High efficiency purification method of ammonium tungstate solution with high Mo content by using special resin

A technology of ammonium tungstate and resin, which is applied in the field of high-efficiency purification of ammonium tungstate solution containing high Mo with special resin, can solve the problems of low efficiency, high cost, complicated process, etc., to simplify the process, reduce the process and reduce the production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

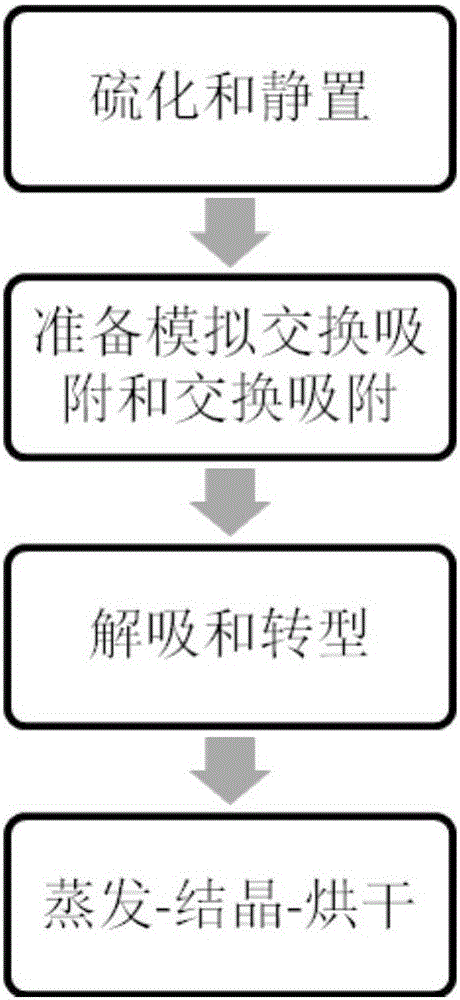

Method used

Image

Examples

Embodiment 1

[0022] Implement the experiment:

[0023] ①Sulphurization, WO in ammonium tungstate solution 3 The concentration is 221.68g / L, the Mo concentration is 1.31g / L, and ammonium sulfide is added for vulcanization. 2- 2.57g / L;

[0024] ②Stationary, vulcanization is completed, standing for 120min, filtration, liquid-solid separation, separation liquid collection for the next step, and separation slag collection and recycling;

[0025] ③ Prepare simulated exchange adsorption. The simulated exchange column is a transparent plexiglass simulated exchange column with a specification of Φ5cm×70cm. The filling resin is special resin WDA918. The quality of the filled resin is 467.5g, and the height of the resin layer is 36.5cm;

[0026] ④ Exchange adsorption, pass the separation liquid through the resin layer, the flow rate is controlled at 15mL / min, when the Mo content in the separation liquid passing through the resin layer is ≥ 0.01g / L, stop the exchange (the special resin WDA918 is reg...

Embodiment 2

[0033] Implement the experiment:

[0034] ①Sulphurization, WO in ammonium tungstate solution 3 The concentration is 254.5g / L, the Mo concentration is 4.5g / L, and ammonium sulfide is added for vulcanization. 2- 2.90g / L;

[0035] ②Stationary, vulcanization is completed, standing still for 150min, filtering, liquid-solid separation, separation liquid collection for the next step, and separation slag collection and recycling;

[0036] ③ Prepare simulated exchange adsorption. The simulated exchange column is a transparent plexiglass simulated exchange column with a specification of Φ5cm×70cm. The filling resin is special resin WDA918. The quality of the filled resin is 467.5g, and the height of the resin layer is 36.5cm;

[0037] ④ Exchange adsorption, pass the separation liquid through the resin layer, the flow rate is controlled at 10mL / min, when the Mo content in the separation liquid passing through the resin layer is ≥ 0.01g / L, stop the exchange (the special resin WDA918 is ...

Embodiment 3

[0044] Implement the experiment:

[0045] ①Sulphurization, WO in ammonium tungstate solution 3 The concentration is 168.40g / L, the Mo concentration is 7.0g / L, ammonium sulfide is added for vulcanization, the vulcanization stirring speed is 60r / min, the stirring time is 120min, the reaction temperature is 298K, and the vulcanization end point controls the S in the vulcanization solution. 2- 3.2g / L;

[0046] ②Stationary, vulcanization is completed, standing for 150min, filtering, liquid-solid separation, separation liquid collection for the next step, and separation slag collection and recycling;

[0047] ③ Prepare simulated exchange adsorption. The simulated exchange column is a transparent plexiglass simulated exchange column with a specification of Φ5cm×70cm. The filling resin is special resin WDA918. The quality of the filled resin is 467.5g, and the height of the resin layer is 36.5cm;

[0048] ④ Exchange adsorption, pass the separation liquid through the resin layer, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com