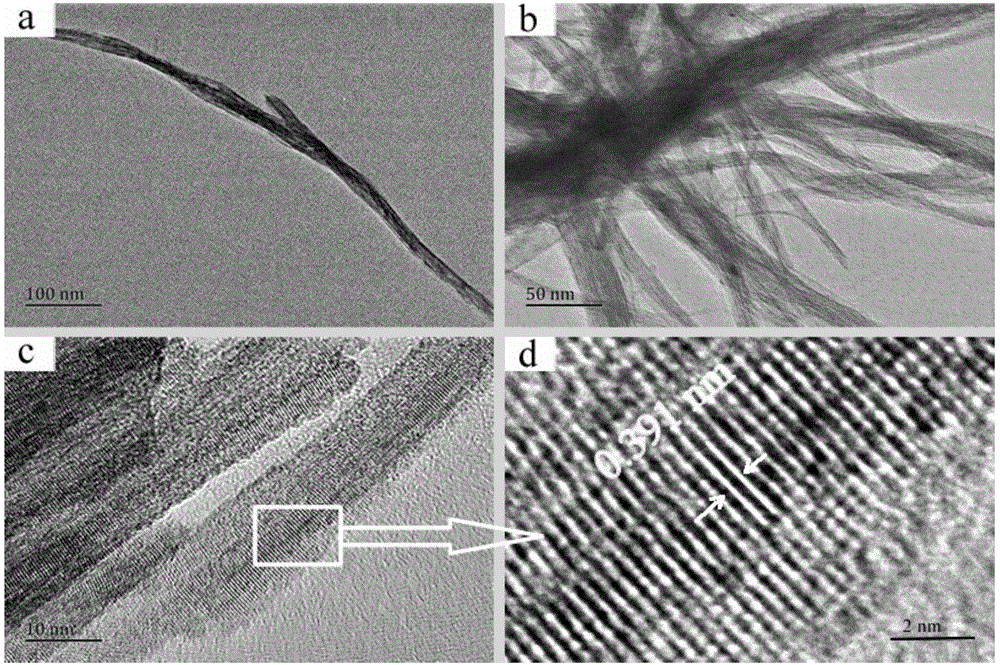

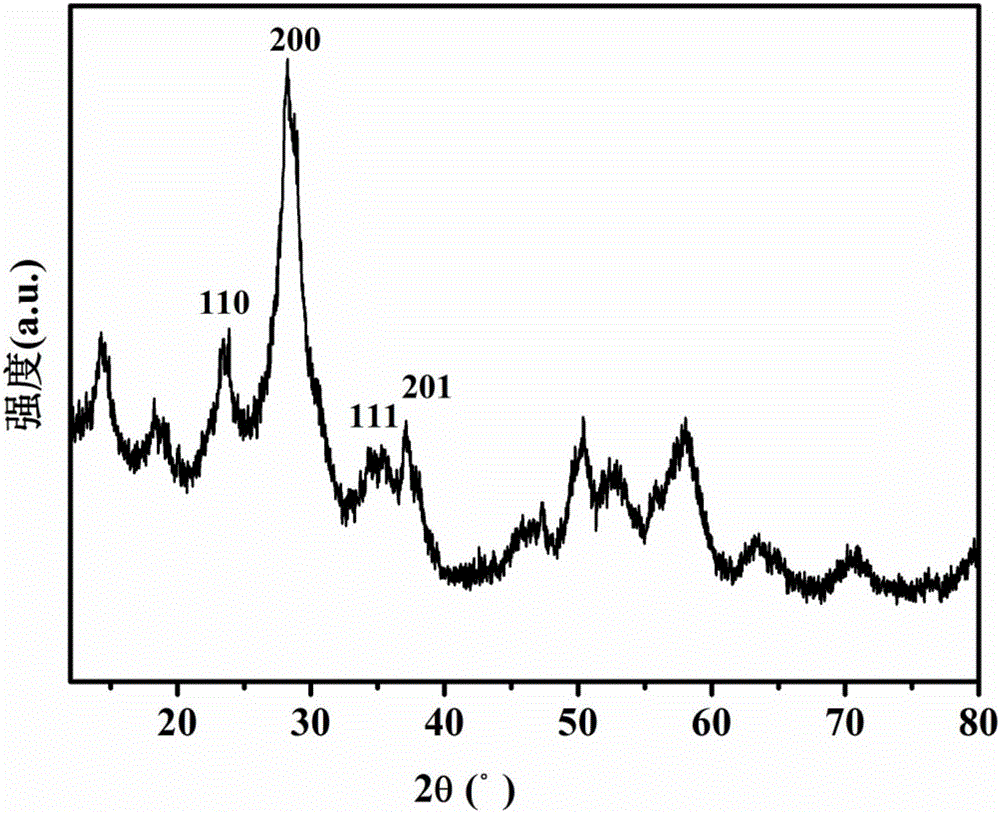

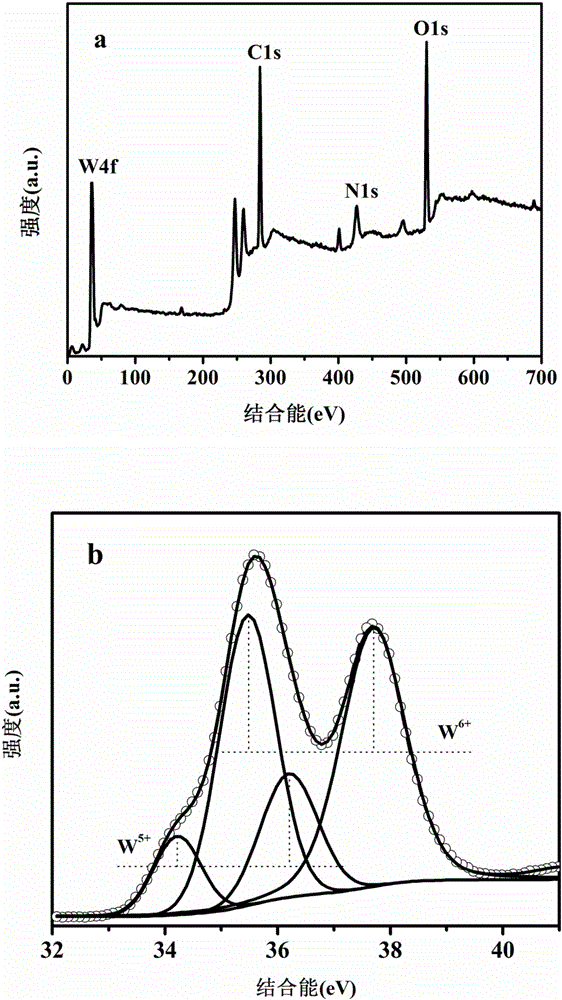

Preparation method and application of ultra-fine WO3 nanowire

A technology of nanowires and reactors, which is applied in the field of photoelectrochemical materials and photocatalysis, can solve problems such as pollution, complex synthesis routes, and expensive precursors, and achieve large application potential, large quantum confinement effect, and improved photocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Weigh 0.1gNa 2 WO 4 2H 2 O with 0.2g (NH 4 ) 2 SO 4 , dissolved in 6mL of deionized water, add 2mL of 0.3mol / L hydrochloric acid solution, stir and mix evenly;

[0019] (2) Measure 5mL cyclohexane and 0.4g oleylamine and mix evenly, pour the obtained transparent mixture into the solution obtained in step (1), stir for 5 minutes to obtain a white milky mixture, pour the mixture into 25mL polytetrafluoroethylene In an ethylene reactor, react at 200°C for 8 hours, and cool to room temperature naturally;

[0020] (3) Add cyclohexane to the reaction kettle that has been cooled to room temperature in step (2) to extract, leave to stand for layering after fully stirring, take the upper layer of blue clear liquid, add ethanol to precipitate the product, and then use a centrifuge to Centrifuge at 10,000 rpm for 15 minutes, remove the supernatant, repeat the treatment with cyclohexane extraction, ethanol precipitation, and centrifugation for 3 times, and dry the centrif...

Embodiment 2

[0023] (1) Weigh 0.05gNa 2 WO 4 2H 2 O with 0.1g (NH 4 ) 2 SO 4 , dissolved in 6mL deionized water, add 2mL 0.1mol / L hydrochloric acid solution, stir and mix evenly;

