Anti-slag-adhering laser pipe cutting machine and cut pipe collecting method

A tube cutting machine and laser technology, applied in laser welding equipment, tubular items, applications, etc., can solve the problems of damage to the tube, splashing of waste residue, falling of the tube to the ground or the receiving car, etc., to achieve low cost and improve the finished product. Quality, the effect of reducing scratches and collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

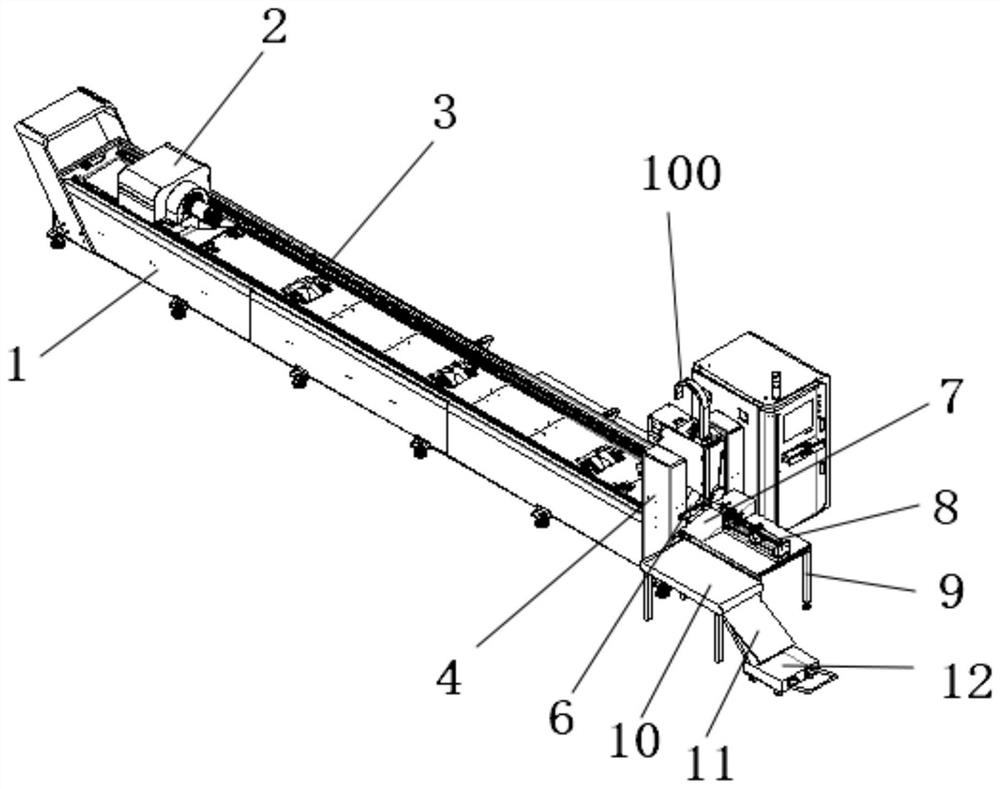

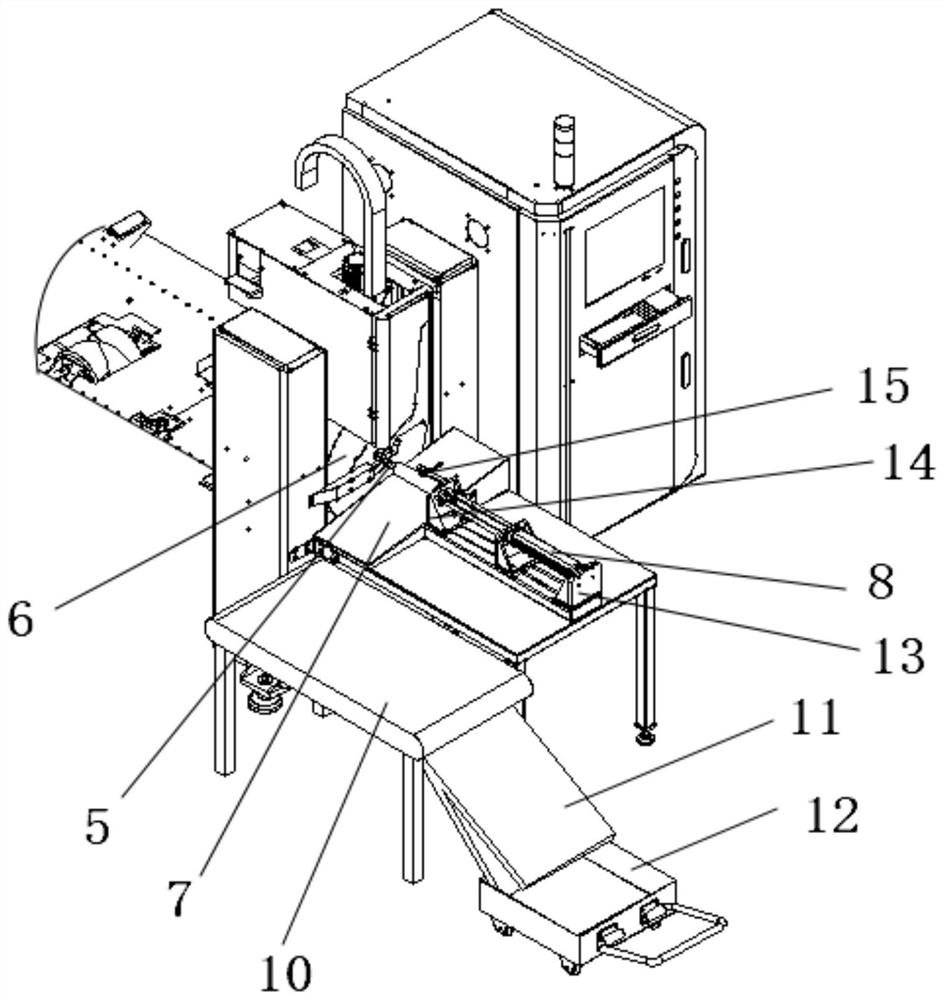

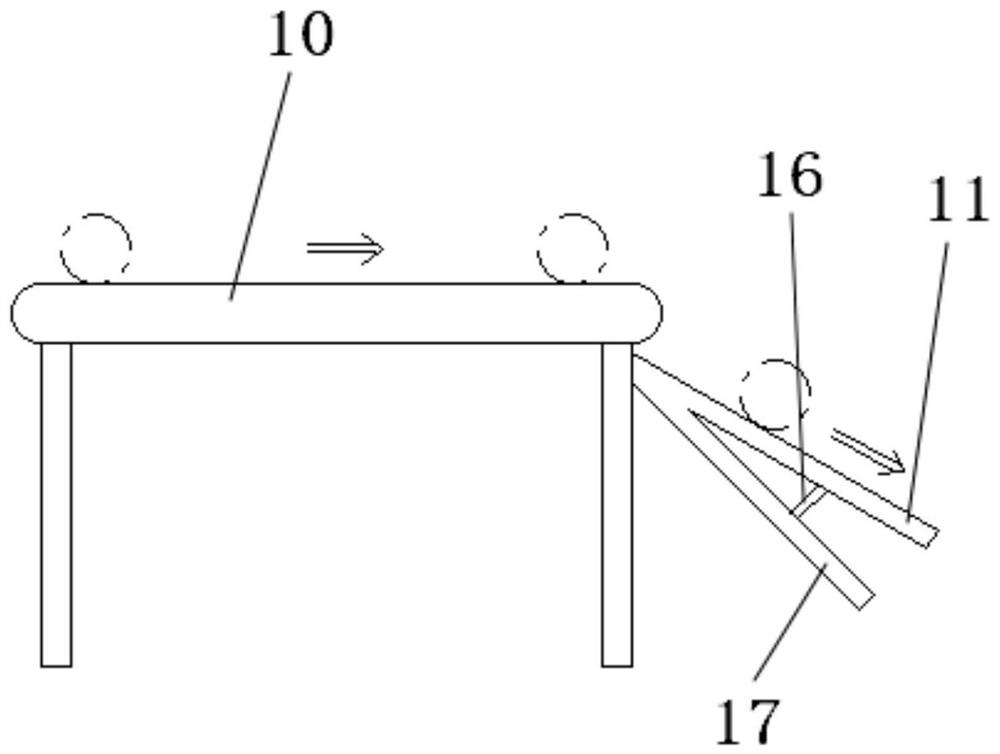

[0038] Such as Figure 1-Figure 8As shown, this specific embodiment provides an anti-dross laser pipe cutting machine, including a cutting bed 1, a waste slag collection mechanism, an underframe 9, a pipe conveying mechanism, a blanking buffer mechanism, and a material receiving device 12. The cutting bed 1 is provided with a gantry 4, a cutting head assembly 100, a front chuck 6 and a rear chuck 2, and the gantry 4 is provided with a transverse guide rail, the cutting head assembly 100 is installed on the transverse guide rail and can slide along the transverse guide rail, the cutting bed The body 1 is provided with a longitudinal guide rail, the rear chuck 2 is slidably installed on the longitudinal guide rail, the front chuck 6 is installed on the cutting bed 1 and is located at the position of the gantry frame 4; the waste residue collection mechanism is installed on the chassis 9 and Close to the front chuck 6, the waste slag collection mechanism includes a slender slag r...

specific Embodiment approach 2

[0043] This specific embodiment provides a method for collecting anti-slag cutting pipes, including the anti-slag laser pipe cutting machine in Embodiment 1, and also includes the following steps:

[0044] A1: Turn the variable-diameter lifting roller 3 according to the pipe specification, and place the pipe on the variable-diameter lifting roller 3;

[0045] A2: The rear chuck 2 moves forward to hold the tail end of the pipe, and the front chuck 6 holds the front end of the pipe;

[0046] A3: The slag receiving pipe 5 extends into the pipe, and the slag receiving hole 51 on the slag receiving pipe 5 is located directly below the cutting head. The cutting head cuts the pipe, and the waste slag during the cutting process falls into the slag receiving pipe 5;

[0047] A4: After the pipe is cut, the pipe falls onto the slag receiving pipe 5, and the sensor switch 15 senses the signal and feeds back to the system, and the slag receiving pipe 5 drives the cut pipe to retract;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com