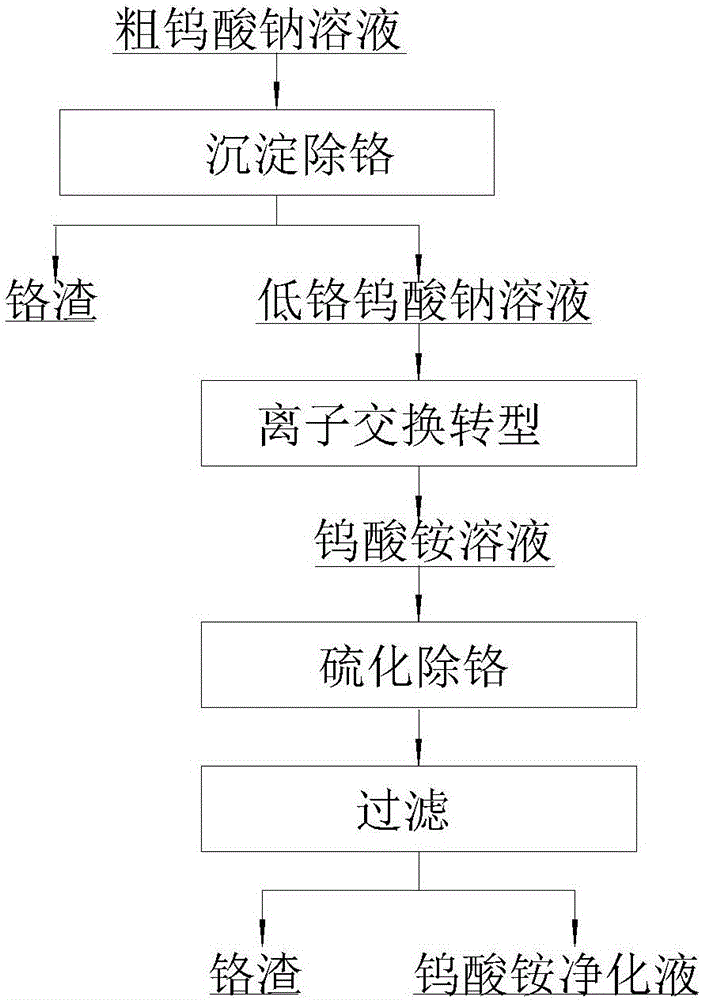

Method for deeply removing chromium in tungsten-containing waste recycling process

InactiveCN106629853AHigh chromium removal rateImprove purification efficiencyTungsten compounds preparationTungstateIon exchange

The invention discloses a method for deeply removing chromium in a tungsten-containing waste recycling process. The method at least comprises the following steps: (1) adding a precipitator in a coarse sodium tungstate solution at the temperature of 60-100 DEG C, carrying out mixing treatment and filtering to obtain filtrate; (2) diluting the filtrate obtained in the step (1), and carrying out adsorption treatment by using anion exchange resin; (3) carrying out analytical treatment on an ion exchange column treated in the step (2) by using an analytical agent to obtain an ammonium tungstate solution; and (4) adding a vulcanizing agent in the ammonium tungstate solution, and carrying out vulcanizing and filtering treatment. According to the scheme, the chromium can be removed deeply, and the chromium removal rate can reach up to 99% or above. Meanwhile, by the scheme, a chromium removal process and a followed-up process of removing other impurities such as molybdenum are integrated, so that the treatment cost is greatly reduced. The method is suitable for a main process of tungsten recycling enterprises. The whole technological process is simple, convenient and practicable, the purifying efficiency is high, the concentration of residual chromium is low, and the treatment cost is low.

Owner:JINGMEN GEM NEW MATERIAL +1

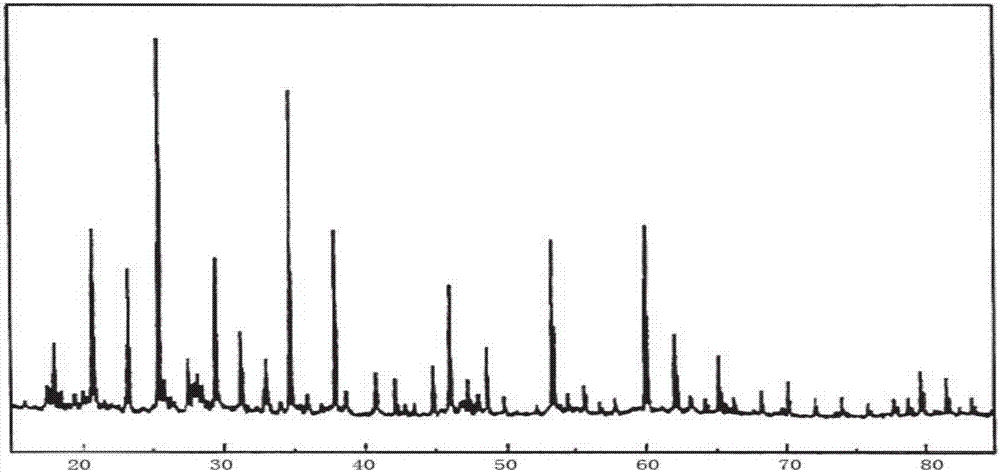

High-purity Wells-Dawson phosphotungstic acid and preparation method thereof

ActiveCN106745266AHigh purityLess impuritiesPhysical/chemical process catalystsTungsten compounds preparationPhosphoric acidSodium tungstate

The invention relates to a high-purity Wells-Dawson phosphotungstic acid and a preparation method thereof, which belong to the field of phosphotungstic acid preparation. The preparation method for the high-purity Wells-Dawson phosphotungstic acid includes the following steps: an aqueous solution of tungstic acid is added into phosphoric acid which is 80 DEG C to 100 DEG C, reaction then takes place under 100 DEG C to 140 DEG C for 12 to 24 hours, so that a phosphotungstic acid solution is obtained, and the molar ratio of the phosphoric acid to the tungstic acid is (7.5 to 15) to 1; and after the phosphotungstic acid solution is acidized, diethyl ether is used for extraction and separation. Since the preparation method for the high-purity Wells-Dawson phosphotungstic acid uses the tungstic acid to replace sodium tungstate as a material, the introduction of Na ions into the product is prevented, and the yield and purity of the phosphotungstic acid product are increased; and moreover, the preparation method is simple in process, is convenient to operate, and is suitable for use in industrialized mass production. The invention further discloses the high-purity Wells-Dawson phosphotungstic acid which is prepared by using the preparation method.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

