Cleaning method of high-frequency flexible microwave printed circuit board

A technology for printed circuit boards and circuit boards, which is used in secondary processing of printed circuits, cleaning/polishing of conductive patterns, etc. The effect of improving the curing effect and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

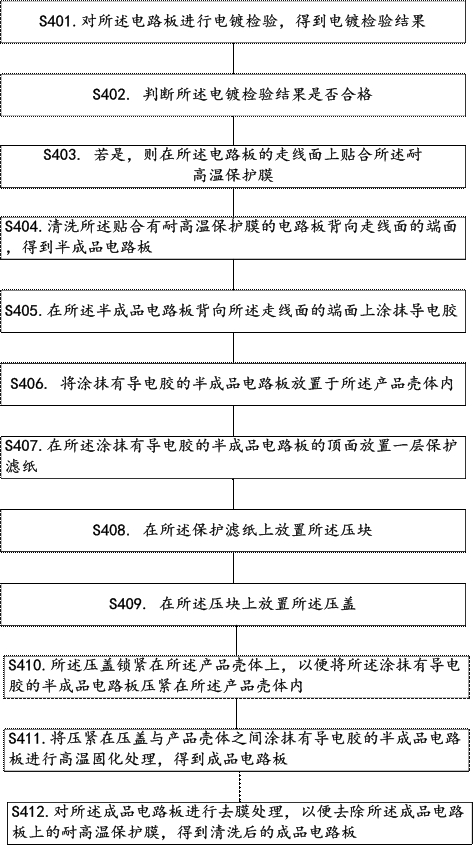

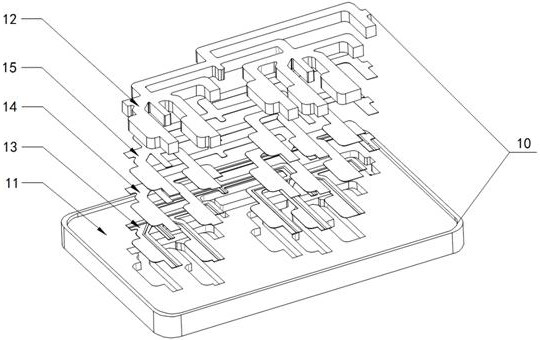

[0061] Such as Figure 1~3 As shown, the high-frequency flexible microwave printed circuit board cleaning method provided in the first aspect of this embodiment can isolate the precipitated epoxy resin from the wires on the surface of the circuit board 13 by using a high-temperature resistant protective film 14, so as to achieve circuit The board 13 is clean and tidy after bonding, not only to ensure that the wires are not damaged, but also to improve the cleaning quality and efficiency, which is conducive to the mass production of the circuit board 13 .

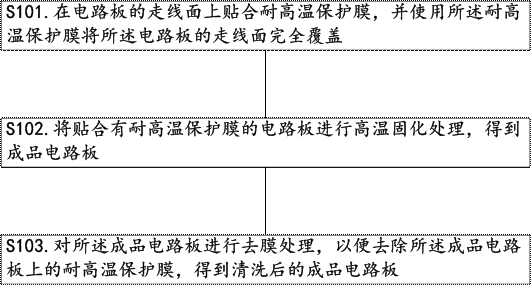

[0062] The method for cleaning a high-frequency flexible microwave printed circuit board provided in this embodiment may, but is not limited to, include the following steps S101-S103.

[0063] S101. Paste a high temperature resistant protective film on the wiring surface of the circuit board, and use the high temperature resistant protective film to completely cover the wiring surface of the circuit board.

[0064] Step S10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com