Patents

Literature

48results about How to "Reduce cleaning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering vanadium from phosphate-removing underflow slag

The invention discloses a method for recovering vanadium from phosphate-removing underflow slag, which comprises the following steps: A)using an oxalate solution for leaching the phosphate-removing underflow slag to obtain an alkalescent vanadium-containing leachate; and B)adjusting pH value of the alkalescent vanadium-containing leachate to 8-11, then performing molybdenum precipitation to obtain ammonium metavanadate. The method for recovering vanadium from phosphate-removing underflow slag uses a oxalate system for leaching the phosphate-removing underflow slag, no mass harmful gas such as ammonia gas and carbon dioxide is generated, cycle usage of waste water can be realized, the method is eco-friendly, and can realize clean production. The method provided by the invention has the advantages of short flow, simple operation and easy industrialization, and has high economic benefit and social benefit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Novel welding device and method based on high-frequency current proximity effects

ActiveCN110369851AHeating fastReduce lossHigh frequency current welding apparatusPower flowButt joint

The invention discloses a novel welding device and method based on high-frequency current proximity effects. The welding device comprises a pressing device, a high-frequency welding heating device, animage acquisition device, a pressure sensor, a central controller and a temperature measuring device, wherein the pressing device is used for pressing a tube blank to realize butt joint of welding seam edges of the tube blank before welding heating and is arranged at the front end of the high-frequency welding heating device; the high-frequency welding heating device is arranged between a squeezeroller and the pressing device; the image acquisition device is used for respectively collecting rear welding seam edge images of the pressing device and welding seam area images after welded tube welding squeezing; the pressure sensor is used for measuring the pressing force of the pressing device on the tube blank; the central controller is used for recording collected welded tube sizes and wall thickness information and preliminarily calculating and adjusting the positions of pressing mechanisms and the distance between an anode contact and a cathode contact of the high-frequency welding heating device; and the temperature measuring device is arranged at the tail end of the high-frequency welding heating device and used for measuring the temperature after welding heating. The welding device can improve the welding quality of the high-frequency welded tube and reduce current losses on invalid paths and suppress generation of burrs.

Owner:北渤智能科技秦皇岛有限公司

Method for producing frosted glass

InactiveCN101618648AReduce cleaning processReduce cleaning costsPattern printingSurface treatment compositionsChemistryAqueous sodium hydroxide

The invention relates to a method for producing frosted glass, which comprises the following steps: firstly, selecting original white glass sheets, jointing the two sheets, and sealing four edges by tapes; putting the glass into a weak acid pool for soaking for 2 minutes; conveying the glass into a corrosion pool for frosting; clearing the frosting liquid after the glass is frosted, and drying the glass; removing the sealing tapes at the four edges of the glass; then, adopting a silk screen to print the preliminarily designed glass pattern on one surface, air-drying the glass for 2 hours, andthen, conveying the glass into a dryer for drying; pasting a protective film on the glass surface which is not printed with the pattern; scrubbing the surface which is printed with the glass pattern with weak acid liquid; soaking the glass into the corrosion liquid for 80-120 minutes; putting the glass into a sodium hydroxide solution for cleaning; and then, conveying the glass into a cleaning and drying machine for cleaning and drying to obtain a finished product. The patterned glass which is produced by the method of the invention has uniform and fine etched depth, strong aesthetic feeling of the pattern, better quality, simple processing method and environment protection, and can greatly reduce the production cost in the production process.