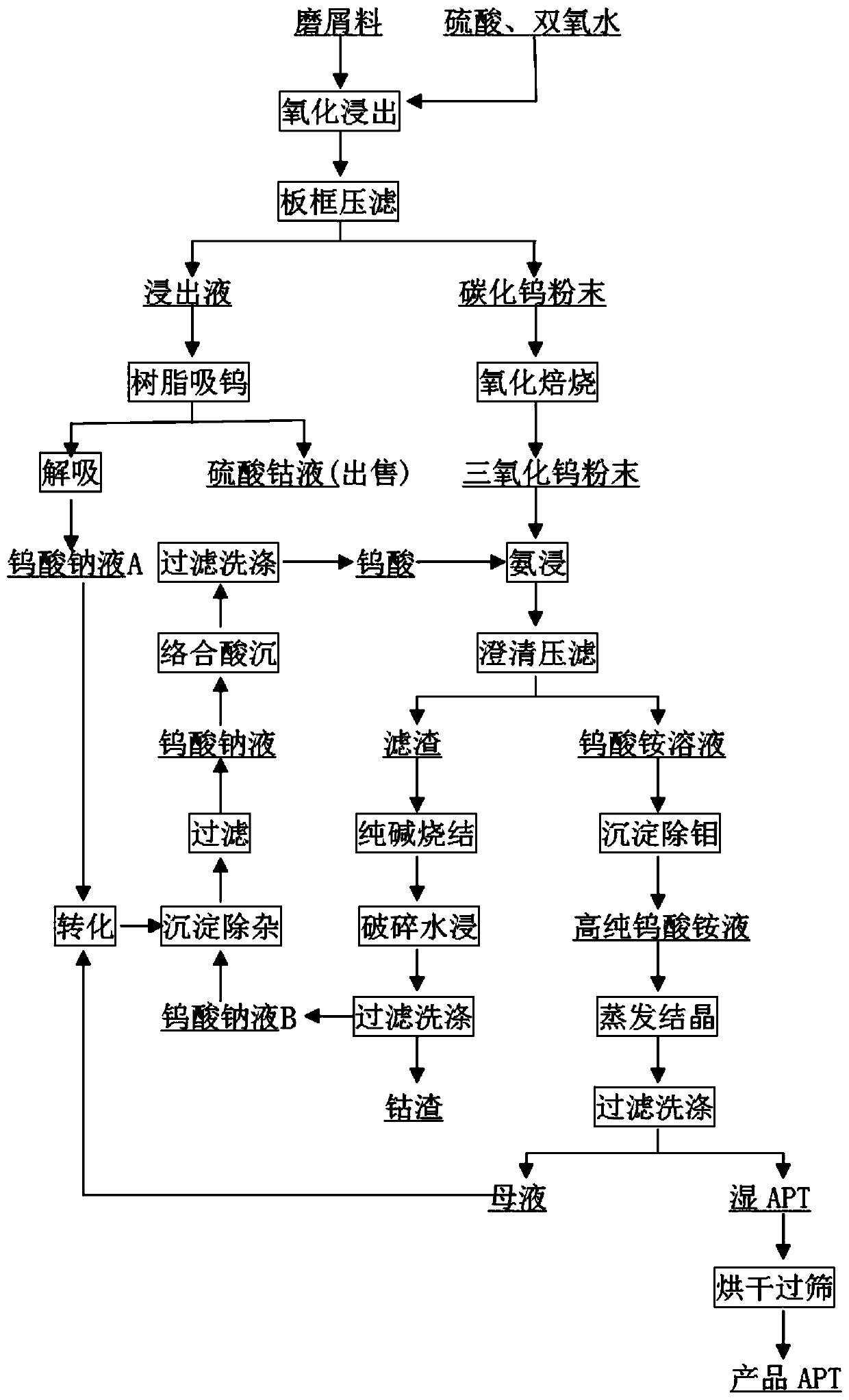

Method for producing ammonium paratungstate from hard alloy scrap

PendingCN110156084AAchieve recyclingReduce processing costsTungsten compounds preparationProcess efficiency improvementSulfite saltFiltration

The invention relates to the field of ammonium paratungstate production and processing, and concretely relates to a method for producing ammonium paratungstate from hard alloy scrap. The method comprises the following steps: 1) performing oxidation leaching; 2) performing oxidation calcining; 3) performing ammonia leaching: adding tungsten trioxide powder and 15% ammonia water into a stainless steel reactor according to a solid-liquid ratio of 1:3, adding a 8% ammonium sulfide solution accounting for 5% of the total addition amount of the tungsten trioxide powder and the ammonia water, stirring and heating the obtained mixture, performing heat insulation for 3 h, cooling the mixture to room temperature, standing for clarifying for 8 h, and performing suction filtration to obtain a filtrateand insoluble residues; and 4) performing complexing acid precipitation: adding a sodium tungstate solution to 30% hydrogen peroxide according to a volume ratio of 10:1, performing stirring for 30 min, slowly adding 1 N hydrochloric acid until the free acidity of the solution is 20-25 g / L, continuously performing stirring for 30 min, adding sodium sulfite to obtain tungstic acid, performing filtration and washing, and returning the obtained product to step 3). The method can reduce the processing cost and shorten the turnaround time, and realizes the comprehensive recycling of the tungsten scrap.

Owner:赣州市海龙钨钼有限公司

Method for adsorbing and purifying tungsten hexafluoride

ActiveCN105668639AImprove the ability to adsorb gaseous impuritiesTungsten halidesTungsten compounds preparationFiberCarbon fibers

The invention relates to a method for adsorbing and purifying tungsten hexafluoride.The method comprises the steps of adding fluorinated carbon fibers into a reaction kettle, and conducting on-load operation, so that adsorbent is obtained; adsorbing industrial-grade tungsten hexafluoride with a chromatographic column filled with the adsorbent, so that a tungsten hexafluoride product is obtained.

