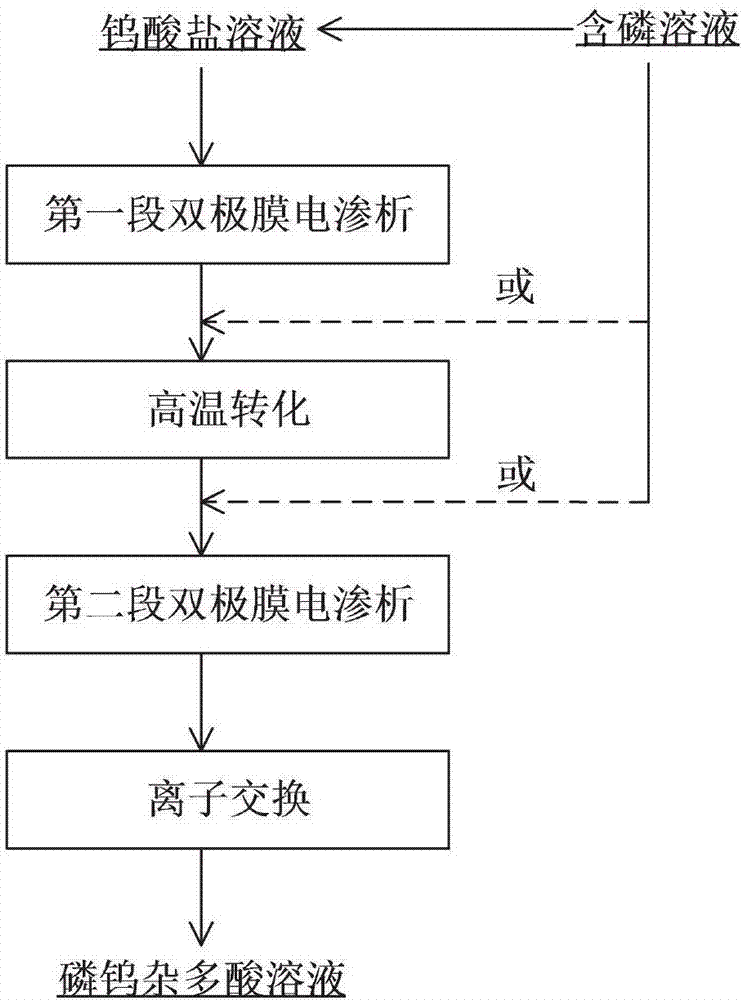

Method for preparing phosphotungstic heteropoly acid solution

A technology of phosphotungstic heteropoly acid and solution, which is applied in the preparation of tungsten compounds, chemical instruments and methods, tungsten compounds, etc., to achieve the effects of low equipment corrosion, high yield and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

