Patents

Literature

31results about How to "Reduce break down cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

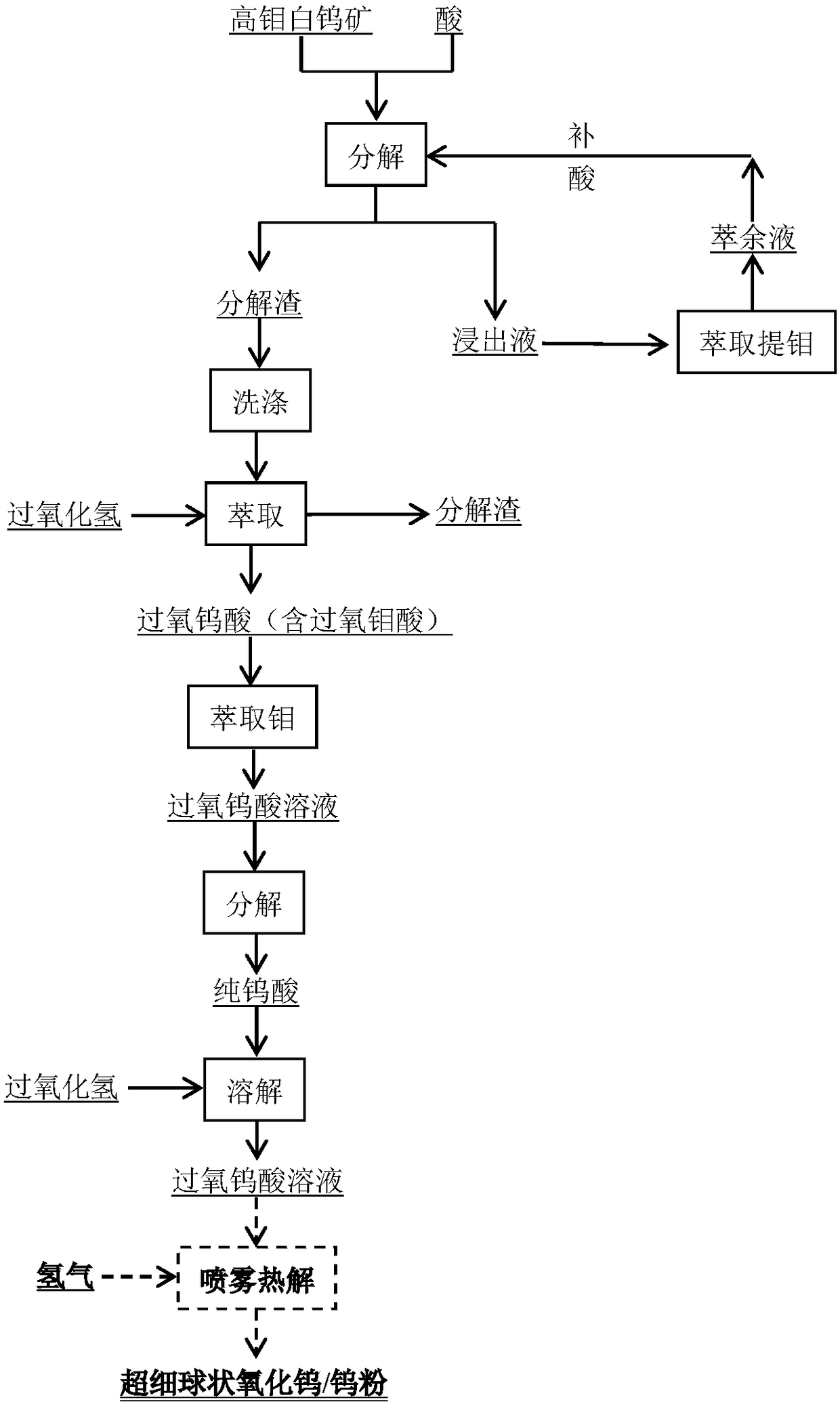

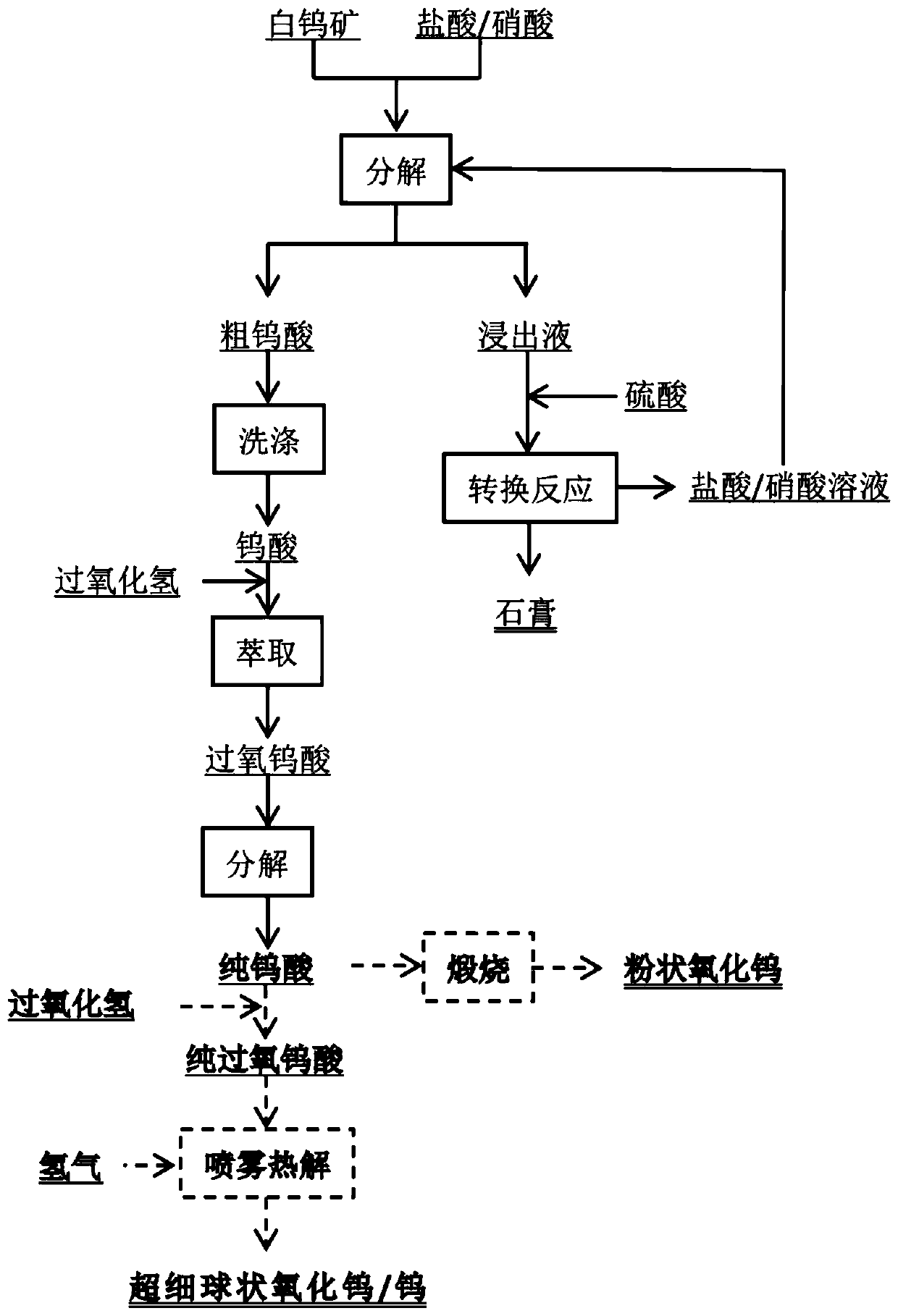

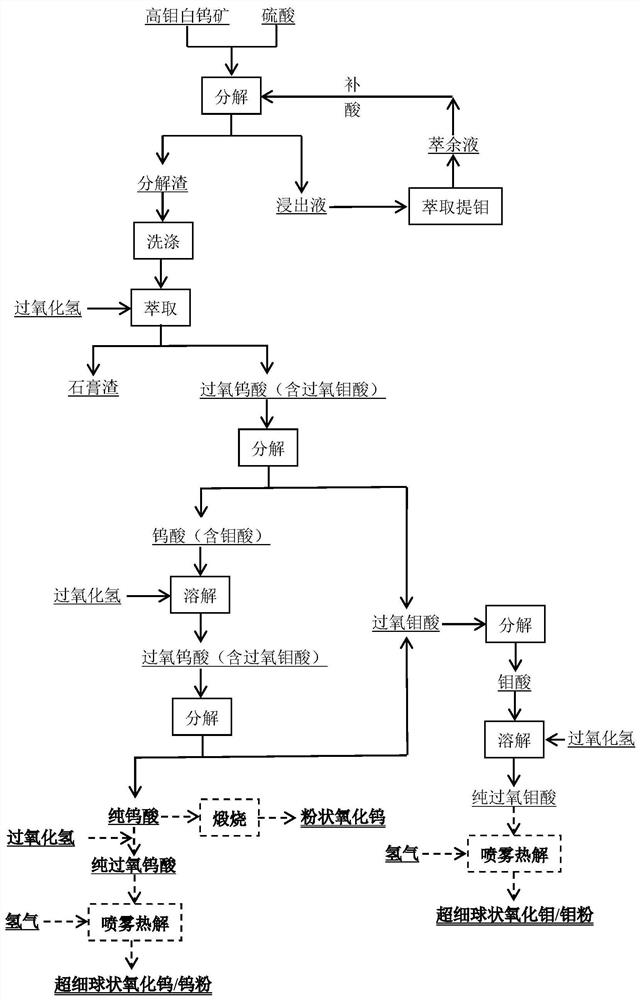

Method for extracting tungsten and molybdenum through acid decomposition of high-molybdenum scheelite

ActiveCN108425010AReduce break down costReduce manufacturing costProcess efficiency improvementDecompositionUltrasonic spray pyrolysis

