Stamping oil composition and use thereof

A technology of composition and stamping oil, applied in lubricating composition, petroleum industry, etc., can solve the problems of inability to clean stains on processed parts, anti-rust oil, and insufficient cleaning performance of oil products, so as to improve cleaning ability, good technical effect, Reduce the effect of the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

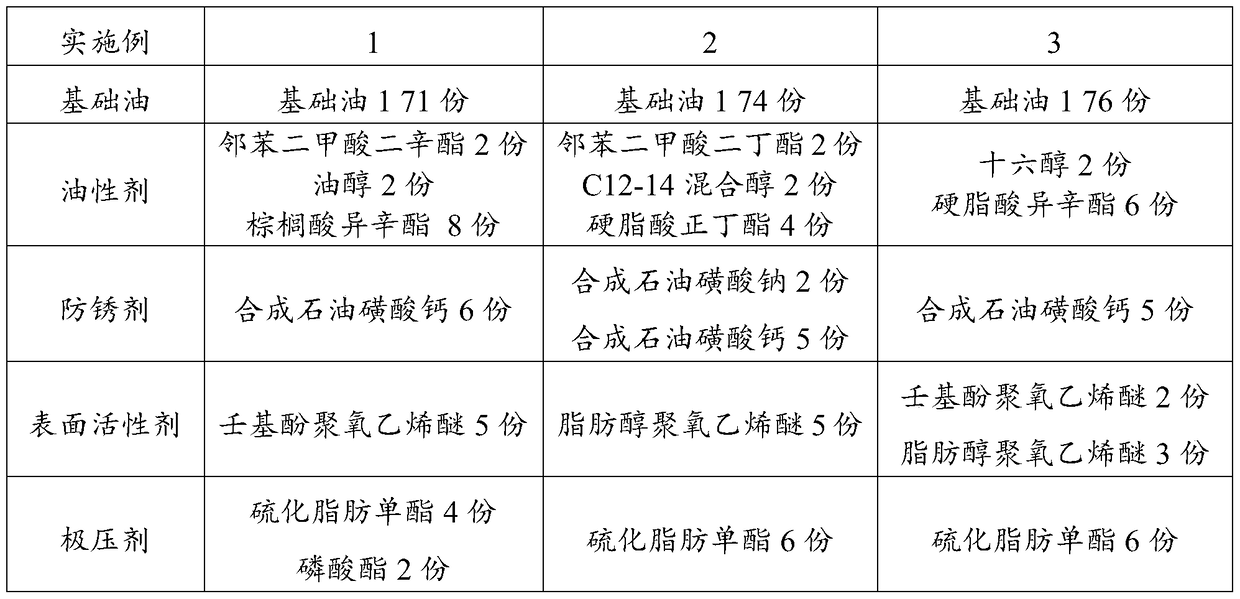

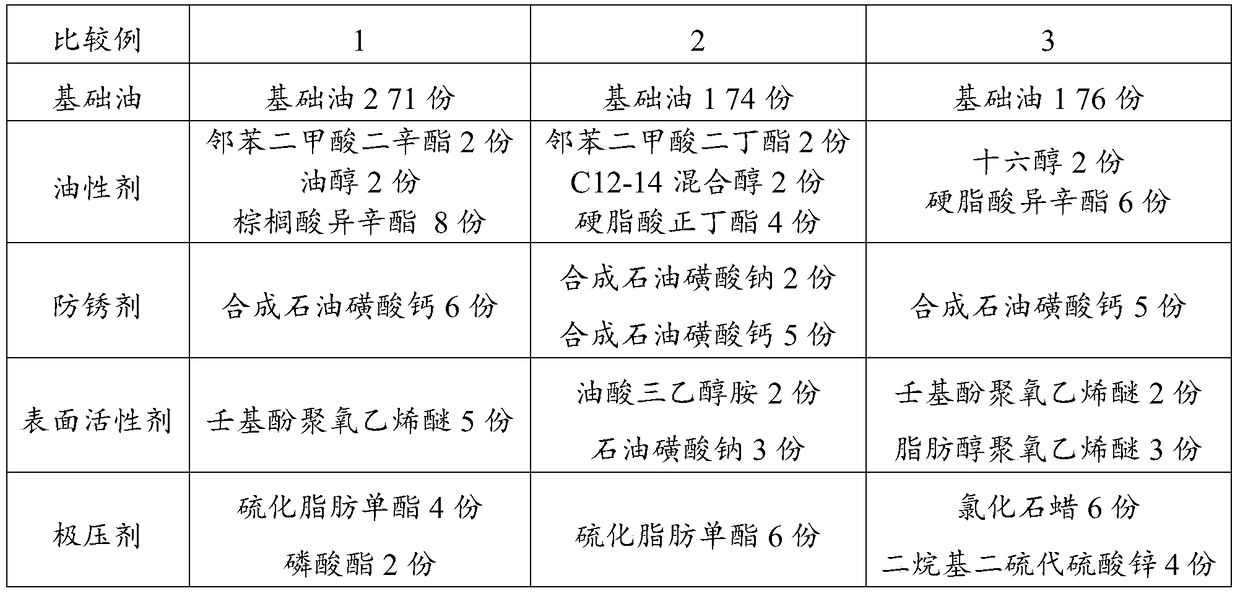

[0026] Heat the refined mineral oil to 40°C, add the required amount of oily agent, extreme pressure agent, oily agent, antirust agent and surfactant in turn during stirring, stop stirring and heating after fully stirring for half an hour, and let it stand for 2 hours Filter the filling. The type and amount of each component in the composition are specifically shown in Table 1. Among them, base oil 1 is refined dearomatized solvent oil with a distillation range of 286-323°C and a viscosity of 5.156 mm 2 / s(40℃), the base oil 2 is 5# white oil, its distillation range is 263~358℃, and its viscosity is 5.358mm 2 / s (40°C).

[0027] Table 1

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com