[0024] (2) Measure 5mL cyclohexane and 0.4g oleic acid and mix evenly, pour the obtained transparent mixture into the solution obtained in step (1), stir for 5 minutes to obtain a white milky mixture, pour the mixture into 25mL polytetrafluoroethylene In an ethylene reactor, react at 150°C for 24 hours, and cool to room temperature naturally;

[0025] (3) Add cyclohexane to the cooled reactor of step (2) for extraction, i.e. leave it to stand for layering after fully stirring, take the upper layer of blue clear liquid, add ethanol to precipitate the product, and then use a centrifuge at 10,000 rpm Centrifuge for 15 minutes at a speed of 1 / min, remove the supernatant, repeat the treatment with cyclohexane extraction, ethanol precipitation, and centrifugation for 3 times, and dry the centrifuged product at 5...

Embodiment 3

[0027] (1) Weigh 0.2gNa 2 WO 4 2H 2 O with 0.4g (NH 4 ) 2 SO 4 , dissolved in 6mL of deionized water, added 2mL of 0.2mol / L hydrochloric acid solution, stirred and mixed evenly;

[0028] (2) Measure 5mL of cyclohexane and 0.4g of octadecylamine and mix evenly, pour the obtained transparent mixture into the solution obtained in step (1), and stir for 5 minutes to obtain a white milky mixture, which is poured into 25mL polytetrafluoroethylene React in vinyl fluoride reactor at 180°C for 12 hours, then cool to room temperature naturally;

[0029] (3) Add cyclohexane to the reaction kettle that has been cooled to room temperature in step (2) for extraction, that is, leave to stand for layering after fully stirring, take the upper layer of blue clear liquid, add ethanol to precipitate the product, and then use a centrifuge to Centrifuge at 10,000 rpm for 15 minutes, remove the supernatant, repeat the treatment with cyclohexane extraction, ethanol precipitation, and centrifugati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com