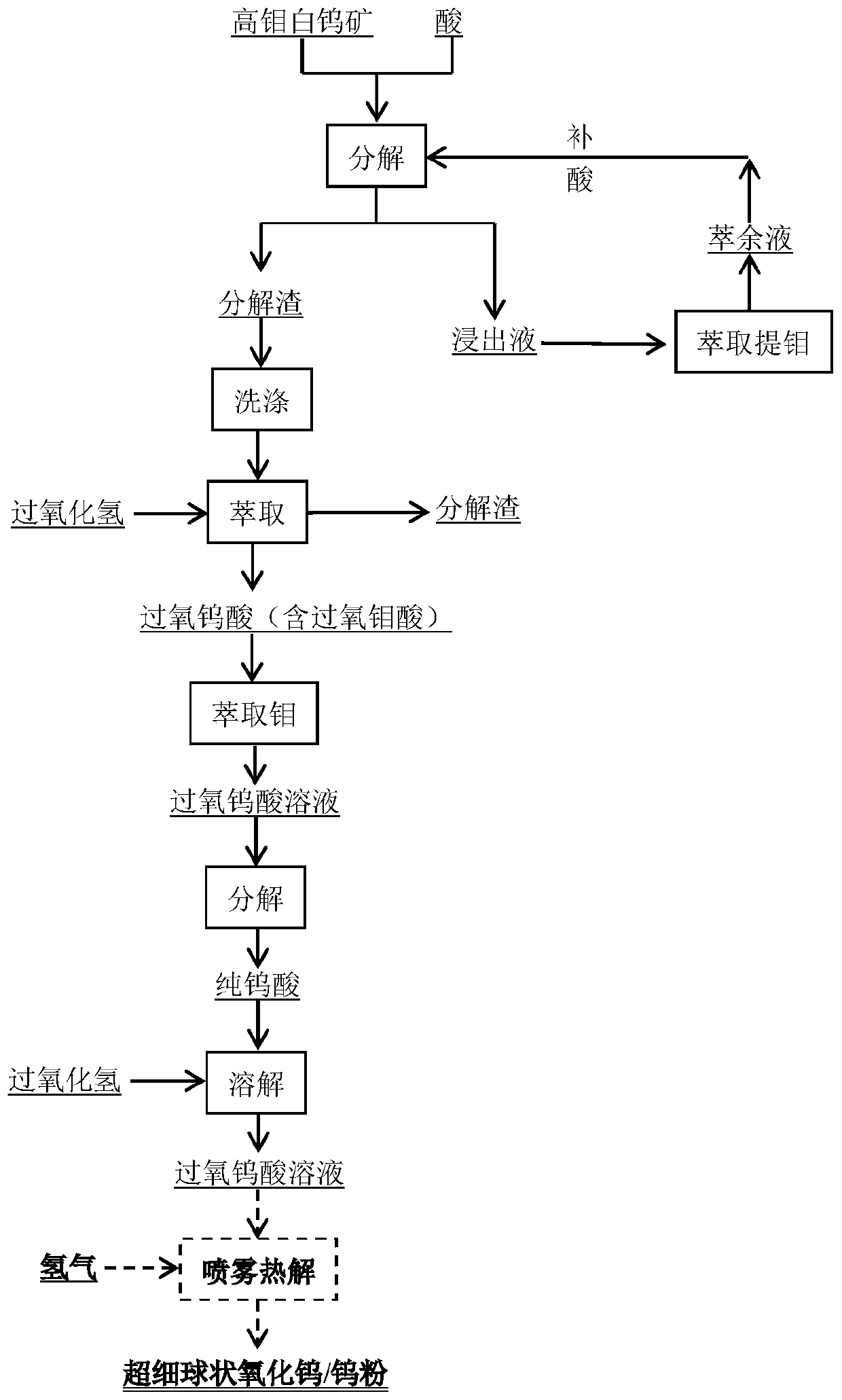

The invention relates to a method for extracting tungsten and molybdenum through acid decomposition of high-molybdenum scheelite. The method comprises the following steps: leaching the high-molybdenumscheelite with an acid solution, and extracting a leachate to extract molybdenum; extracting a leaching residue with hydrogen peroxide to obtain a solution containing peroxotungstic acid and peroxymolybdic acid, and heating or introducing SO2 to obtain tungstic acid and a solution containing the peroxomolybdic acid; extracting the tungstic acid with hydrogen peroxide, and heating or introducing SO2 to obtain tungstic acid and a solution containing the peroxomolybdic acid; repeating for several times till pure tungstic acid is obtained; preparing tungsten trioxide or tungsten powder from the pure tungstic acid; and heating or introducing SO2 into the solution containing the peroxomolybdic acid, dissolving obtained molybdic acid in a hydrogen peroxide solution to prepare a peroxomolybdic acid solution, and performing ultrasonic spraying pyrolysis to prepare molybdenum trioxide powder or molybdenum powder. By the method, the separation effect is good and the operation process is simple and easy to control, so that the method is easy to popularize and apply industrially.

Owner:CENT SOUTH UNIV

Method for producing ammonium sulfur and potassium-calcium-silicon fertilizer by using phosphogypsum

InactiveCN101792154ALow melting pointReduce break down costAmmonium salt fertilisersAmmonia compoundsPhosphogypsumDiammonium carbonate

The invention discloses a method for producing ammonium sulfur and potassium-calcium-silicon fertilizer by using phosphogypsum. The method comprises the followings steps of: adding solution of ammonium carbonate and dried phosphogypsum into a reaction kettle, and performing solid-liquid separation of the obtained pulp by a filter press after reaction; adjusting a pH value of filtrate to 5.6 to 6.0, performing concentration and crystallization of the filtrate and drying the crystals to obtain the fertilizer-graded ammonium sulfate products; washing filter cakes by water, putting the filter cakes in drying equipment, introducing tail gas in a roller kiln furnace to dry the materials, performing heat-exchange drying of the materials in the drying equipment, and using the dried filter cakes a raw material for producing the potassium-calcium-silicon fertilizer; and drying and grinding potassium feldspar and the phosphogypsum, mixing the powder of the potassium feldspar and the phosphogypsum and the dried filter cakes, putting the mixture in a ball mill, putting the mixture in the drying equipment for drying, continuously putting the mixture in the roller kiln furnace for calcining, performing a solid-phase reaction, cooling the reaction products, and dry-grinding and granulating the cooled reaction products to obtain the potassium-calcium-silicon fertilizer, wherein the tail gas in the roller kiln furnace enters the drying equipment to perform the heat-exchange drying of the materials. The method has the advantages of simple process, low raw material cost and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