Owner:杜广武

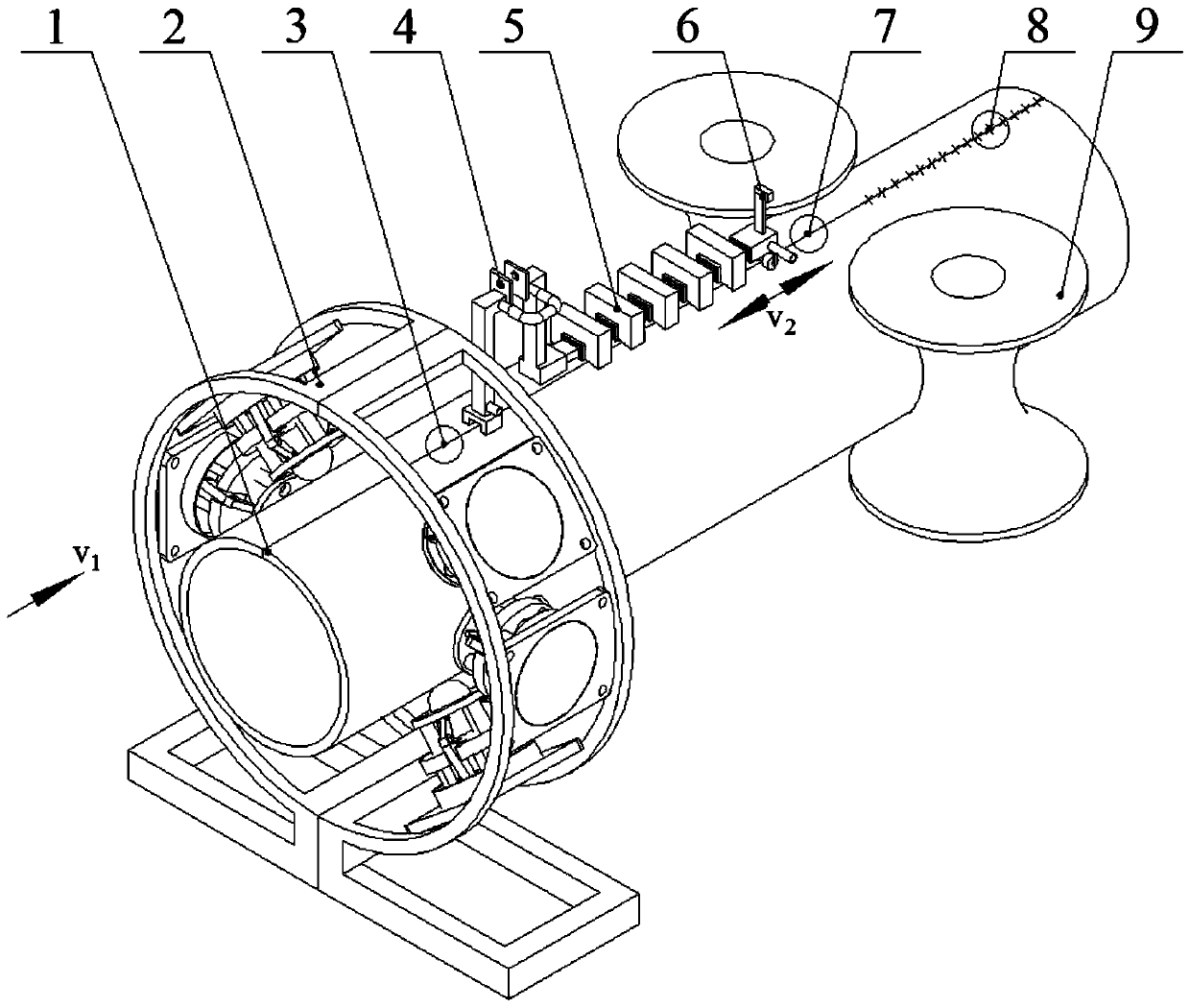

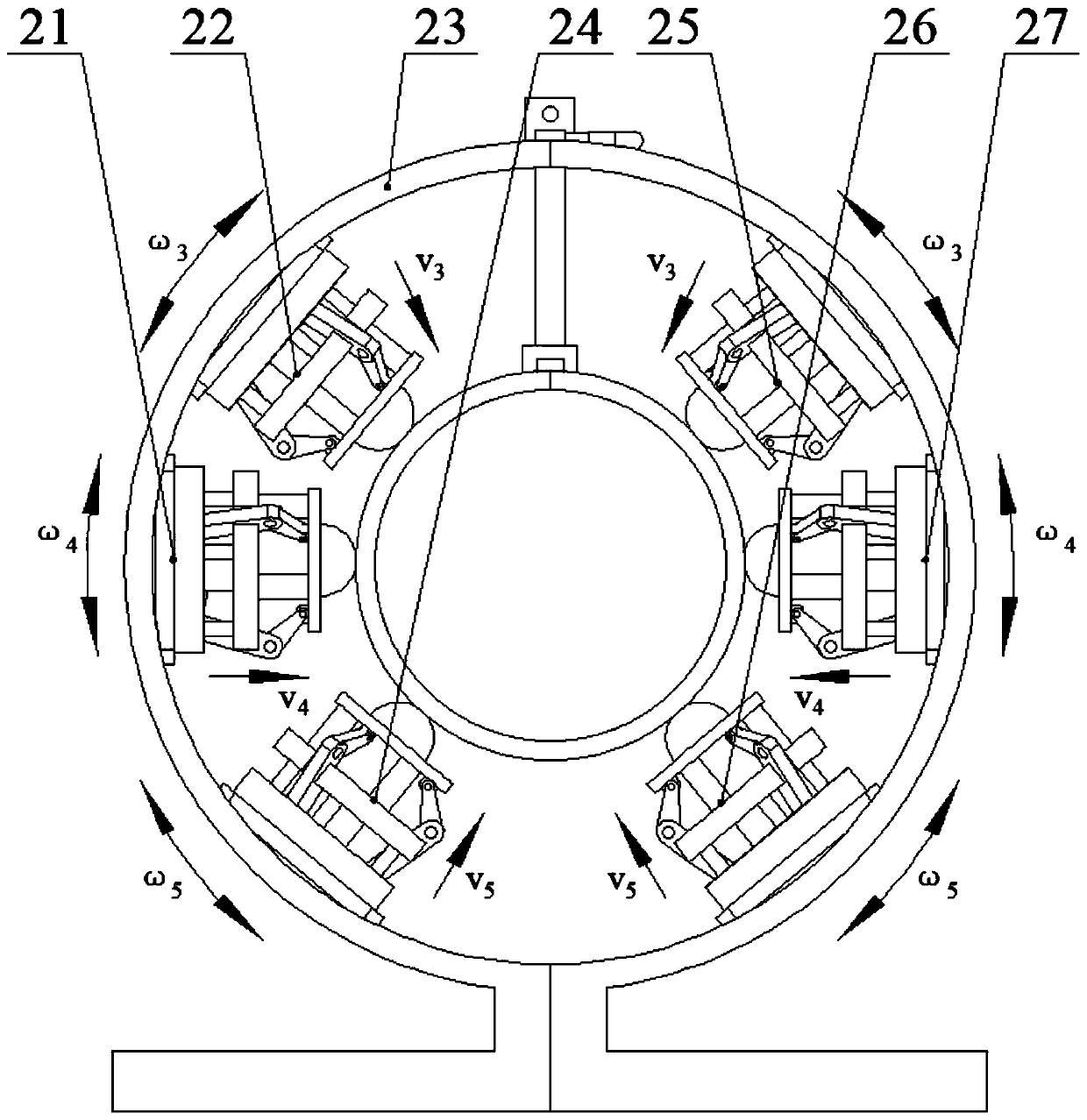

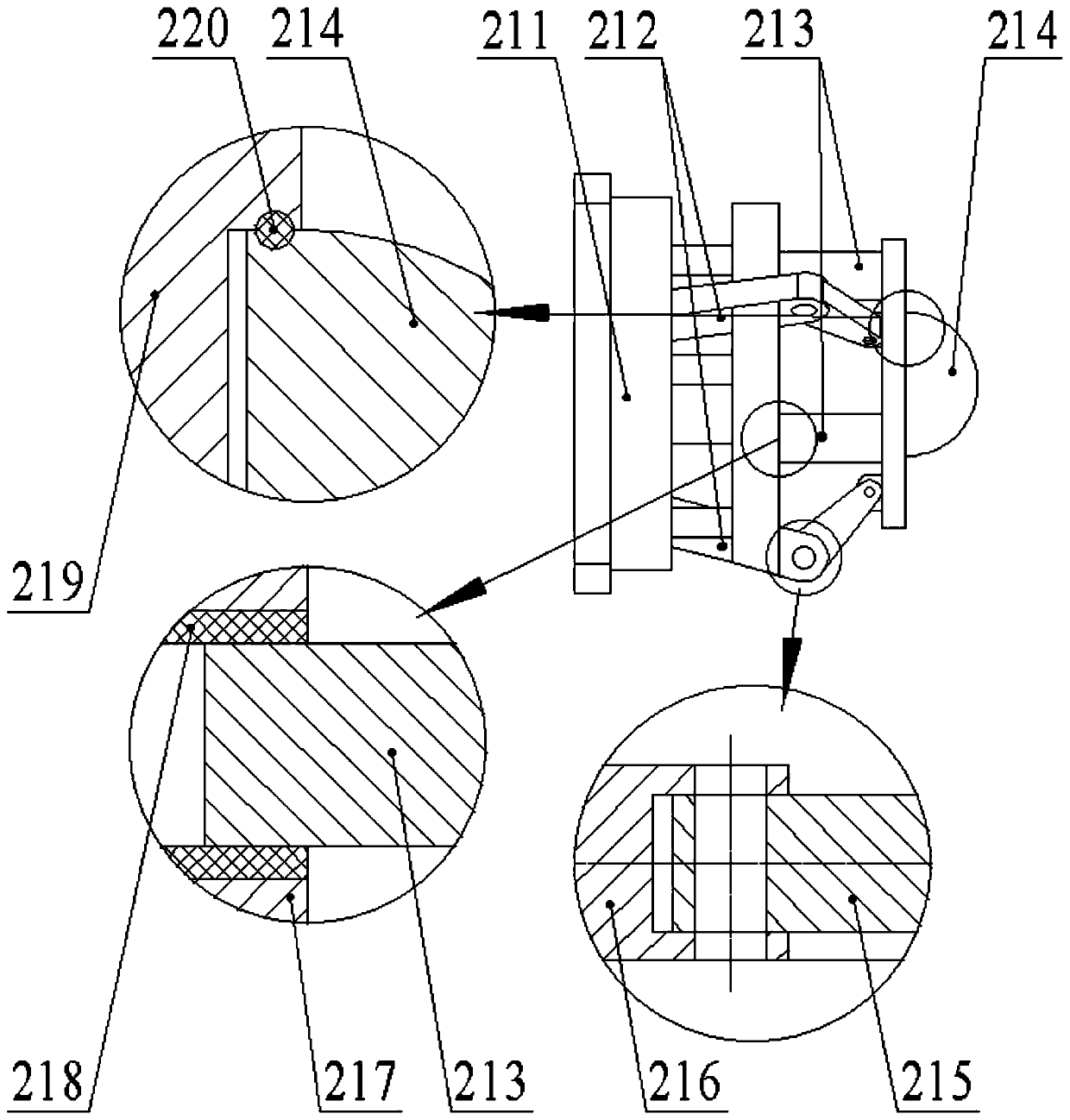

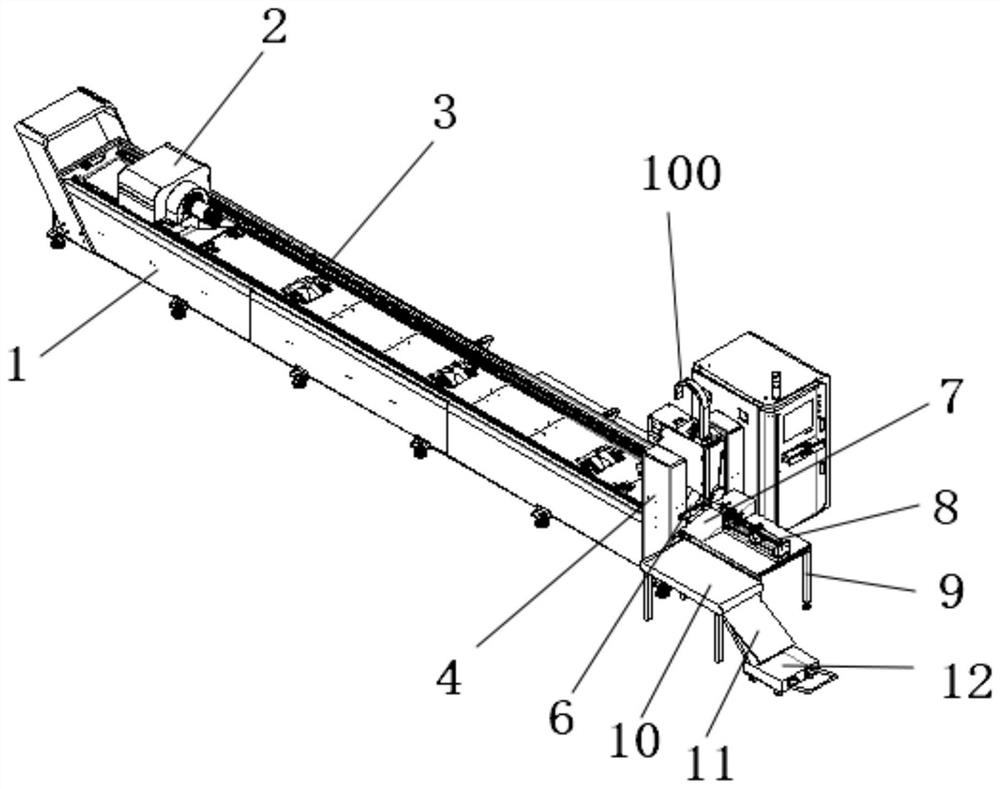

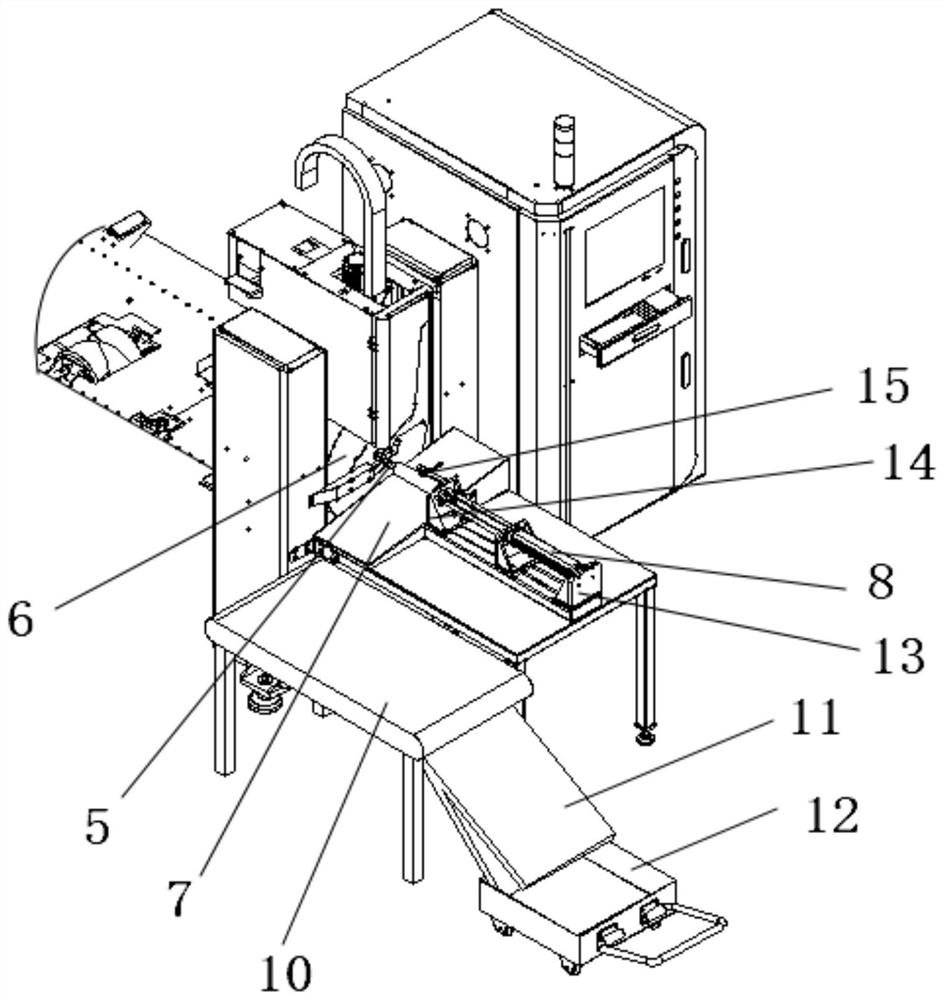

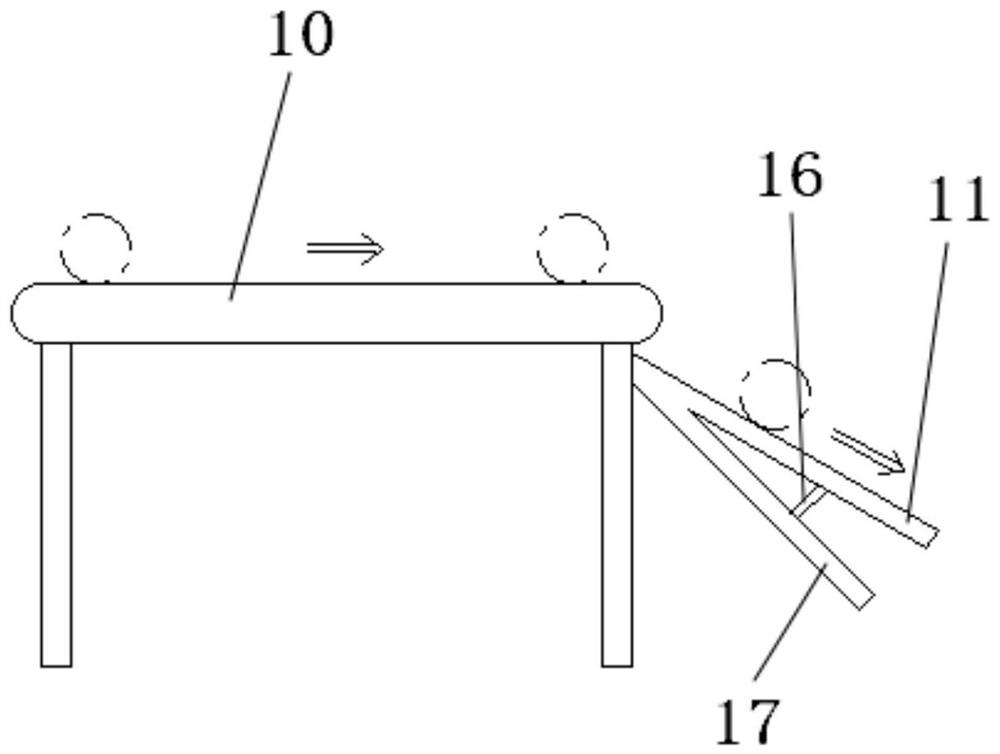

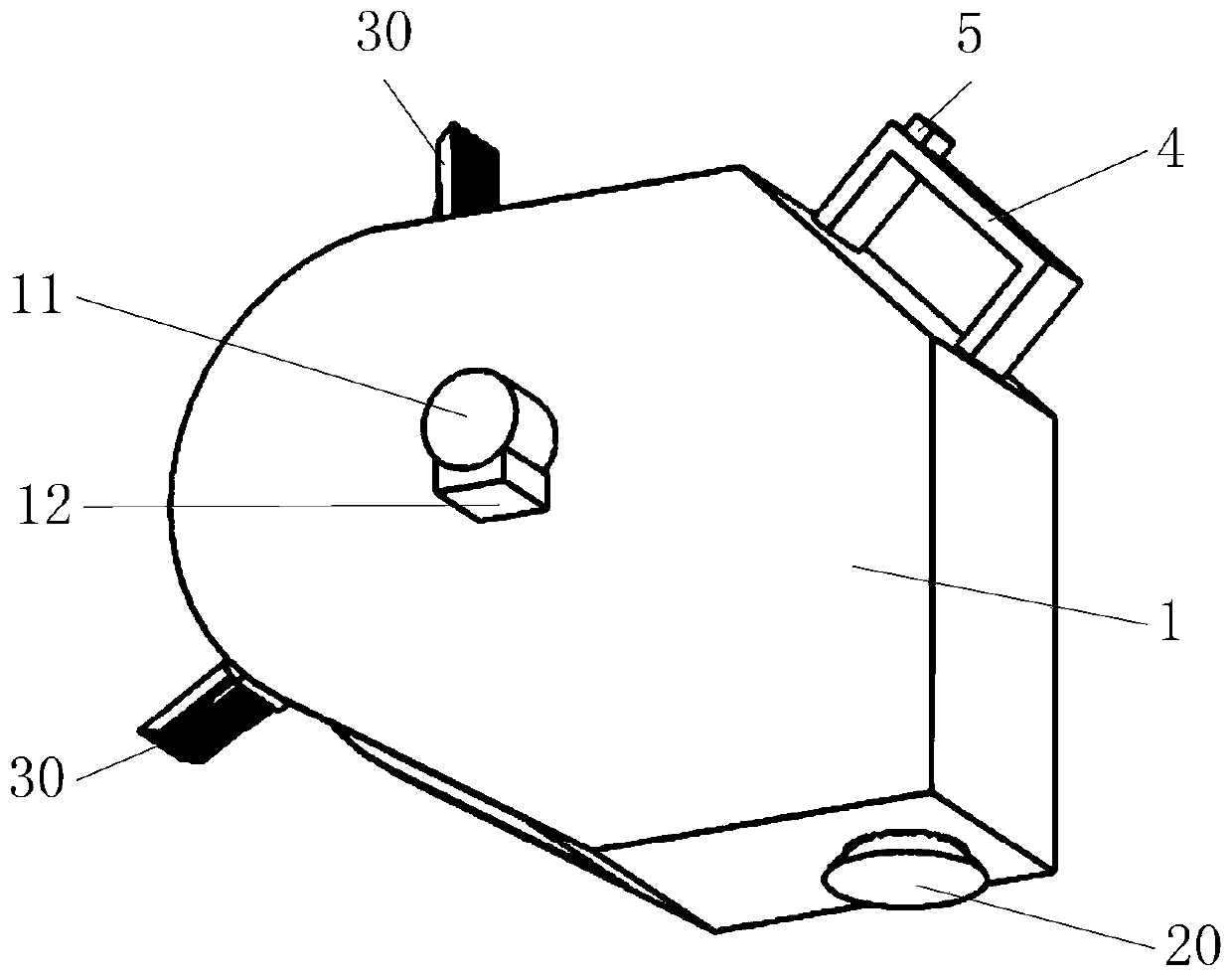

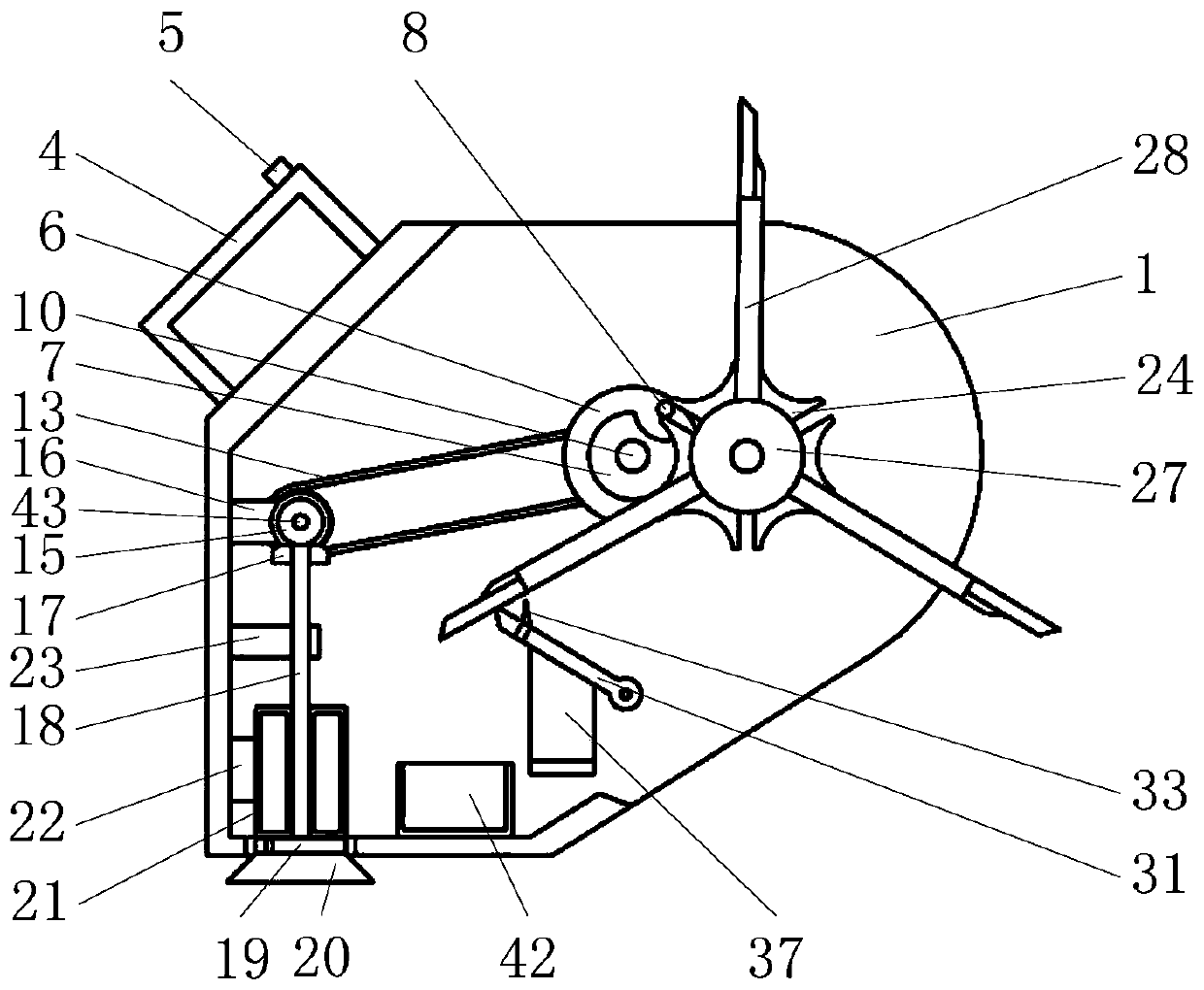

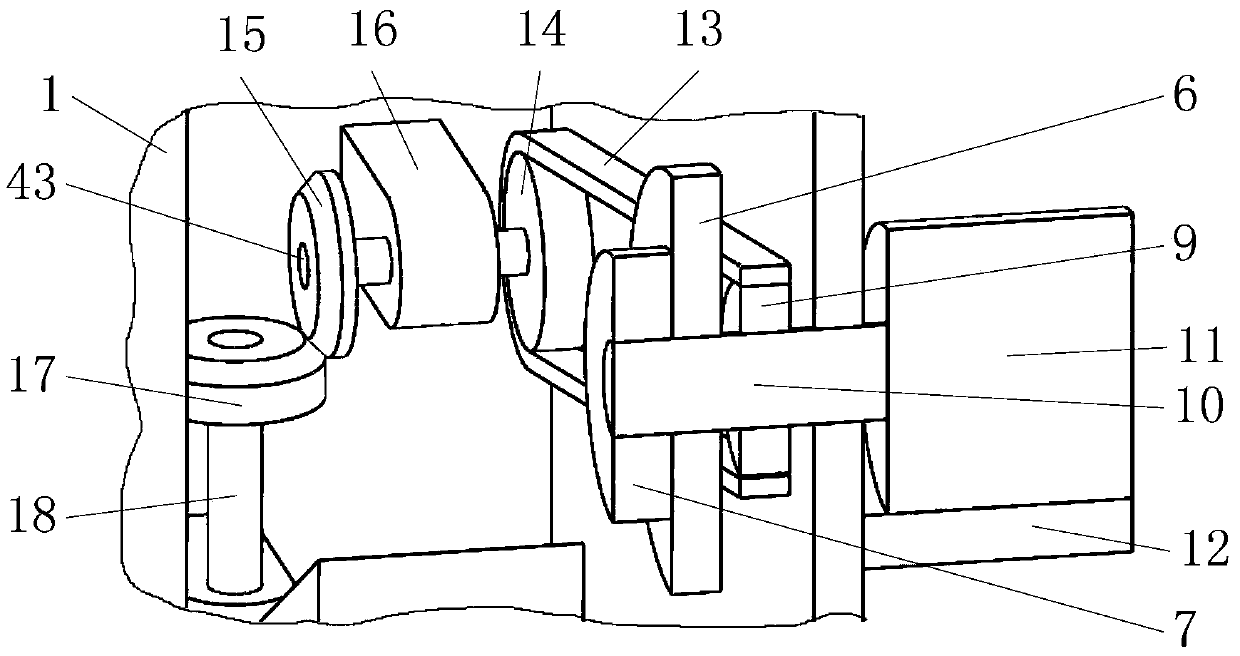

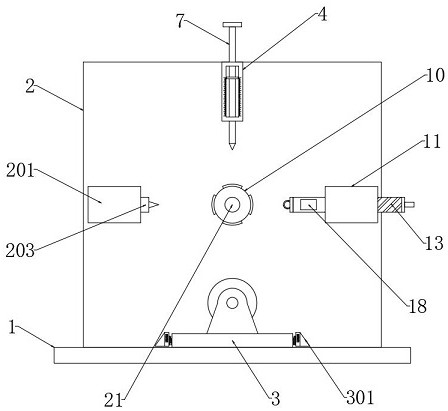

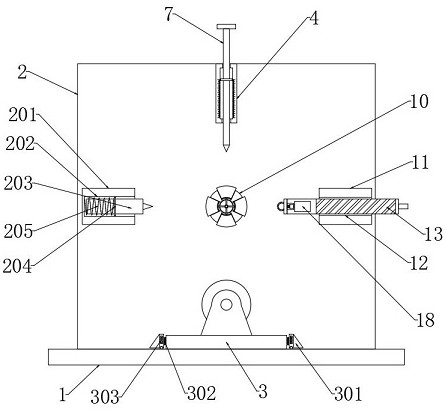

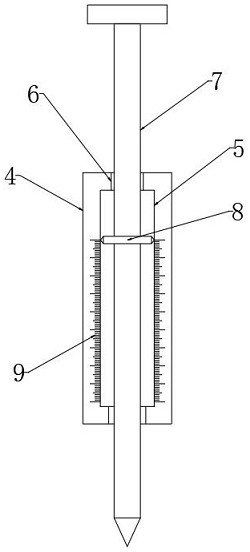

Anti-slag-adhering laser pipe cutting machine and cut pipe collecting method

InactiveCN112338366APrevent adhesionAvoid cutsMetal working apparatusLaser beam welding apparatusThermodynamicsSlag

The invention provides an anti-slag-adhering laser pipe cutting machine and a cut pipe collecting method. The anti-slag-adhering laser pipe cutting machine comprises a cutting machine body, a waste slag collecting mechanism, a bottom frame, a pipe conveying mechanism, a material falling buffer mechanism and a material receiving device. The cutting machine body is provided with a portal frame, a cutting head assembly, a front chuck and a rear chuck. The waste slag collecting mechanism is installed on the bottom frame and close to the front chuck. The waste slag collecting mechanism comprises along and thin slag receiving pipe and a telescopic driving mechanism, a slag receiving hole is formed in the side wall of the front portion of the slag receiving pipe, a protective layer is arranged in the slag receiving pipe, and the rear portion of the slag receiving pipe is connected with the telescopic driving mechanism. A material falling slope is arranged on the bottom frame, the material falling slope is located below the slag receiving pipe, the pipe conveying mechanism is located between the material falling slope and the material falling buffer mechanism, and the material falling buffer mechanism is located above the material receiving device. The problems that at present, waste slag splashes during pipe cutting, and machined pipes directly fall onto the bottom face or a materialcollecting trolley and are prone to being damaged are solved.