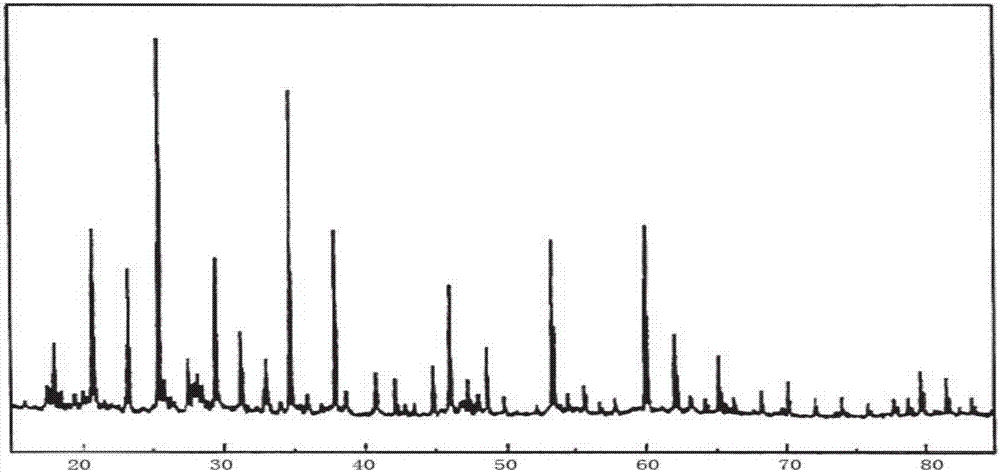

Examples

Embodiment 1

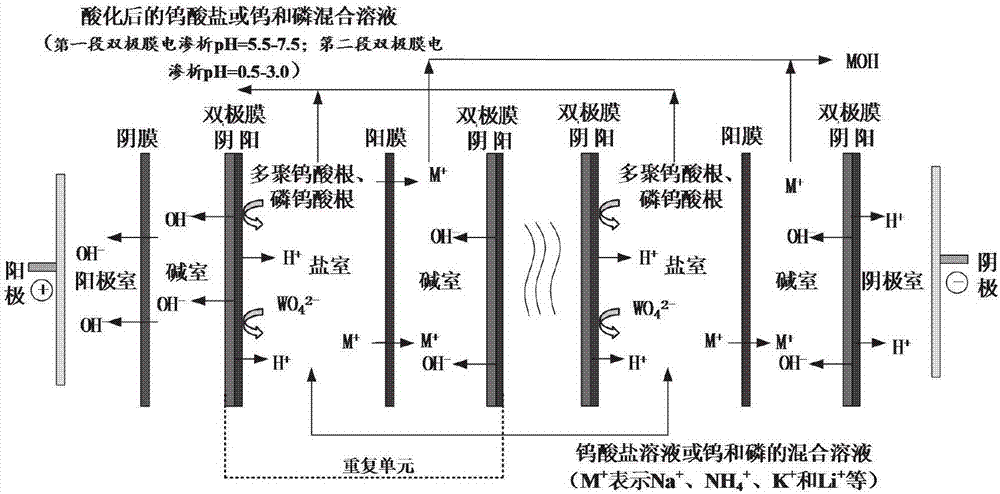

[0065] The first stage of bipolar membrane electrodialysis: the feed liquid chamber (salt chamber) contains WO 3182.8g / L sodium tungstate solution, the initial pH value is 12.91; the alkali chamber solution is 0.05mol / L NaOH solution; the pole chamber solution is 0.1mol / L NaOH solution; the initial volume of the three-chamber solution is 4L. The current density of the first bipolar membrane electrodialysis is 500A / m 2 , the electrolysis time is 40min, and the tungsten-containing sodium salt solution with pH value of 6.78 is obtained, WO 3 The concentration is 228.5g / L;

[0066] Transformation: After the first stage of bipolar membrane electrodialysis, the solution is boiled for 4 hours for transformation; after transformation, the solution can be diluted with an appropriate amount of pure water, and sodium dihydrogen phosphate is added according to the P / W molar mass ratio of 1 / 12 to obtain WO containing 3 The mixed solution with a concentration of 155.6g / L has a pH of 7.89;...

Embodiment 2

[0070] The first stage of bipolar membrane electrodialysis: the material-liquid chamber contains WO 3 50g / L ammonium tungstate solution, add phosphoric acid according to the P / W molar mass ratio of 1 / 9, the initial pH value is 9.50, and the alkali chamber solution is 1.0mol / L NH 4 HCO 3 solution; pole chamber solution is 0.5mol / LNH 4 OH solution; the initial volume of the three-chamber solution is 5L. The current density of the first bipolar membrane electrodialysis is 750A / m 2 , the electrolysis time is 25min, the mixed solution of tungsten and phosphorus with pH value of 7.5 is obtained, WO 3 The concentration is 62.5g / L;

[0071] Transformation: After the first stage of bipolar membrane electrodialysis, the solution was transformed at 90 °C for 48 h; 3 The mixed solution with a concentration of 65.3g / L, the pH value is 7.25;

[0072] The second-stage bipolar membrane electrodialysis: take 4.1L of the mixed solution for the second-stage bipolar membrane electrodialysis...

Embodiment 3

[0075] The first stage of bipolar membrane electrodialysis: the material-liquid chamber contains WO 3 300.0g / L sodium tungstate solution, initial pH value is 13.5; alkali chamber solution is 1.0mol / L NaHCO 3 solution; the polar compartment solution is 1.0mol / L NaOH solution; the initial volume of the three compartment solutions is 4L. The current density of the first bipolar membrane electrodialysis is 600A / m 2 , the electrolysis time is 45min, and the tungsten-containing sodium salt solution with pH value of 5.50 is obtained, WO 3 The concentration is 375g / L;

[0076] Transformation: After the first stage of bipolar membrane electrodialysis, add sodium dihydrogen phosphate to the solution with a P / W molar mass ratio of 1 / 11, and boil for 12 hours for transformation; the transformed solution can be diluted with an appropriate amount of pure water to obtain WO containing 3 The mixed solution with a concentration of 220.5g / L, the pH value is 8.02;

[0077] The second stage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com