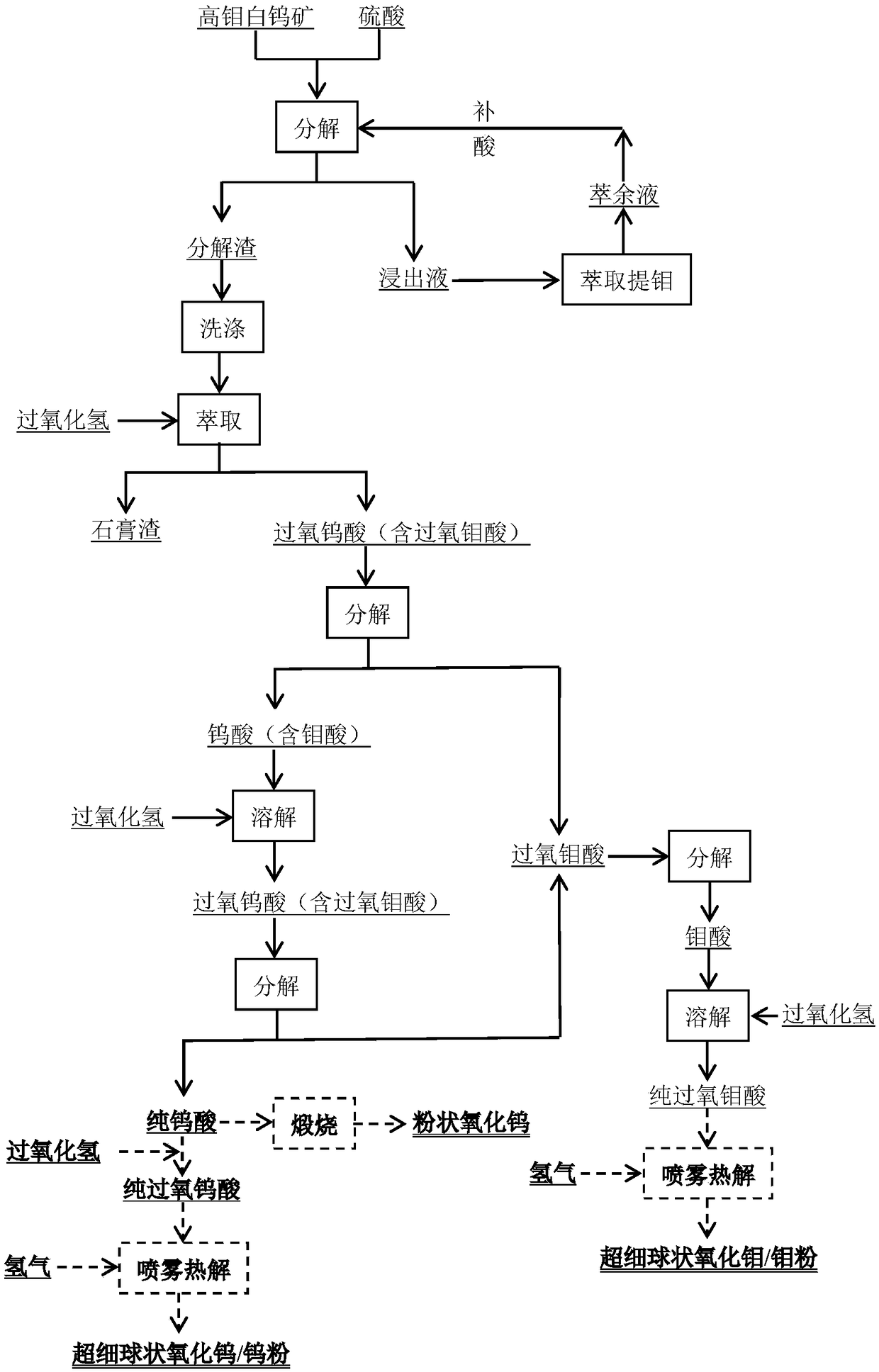

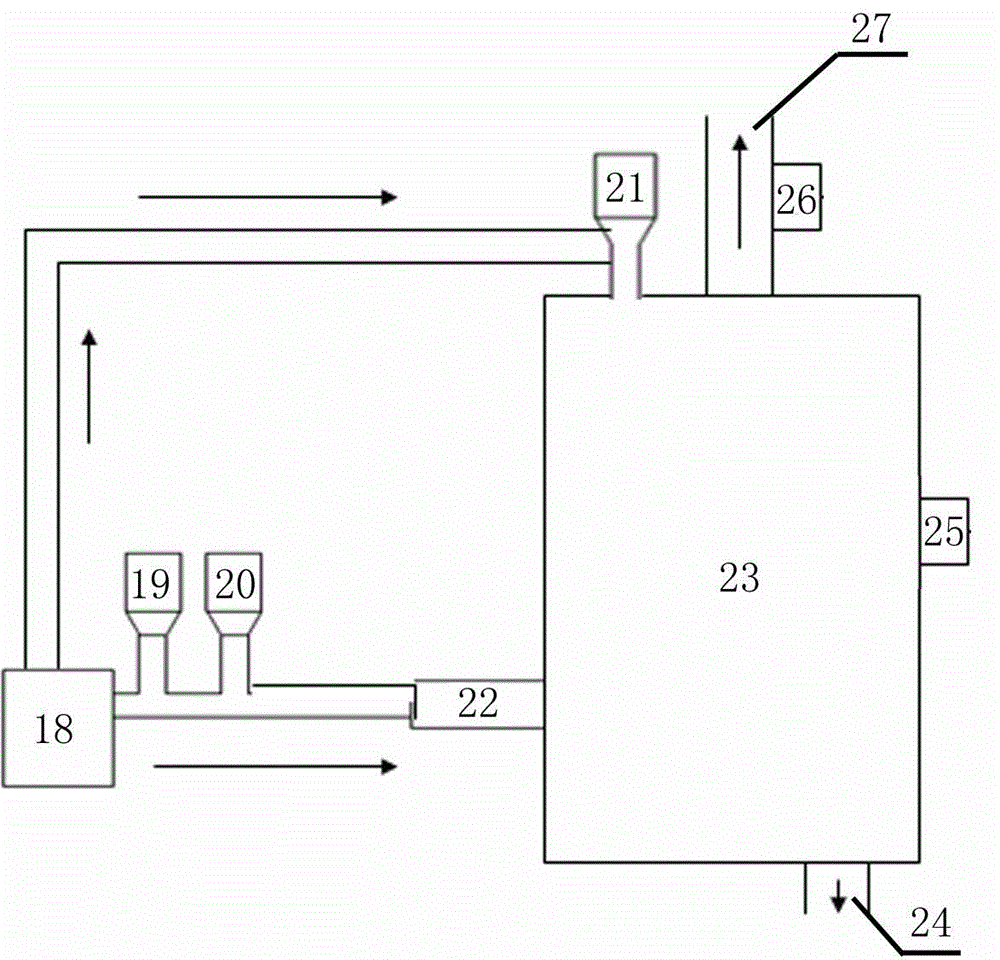

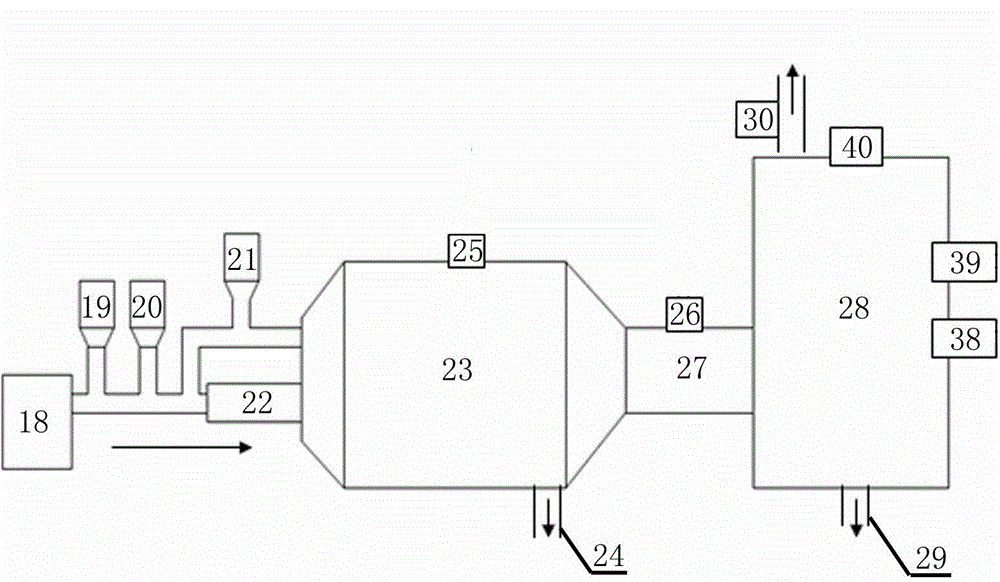

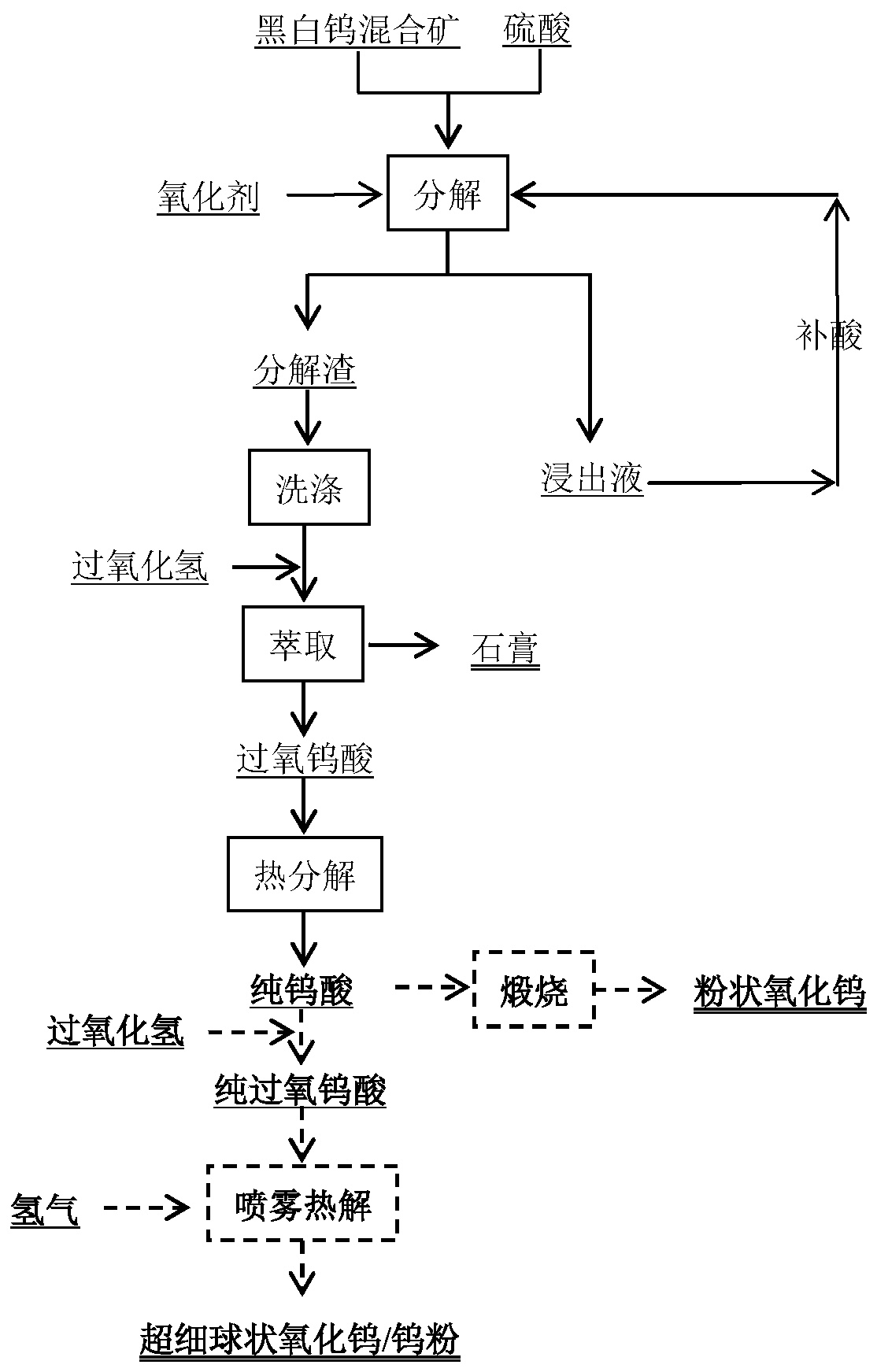

Method for extracting tungsten-molybdenum from high-molybdenum scheelite

ActiveCN108425011AReduce break down costReduce manufacturing costProcess efficiency improvementMolybdateTungstate

The invention relates to a method for extracting tungsten-molybdenum from high-molybdenum scheelite. The method comprises the following steps: leaching high-molybdenum scheelite with a sulfuric acid solution, and extracting molybdenum from the leaching liquid; extracting leaching residues with hydrogen peroxide so as to obtain a solution with peroxy-tungstate and peroxy-molybdate, and heating or introducing SO2 so as to obtain a solution with tungstate and peroxy-molybdate; dissolving the tungstate with hydrogen peroxide, heating the obtained solution, and introducing SO2 so as to obtain tungstate and a solution with peroxy-molybdate; repeating the operation for multiple times till pure tungstate is prepared; preparing tungsten trioxide or tungsten powder from the pure tungstate; heating the solution with the peroxy-molybdate, or introducing SO2, dissolving the obtained molybdate with a hydrogen peroxide solution so as to obtain a peroxy-molybdate solution, and performing ultrasonic spray pyrolysis, so as to obtain a molybdenum trioxide powder or a molybdate powder. The method is good in separation effect, simple in operation process, easy in operation process control, and easy inindustrial popularization and application.

