A device for removing slag at the bottom of cast-in-situ piles and a method for removing slag using the device

A technology of cast-in-place piles and cast-in-place piles, which is applied to earthwork drilling, boreholes/well parts, flushing boreholes, etc., which can solve problems such as increased construction costs, large water and electricity consumption, and serious pollution, so as to speed up construction progress and reduce The effect of clearing and transporting process and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

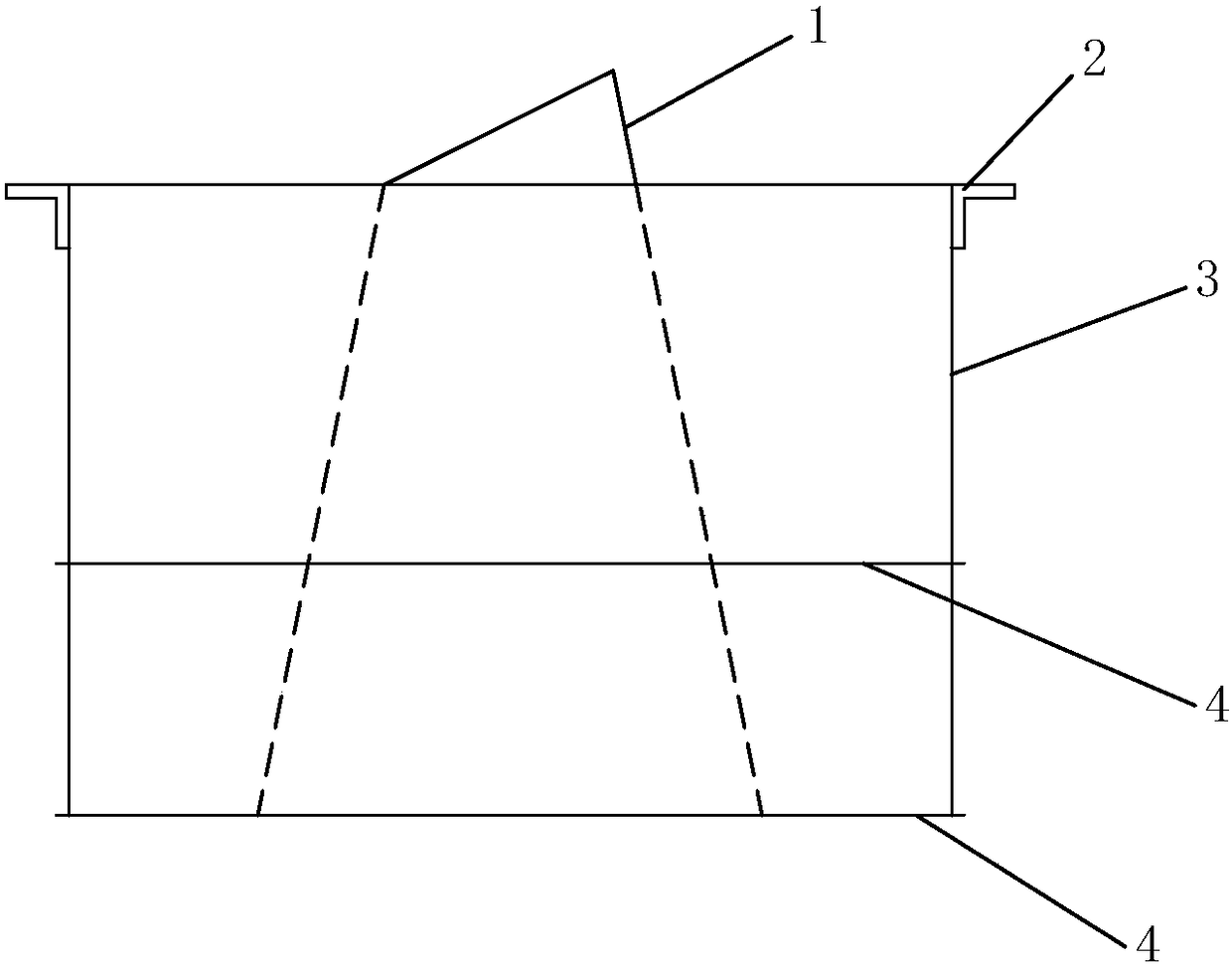