Owner:JINAN SENFENG TECH CO LTD

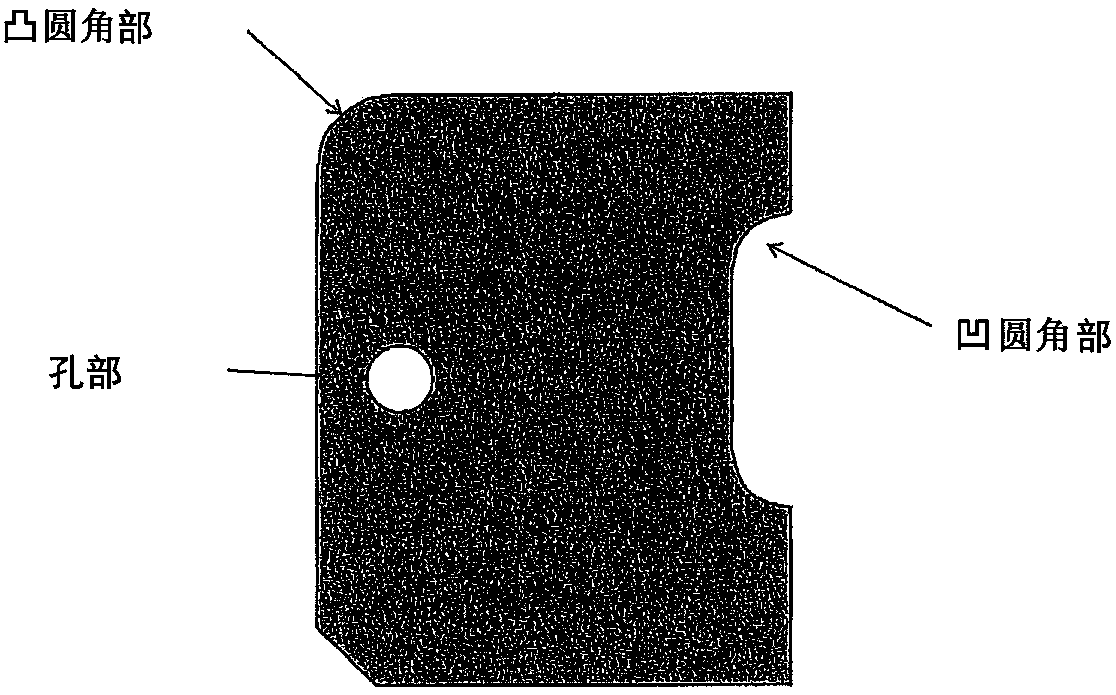

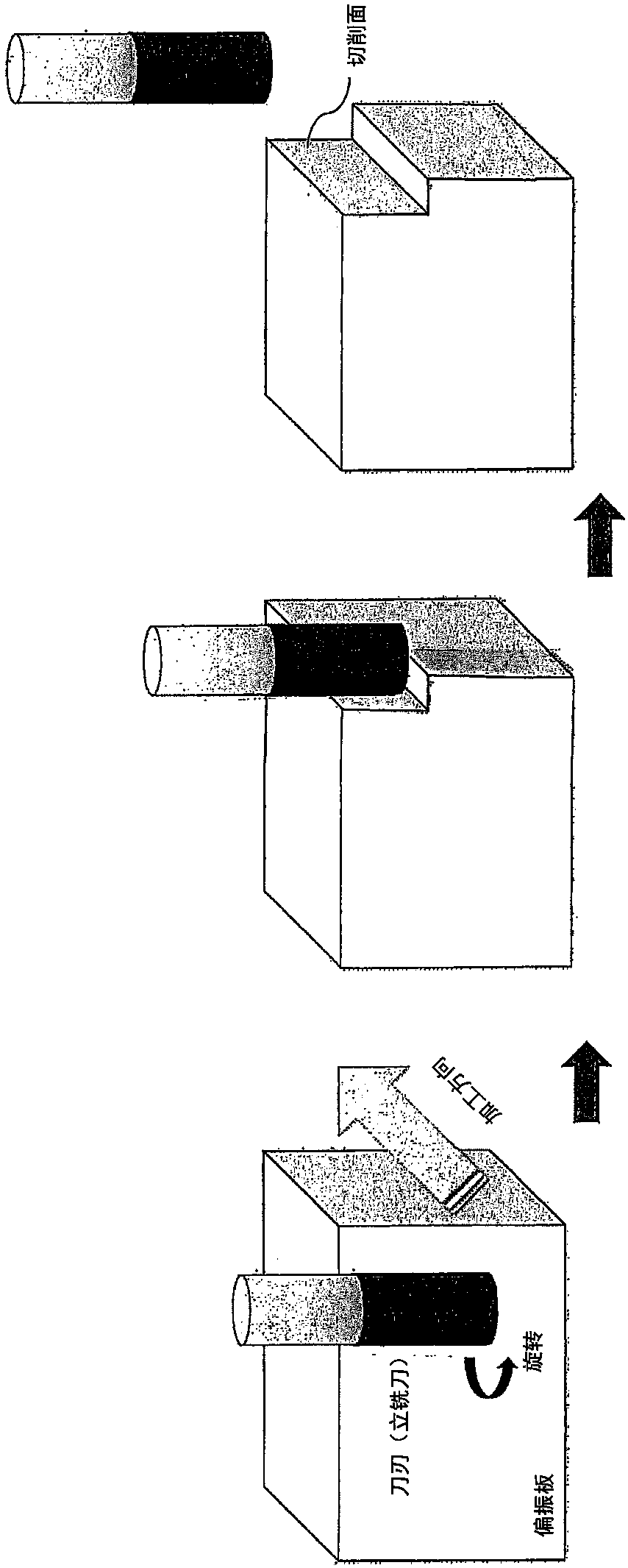

Method for manufacturing polarization plate and manufacturing device therefor

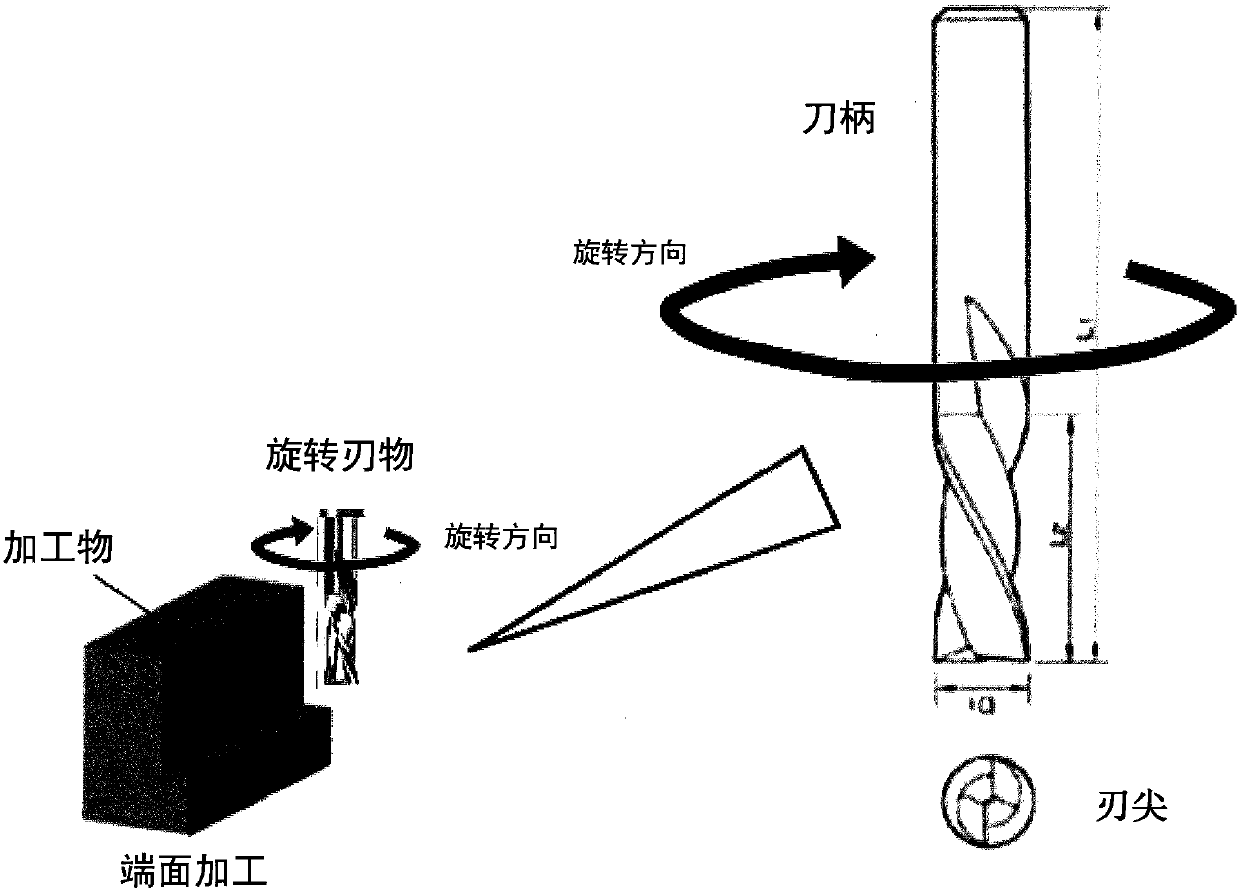

InactiveCN107921555ACrack suppressionSuppress bendMilling cuttersPolarising elementsEngineeringClockwise

The present invention pertains to providing: a method for manufacturing an irregularly shaped polarization plate having in particular a small-diameter recessed round part and / or hole part, wherein discoloration, or cracking or snapping, produced in the irregularly shaped polarization plate during machining, and the accumulation of scraping residue at the root section of a blade of an end mill, areinhibited; and a manufacturing device therefor. A method for manufacturing an irregularly shaped polarization plate having a recessed round part, wherein the method is characterized in including a step for forming the recessed round part using a cutting means in which a blade comes into contact from the lateral direction with a surface to be cut and performs cutting, the cutting means being an end mill, and the direction of rotation of the end mill being counterclockwise as viewed from the shank side if the blade of the end mill is a left hand cut right hand helix, and clockwise as viewed from the shank side if the blade of the end mill is a right hand cut left hand helix.

Owner:NITTO DENKO CORP

Method for preparing and modifying chloroprene rubber powder

The present invention relates to a processing and preparation method of high-performance chloroprene rubber powder by using the waste rubber products as the raw materials, the waste chloroprene rubber products are washed to be clean by using water, then the high-temperature disinfection and viruses and bacteria removal are carried out at 80 to 120 DEG C, the disinfected rubber products are placed in a rubber crusher to carry out the initial grinding to get the crude rubber powder; the crude rubber powder after the initial grinding is arranged in a water-isolating plastic bag and then is placed in an oven to carry out the heating and baking, after that, the rubber powder is taken out and cooled; the crude rubber powder after the cooling and the grafting and grinding agents are added in a ball mill to carry out the mixing grinding, so as to get the fine rubber powder; the fine rubber powder is arranged in a microwave generator to carry out the microwave modification, so as to get the modified rubber powder; the modified rubber powder and the surface treatment agent are stirred and mixed; the mixing rubber powder is placed in an ultrasonic generator to carry out the ultrasonic treatment, so as to get the final product of the rubber powder, and the prepared rubber powder has the advantages of small particle size, big surface area, wide usage, convenient use, energy conservation and so on.

Owner:QINGDAO UNIV OF SCI & TECH

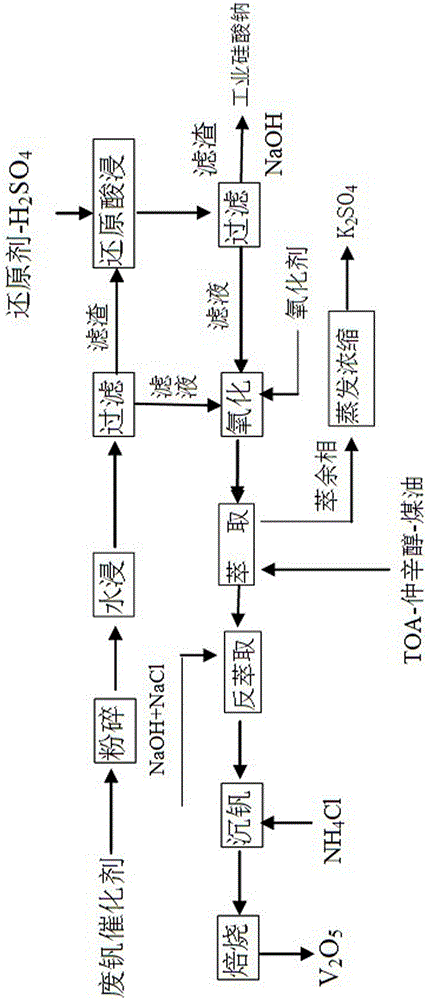

Recovery method of vanadium potassium silicon in waste vanadium catalyst

InactiveCN103789550BGood choiceLarge distribution ratioMetal recyclingAlkali metal silicatesSlagMetal impurities

The invention discloses a method for recovering vanadium, potassium and silicon from a waste vanadium catalyst. The method comprises the following steps: firstly, leaching the waste vanadium catalyst in water, and leaching in a reductic acid, wherein the total leaching rate of vanadium is greater than or equal to 95.0%, separating the silicon from vanadium and potassium transferred to a leaching solution in a form of a leaching slag; preparing liquid sodium silicate to recover silicon from the leaching slag by alkali dissolution; separating the vanadium from potassium in the leaching solution in an extraction manner; preparing potassium sulphate to recover potassium from a raffinate phase in an evaporative crystallization manner; and preparing vanadium pentoxide from an extract phase by the procedures of re-extraction, molybdenum precipitation, calcination and the like. Meanwhile, the vanadium in the extract phase and the raffinate phase is larger in distribution ratio, and does not react with other metal impurities such as iron and the like due to excellent selectivity of an extraction agent TOA on vanadium, other metal impurity ions such as iron and the like do not need to be removed in advance, and the vanadium can be directly extracted. Thus, a part of edulcoration procedures are reduced, the raw material consumption is saved, and a high-purity product of vanadium can be directly prepared. By adopting the method disclosed by the invention, not only can the vanadium, potassium and silicon in the waste vanadium catalyst be comprehensively recovered, but also the targets of turning the waste into treasure and protecting the environment are achieved.

Owner:KAIFENG UNIV

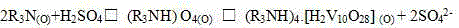

High efficiency purification method of ammonium tungstate solution with high Mo content by using special resin

InactiveCN105967238AReduce cleaning processSimple processTungsten compounds preparationPurification methodsTungstate

The invention belongs to the field of metallurgy of rare metals, and concretely relates to a high efficiency purification method of an ammonium tungstate solution with high Mo content by using special resin. The invention discloses the high efficiency purification method of the ammonium tungstate solution with high Mo content by using special resin, and disadvantages of low efficiency in the production method of 0 grade APT, complex processes, and high cost. The method comprises the following steps: a. the solution is sulfurated and permitted to stand; b. simulated exchange adsorption and exchange adsorption are prepared; c. desorption and transition are carried out; d. evaporation-crystallization-drying are carried out. The special resin WDA918 is used for high efficiency purification of the ammonium tungstate solution with high Mo content, and the link for removing impurities by copper salts is reduced; compared with the classic purification method of the ammonium tungstate solution with high Mo content including combination of selective precipitation and ion exchange, the links for removing Mo, P, As, Si and other impurities by adding copper sulphate or copper sulphide or copper oxide; the technology is simplified, production cost is reduced, and the recovery rate of WO3 is improved.

Owner:XINYANG HUARUI MOLYBRENUM NEW MATERIALS CO LTD

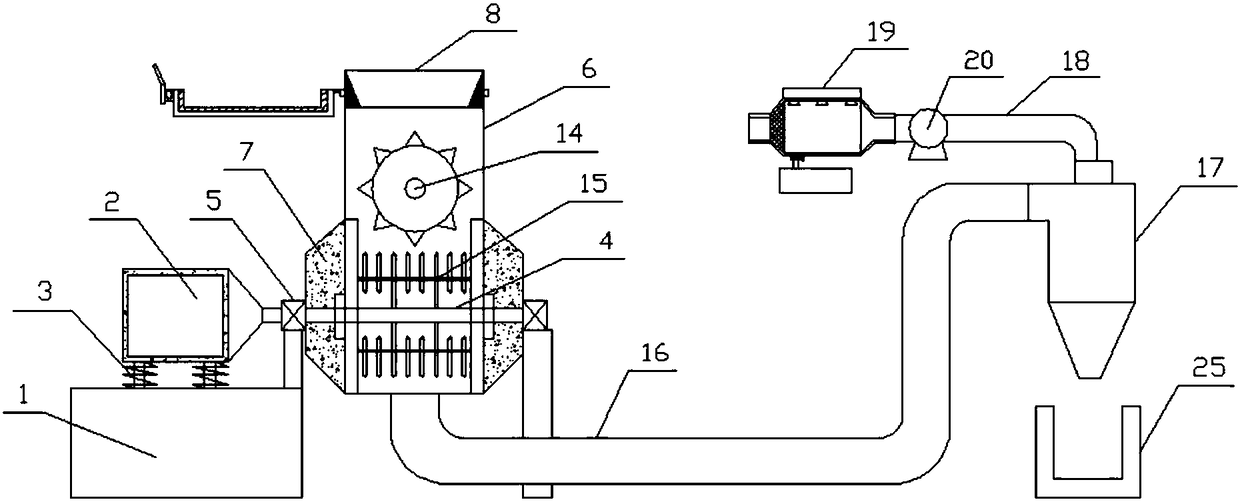

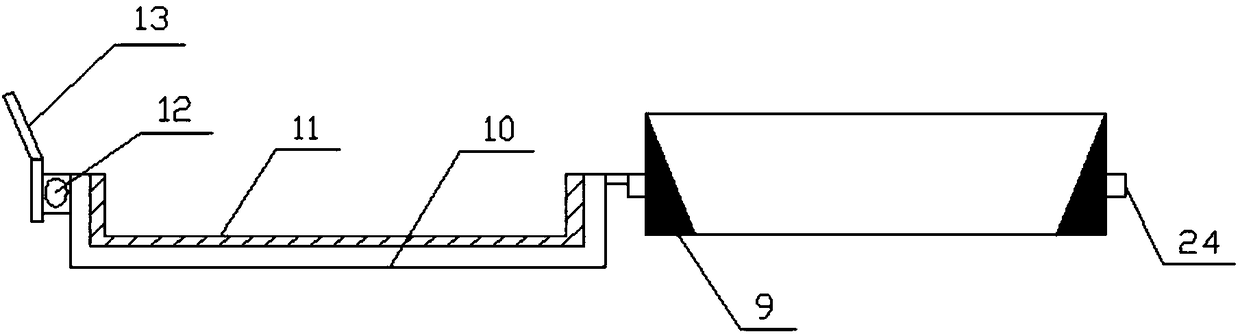

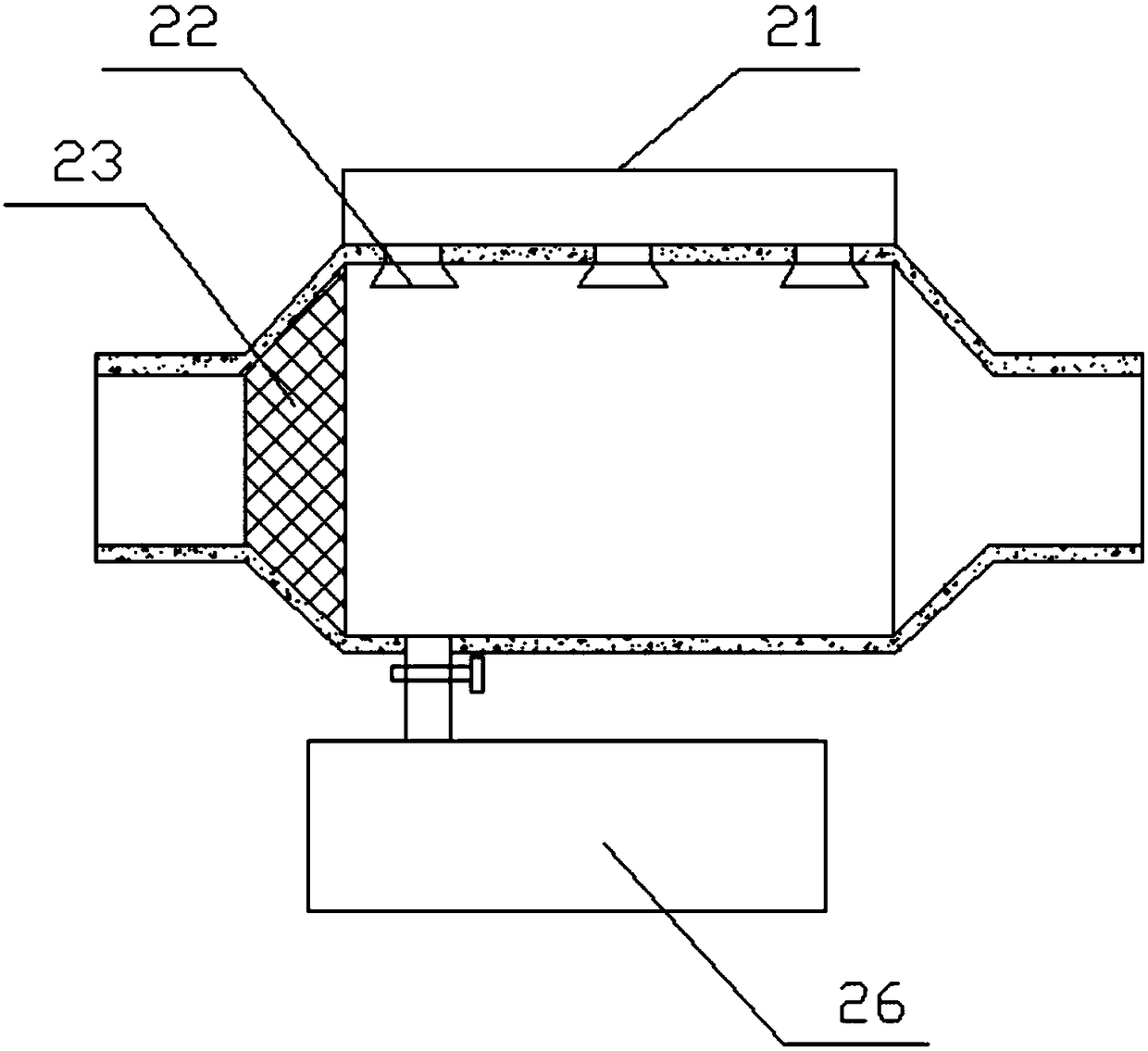

Dust control and noise reduction type feed crushing device

InactiveCN108355791AAvoid enteringReduce vibrationFeeding-stuffUsing liquid separation agentDust controlEngineering

The invention discloses a dust control and noise reduction type feed crushing device. The feed crushing device comprises a machine frame; an engine is arranged on the upper surface of the left side ofthe machine frame; damping devices are arranged at the bottom of the engine; a rotating shaft is arranged at the right end of the engine; bearings are arranged at the left end and the right end of the rotating shaft; sealing boxes are arranged between a feed crushing box and the bearings; magnetic strips are arranged at the left end and the right end of the inner wall of a feed port; an opening and closing bolt is arranged at the left end of a box cover; a coarse crushing wheel is arranged at the upper end of the inner wall of the feed crushing box; hammer carrier plates are arranged at the upper end and the lower end of the rotating shaft in the feed crushing box; the bottom of the feed crushing box communicates with a discharging device through a first pipeline; the discharging device communicates with a dust removal box through a second pipeline; a water tank is arranged on the upper surface of the dust removal box; spray heads are arranged at the top end of the inner wall of the dust removal box; and a filter screen is arranged at the left end of the inner wall of the dust removal box. The feed crushing device relates to the technical field of feed crushing. The dust control and noise reduction type feed crushing device has the advantages that the purposes of dust control and noise reduction and good crushing effect can be achieved, and dust pollution and noise pollution can be reduced.