Owner:CENT SOUTH UNIV

Method for decomposing scheelite through pressurizing by adopting phosphorus-sulfur mixed acid

The invention relates to a method for decomposing scheelite through pressurizing by adopting phosphorus-sulfur mixed acid. According to the main improved point, in the process of extracting the tungsten from the scheelite by using the mixed acid of phosphoric acid and sulfuric acid, pressurization treatment is carried out on a reaction system, so that the temperature of the reaction system is higher than 100 DEG C. According to the method, pressurized high-temperature treatment is carried out on the reaction system of extracting the tungsten from the scheelite by the phosphoric acid and the sulfuric acid, under the condition that the extraction rate of the tungsten is guaranteed, the addition amount of the phosphoric acid and the sulfuric acid is reduced, and the addition of calcium sulfate crystal seeds is omitted; and compared with an existing non-pressurization method, the method still has the advantages of being high in decomposition rate, free of generation of hazardous waste decomposition slag and low in decomposition cost.

Owner:CENT SOUTH UNIV

Method for extracting tungsten by pressurization decomposition on wolframite or black and white tungsten mixed ore through hydrochloric acid-phosphoric acid

ActiveCN108642307AEasy to produceReduce manufacturing costProcess efficiency improvementDecompositionPhosphoric acid

The invention relates to a method for extracting tungsten by pressurization decomposition on wolframite or black and white tungsten mixed ore through hydrochloric acid-phosphoric acid. The method is mainly characterized in that a reaction system is pressurized in the process of extracting tungsten from wolframite or the black and white tungsten mixed ore with mix acid of phosphoric acid and hydrochloric acid, so that the temperature of the reaction system is higher than 100 DEG C. According to the method, by pressurizing, calcium-containing compounds do not need to be added to conduct conversion on the black tungsten in the extracting process of the tungsten, that is, the tungsten can be directly extracted from wolframite or the black and white tungsten mixed ore, so that the production process is simplified, and the production cost is reduced.

