Method for manufacturing polarization plate and manufacturing device therefor

A manufacturing method and a manufacturing device technology, which are applied in the field of manufacturing methods and manufacturing devices of special-shaped polarizing plates, and can solve the problems that the blade cannot rotate stably and the resistance to rotation becomes high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0126] Hereinafter, Examples etc. which concretely show the structure and effect of this invention are demonstrated.

[0127] [Example, Comparative Example]

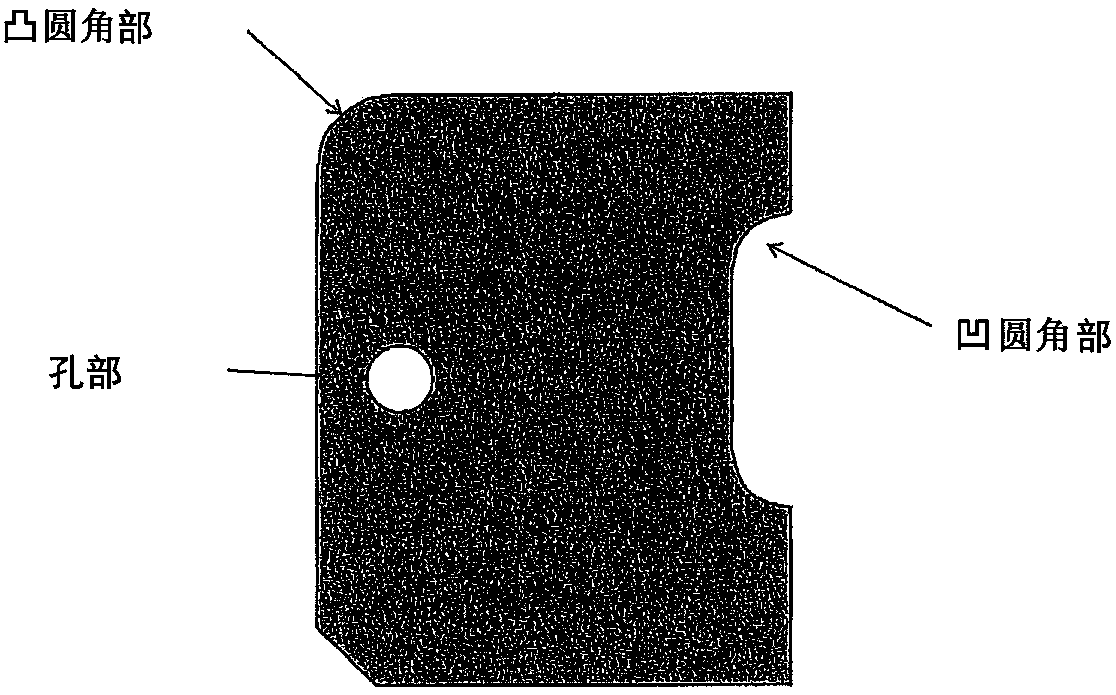

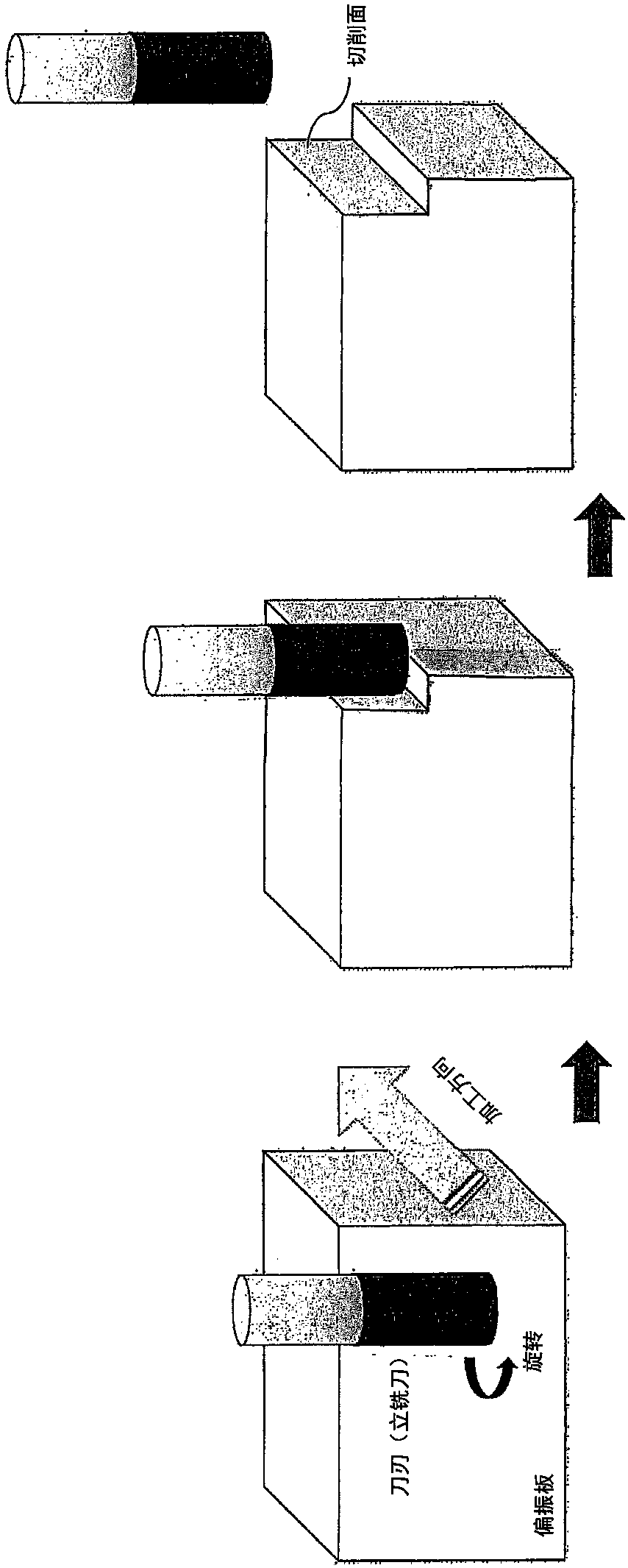

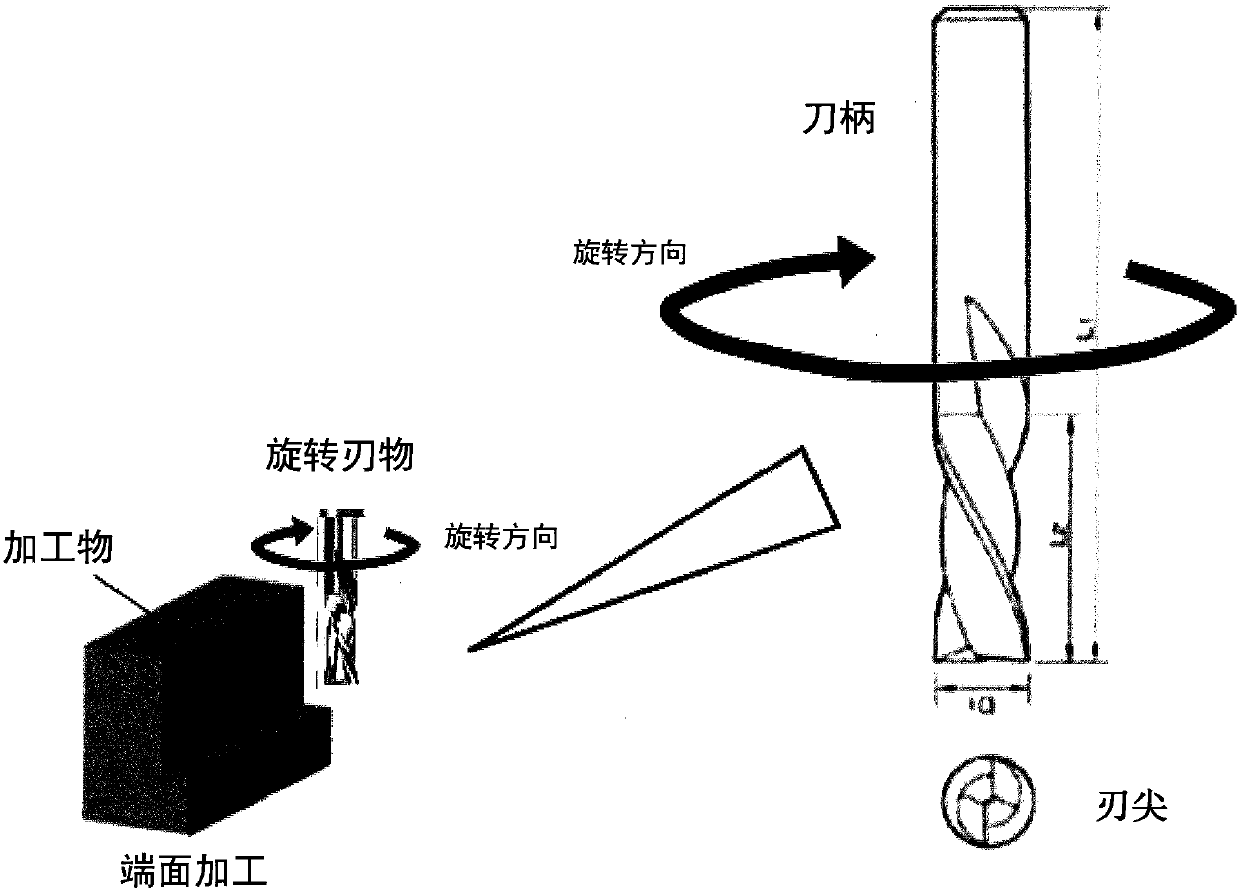

[0128] Regarding the implementation of processing in Examples and Comparative Examples, the conditions and processing methods shown in the following Table 1 were used. Figure 5 The machining shape shown is carried out. Moreover, the laminated body which laminated the surface protection film (PPF-100T) by Nitto Denko Co., Ltd. on the polarizing plate (NPF-CWQ1463VDUAG380-ACJ) by Nitto Denko Co., Ltd. was used as a to-be-processed body. be explained, Figure 5 The unit in is mm. In addition, in Examples 1 and 2 and Comparative Examples 1 and 2, cutting was performed with the cutting edge of the end mill facing downward.

[0129]

[0130] (Measurement and Evaluation of Shape Freedom)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com