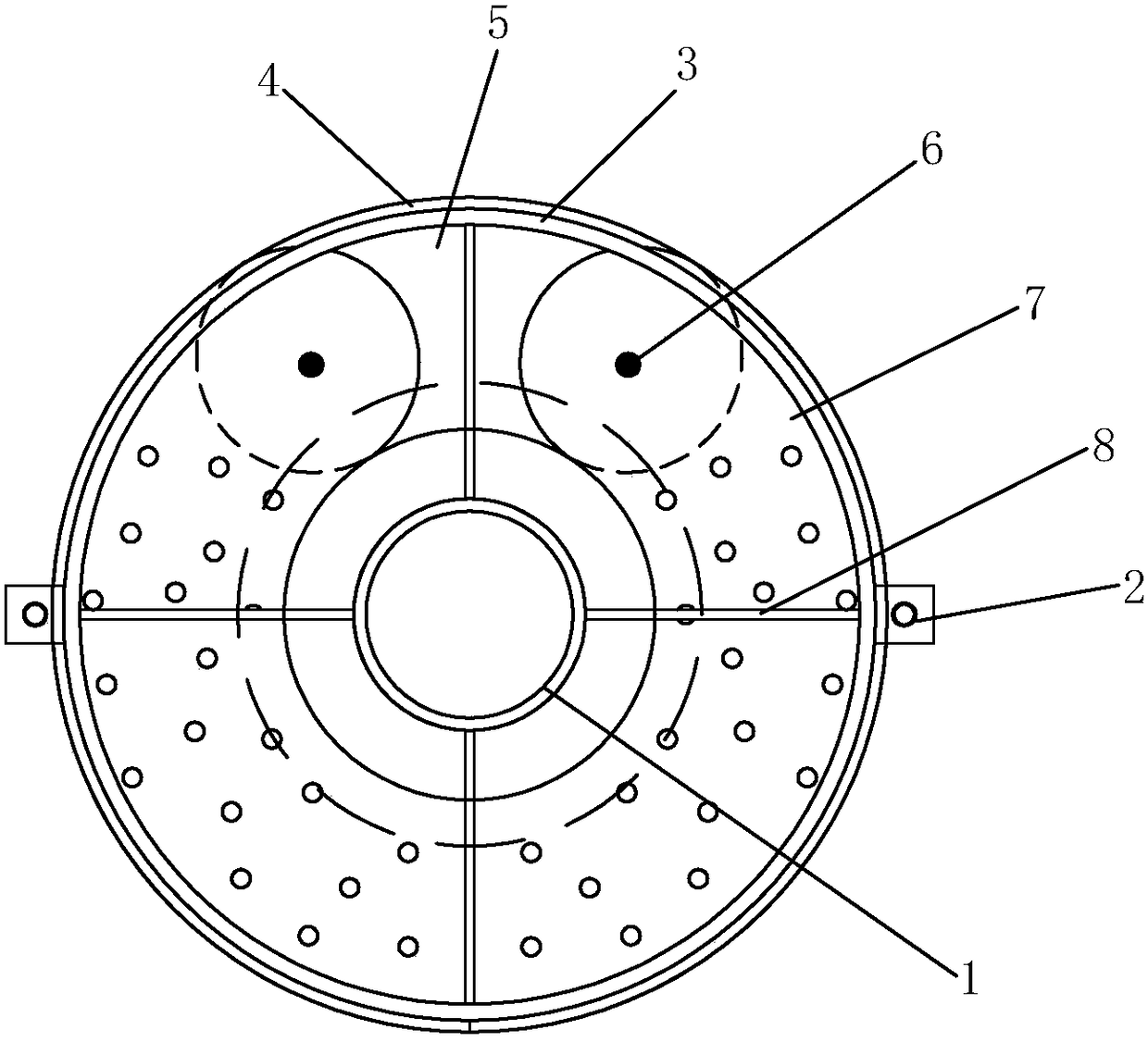

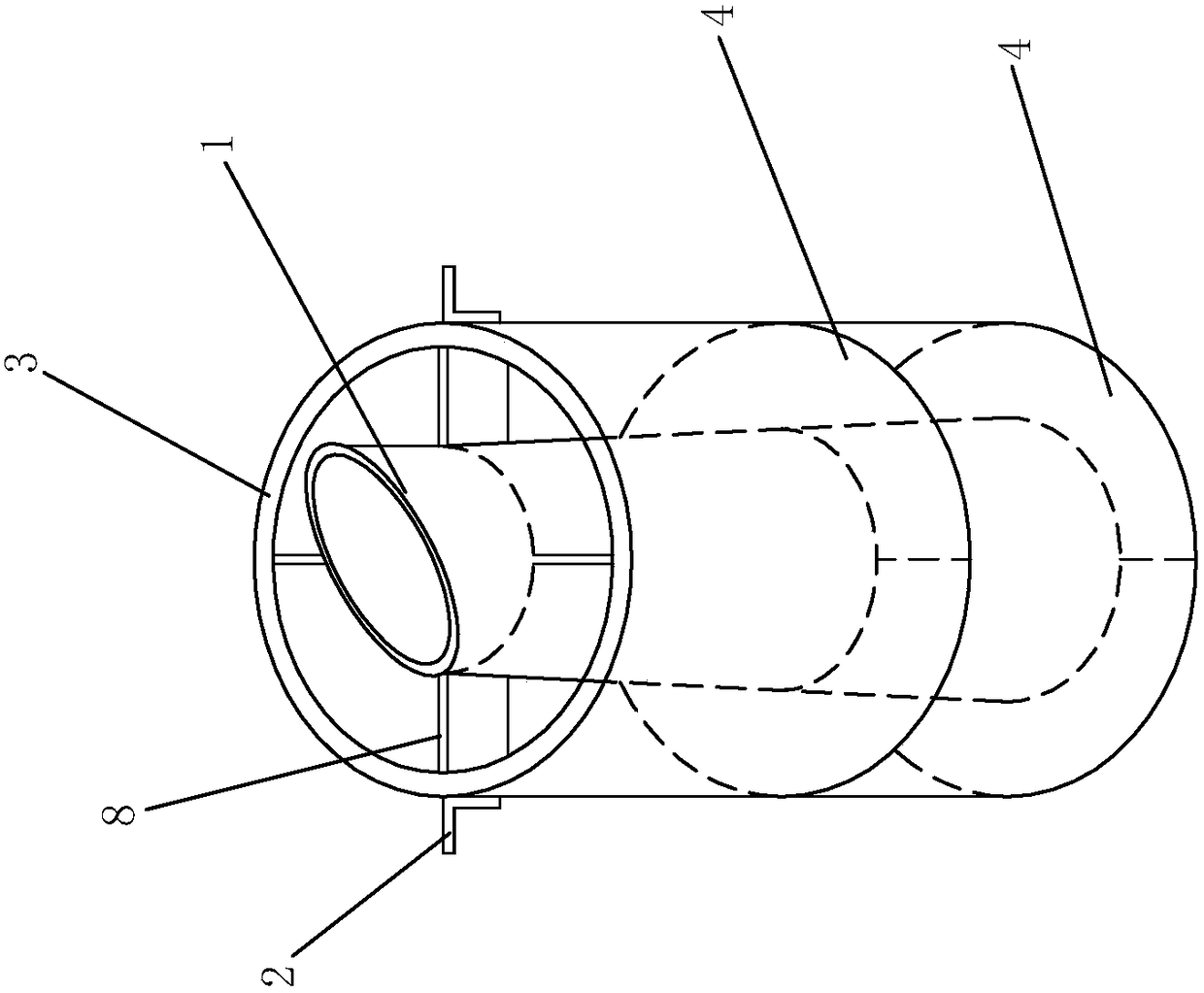

[0021] Such as Figure 1 to Figure 8 As shown, the slag removal equipment at the bottom of the cast-in-situ pile of the present invention includes a slag storage tank, a conical cylinder 1, and a check plate 11. The slag storage tank includes a cylindrical outer cylinder 3, and the upper surface of the conical cylinder 1 The mouth 9 is small and the bottom mouth is large, which is beneficial to the discharge of sediment and can effectively limit the sediment from falling back to the bottom of the hole. The non-return plate 11 is hinged on one side of the upper opening 9 of the conical cylinder 1 and can cover the upper opening 9 of the conical cylinder 1. The conical cylinder 1 is integrally arranged inside the outer cylinder 3 of the slag storage tank. The upper opening 9 of the conical cylinder 1 is inclined, and the height difference between the lowest side wall and the highest side wall of the upper opening 9 is 10-15 cm. The non-return plate 11 includes a non-return cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com