Owner:CENT SOUTH UNIV

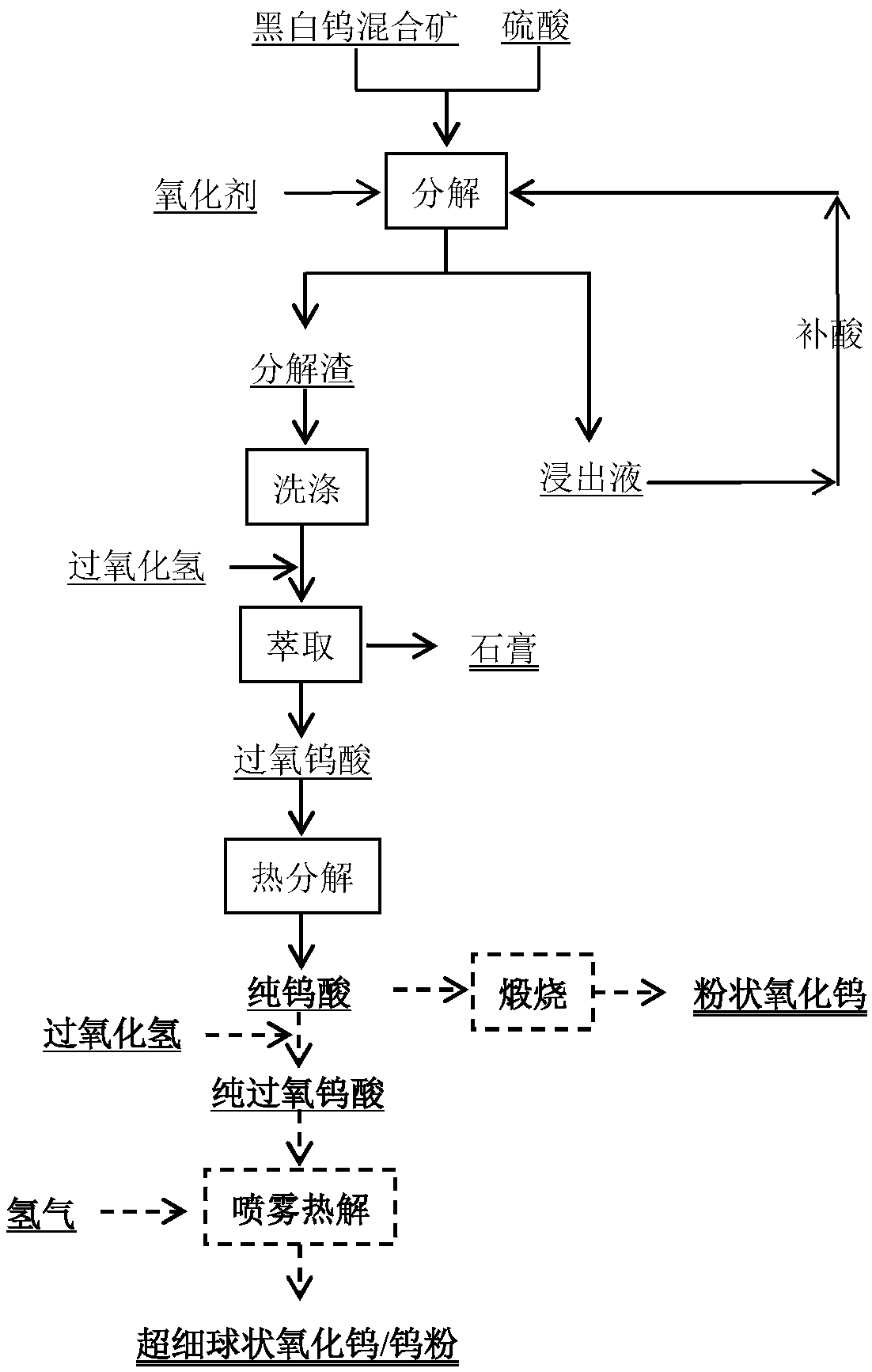

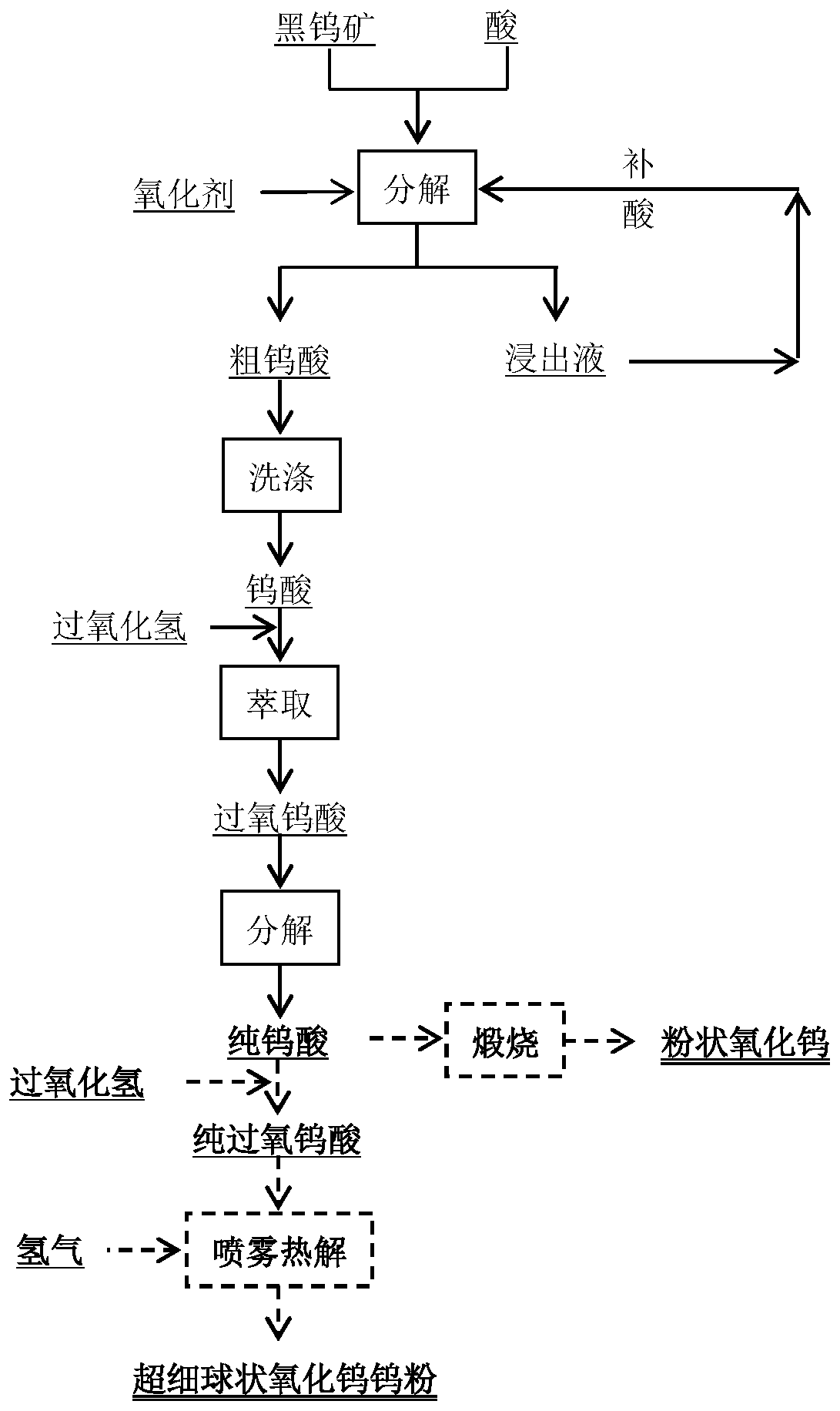

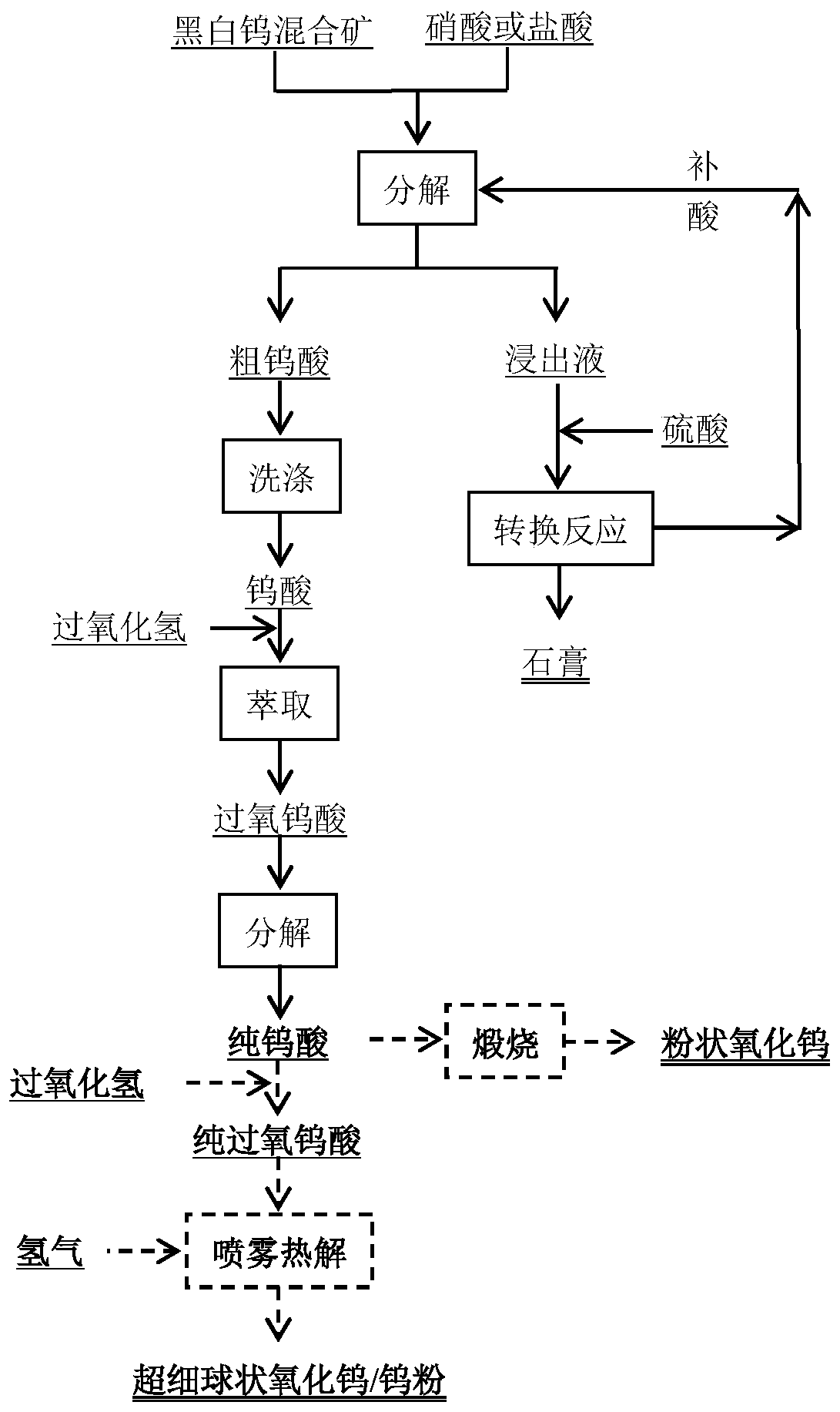

Method for preparing tungsten products through acid decomposition of wolframite and scheelite mixed ore

ActiveCN108559841AReduce break down costReduce manufacturing costProcess efficiency improvementDecompositionSlag

The invention relates to a method for preparing tungsten products through acid decomposition of wolframite and scheelite mixed ore. The wolframite and scheelite mixed ore serves as a raw material in the method, the method comprises the following steps that firstly, the leaching reaction is conducted; secondly, filtering and washing are conducted; thirdly, hydrogen peroxide extraction-decompositionare conducted for tungsten extraction; fourthly, multi-time hydrogen peroxide dissolving-decomposition are conducted for tungstic acid purification; fifthly, tungsten trioxide is prepared through pure tungstic acid roasting; and sixthly, a peroxotungstic acid solution is subjected to spray pyrolysis, and tungsten oxide and tungsten powder are prepared. According to the method, only the cheap sulfuric acid easy to obtain is consumed, and the wolframite and scheelite mixed ore decomposition cost is greatly reduced; the sulfuric acid is adopted for decomposition, decomposition slag is gypsum andcan be used as building materials, dangerous waste alkali boiling slag is not generated, and the enterprise producing and operating cost is greatly reduced; hydrogen peroxide is adopted as an extraction agent for tungstic acid, ammonia-nitrogen waste water is not produced, an ammonia-nitrogen waste water production technology used for many years for tungsten smelting is removed, and the environment protection cost is greatly reduced; and various tungsten terminal products and tungsten powder are directly produced, and the product added value of the tungsten smelting enterprise is improved.

Owner:CENT SOUTH UNIV

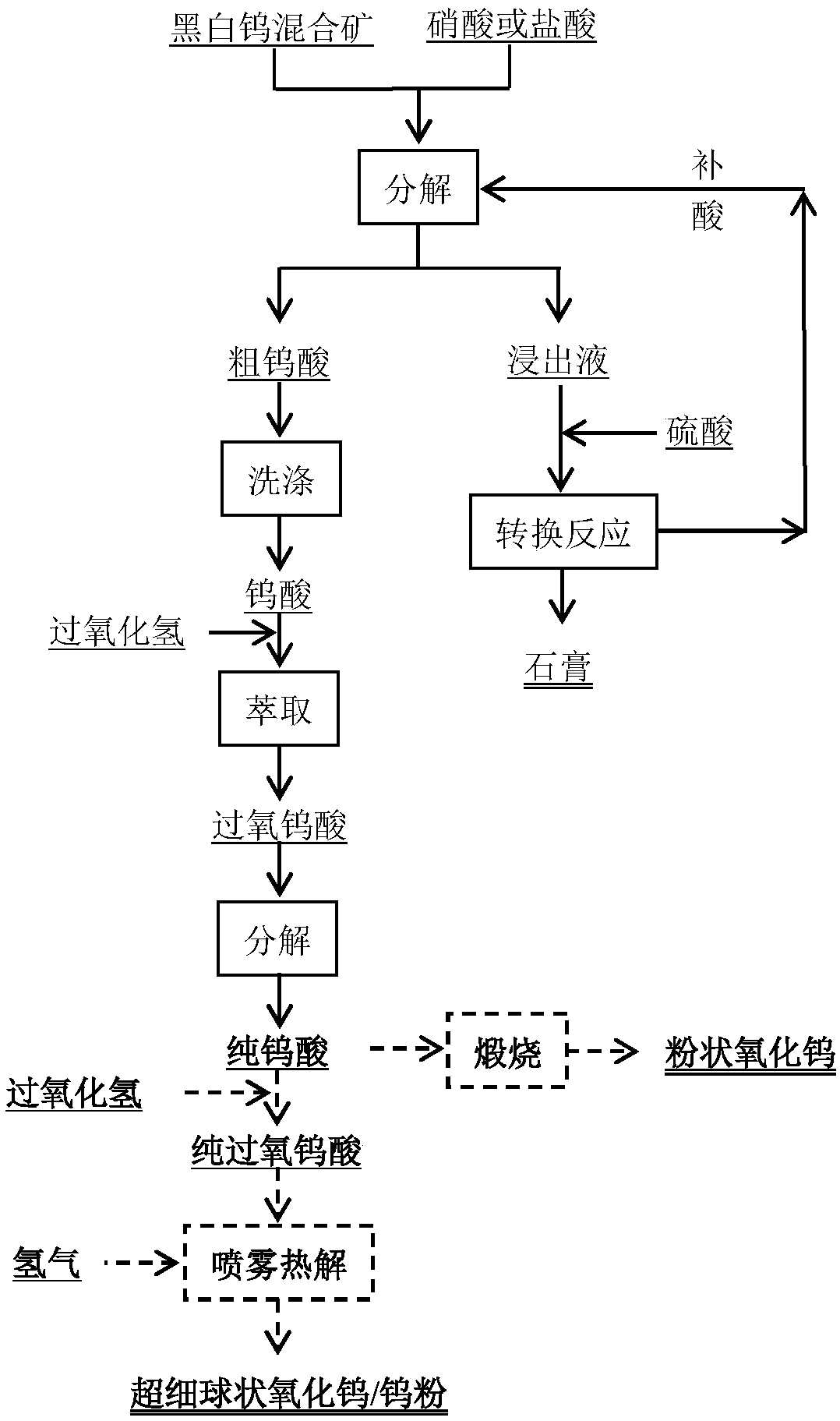

Method for carrying out acid decomposition on wolframite-scheelite mixed ore to prepare tungsten oxide and tungsten powder

ActiveCN108441629AReduce break down costReduce manufacturing costProcess efficiency improvementDecompositionDirect production

The invention relates to a method for carrying out acid decomposition on wolframite-scheelite mixed ore to prepare tungsten oxide and tungsten powder. According to the method, the wolframite-scheelitemixed ore is taken as a raw material, and the method comprises the following steps: (1) carrying out a leaching reaction; (2) carrying out filtering and washing; (3) carrying out extraction-decomposition through hydrogen peroxide to extract tungsten; (4) carrying out dissolution-decomposition through hydrogen peroxide for many times to purify tungsten acid; (5) calcining the pure tungsten acid toprepare tungsten trioxide; and (6) carrying out spray pyrolysis on peroxotungstic acid solution to prepare tungsten oxide and tungsten powder. According to the method disclosed by the invention, onlycheap and easily-available sulfuric acid is consumed actually, so that the decomposition cost for the wolframite-scheelite mixed ore is greatly lowered; the acid is used for decomposition, the decomposition slag is gypsum and can be used as a building material, and hazardous waste soda-boiling slag is not generated, so that the production and operation costs of an enterprise are greatly lowered;the hydrogen peroxide is used as an extraction agent for the tungsten acid, ammonia-nitrogen wastewater is not generated, and the process generating ammonia-nitrogen wastewater, which is used for manyyears, in tungsten smelting, is abolished, so that the environmental protection cost is greatly lowered; and the various terminal products of tungsten, and the tungsten powder are directly produced,so that the added value of products in the tungsten smelting enterprise is increased.

