A milling and grinding dual-function rope groove processing machine tool

A machine tool, dual-function technology, used in metal processing machinery parts, milling machine equipment, metal processing equipment, etc., can solve the problems of reducing the product qualification rate, final product quality, adverse effects, etc., to ensure the final quality, save the cleaning process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

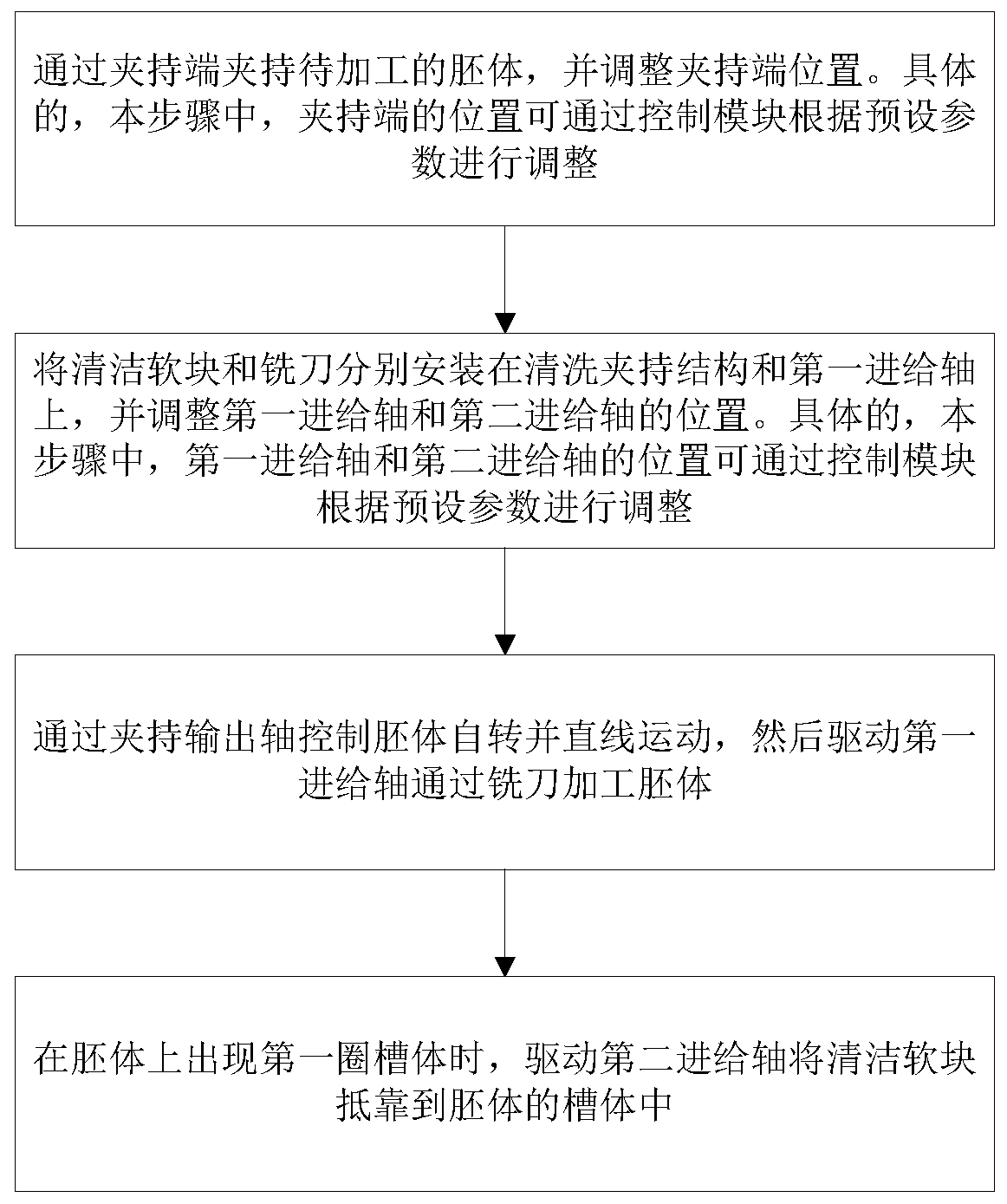

[0020] Refer to figure 1 The invention proposes a milling and grinding dual-function rope groove processing machine tool, which includes: a clamping output shaft, a first feed shaft, a second feed shaft and a control module.

[0021] The clamping output shaft is rotatably installed on the machine tool, the clamping output shaft is equipped with a clamping end for clamping the embryo body, and the clamping end moves linearly on the machine tool through the clamping output shaft. In this way, when the embryo body is installed on the clamping end, the embryo body can be driven to rotate in a straight line through the clamping end, which lays the foundation for the processing of the spiral structure of the rope groove.

[0022] Both the first feed axis and the second feed axis are mounted on the machine tool and are located on opposite sides of the clamping output axis. The movement trajectory of the first and second feed axis is perpendicular to the clamping The direction of linear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com