Process for reclaiming honeycomb SCR waste catalyst

A waste catalyst and honeycomb technology, applied in the preparation of vanadium compounds, tungsten compounds, vanadium compounds, etc., can solve the problems of low environmental risk, low energy consumption, high recovery rate, etc., achieve good product quality and reduce safety factor , High recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, a recovery process for a cellular SCR waste catalyst proposed according to the present invention, its specific implementation , structure, feature and effect thereof, detailed description is as follows.

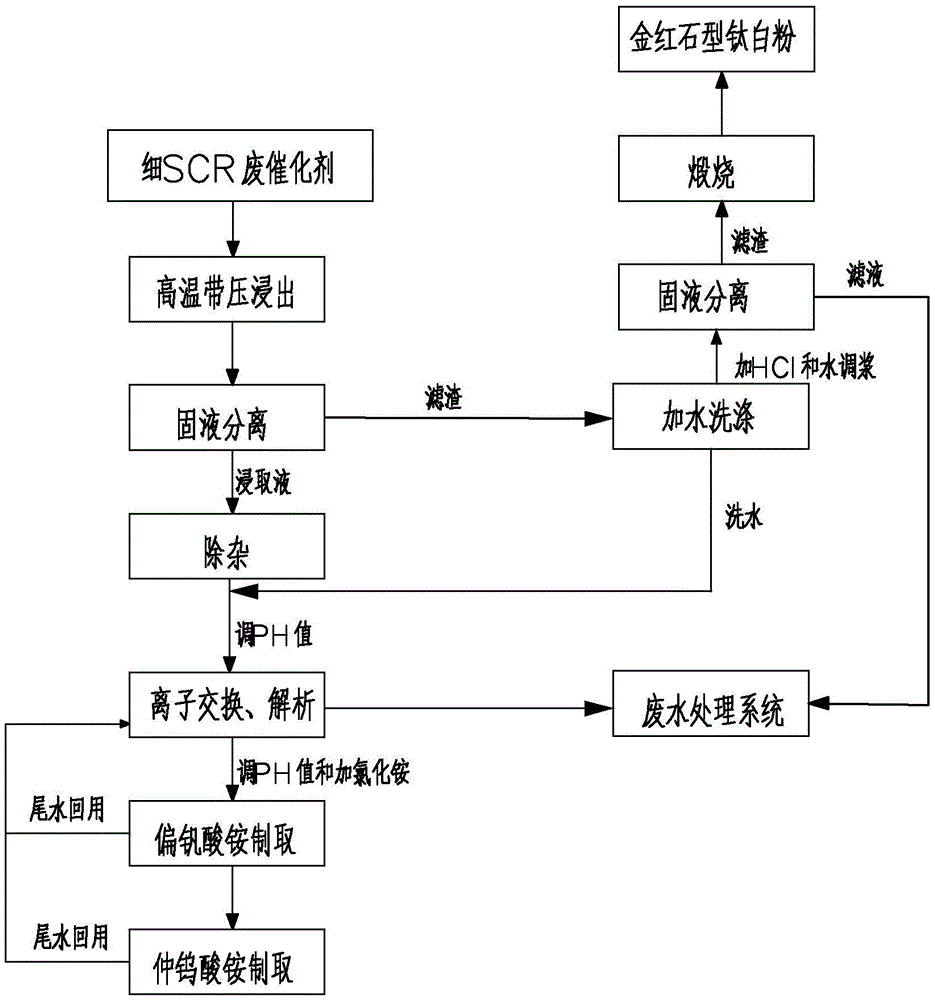

[0032] The invention is a recovery process of honeycomb SCR waste catalyst, including pretreatment and fine grinding of SCR waste catalyst; high-temperature pressure leaching; adding hydrochloric acid to the leaching slag to remove sodium, and calcining to prepare rutile titanium dioxide; leachate is impurity-removed and ion-exchanged Equipment enrichment; preparation of ammonium metavanadate; preparation of ammonium paratungstate; wastewater treatment and reuse.

[0033] Specifically include the following steps:

[0034] (1) Crush the spent SCR catalyst, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com