Owner:ZHEJIANG BRITECH CO LTD

Method and system for producing ammonium paratungstate through alkaline extraction

ActiveCN111422907AQuality improvementReduce lossesTungsten compounds preparationAmmonium paratungstateTungstate

The invention relates to a method and system for producing ammonium paratungstate through alkaline extraction, and the method comprises the following steps: (1) leaching a tungsten mineral raw material to obtain mixed slurry; (2) carrying out solid-liquid separation on the mixed slurry to obtain a sodium tungstate solution; (3) performing advanced oxidation on the sodium tungstate solution to obtain a primarily purified sodium tungstate solution; (4) performing extraction and back extraction to obtain an ammonium tungstate solution; (5) removing molybdenum to obtain a purified ammonium tungstate solution; (6) crystallizing to obtain an ammonium paratungstate product; the system comprises a leaching device, a filtering device, an advanced oxidation device, an extraction and back extractiondevice, a molybdenum removal device and a crystallization device which are connected in sequence. The method provided by the invention can be used for producing high-quality ammonium paratungstate products, reducing the loss of metal raw materials and avoiding the waste of a leaching agent, and has the advantages of low energy consumption, low labor intensity, good operation environment, no pollution gas release and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Purification process for purifying sodium tungstate solution

InactiveCN108773856AIncrease concentrationDoes not affect purityTungsten compounds preparationMagnesium saltTungstate

The invention discloses a purification process for purifying a sodium tungstate solution, comprising the following steps: S1: acid neutralization of the sodium tungstate solution, wherein acid used for acid neutralization is inorganic diluted acid, preferably dilute sulphuric acid; S2: adding of a magnesium salt solution, wherein the calculation formula of the magnesium salt adding amount according to according to the molar ratio of P, As and Si in the sodium tungstate solution is n(Mg)=X*n(P)+Y*n(As)+Z*n(Si), the scope of X value is 1-30, the scope of Y value is 1-30, and the scope of the Z value is 1-20; S3: heating and preserving heat, wherein the heating temperature of the sodium tungstate solution is 40-100 DEG C, preferably 70-80 DEG C; S4: cooling and filtering, namely cooling and filtering the sodium tungstate solution after heating and heat preservation. According to the purification process for purifying a sodium tungstate solution, in the sodium tungstate solution purified by adopting the method, P is less than or equal to 0.007g / L, As is less than or equal to 0.01g / L, and SiO2 is less than or equal to 0.1g / L, and ammonium tungstate is prepared by adopting an extractionmethod, wherein P is less than or equal to 5ppm, As is less than or equal to 5ppm, and Si is less than or equal to 5ppm, and therefore, not only is the impurity removal effect good due to adding of insoluble magnesium salt, but also the price of the reagent is low, and cost is saved.