Owner:CENT SOUTH UNIV

Method for carrying out pressurization and reverse-flow decomposition on wolframite with mixed acid of phosphoric acid and sulfuric acid

The invention relates to a method for carrying out pressurization and reverse-flow decomposition on wolframite with mixed acid of phosphoric acid and sulfuric acid. According to the method, the main improvements are that a reaction system is pressurized and the temperature is controlled to be higher than 100 DEG C in the process of extracting tungsten from wolframite powder with the mixed acid ofphosphoric acid and sulfuric acid, and a reverse-flow decomposition method is adopted in the operation process. According to the method, by pressurizing, calcium-containing compounds do not need to beadded to conduct conversion on the wolframite in the extracting process of the tungsten, the tungsten can be directly extracted from the high-tin wolframite or a high-tin black and white tungsten mixed ore, so that the production process is simplified, and the production cost is reduced; and through the process of reverse-flow decomposition, the mixed acid can be recycled, and the production costis further reduced.

Owner:CENT SOUTH UNIV

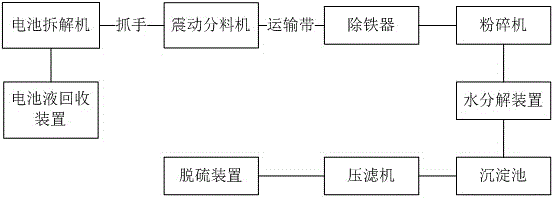

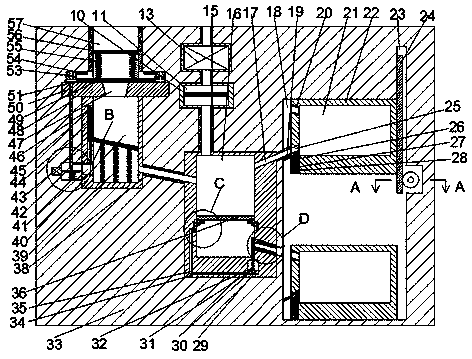

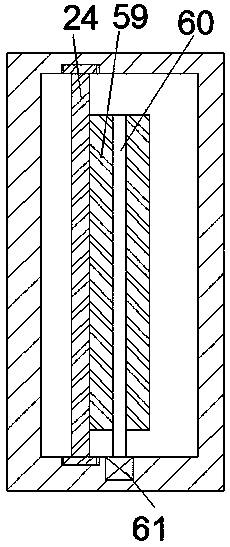

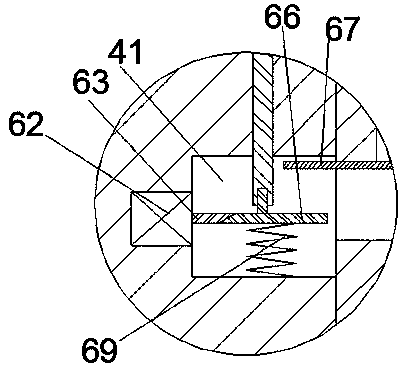

System for disassembling waste battery

InactiveCN104577245AAvoid churnAvoid pollutionWaste accumulators reclaimingBattery recyclingDecompositionSulfur

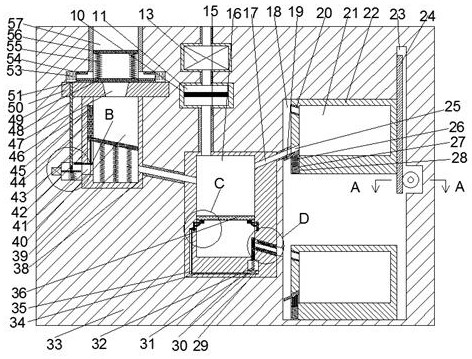

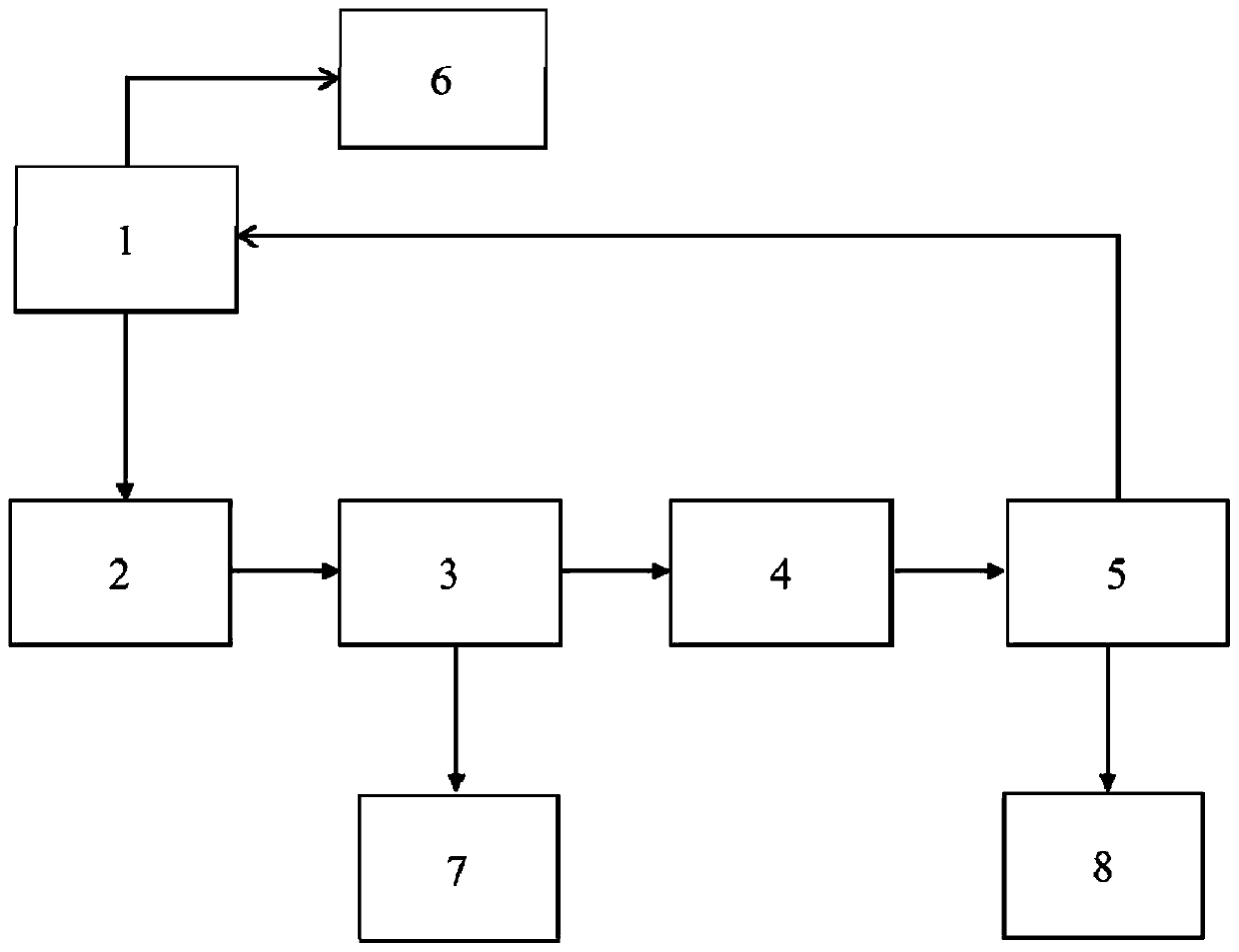

The invention relates to the field of battery disassembly and in particular relates to a system for disassembling a waste battery. The system comprises a battery fluid recycling pool, a battery disassembling machine, a vibrating separator, an iron remover, a crusher, a water decomposition device, a settling pond, a filter press and a sulfur removal device, wherein the battery fluid recycling pool is positioned below the battery disassembling machine; transportation is performed between the battery disassembling machine and the vibrating separator by virtue of a grip; the vibrating separator is connected with the crusher by virtue of a conveyer belt; and the iron remover is arranged on the conveyer belt. According to the method for disassembling the waste battery in the invention, the operation is simple, mechanical disassembly is performed in the disassembling process, the manual labor is avoided, the disassembling efficiency is improved, resource loss and environmental pollution are avoided, and battery fragments are repeatedly separated by utilizing water cycle, so that the components in the fragments are reasonably separated. Therefore, the regenerated lead post-production energy consumption is low, and the disassembly cost is low.

Owner:ANHUI HUAXIN LEAD IND GROUP

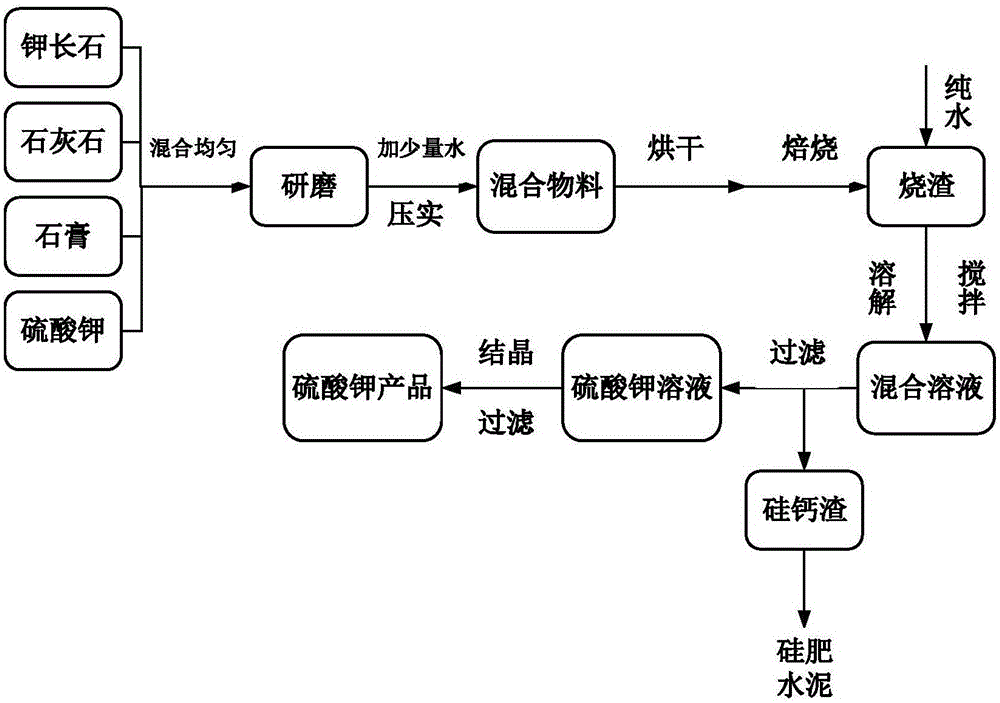

Method for extracting potassium from potassium feldspar through calcium-based quaternary roasting treatment

The invention provides a method for extracting potassium from potassium feldspar through calcium-based quaternary roasting treatment.The method includes the following steps that firstly, roasting of mixed materials is carried out, wherein 50-100-mesh potassium feldspar particles are adopted, limestone is added at the proportion of 1:1-1:3, then calcium sulfate is added at the proportion of 1:2-1:4, sodium sulfate serves as an additive with the addition quantity of 3%-7%, the mixed materials are mixed evenly and ground into 100-200-mesh particles, roasting is carried out at 800-1200 DEG C, the reaction time is controlled to be 1-3 h, and slag is obtained; secondly, crystallization of a potassium sulfate solution is carried out, wherein the slag is dissolved with pure water at 400-100 DEG C and stirred for 1-3 h, filtering is carried out, and potassium sulfate filter liquor is obtained; the filter liquor is crystallized, filtered and dried in sequence, and potassium sulfate is obtained.The method is simple in process, low in energy consumption and suitable for large-scale production.

