Method for manufacturing universal backing plate of PCB solder mask plug hole

A manufacturing method and technology of plugging holes, which are applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as confusion and loss of plug hole backing plates, difficulty in finding, increasing production costs of enterprises, high manufacturing and use costs, and reduce storage costs. Cost management, production cost reduction, high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

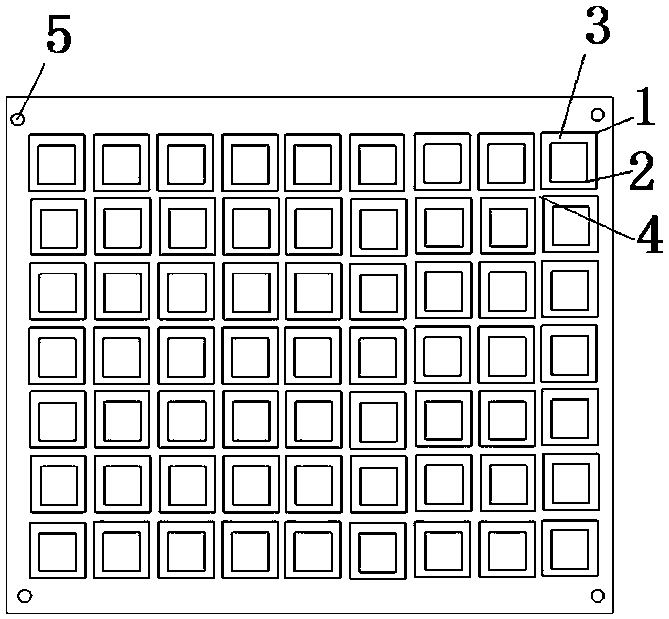

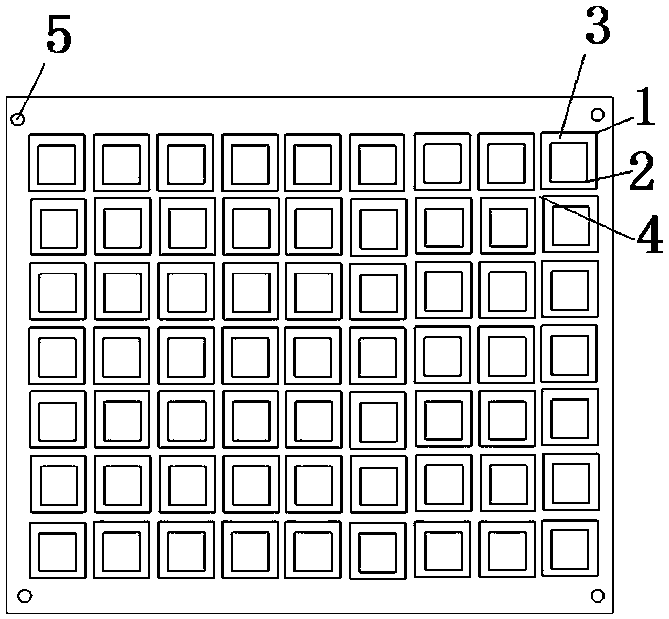

[0031] A method for manufacturing a PCB solder-resisting plug hole universal backing plate, comprising the following steps:

[0032] Get the substrate to be processed, the specification of the substrate is 680mm in length, 610mm in width, and 2.4mm in thickness, and the material is a fiber plate. Drill positioning holes 5 on the substrate and fix them on the gong platform with fixing pins. The positioning holes 5 are arranged on four sides of the substrate. At a corner of 5mm, the aperture is 2.05mm;

[0033] Set the specifications of the first groove according to the first stroke data, the length of the first groove 1 is 20mm, and the width is 20mm, and the first groove 1 is arranged at equal intervals along the long side and the wide side of the substrate, The distance between the adjacent first grooves 1 is 0.25mm, the depth of the first groove is adjusted to 20mm and the substrate is sunk, the depth of the sinking is 0.5mm, and the first groove 1 is obtained. The first go...

Embodiment 2

[0036] A method for manufacturing a PCB solder-resisting plug hole universal backing plate, comprising the following steps:

[0037] Get the substrate to be processed, the specification of the substrate is 700mm in length, 610mm in width, and 2.0mm in thickness, and the material is a fiber plate. Drill positioning holes 5 on the substrate and fix them on the gong platform with fixing pins. The positioning holes 5 are arranged on four sides of the substrate. At a corner of 5mm, the aperture is 2.05mm;

[0038] Set the specifications of the first groove according to the first stroke data, the length of the first groove 1 is 25mm, and the width is 25mm, and the first groove 1 is arranged at equal intervals along the long side and the wide side of the substrate, The distance between the adjacent first gong grooves is 0.25 mm, adjust the depth of the first gong knife to 18 mm and sink the substrate, the depth of the gong sinking is 0.8 mm, and the first gong groove 1 is obtained. ...

Embodiment 3

[0041] A method for manufacturing a PCB solder-resisting plug hole universal backing plate, comprising the following steps:

[0042] Get the substrate to be processed, the specification of the substrate is 720mm in length, 650mm in width, and 3.0mm in thickness, and the material is a fiber plate. Drill positioning holes 5 on the substrate and fix them on the gong platform with fixing pins. The positioning holes 5 are arranged on four sides of the substrate. At a corner of 5mm, the aperture is 2.05mm;

[0043] Set the specifications of the first groove according to the first stroke data, the length of the first groove 1 is 30mm, and the width is 20mm, and the first groove 1 is arranged at equal intervals along the long side and the wide side of the substrate, The distance between the adjacent first gong grooves 1 is 0.25 mm, adjust the depth of the first gong knife to 20 mm and sink the substrate, the sinking depth is 1.0 mm, and the first gong groove is obtained. The first go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com