Owner:江钨世泰科钨品有限公司

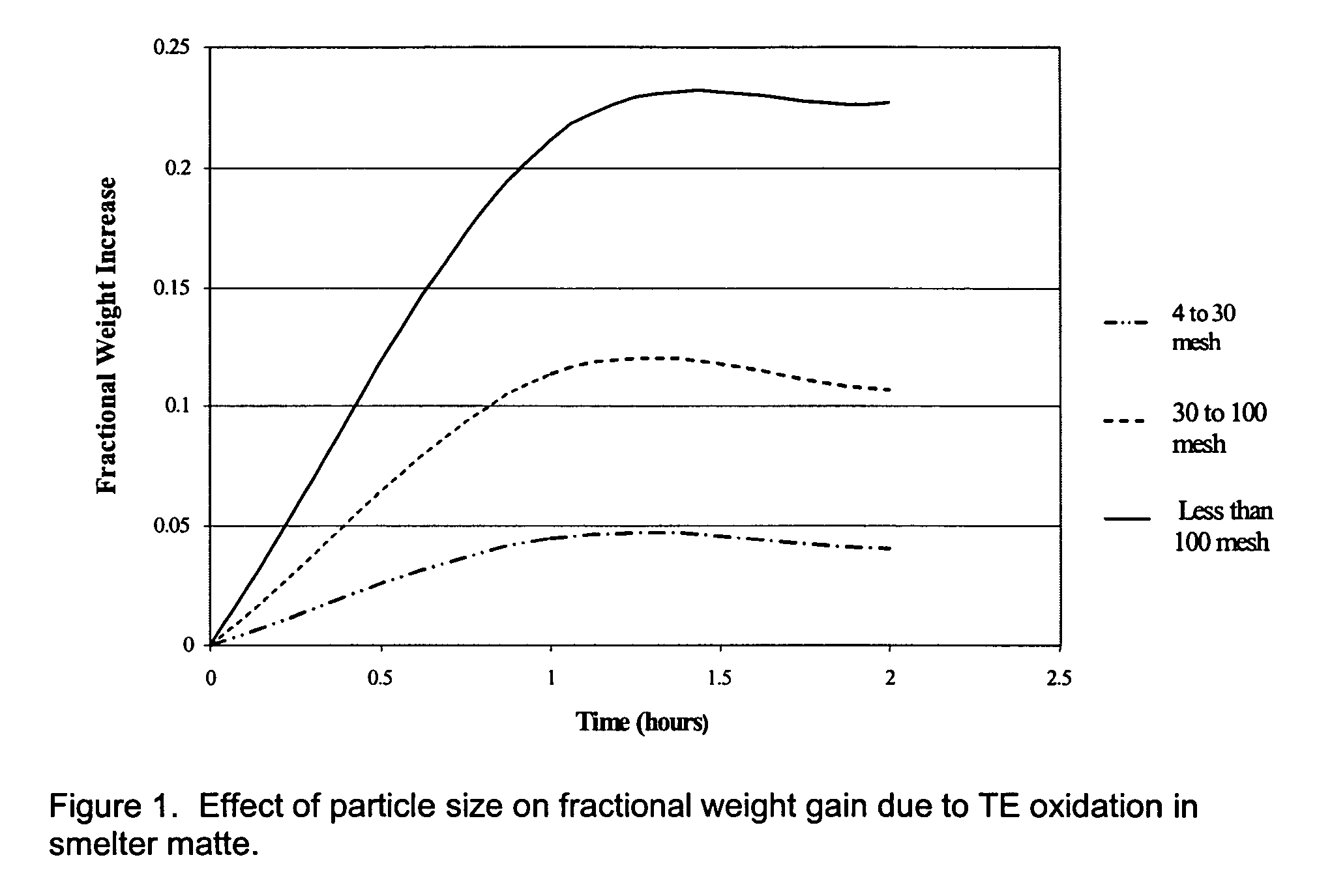

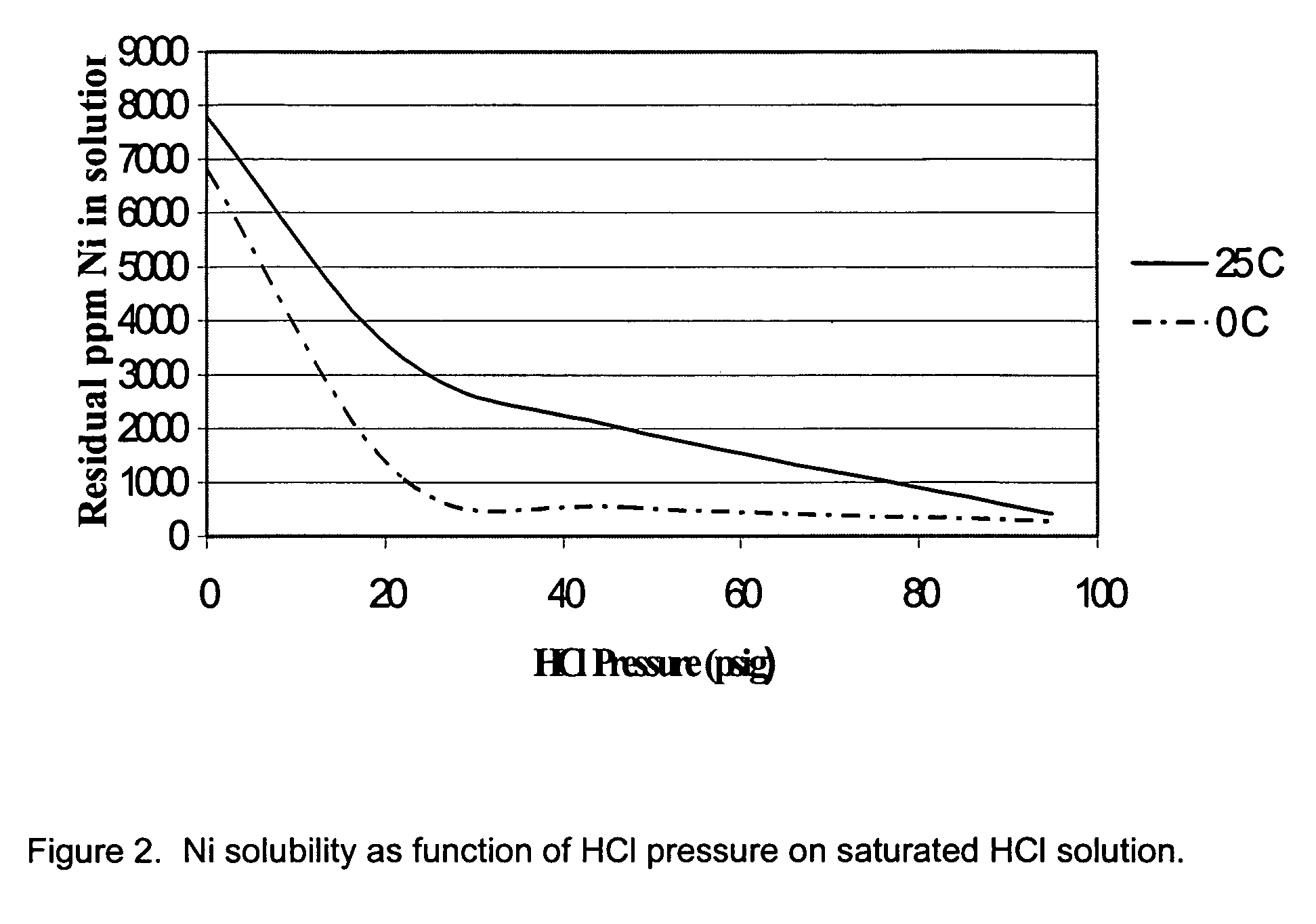

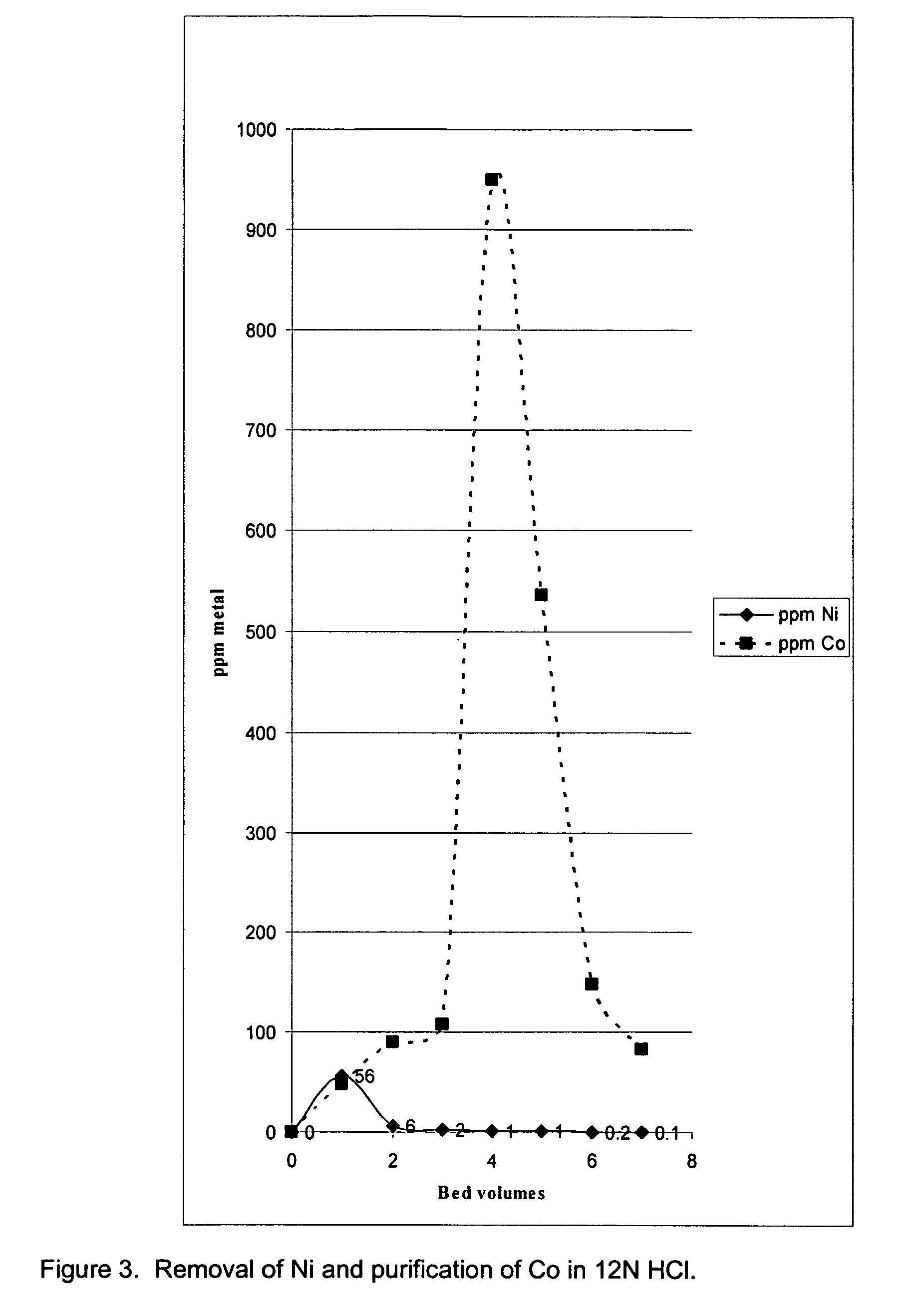

Process for the extraction of specific transition metals with gaseous HCL

A process is disclosed for separation and recovery of vanadium, molybdenum, iron, tungsten, cobalt and nickel from alumina-based materials, mattes, ores, manufacturing by-products and waste. These elements are oxidized. The oxides are reacted with gaseous HCl to form volatile chloride-bearing compounds that subsequently sublimate. The volatile compounds are condensed in a downward-stepped thermal gradient that allows collection of moderate to high purity compounds of individual elements with exception of a nickel-cobalt co-condensate. Nickel is separated from cobalt by precipitation of nickel chloride from concentrated HCl pressurized with gaseous HCl.

Owner:METALS RECOVERY TECH

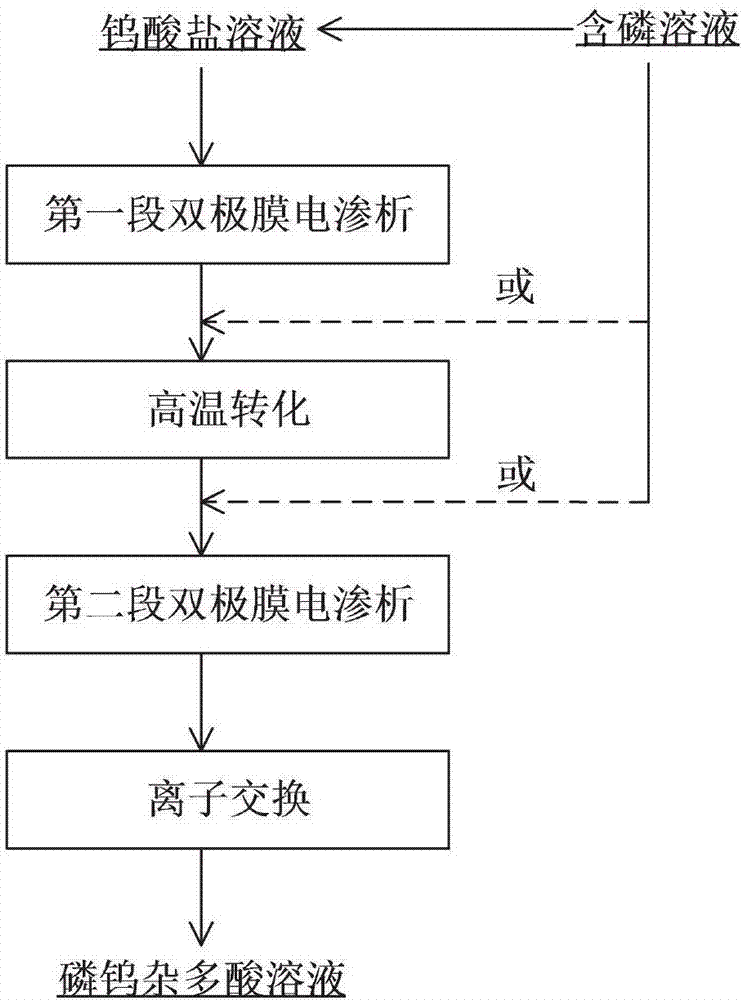

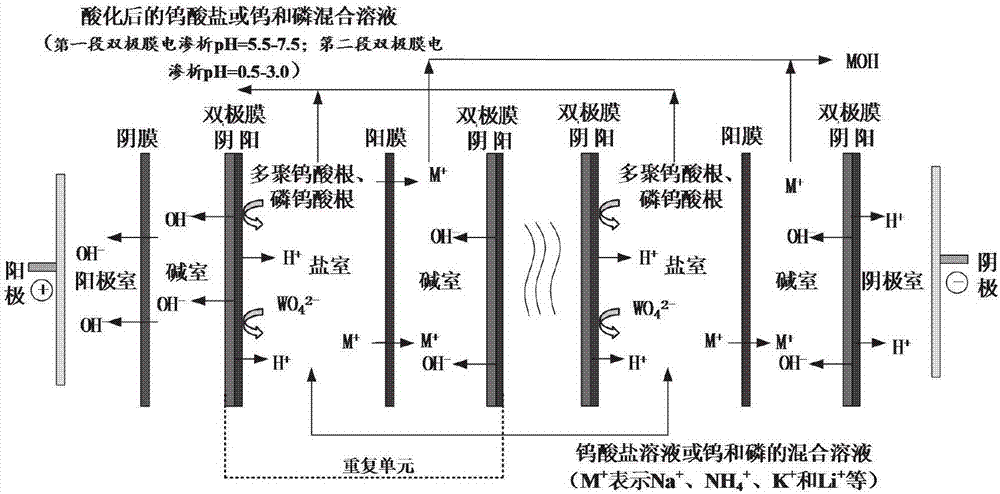

Method for preparing phosphotungstic heteropoly acid solution

ActiveCN106976912AImprove qualityReduce pollutionMembranesSemi-permeable membranesHeteropoly acidTungstate

The invention discloses a method for preparing a phosphotungstic heteropoly acid solution. The method comprises the following steps: performing first-section bipolar membrane electrodialysis on a tungstate solution (or a mixed solution of tungsten and phosphorus), so the pH value of the solution is reduced to 5.5-7.5; performing heating conversion after phosphorous coordination for one-section electrodialysis solution (or the mixed solution of the tungsten and the phosphorus is directly subjected to heating conversion after one-section electrodialysis); cooling the solution, then performing second-section bipolar membrane electrodialysis, and controlling the pH value to be 1.0-3.0 to obtain a heteropolyphosphatotungstate solution; performing ion exchange transformation decontamination to obtain the phosphotungstic heteropoly acid solution. According to the method, inorganic acid is not consumed, and impurity anions are not introduced, so that not only a tungstate solution can be acidified, but also most of salt cations can be removed, thereby greatly reducing burdens on subsequent ion exchange for removing the salt cations. The obtained phosphotungstic heteropoly acid solution can be used for preparing a high-quality phosphotungstic heteropoly acid product, and the method for preparing the phosphotungstic heteropoly acid solution is a phosphotungstic heteropoly acid solution preparation process which is efficient in cleanness.