Owner:WUHAN UNIV OF TECH

A method for extracting tungsten by decomposing wolframite or black and white tungsten mixed ore under pressure with sulfur-phosphorus mixed acid

ActiveCN108642278BEasy to produceReduce manufacturing costProcess efficiency improvementO-Phosphoric AcidPhysical chemistry

Owner:CENT SOUTH UNIV

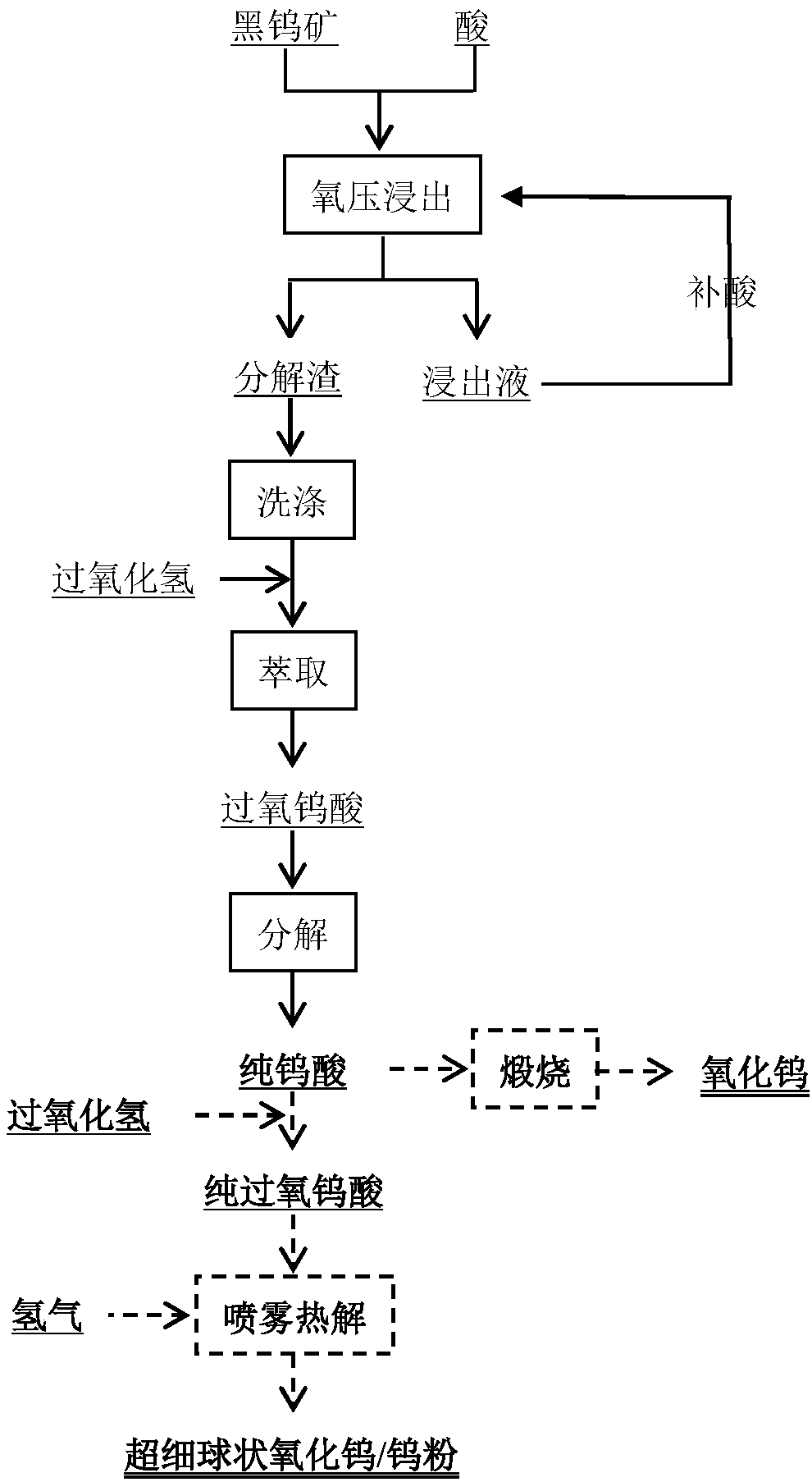

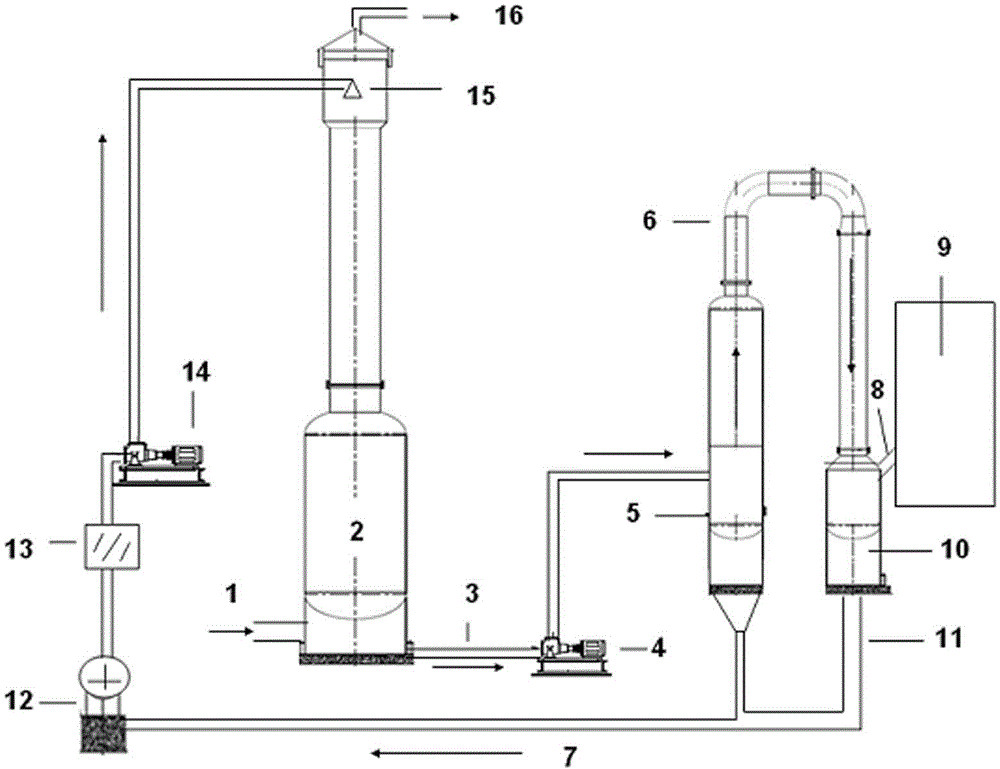

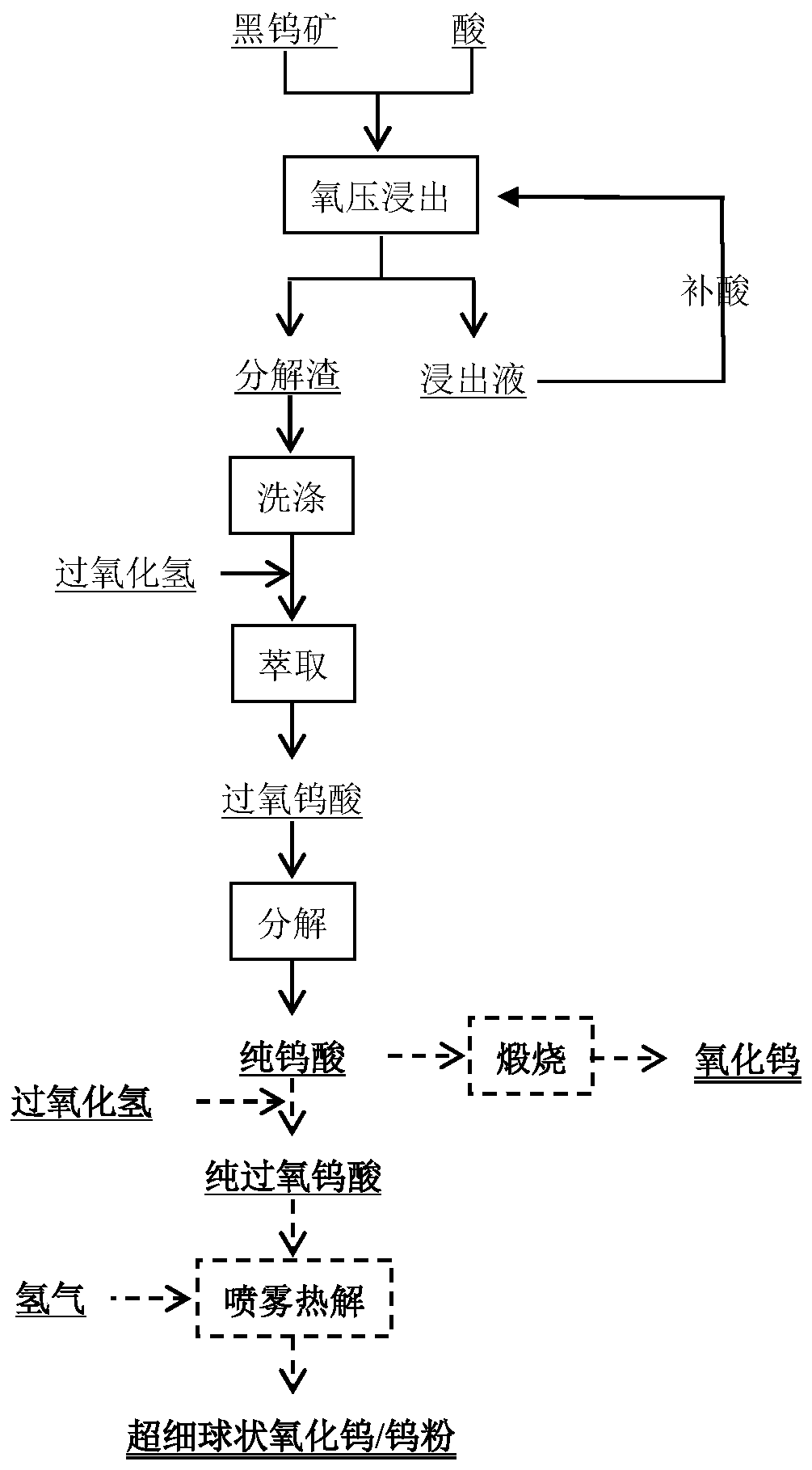

Method for oxygen-pressing and decomposing wolframite and preparing tungsten oxide and tungsten powder