Owner:佛山杰致信息科技有限公司

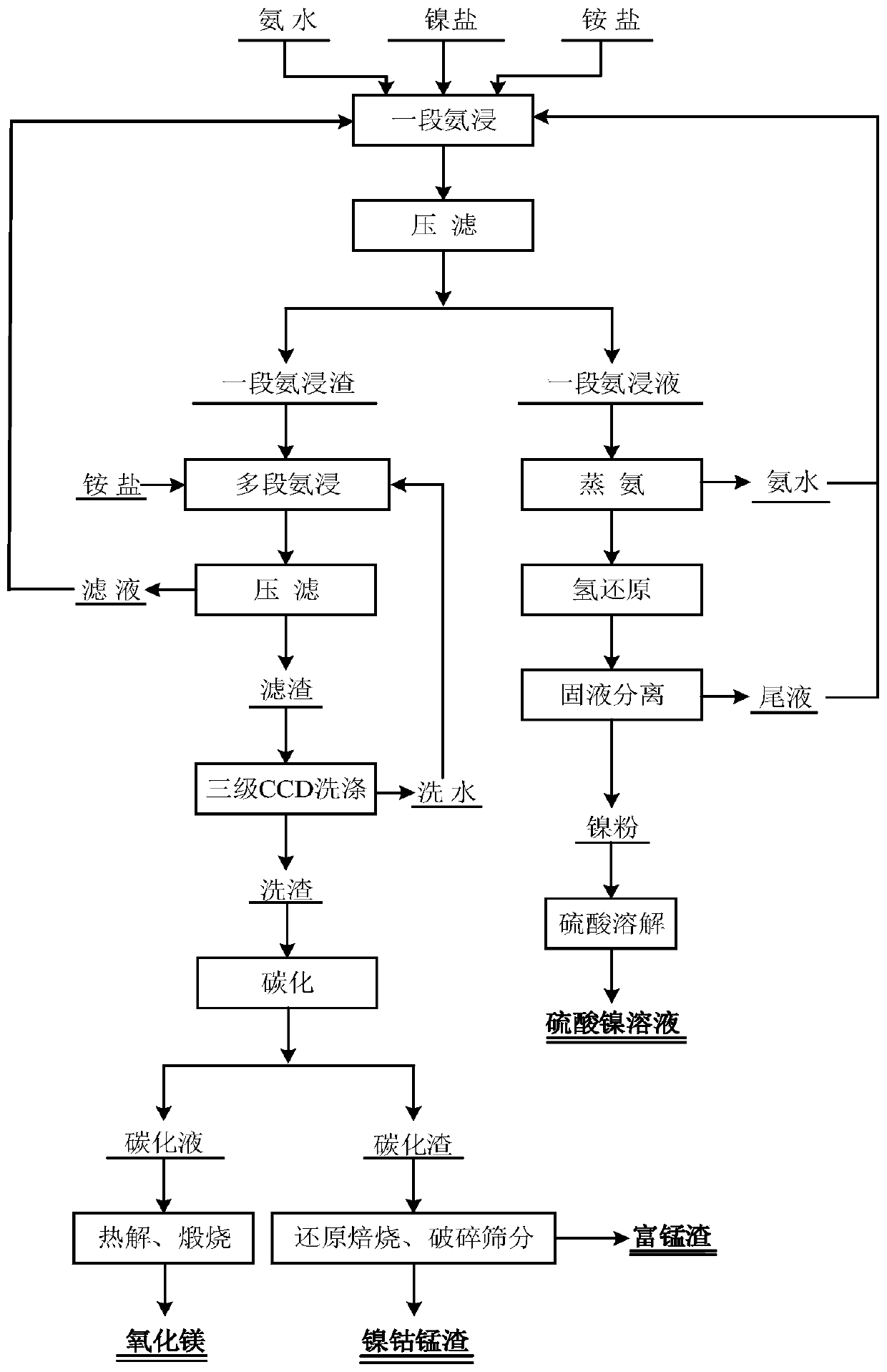

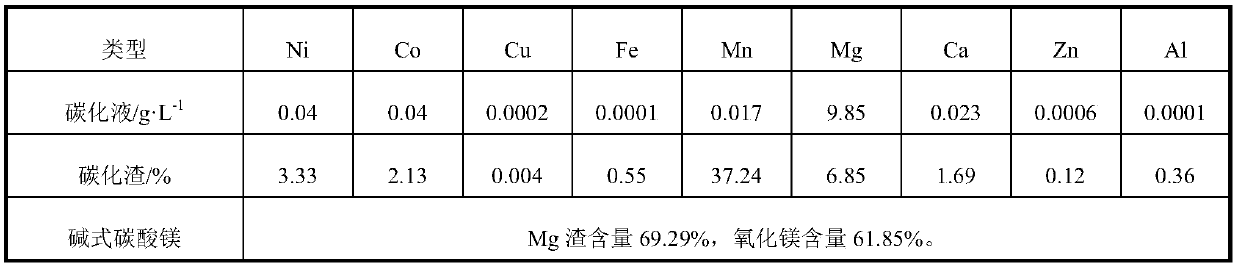

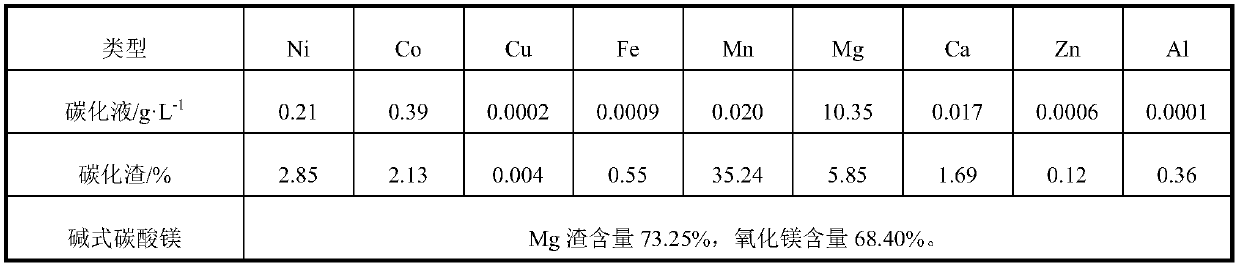

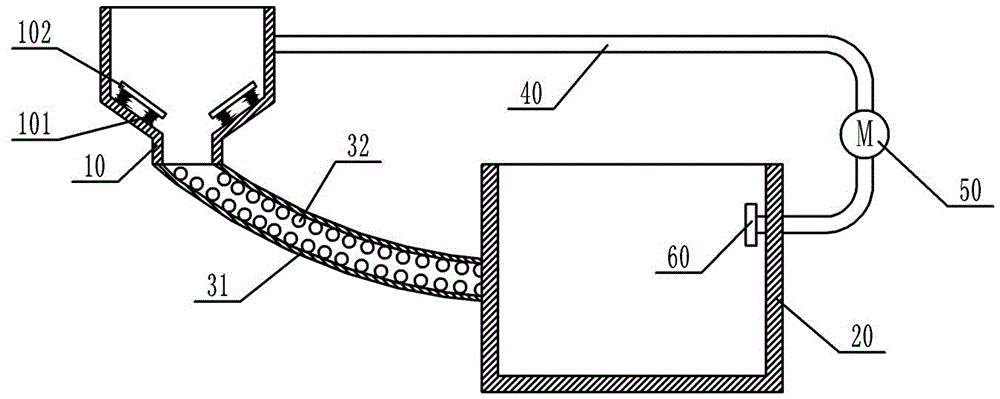

Green method for preparing battery grade nickel sulfate from nickel salt

PendingCN111057847AReduce cleaning processReduce environmental burdenNickel sulfatesProcess efficiency improvementNickel saltElectrical battery

The invention discloses a green method for preparing battery grade nickel sulfate from nickel salt. The green method for preparing battery grade nickel sulfate from the nickel salt comprises the stepsthat the nickel salt and ammonium salt are mixed, ammonia water is added, ammonia leaching reaction is carried out, a first-stage ammonia leaching solution and first-stage ammonia leaching residues are obtained through solid-liquid separation, the first-stage ammonia leaching solution is subjected to ammonia distillation, the pH of the solution obtained after ammonia distillation is adjusted, then nickel powder is prepared through adopting a pressurized hydrogen reduction method; filtrate obtained by carrying out multi-stage ammonia leaching reaction and solid-liquid separation on the first-stage ammonia leaching residues returns to first-stage ammonia leaching slurrying, filter residues is washed by using a three-stage CCD, then a carbonization process is adopted, CO2 partial pressure, reaction time and reaction temperature are controlled, a carbonized liquid and carbonized residues are obtained, and pyrolysis and calcination on the carbonized liquid are carried out, then a magnesiumoxide product is obtained; and the carbide residues are subjected to reduction smelting through a pyrogenic process, and upper-layer rich-manganous slags and lower-layer nickel-cobalt-manganese slagsare obtained after crushing and screening. According to the green method for preparing battery grade nickel sulfate from the nickel salt, the method is easy to control, green and energy-saving, the ammonia water and the ammonium salt in the system can be recycled, a new process for preparing battery grade nickel sulfate without wastewater, waste residues and extraction is realized, and the production cost is greatly reduced.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Egg quality detector

The invention belongs to the field of preparation or processing of food or food materials, and specifically discloses an egg quality detector. The detector comprises a brine tank used for storing brine, a feeding channel, an egg collection box and a liquid supplement pipe. The brine tank is funnel-shaped, and the concentration of the brine is 5%-10%. The feeding channel is connected between the brine tank and the egg collection box. The feeding channel is internally provided with multiple cleaning units, and brush rollers which are oppositely arranged serve as the cleaning units. A water inlet pipe is connected between the brine tank and the egg collection box, and a water pump is arranged on the water inlet pipe. According to the invention, eggs are screened based on a principle that high-quality eggs and inferior eggs have different concentrations. Compared with a conventional manual screening method, the detector has advantages that the eggs can be screened in batch, and the egg screening efficiency is greatly improved.

Owner:CHONGQING CHANGSHOU DISTRICT BIAOGAN CHICKEN RAISING COOP

Manufacture by Dimashg process

InactiveCN1855419AThere are few types of useShorten back etchSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusL&D processMono layer

The method uses the intercombination of double layer light sensitiveness material and single layer light sensitiveness material, and employs multiple steps process to manufacture through-hole and metal wire slot, and uses Damascus Process to make integrated circuit. The Damascus Process is a new wiring technology having problem of filling through hole. The invention uses a new process that is: first completing the filling of through hole; then after plasma processing, using the double layer light sensitiveness material to form an oxidizing coating to overlap the through hole; and later, making deposition and fabricating metal wire slot so as to achieve fabrication process.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

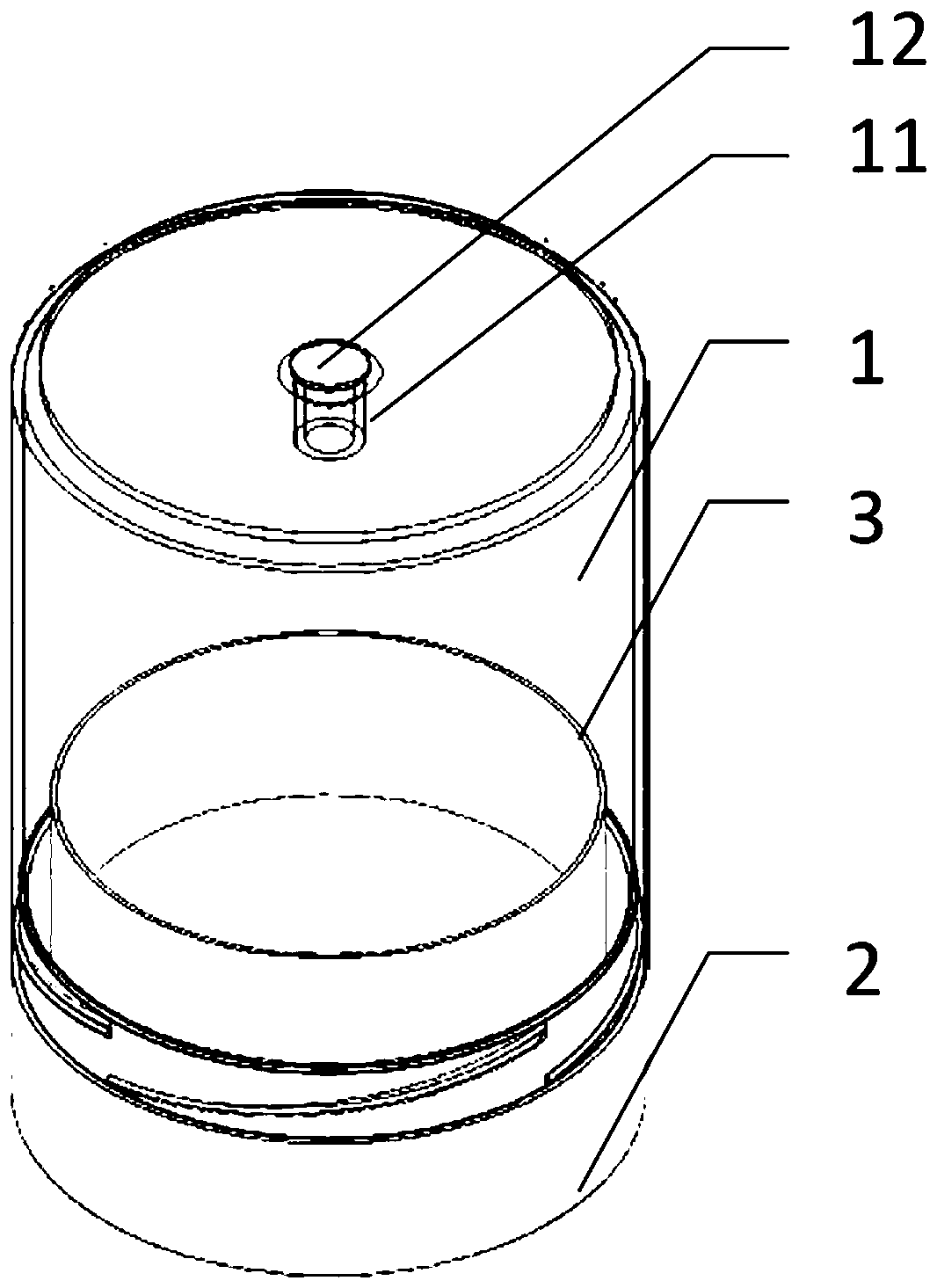

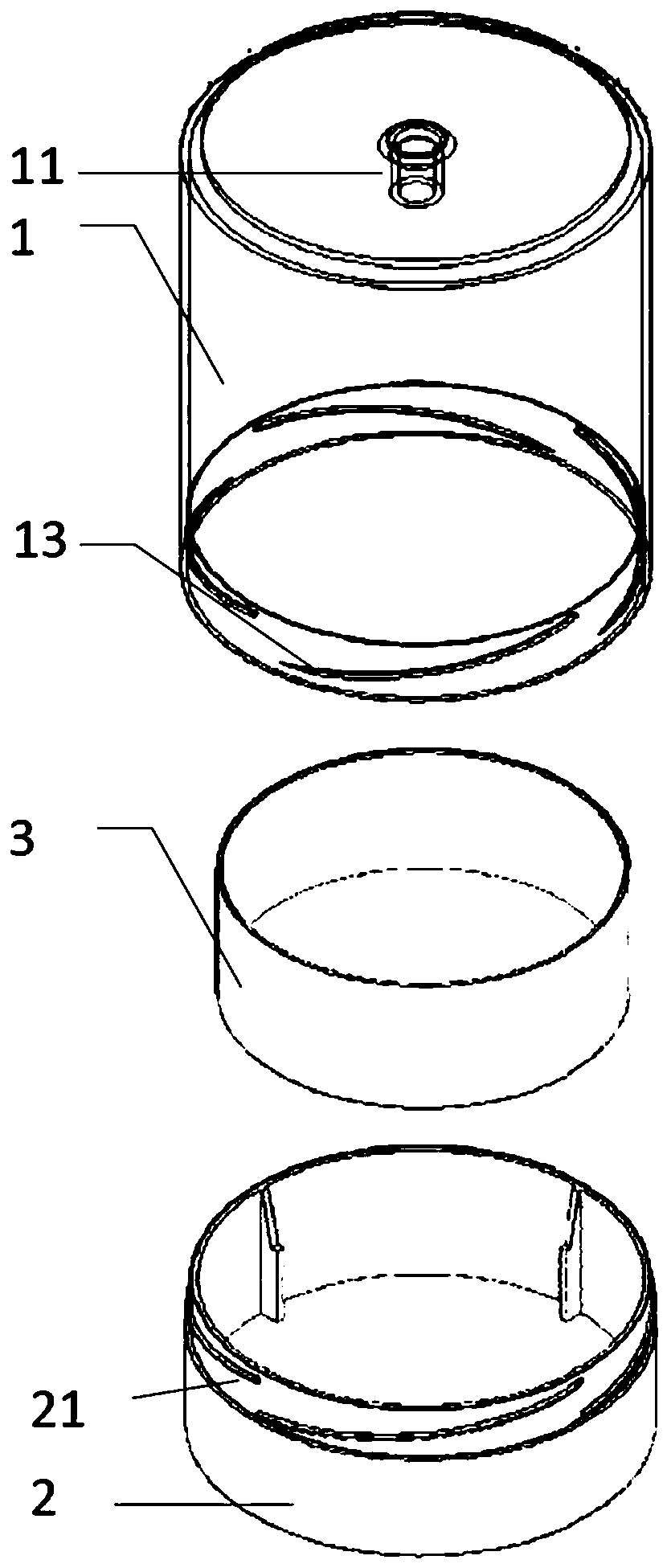

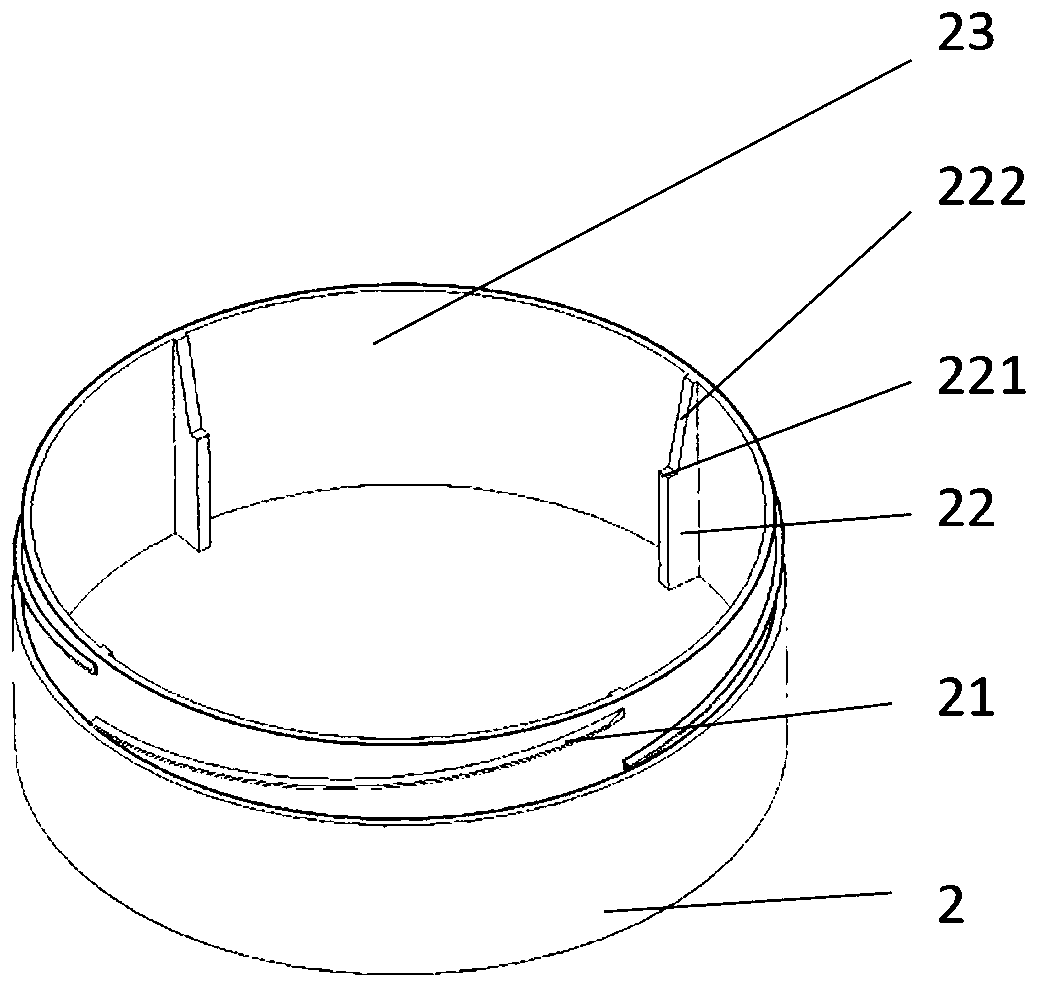

Tissue culture bottle and tissue culture operation method

PendingCN108040878AEasy to operateReduced sterilization and cleaning processesHorticulture methodsPlant tissue cultureBiologyPlant tissue culture