Owner:CENT SOUTH UNIV

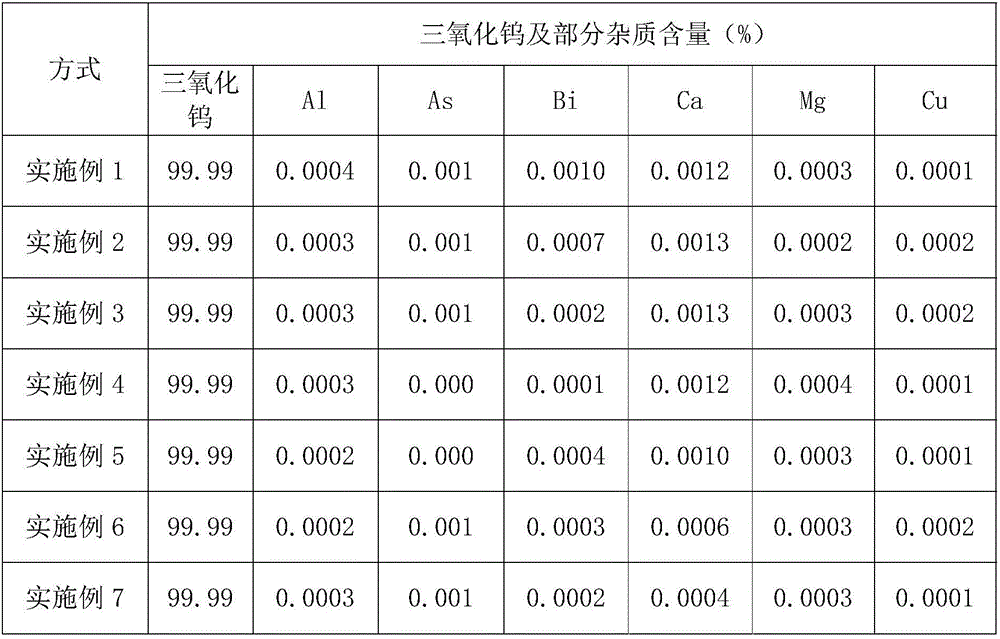

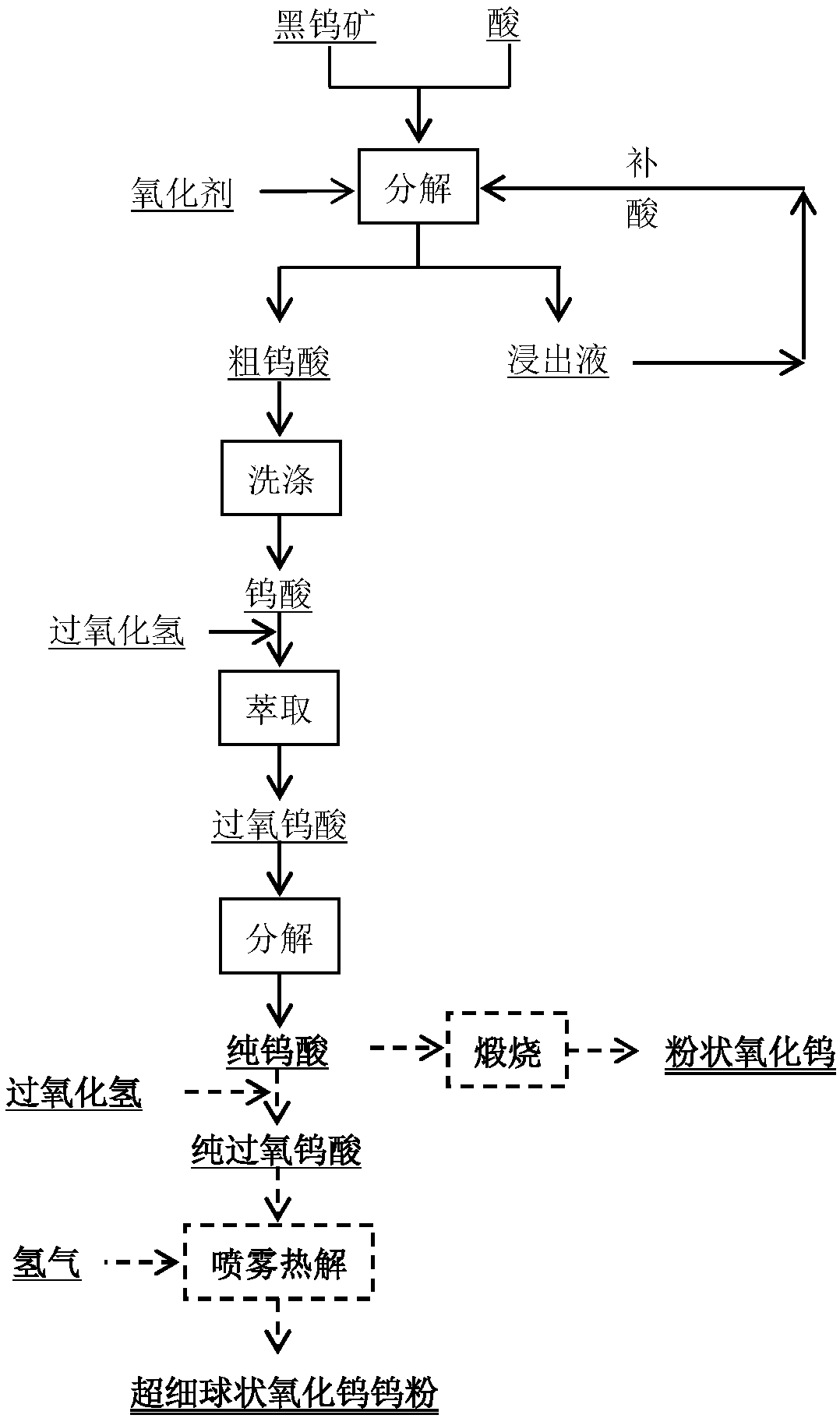

Preparation method of high-purity tungsten trioxide

ActiveCN106379941AShort cycleReduce contentTungsten compounds preparationTungsten oxides/hydroxidesHydrolysateInstability

