an adhesive film

A technology for bonding films and films, applied in the direction of film/sheet-shaped adhesives, adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

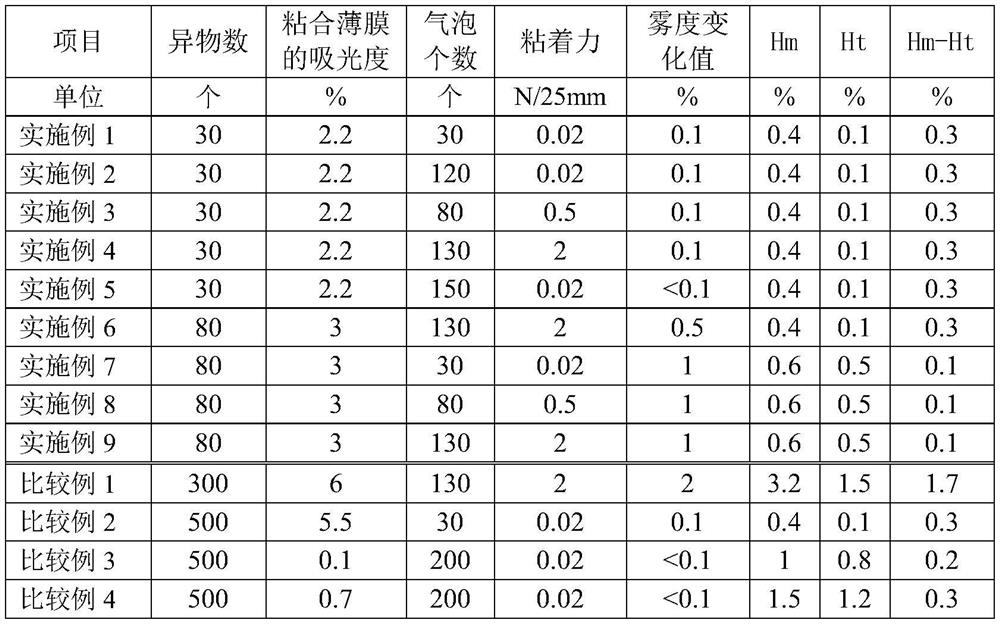

Examples

Embodiment 1

[0092] Adhesive I (solid content 30%) was coated on one surface of base film A (thickness 75 μm) with a comma roll coater, with a wet thickness of about 67 μm. After drying at 120°C for 1 minute and 30 seconds, the obtained adhesive layer has a dry thickness of 20 μm. The adhesive film was compounded with a release film, and aged in an oven at 50° C. for 48 hours to prepare a sample. Various tests were performed after the release film was peeled off.

Embodiment 2

[0094] Adhesive I (solid content 30%) was coated on one surface of base film B (thickness 75 μm) with a comma roll coater, with a wet thickness of about 67 μm. After drying at 120°C for 1 minute and 30 seconds, the obtained adhesive layer has a dry thickness of 20 μm. The adhesive film was compounded with a release film, and aged in an oven at 50° C. for 48 hours to prepare a sample. Various tests were performed after the release film was peeled off.

Embodiment 3

[0096] Adhesive II (solid content 30%) was coated on one surface of base film A (thickness 75 μm) with a comma roll coater to a wet thickness of about 67 μm. After drying at 120°C for 1 minute and 30 seconds, the obtained adhesive layer has a dry thickness of 20 μm. The adhesive film was compounded with a release film, and aged in an oven at 50° C. for 48 hours to prepare a sample. Various tests were performed after the release film was peeled off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com