The invention relates to the technical field of plant tissue culture, and discloses a tissue culture bottle. The tissue culture bottle comprises a bottle body and a bottle bottom. The bottle body is detachably and hermetically connected with the bottle bottom. An opening is formed in the upper side of the bottle body, and is provided with an air-permeable film. The bottle body is larger than the bottle bottom in height. The invention further discloses a tissue culture operation method by the tissue culture bottle. According to the method, inoculation and plant collection are completed directlyin the bottle bottom or a culture dish. The plant tissue culture and the tissue culture operation method have the advantages that the tissue culture bottle is simple and reasonable in structure and convenient to operate and apply, labor intensity, production cost and pollution are reduced, efficiency of factory-like tissue culture is improved greatly, completeness and survival rate of seedlings are increased, and gains are also increased.

Owner:上海曼森生物科技有限公司

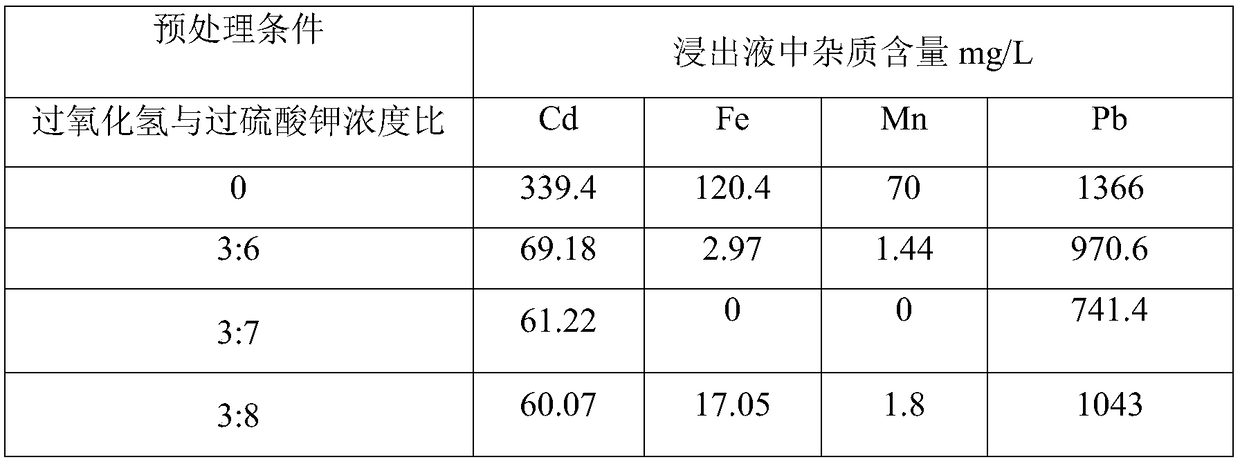

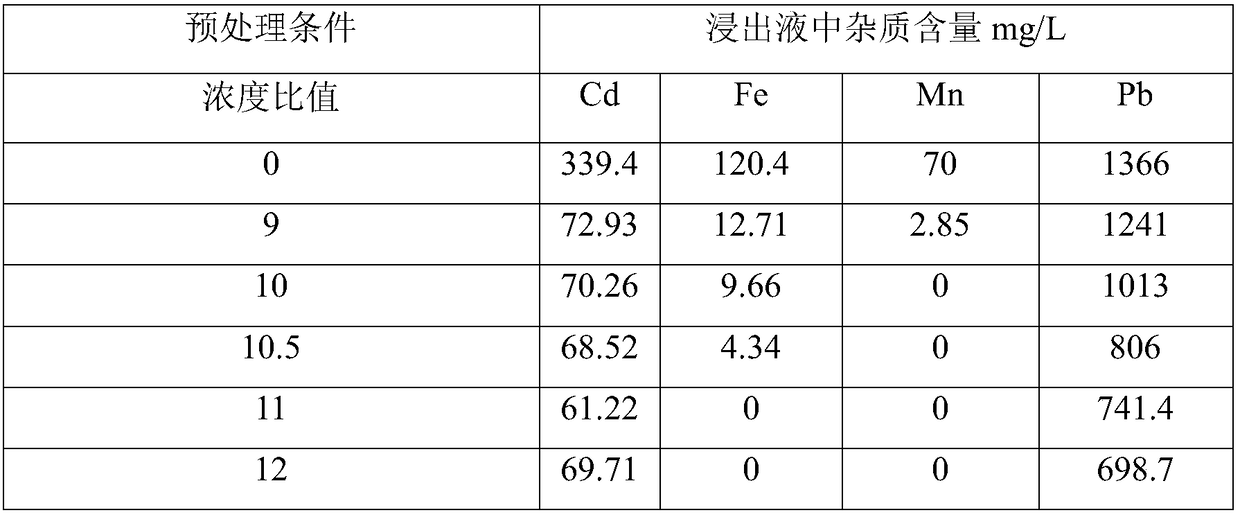

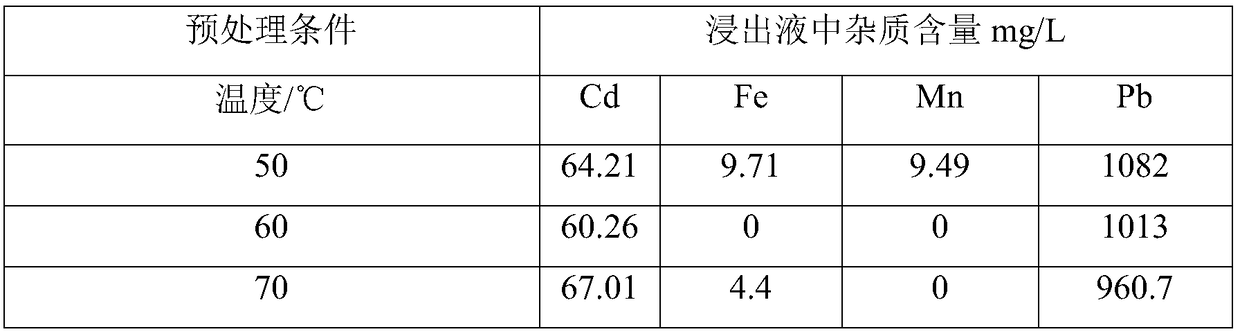

Method for oxidization pretreatment of zinc-containing secondary materials

ActiveCN108754179AStrong oxidation abilityImprove oxidation capacityProcess efficiency improvementPersulfatePhysical chemistry

The invention discloses a method for oxidization pretreatment of zinc-containing secondary materials. The method comprises the following steps of before impregnating the zinc-containing secondary material by ammonia, adding at least two types of oxidants into the zinc-containing secondary material to perform oxidation pretreatment reaction; after reaction is finished, filtering, so as to obtain the pretreated zinc-containing secondary material, wherein at least two oxidants comprise hydrogen peroxide and persulfate. The method has the advantages that the impurity element removal effect is good, the other impurity ions are not introduced, the zinc loss is less, and the subsequent purifying steps are greatly simplified; the problems of poor removal effect, easiness in introducing of impurityions, and complicated subsequent purifying technology in the existing wet type impurity element removal method of the zinc-containing secondary materials are solved.