The invention discloses a preparation method of high-purity tungsten trioxide. According to the method, firstly, tungsten is precipitated through hydrolysis; insoluble impurities are removed through the filtering under the acidic condition; then, obtained tungsten hydrolysate is added into a potassium hydroxide solution; precipitates are removed through filtering; next, a potassium carbonate solution is added; stirring is performed, and then, precipitates are removed through filtering; finally, a trace of polyvalent metal cation impurities are removed through cation exchange resin. The method has the advantages that the high-purity tungsten trioxide is obtained through preparation; the process is simple; the operation is easy; the technological flow process is shortened; the preparation cost is low; high economic benefits are realized; the problems of high production cost, product quality instability, great quantity of waste water in the production process and process complexity during the high-purity tungsten trioxide preparation in the prior art are solved.

Owner:江西翔鹭钨业有限公司

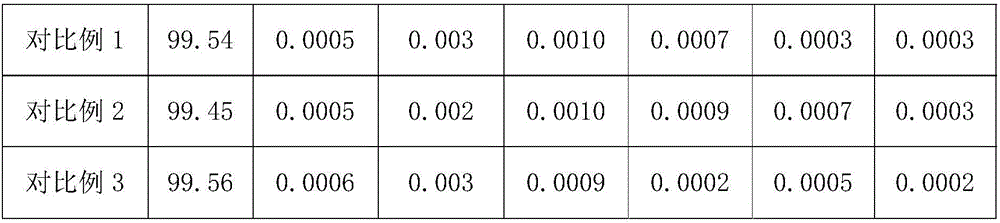

Method for extracting tungsten by acid decomposition of wolframite

ActiveCN108677037AReduce break down costReduce environmental costsTungsten compounds preparationTungsten oxides/hydroxidesDecompositionCalcination

The invention relates to a method for extracting tungsten by acid decomposition of wolframite. The method comprises the following steps: (1) a leaching reaction; (2) filtering and washing; (3) hydrogen peroxide extraction-tungsten decomposition extraction; (4) multi-time hydrogen peroxide dissolving-decomposition for purifying tungstic acid; (5) preparation of tungsten trioxide by calcination of pure tungstic acid; and (6) preparation of tungsten oxide and tungsten powder by spray pyrolysis of a peroxotungstic acid solution. A small amount of nitric acid or hydrochloric acid and a large amountof cheap and easily available sulfuric acid are actually consumed in the decomposition process of the method, so the decomposition cost of tungsten ores is greatly reduced; hydrogen peroxide is usedas an extractant for tungstic acid, so ammonia nitrogen wastewater is not generated, an ammonia nitrogen wastewater generating technology used in tungsten smelting for many years is abolished, and the environmental protection cost is greatly reduced; and the method allows various tungsten end products (tungsten oxide and tungsten powder) of tungsten to be directly produced, so the added values oftungsten smelting enterprises are increased.

Owner:CENT SOUTH UNIV

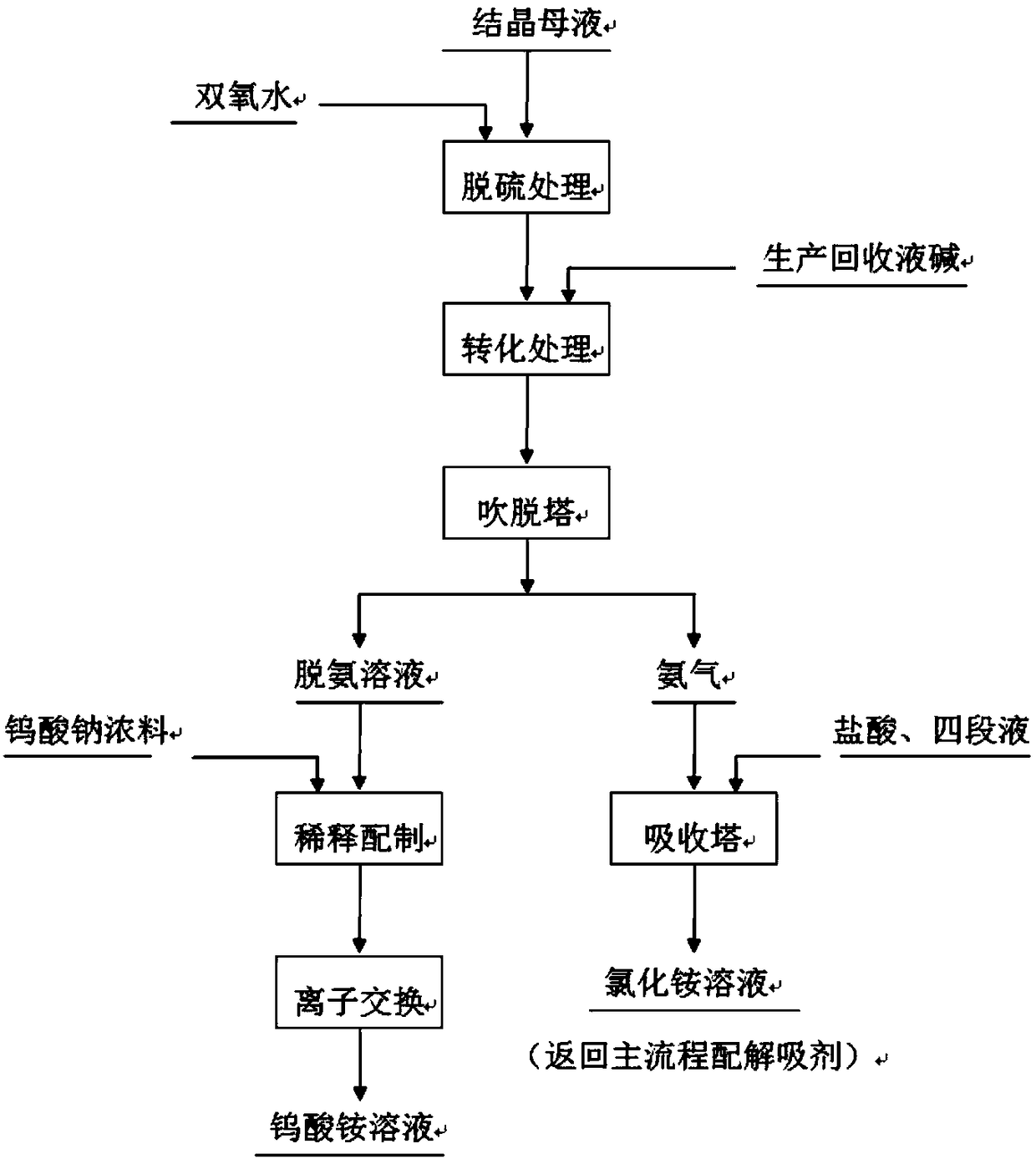

Method for treating ammonium paratungstate crystal crystallization mother liquor

InactiveCN108439471AAchieving zero emissionsEfficient removal of impuritiesTungsten compounds preparationChemistryMother liquor