Owner:CENT SOUTH UNIV

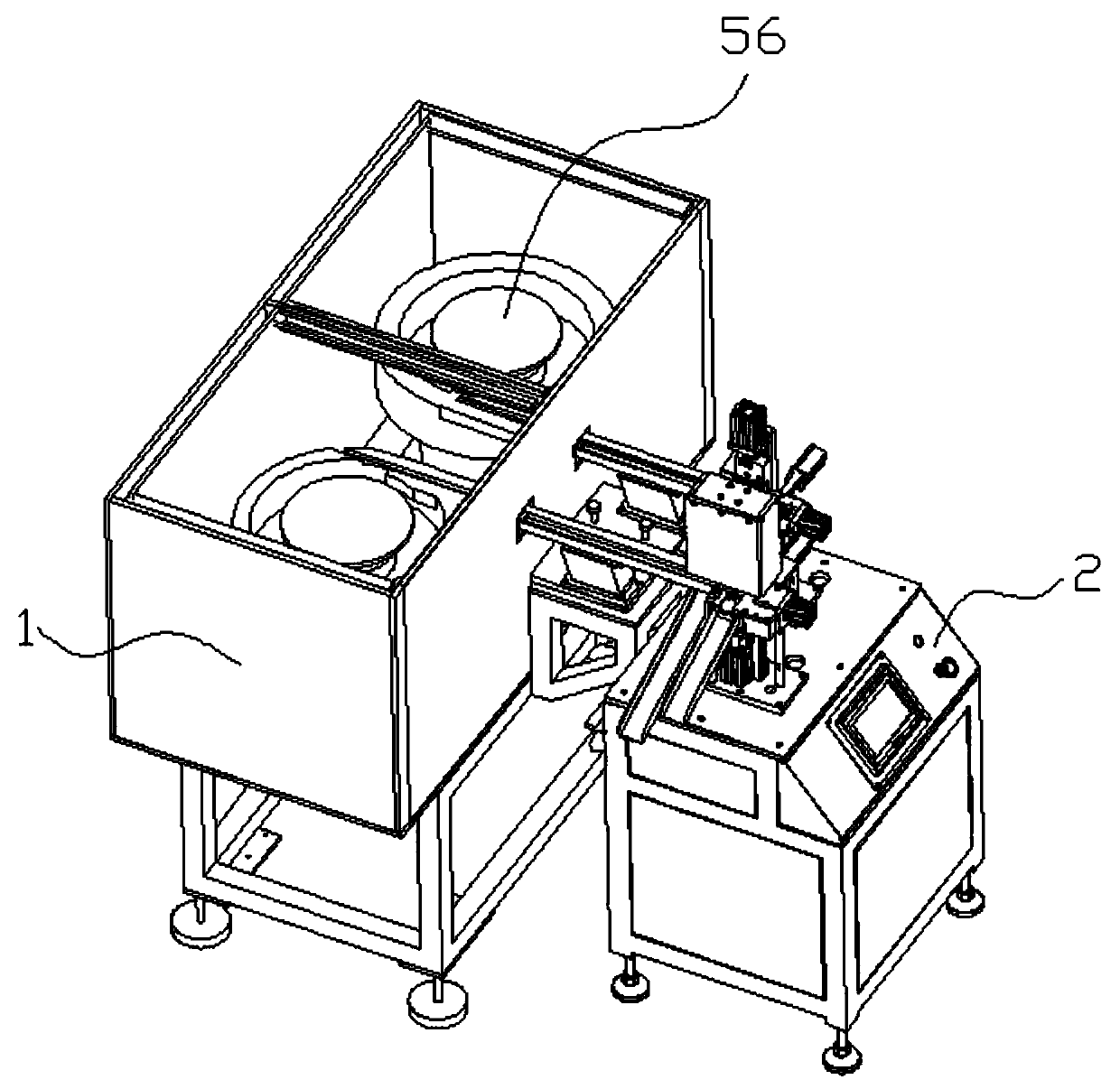

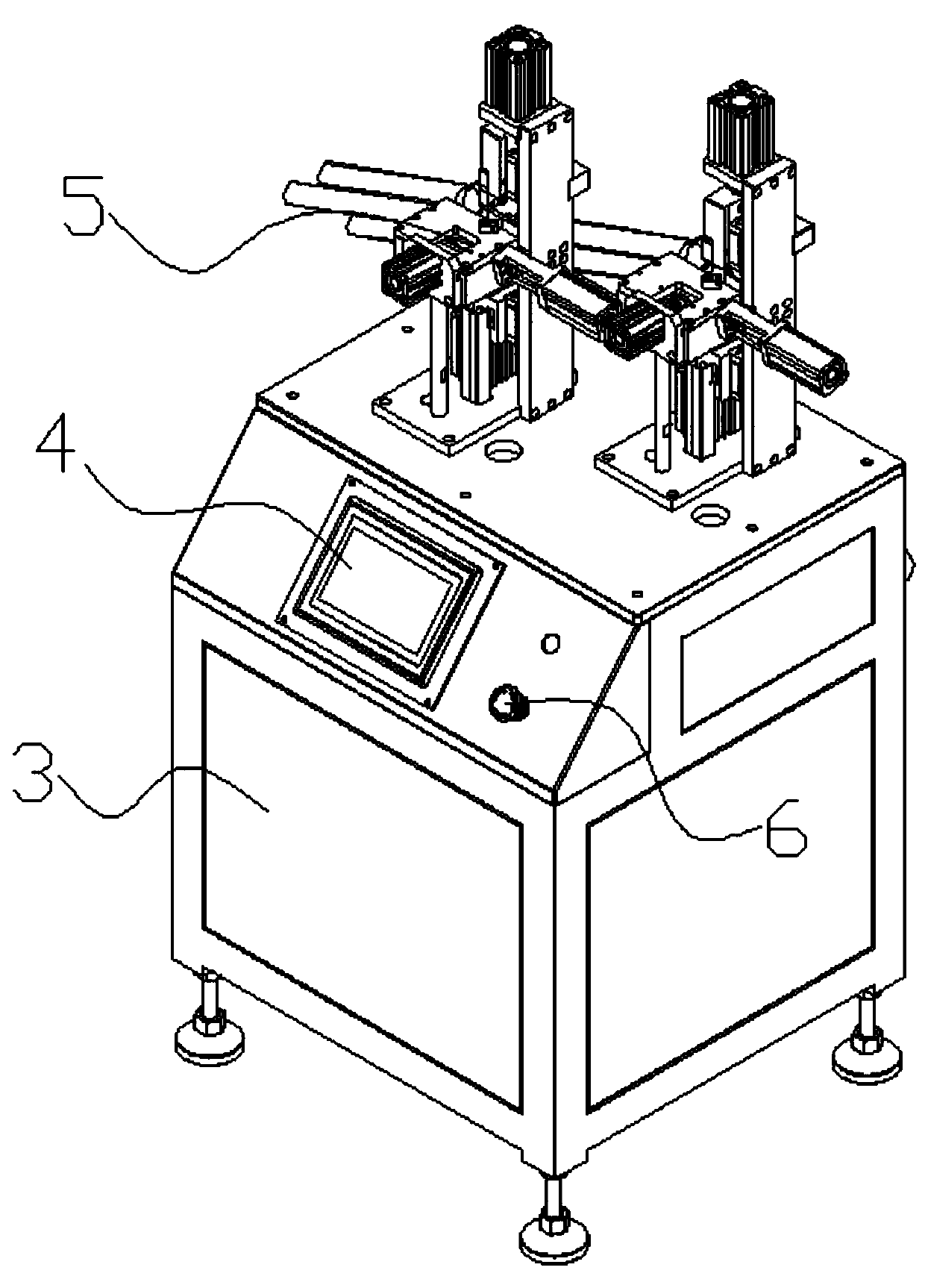

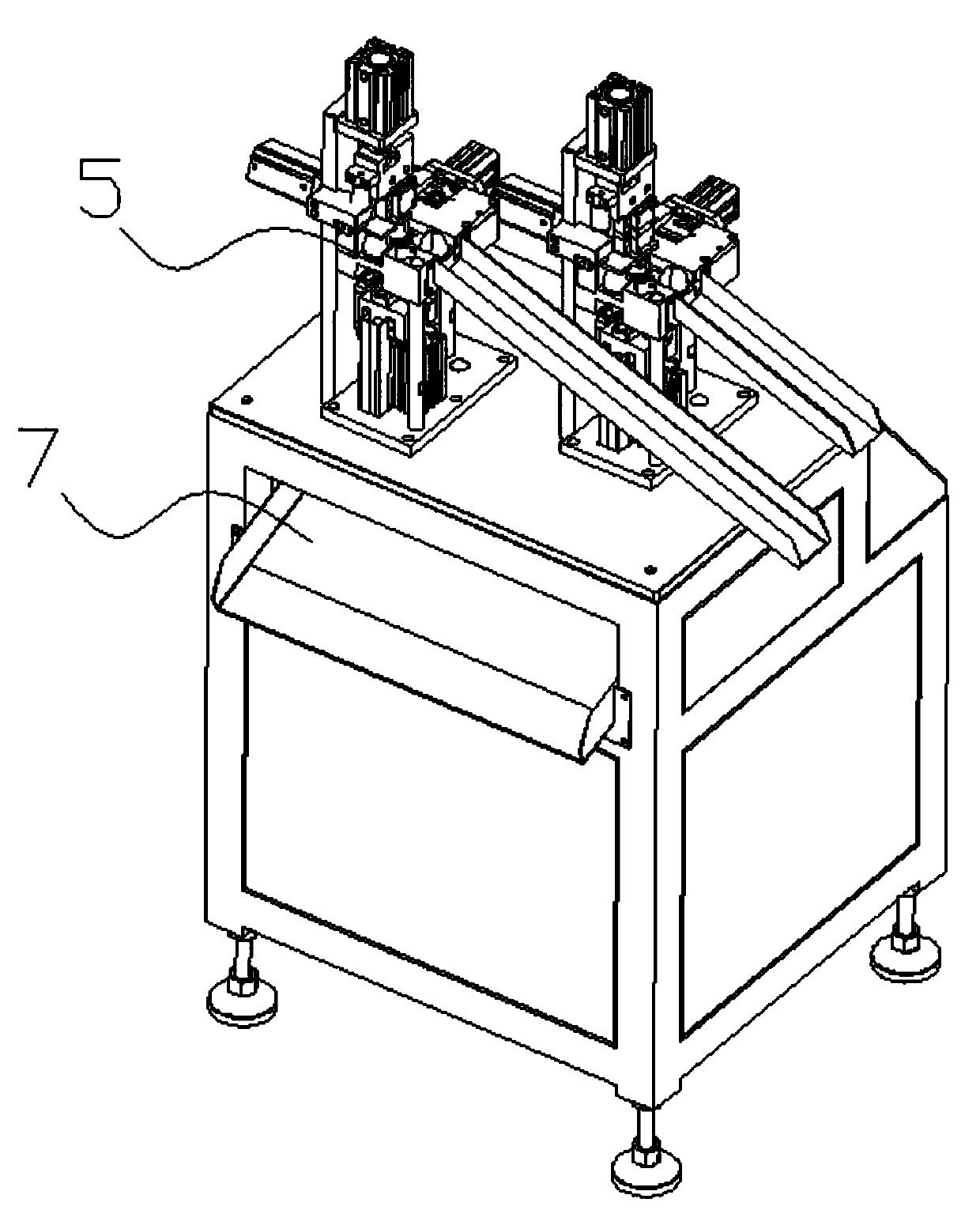

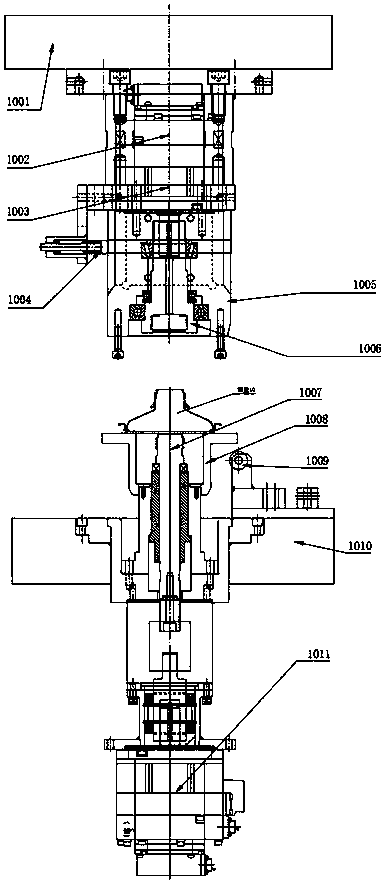

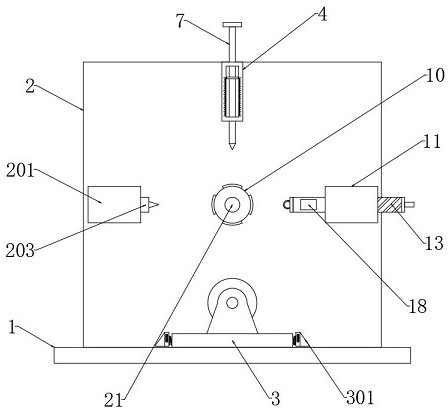

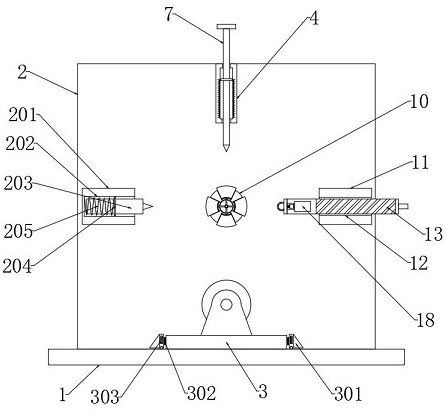

Tapping machine for toy rubber shell

InactiveCN107803875AAchieve positioningAvoid stickingMetal working apparatusEngineeringDischarge pressure

The invention relates to a toy rubber shell drilling machine, which includes a feeding mechanism and a hole-opening mechanism, the hole-opening mechanism includes a hole-opening frame, and a hole-opening device is fixedly installed on the hole-opening frame, and the hole-opening device includes The loading device fixed on the perforated frame, the upper part of the loading device is correspondingly provided with a pushing device docked with the feeding mechanism, and the upper part of the pushing device is correspondingly provided with a down-pressing device, which includes a down-pressing cylinder. The lower end of the cylinder is connected to the down-pressing adapter plate through the push rod, and the down-pressing adapter plate is fixedly connected with the down-pressing head; The matching unloading pressure plate realizes the positioning of the material by the unloading platen when the lower pressure head is pressed down, and will not cause damage to the material under the buffering effect of the spring. Under the action, it reacts on the material to prevent the material from sticking to the perforated needle. The structure is simple and the applicability is strong.

Owner:DONGGUAN UNIV OF TECH

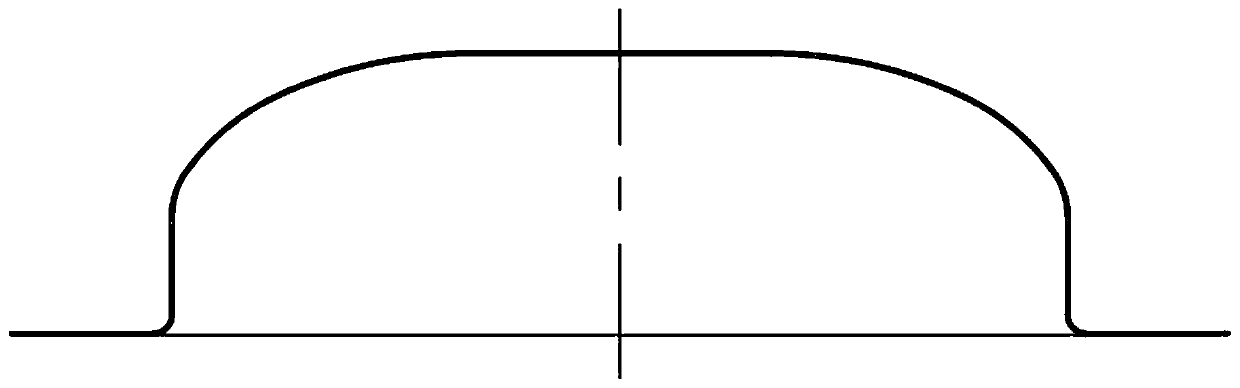

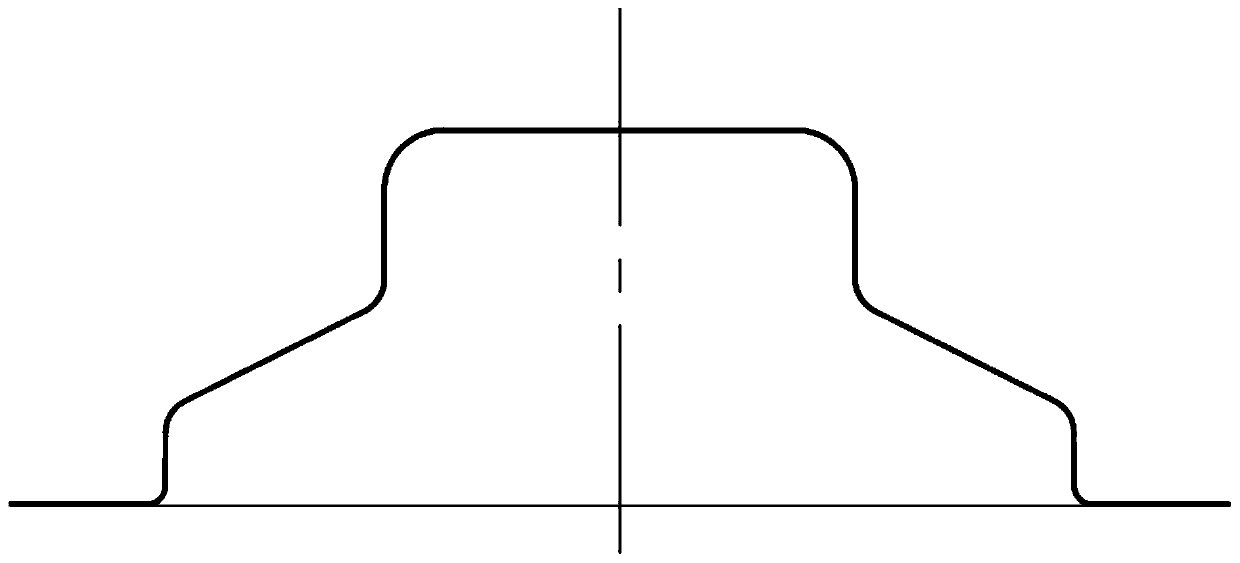

Molding process of beer can screw cap

ActiveCN110576116AEmission reductionProduction process is environmentally friendlyShaping toolsClosure capsPunchingEngineering

The invention aims to provide a molding process of a beer can screw cap. In the process, a laminated film is used as a raw material, and according to the characteristics of the material, through a lotof experiments, a production process for preparing the beer can screw cap from the laminated film as the raw material can be obtained. The molding process adopting the technical scheme comprises thefollowing steps of 1, stretching a sheared blank into a beer can screw cap blank; 2, stretching the beer can screw cap blank for multiple times to form a semi-finished product; 3, trimming the semi-finished product and punching; 4, preliminarily curling the edge contour of the bottom of the semi-finished product and the circumferential edge of a punched hole; and 5, curling the edge contour of thebottom of the semi-finished product and the circumferential edge of the punched hole; and 6, flattening the curled parts, and tapping the surfaces, thereby obtaining the beer can screw cap.

Owner:广东韩江轻工机械有限公司

Method for preparing isooctyl thioglycolate by utilizing thionocarbamate tail liquid

The invention discloses a method for producing isooctyl mercaptoacetate by utilizing thiourethane tail liquid, which is characterized in that it includes the process steps of impurity removal acidification, Zn powder decolorization, extraction, rough distillation and rectification, and the impurity removal acid compound is First, the use of benzene-based high-efficiency extractant instead of ether reduces the risk and pollution, and simplifies the operation steps. At the same time, the benzene-type high-efficiency extractant can be recycled, which is easy to operate, and the zinc powder decolorization process is added to ensure the stability of product quality. During the crude distillation process, the esterification reaction is completed at the same time, and a qualified crude ester semi-product is obtained at one time, which reduces the operation steps and improves the efficiency. Produced, increased production capacity and product yield, and reduced costs.

Owner:YANTAI HUMON CHEM AUX CO LTD

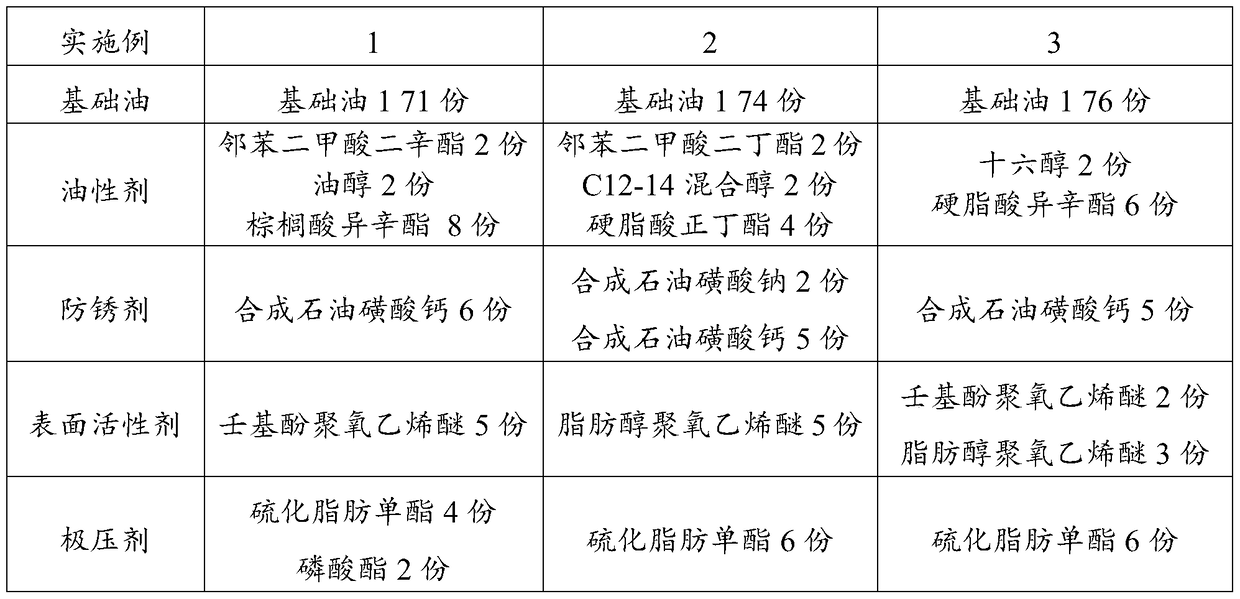

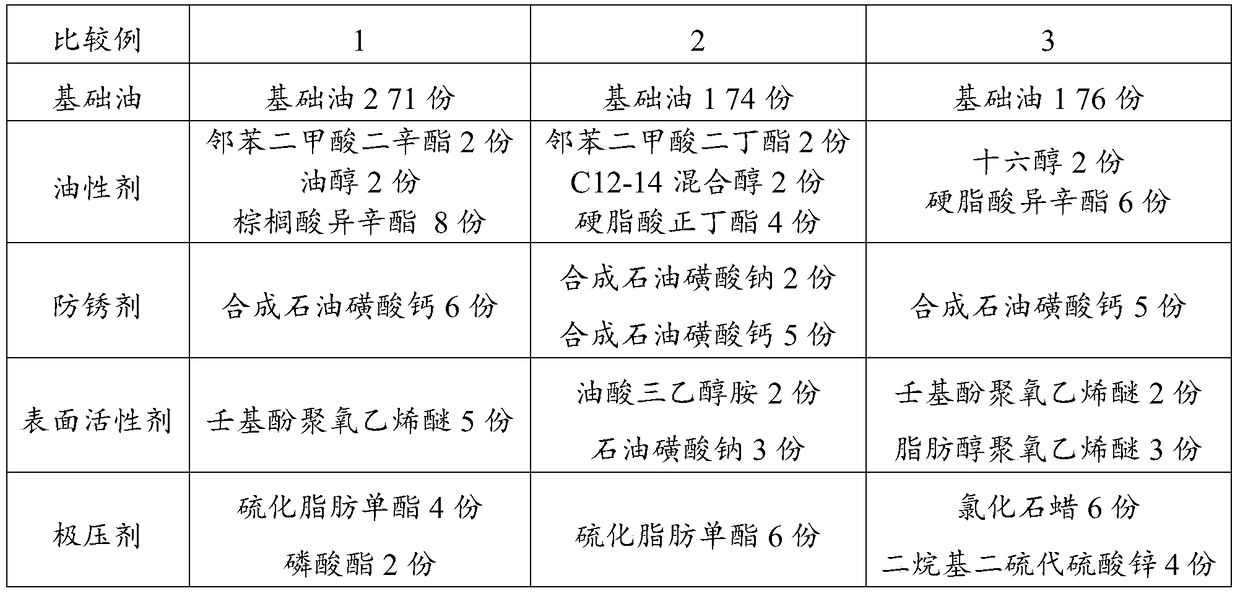

Stamping oil composition and use thereof

ActiveCN105296085BEasy to cleanReduce cleaning processLubricant compositionMining engineeringActive agent

The invention relates to a stamping oil composition and application thereof. The stamping oil composition mainly solves the problems that in the prior art, oil cleaning performance is poor, dirty marks, anti-rust oil and the like on the surface of a work-piece can not be cleaned, and as a result, before stamping is carried out, pretreatment must be carried out on the work-piece. The stamping oil composition is prepared from, by weight, 60-85 parts of refined mineral oil, 5-25 parts of oiliness agent, 0.5-10 parts of antirust agent, 2-10 parts of surfactant and 2-10 parts of extreme pressure agent. According to the technical scheme, the problems are solved, and the stamping oil composition can be used in industrial production of carbon steel plate stamping oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing triethyl citrate through using nanometer intercalated hydrotalcite catalyst

InactiveCN105399630AEfficient productionThe preparation method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrotalciteEsterification reaction

The invention discloses a method for preparing triethyl citrate through using a nanometer intercalated hydrotalcite catalyst. The method comprises the following steps: 1, charging: adding the nanometer intercalated hydrotalcite catalyst, citric acid and excess ethanol to a container, and stirring the added materials until uniformity; 2, carrying out an esterification reaction: carrying out oil bath heating, continuously adding ethanol in the heating process until ethanol is excess, and carrying out condensation refluxing and evaporated ethanol collection, wherein the esterification reaction is carried out for 16-20h; and 3, purifying: filtering out the nanometer intercalated hydrotalcite catalyst after the esterification reaction ends, dealcoholizing, neutralizing the dealcoholized material, washing the neutralized material with water, decolorizing the washed material, and purifying the decolorized material to obtain the finished triethyl citrate. The method for preparing triethyl citrate by using the nanometer intercalated hydrotalcite catalyst allows the citric acid conversion rate to be not lower than 99%, the product prepared in the invention is highly pure, the whole catalysis reaction is easy to operate, the temperature is easy to control, and the catalyst can be repeatedly used after being filtered.

Owner:JIANGSU RUIJIA CHEM

Environmental device for cleaning viscous garbages

InactiveCN109914310AReduce cleaning processImprove sanitation work efficiencyRoad cleaningElectric driveElectricity

The invention belongs to the field of environmental protection and cleaning, especially relates to an environmental protection device for cleaning viscous garbages. The device comprises a housing, a electric drive module, a strip swing plate and a collection box, wherein a dial plate and locking plate interconnecting with each other are concentrically installed on the inner wall of the housing through a transmission shaft A, and the transmission shaft A is bearing fit with the shaft hole on the side wall of the housing; a shovel plate in the invention carries out the preliminary elimination ofthe viscous garbage on the ground, and a shovel block further eliminates the viscous garbages or stubborn viscous garbages which are not eliminated by the shovel plate on the ground; the viscous garbages that are scooped up from the ground stick to the shovel plate or the shovel block, and through the interaction between the teeth and wedge scraping blades on a U-shaped swing plate and the shovelplate or the shovel block, the viscous garbages that stick to the shovel plate or the shovel block are cut off and fall into the collection box below.

Owner:苏州知遇光电科技有限公司

Method for recovering lithium from lithium-containing waste liquid

The invention discloses a method for recovering lithium from lithium-containing waste liquid. The method includes the steps of distillation, impurity removal, evaporation, absolute ethyl alcohol dissolution and spray drying. Through treatment with the process steps, the lithium in the lithium-containing waste liquid can be recovered in the form of lithium chloride. According to the method, the impurity removal process is simple and practical, no new impurities are introduced, the step of repeatedly removing impurities is avoided, the number of process procedures is reduced, and cost is saved.

Owner:TIANQI LITHIUM CORP

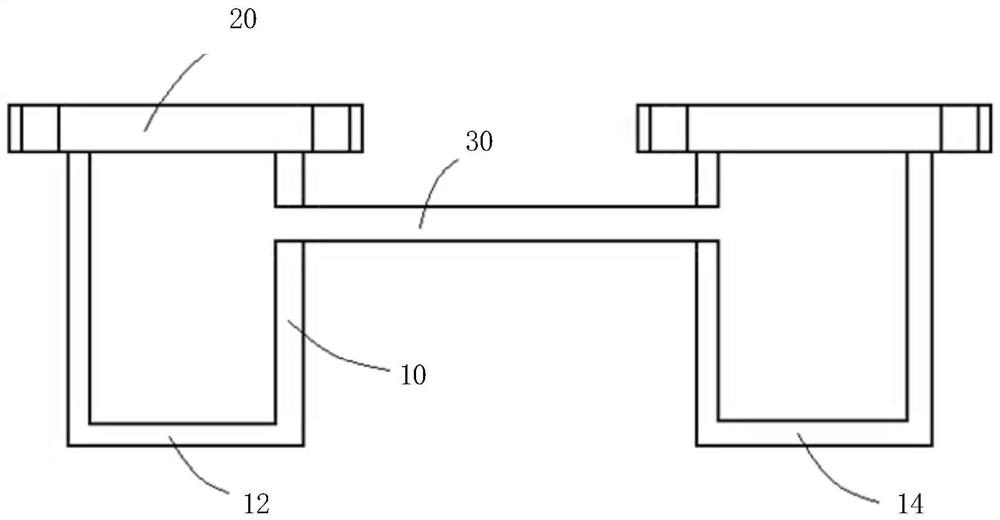

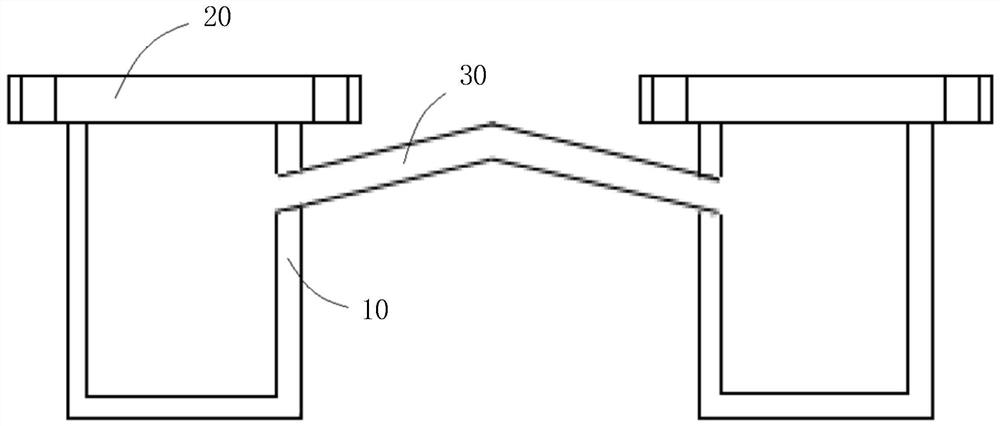

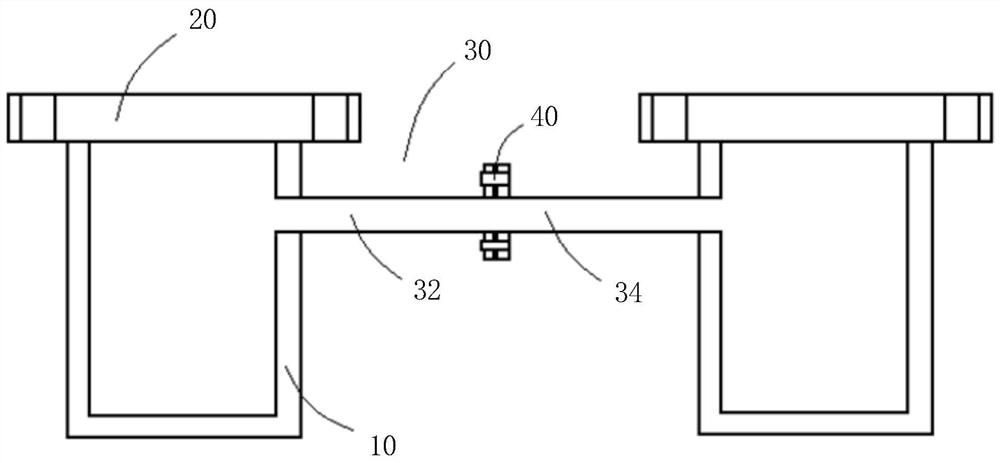

Reactor

PendingCN113351143AAchieve separationReduce cleaning processChemical/physical/physico-chemical stationary reactorsThermodynamicsEngineering

The invention relates to a reactor, which comprises at least two tank bodies, a cover body and at least one connecting pipeline, and each tank body is provided with an opening; the cover body covers the tank body and is used for sealing or opening the opening of the tank body; the two ends of each connecting pipeline are respectively connected with one tank body, and each tank body is connected with one connecting pipeline. According to the reactor, raw materials with excessive mass are independently placed in one tank body, the raw materials are subjected to high-temperature gasification reaction, other reaction materials are placed in other tank bodies, the raw materials in the gas state enter other tank bodies through the pipelines to start reaction by arranging the pipelines communicated with the different tank bodies, and after the reaction is completed, the required negative electrode material is arranged in the tank body for a reaction, and the raw material which does not participate in the reaction is arranged in the tank body for loading the raw material with excessive mass, so that the separation of the raw material which does not participate in the reaction from the finished product is realized, the impurity removal process of the finished product is reduced, and the industrial production cost is reduced.

Owner:TSINGHUA UNIV +1

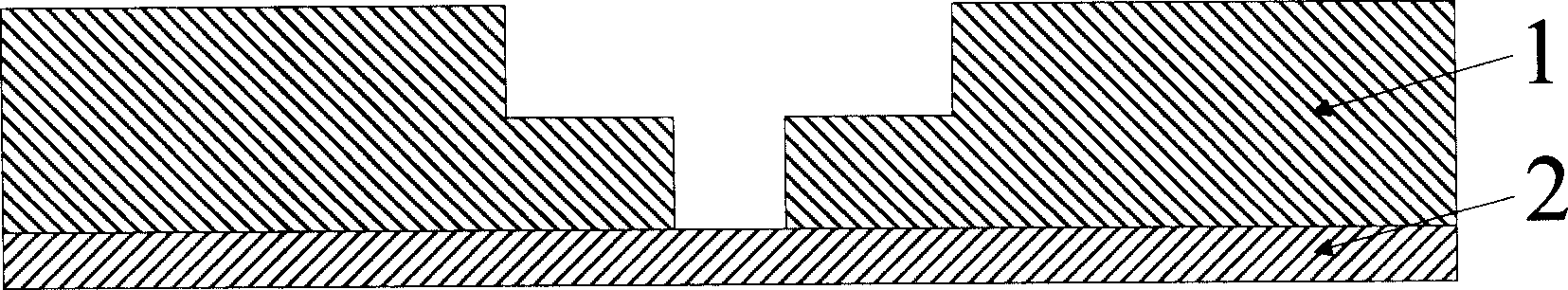

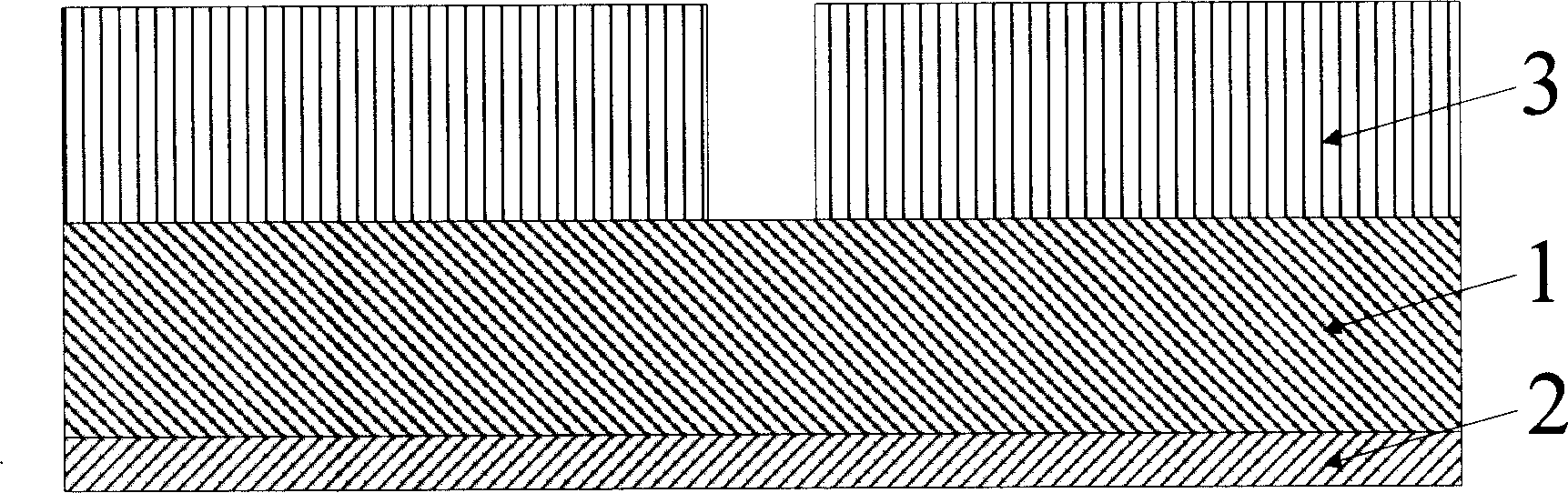

Adhesive film and method for forming metal film using same

ActiveCN1846295AInhibit damageReduce cleaning processFilm/foil adhesivesSemiconductor/solid-state device manufacturingSolventProduction rate

The present invention relates to an adhesive film capable of preventing damage to the metal non-film-forming surface of a semiconductor wafer during metal film formation and reducing contamination of the wafer surface. By using an adhesive film with an adhesive layer formed on one surface of a base film with at least one layer of film with a gas permeability of 5.0cc / m2·day·atm or less, the metal non-film-making surface can be protected, and the use of The solvent cleaning process can further reduce the contamination of the metal non-film-forming surface, and improve productivity and workability.

Owner:MITSUI CHEM TOHCELLO INC

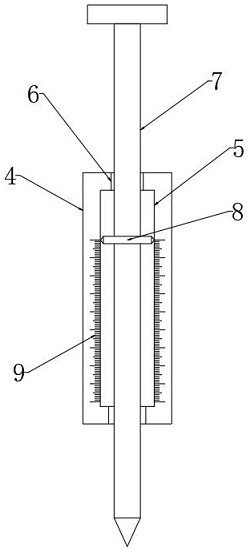

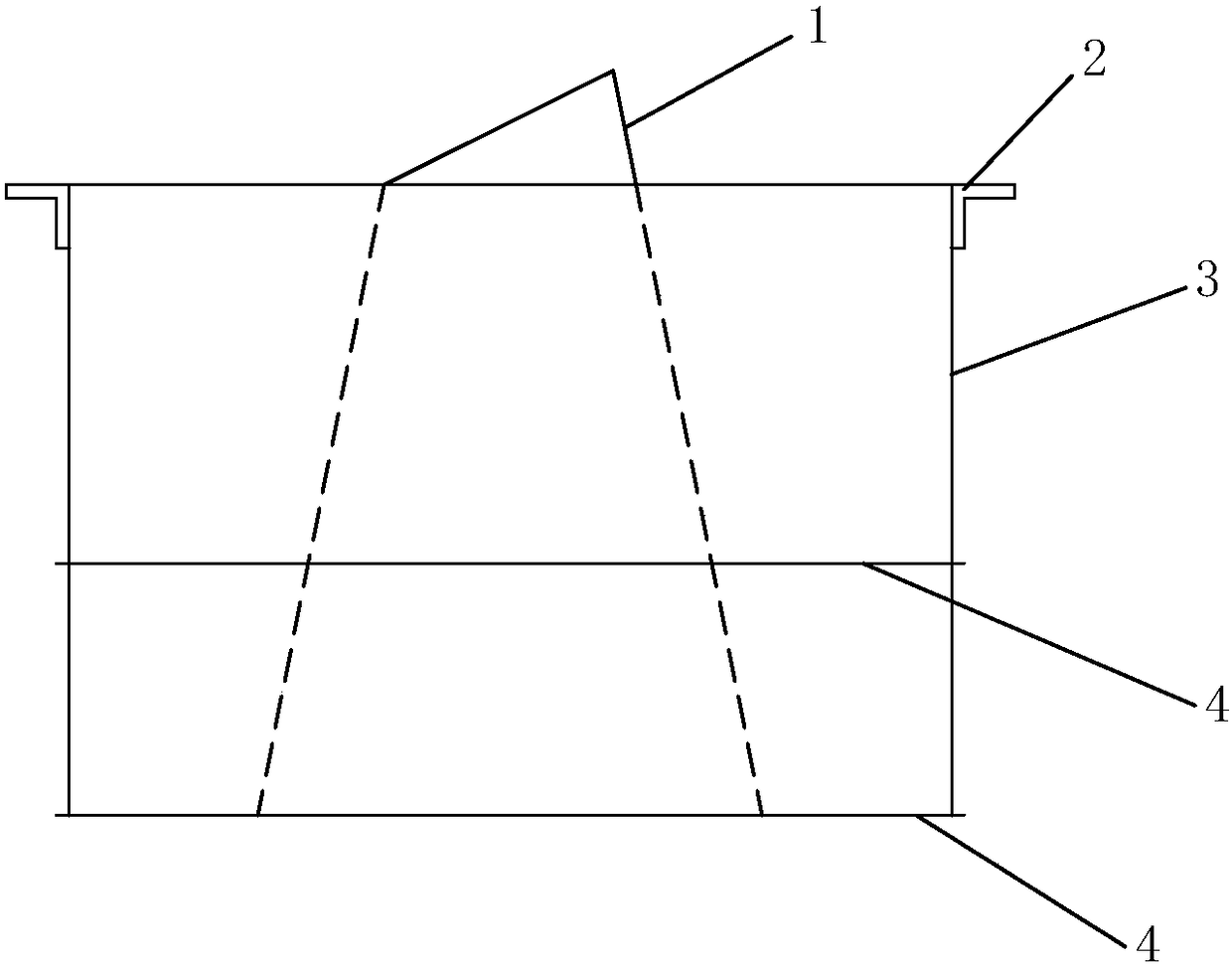

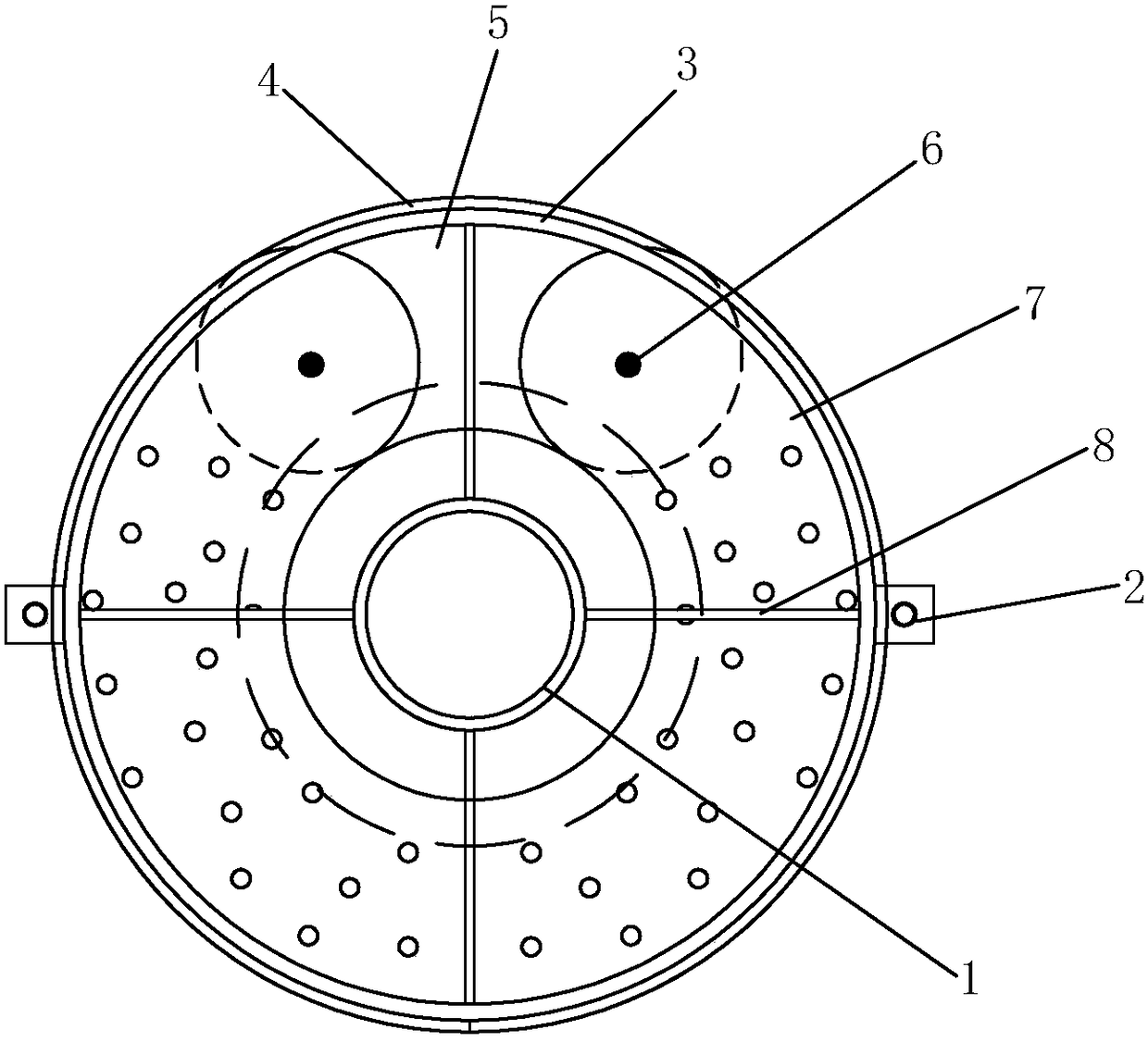

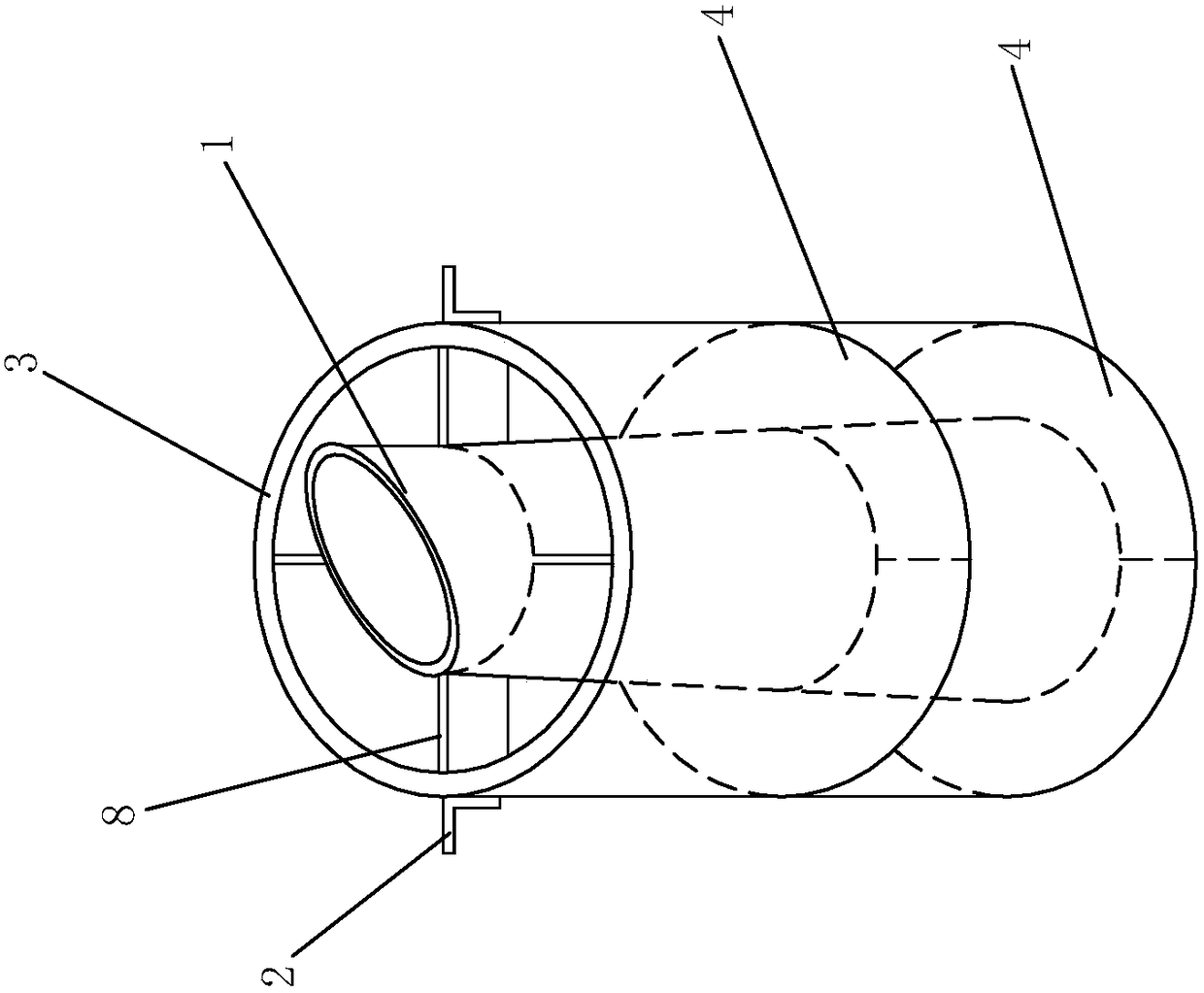

Metal plate polishing thickness detection device for mechanical manufacturing

ActiveCN113561038AReduce operating proceduresImprove work efficiencyGrinding carriagesPolishing machinesMachine buildingPolishing