The invention relates to the technical field of production of ammonium paratungstate, specifically to a method for production post-processing of ammonium paratungstate. More specifically, the invention relates to the method for treating an ammonium paratungstate crystal crystallization mother liquor. The method comprises the following steps: (1) desulfurization treatment; (2) a conversion reaction; (3) an air-stripping reaction; (4) spraying; and (5) preparation of an ammonium tungstate solution. The method provided by the invention has the advantages of simple process flow, easy operation andlow treatment cost, realizes zero discharge of a mother liquor, effectively utilizes excess alkali and four-stage liquids recovered from production, achieves considerable economic benefits, effectively removes impurities from the mother liquor, recovers tungsten in the mother liquor to a maximum extent, and improves profits.

Owner:CNMC GUANGXI PGMA

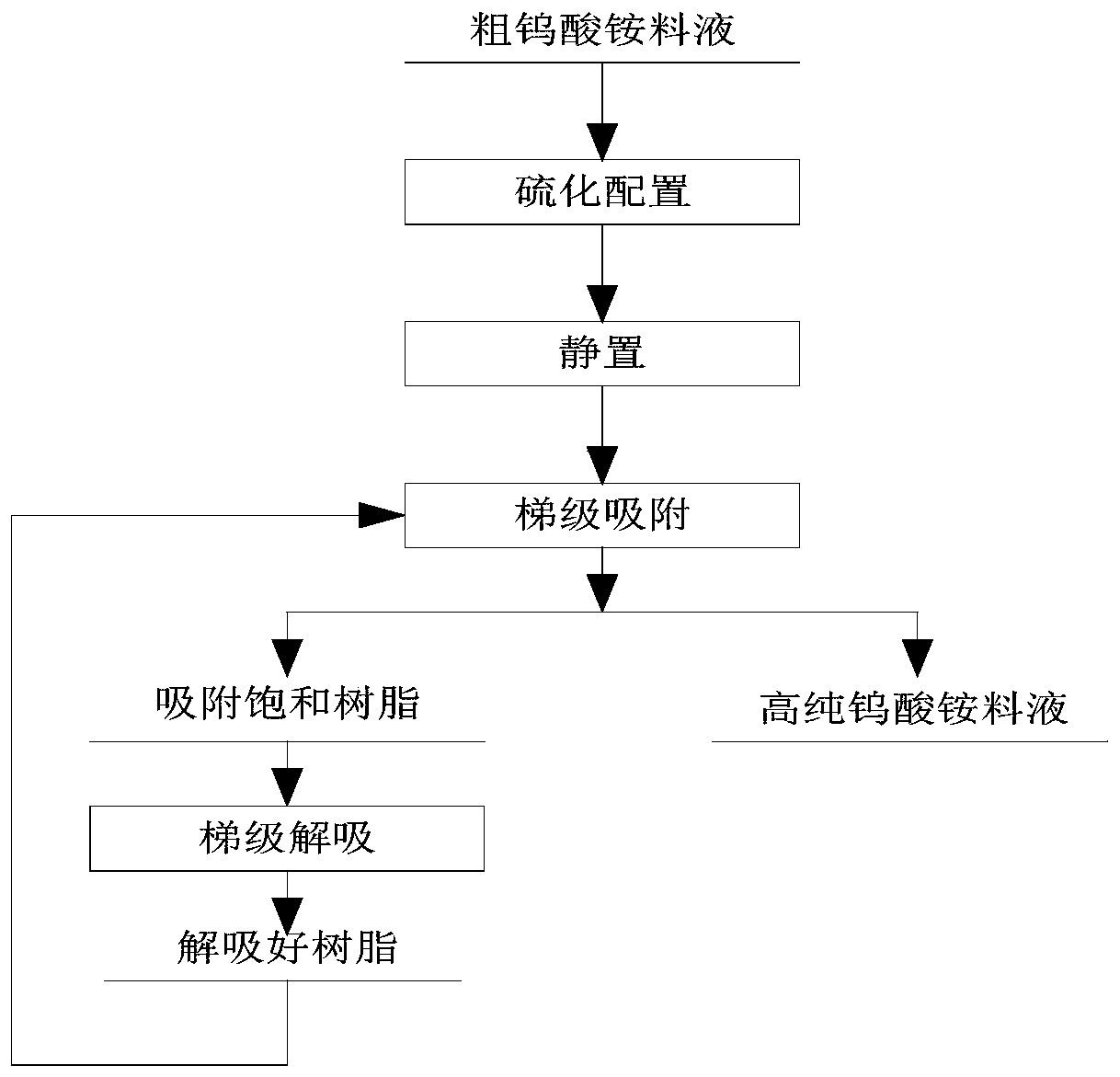

Molybdenum removal method of ammonium tungstate feed liquid

ActiveCN110104688AImprove adsorption capacityAvoid the disadvantage of poor absorption effectTungsten compounds preparationTungstateAdsorption effect

The invention provides a molybdenum removal method of ammonium tungstate feed liquid. The method comprises the steps of a sulfurizing step, wherein a sulfurizing agent is added in the ammonium tungstate feed liquid, and sulfurizing feed liquid is obtained; a stepped adsorption step, wherein the sulfurizing feed liquid is subjected to primary adsorption through WDA918 resin until achieving saturation, primary post-adsorption liquid is obtained and subjected to secondary adsorption through 201*7 resin until achieving saturation, and the molybdenum-removed ammonium tungstate feed liquid is obtained. Two kinds of resin are combined for use, the two kinds of the resin can achieve high adsorption capacity, and the good adsorption effect is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com