The invention discloses a metal plate polishing thickness detection device for mechanical manufacturing, and belongs to the field of mechanical manufacturing. According to the metal plate polishing thickness detection device for mechanical manufacturing, a metal plate part can sleeve a central column, a screw rod is rotated to move to the side of the metal plate part, a main clamping plate is pulled out to clamp the metal plate part between the main clamping plate and an infrared measuring head, meanwhile, a displayer measures the thickness of the metal plate part through the infrared measuring head and displays the thickness, then a positioning rod slides in a thickness measuring mechanism to measure the thickness of the metal plate part and fix the metal plate part at the same time, an indicator moves to the scale corresponding to the thickness along with the positioning rod, and the thickness is displayed; and in the polishing process, the positioning rod can descend along with reduction of the surface thickness, and feedback is provided between the infrared measuring head and an auxiliary clamping plate to the dispalyer after the outer wall of the metal plate part is cut down, so that measurement can be directly carried out in the polishing process, and operation procedures are reduced.

Owner:JIANGSU WANLI MACHINERY

A device for removing slag at the bottom of cast-in-situ piles and a method for removing slag using the device

The invention discloses filling pile bottom dreg cleaning equipment and a dreg cleaning method adopting the same, and relates to the technical field of building construction. The dreg cleaning equipment comprises a dreg storage pool, a conical barrel and a check plate, wherein the dreg storage pool comprises an outer cylindrical barrel; an upper opening of the conical barrel is small, and a lower opening of the conical barrel is big; the check plate is hinged to one side of the upper opening of the conical barrel and can cover the upper opening of the conical barrel; the whole conical barrel is arranged on the inner side of the outer barrel of the dreg storage pool; and the dreg storage pool further comprises at least one layer of dreg storage board capable of being positioned between the inner wall of the outer barrel and the outer wall of the conical barrel. The dreg cleaning method adopting the filling pile bottom dreg cleaning equipment comprises the following steps that the dreg cleaning equipment is hoisted to the bottom of a filling pile hole; the check plate is automatically opened under the action of buoyancy, and dregs at the hole bottom flow to the position above the dreg storage pool through the upper opening of the conical barrel; the dreg cleaning equipment is subjected to standing for five to eight minutes; the dreg cleaning equipment is slowly lifted upwards, the dregs sink on a dreg storage plate of the dreg storage pool, and the dregs deposited in the dreg storage pool are cleaned up; and the above steps are executed again until the dregs at the bottom of the filling pile hole are cleaned up thoroughly.

Owner:GUANGXI CONSTR ENG GROUP THE THIRD CONSTR ENG

A device for detecting the thickness of sheet metal polishing in mechanical manufacturing

ActiveCN113561038BReduce operating proceduresImprove work efficiencyGrinding carriagesPolishing machinesMachine buildingPolishing

The invention discloses a thickness detection device for sheet metal polishing used in mechanical manufacturing, which belongs to the field of mechanical manufacturing. It is a device for detecting the thickness of sheet metal polishing in mechanical manufacturing. Turn the screw to move to the side of the sheet metal part, and pull out the main splint to clamp the sheet metal part between the infrared measuring heads. At the same time, the display will measure the thickness of the sheet metal part through the infrared measuring head, and the display will display the thickness, and then position the rod Sliding in the thickness measuring mechanism measures the thickness of the sheet metal part and fixes the sheet metal part at the same time. The indicator moves to the scale corresponding to the thickness along with the positioning rod to display the thickness. When polishing, the positioning rod will follow the As the thickness of the surface decreases, the infrared measuring head will feed back to the display between the outer wall of the sheet metal part after cutting and the sub-splint, so that the measurement can be carried out directly during the polishing process, reducing the operating procedures.

Owner:JIANGSU WANLI MACHINERY

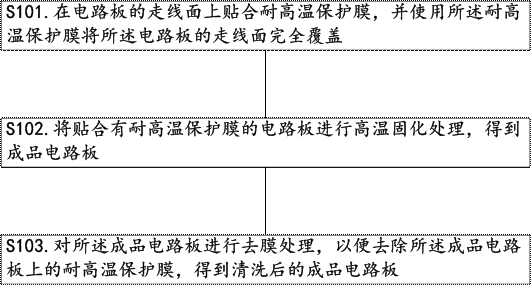

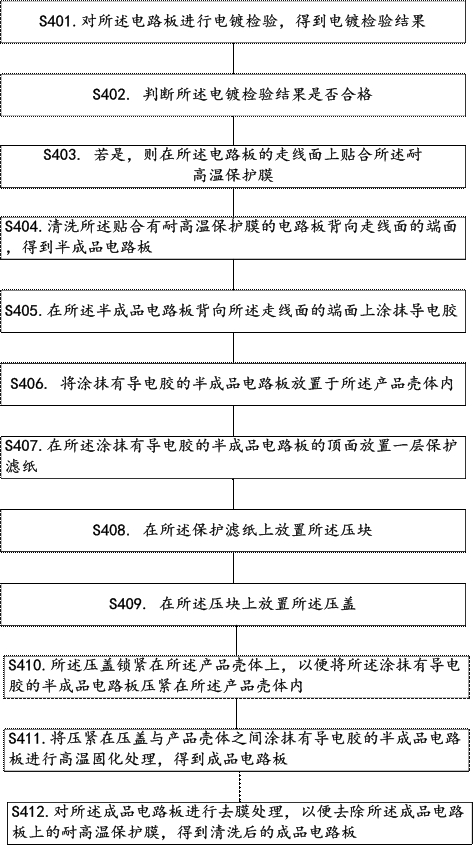

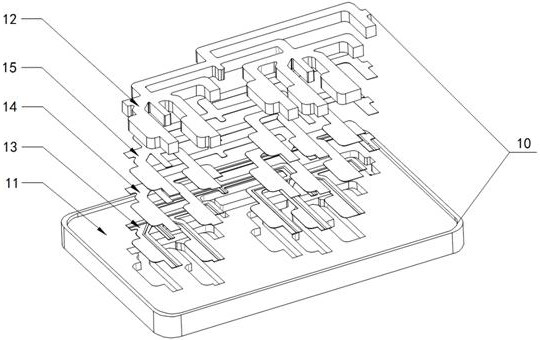

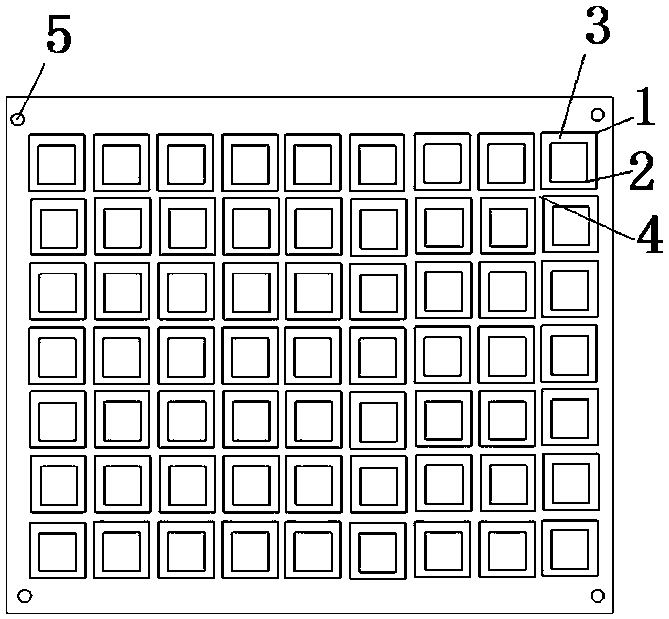

Cleaning method of high-frequency flexible microwave printed circuit board

ActiveCN112702848AReduce cleaning processIncrease productivityConductive pattern polishing/cleaningBatch productionPrinted circuit board

The invention discloses a cleaning method of a high-frequency flexible microwave printed circuit board, and the method comprises the steps: attaching a high-temperature-resistant protection film to a wiring surface of a circuit board, and enabling the wiring surface of the circuit board to be completely covered by the high-temperature-resistant protection film; performing high-temperature curing treatment on the circuit board attached with the high-temperature-resistant protective film to obtain a finished circuit board; carrying out film removing treatment on the finished circuit board so as to remove the high-temperature-resistant protective film on the finished circuit board and obtain a cleaned finished circuit board; according to the invention, the precipitated epoxy resin is isolated from the wire on the surface of the circuit board by using the high-temperature-resistant protective film, so that the purpose that the circuit board is clean and tidy after being bonded is achieved, the wire is not damaged, the cleaning quality and efficiency can be improved, and the large-batch production of the circuit board is facilitated.

Owner:四川省华盾防务科技股份有限公司

Method for manufacturing universal backing plate of PCB solder mask plug hole

ActiveCN109714898ASimple preparation stepsImprove general performancePrinted circuit manufactureSolder maskMilling cutter

The invention discloses a method for manufacturing a universal backing plate of a PCB solder mask plug hole, and the method comprises the following steps: taking a to-be-processed substrate, drillinga positioning hole in the to-be-processed substrate, and fixing the to-be-processed substrate on a gong table by using a fixing pin; setting the specification of first milling grooves according to first milling path data, wherein the first milling grooves are arranged at equal intervals along the long edge and the wide edge of the substrate; adjusting the depth of a first milling cutter, and performing the sinking milling of the substrate to obtain the first milling grooves, wherein the first milling grooves are arranged in a grid shape; and setting the specification of second milling groovesaccording to the second milling process data, wherein the specification of the second milling grooves are smaller than the specification of the first milling grooves; adjusting the depth of a second milling cutter, and milling through the substrate in the first milling grooves according to the specification of the second milling grooves. The method has the advantages that the manufacturing steps are simple, the manufactured base plate is high in universality, the manufacturing cost and the storage management cost of the hole plugging base plate are greatly reduced, and production, operation and use are facilitated.

Owner:KIN YIP TECHNOLDGY ELECTRONICS HUI ZHOUCO LTD

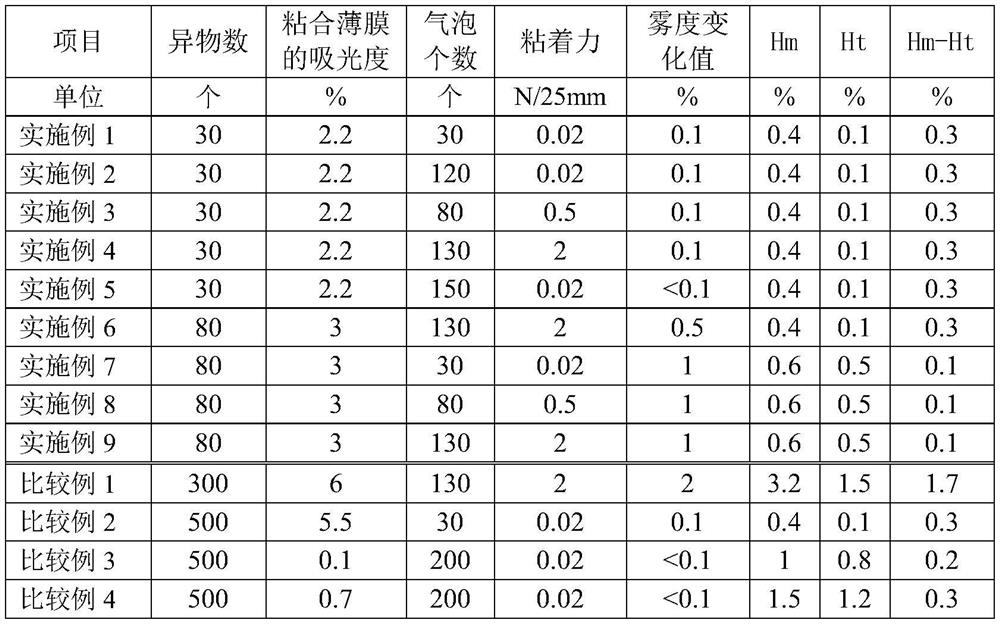

an adhesive film

ActiveCN109536061BReduce manufacturing costReduce cleaning processFilm/foil adhesivesAdhesive cementPolyethylene terephthalate glycol

The invention provides an adhesive film for an organic electroluminescence display element or an organic electroluminescence lighting element, comprising one or more base films and one or more adhesive layers, the base film is a poly Ethylene terephthalate film; in the wavelength range of 304nm to 312nm, the absorbance of the adhesive film is in the range of 1.5% to 5.0%; the adhesive film is temporarily bonded to the organic electrical The side of the light-emitting surface of a luminescent display element or an organic electroluminescent lighting element. When the adhesive film is bonded to the organic EL substrate, it should have good adhesion, air bubble exclusion and reworkability. In addition, there is no foreign matter that may affect subsequent projects when being laser cut.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

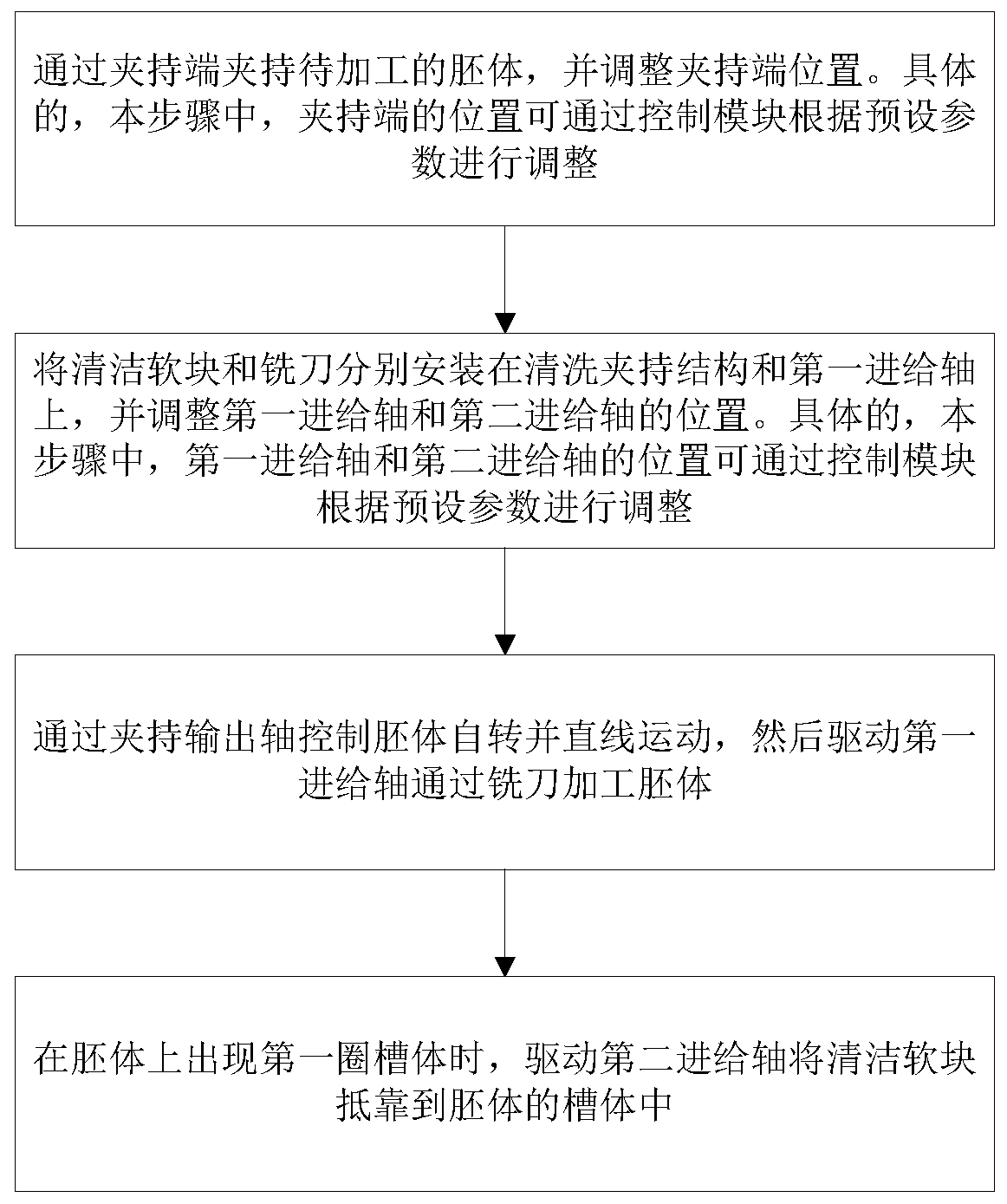

A milling and grinding dual-function rope groove processing machine tool

ActiveCN108326351BClean thoroughlyReduce cleaning processMilling equipment detailsMaintainance and safety accessoriesMilling cutterRelative motion

The invention discloses a bidirectional rope race machining machine tool with milling and grinding functions. Under the condition that a milling cutter abuts against a blank, a clamping output shaft drives the blank to rotate and horizontally move, a groove can be machined in the surface of the blank through the milling cutter, and a rope groove is formed. After the groove is formed, a cleaning soft block is driven to abut against the groove, relative motion of the cleaning soft block and the blank can be achieved through motion of the blank, and residual cutting bits on the blank are cleanedaway through the cleaning soft block.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com