ActiveCN108611503AReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementSlagDecomposition

The invention relates to a method for oxygen-pressing and decomposing wolframite and preparing tungsten oxide and tungsten powder. The method takes wolframite as a raw material and comprises the following steps of: (1) performing oxygen-pressing and leaching reaction; (2) filtering and washing; (3) performing hydrogen peroxide extraction and decomposing extracted tungsten; (4) performing hydrogenperoxide multi-time extraction and decomposing and purifying tungstic acid; (5) roasting pure tungstic to prepare tungsten trioxide; and (6) spraying a tungsten acid peroxide solution and performing pyrolysis to prepare tungsten oxide and tungsten powder. An acid decomposition reagent adopted by the method is cheap and easily available, so that tungsten ore decomposition cost is greatly reduced; acid is adopted to decompose under an oxygen-pressure condition, so that hazardous waste alkali cleaning slag is not generated, and enterprise production and operation cost is greatly reduced; hydrogenperoxide is adopted as an extracting agent of tungstic acid, so that ammonia-nitrogen wastewater is not generated, the process of using ammonia-nitrogen wastewater generated by many years by tungstensmelting is abolished, and environment-friendly cost is greatly reduced; and various tungsten terminal products (tungsten oxide) and tungsten are directly generated, so that the product additional value of tungsten smelting enterprises is increased.

Owner:CENT SOUTH UNIV

Preparation method for carbon dioxide capture and catalytic recycling

ActiveCN103143247BIncrease capture rateImprove conversion rateDispersed particle separationAir quality improvementCombustionActive agent

The invention relates to the field of utilization and conversion of carbon dioxide, in particular to a preparation method of gathering and catalytic cyclic utilization of carbon dioxide. The method includes that carbon dioxide which is gathered from smoke and generated through pyrolysis is catalyzed by high-power plasma to generate carbon monoxide, and the carbon monoxide is gathered and recycled after being used for combustion or industrial application. The method had the advantages that through the synergistic effect of carbonic acid, catalysts, active agents, the gathering efficiency of the carbon dioxide is obviously promoted, the carbon dioxide is decomposed by solution rapidly to reduce decomposition cost, under the synergistic effect of the plasma, the catalysts and the active agents, the conversion temperature of the carbon dioxide is obviously reduced, the conversion ratio of the carbon dioxide is obviously promoted, the method is energy-saving and environment-friendly, saves fire coal by 10-85% and achieves near zero release of the carbon dioxide, the equipment investment is small, the carbon dioxide resource can be gathered, converted and recycled by a large amount, and the method is suitable for large-scale energy conservation and environmental protection in the major coal consumption industries.

Owner:浙江森井生物技术股份有限公司

A method for decomposing high-tin tungsten ore under pressure with sulfur-phosphorus mixed acid

ActiveCN108642308BEasy to produceReduce manufacturing costProcess efficiency improvementO-Phosphoric AcidSlag

The invention relates to a method for pressurizing decomposing a high-tin tungsten ore with mixed acid of phosphoric acid and sulfuric acid. According to the method, the improvements comprise the following that a reaction system is pressurized and the temperature of the reaction system is 110-250 DEG C in the process of extracting tungsten from a high-tin wolframite ore or high-tin black and whitetungsten mixed ore with the mixed acid of phosphoric acid and sulfuric acid, and tin concentrate can be obtained directly or through the ore dressing process from decomposed slag with the tungsten being already extracted. According to the method, by pressurizing, calcium-containing compounds do not need to be added to conduct conversion on the wolframite in the extracting process of the tungsten,the tungsten can be directly extracted from wolframite or the black and white tungsten mixed ore, meanwhile, the tin concentrate is obtained, so that the production process is simplified, and the production cost is reduced.

Owner:CENT SOUTH UNIV

A method of carbon dioxide capture and pyrolysis

The invention relates to the field of emission reduction and conversion of carbon dioxide, in particular to a trapping and pyrolysis method for carbon dioxide. The carbon dioxide in smoke is converted into a sodium bicarbonate solution by a sodium carbonate solution in a carbonizer, and a pyrolyzer resolves high-purity carbon dioxide quickly. The pollution due to excessive carbon dioxide generated when fossil fuel is burnt is avoided, and energy conservation, environmental protection, energy crisis reduction and greenhouse effect reduction are realized. The method has the benefits that (1) the trapping rate of the carbon dioxide is significantly increased by the synergistic action of sodium carbonate, a catalyst and an activating agent; (2) the solution decomposes the carbon dioxide quickly, and the dissociation cost is lowered; and (3) the equipment investment is low, a large amount of carbon dioxide can be trapped and pyrolyzed, near zero release of the carbon dioxide can be realized, and the method is suitable for key coal-consumption industries of coal power, coal chemistry, steel, cement, papermaking, metallurgy, printing and dyeing, chemical engineering and the like to trap, recover and apply carbon dioxide resources on a large scale, and reduces the greenhouse effect.

Owner:浙江森井生物技术股份有限公司

A kind of method that acid decomposes scheelite to prepare tungsten oxide and tungsten powder

ActiveCN108642276BReduce break down costReduce manufacturing costProcess efficiency improvementSlagMaterials science

Owner:CENT SOUTH UNIV

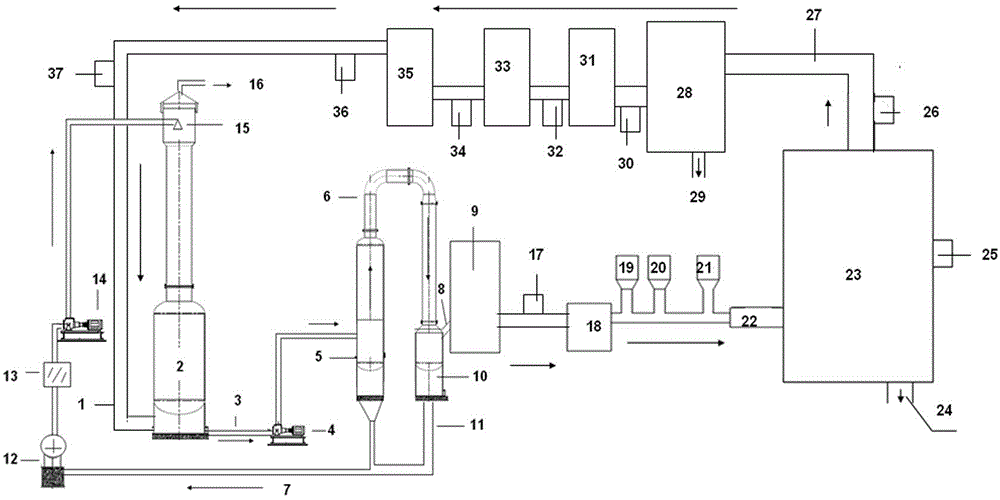

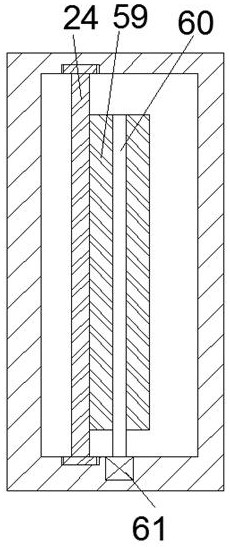

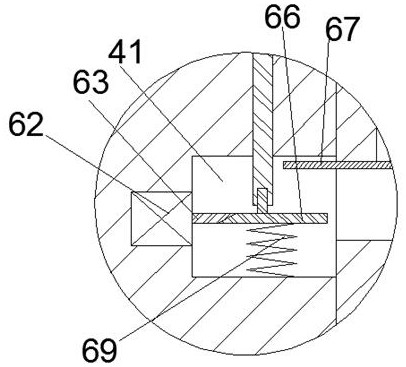

A recycling device for waste mobile terminals

ActiveCN111229788BReduce manual dependenceImprove efficiencySolid waste disposalStationary filtering element filtersToxic gasGear wheel

The invention discloses a recovery device for waste mobile terminals, which includes an outer shell, a circulation cavity is arranged in the outer shell, and a rack is slidingly installed in the front and rear end walls on the right side of the cycle cavity, and the right side of the rack is The side rack and pinion are connected with gears, the gears are fixedly installed on the shaft, and the motor is fixedly installed in the front wall of the circulation chamber. This device is less dependent on labor and has high efficiency. When a large number of waste mobile terminals are piled up, they are sent to the separation chamber through the transmission channel for decomposition, which greatly saves the decomposition cost, and there is a circulation component, and an air purification device is installed at the exhaust to filter toxic gases.

Owner:泰安智慧谷产业园运营管理有限公司

A method for extracting tungsten and molybdenum from acid-decomposed high-molybdenum scheelite

ActiveCN108425010BReduce break down costReduce manufacturing costProcess efficiency improvementPhysical chemistryUltrasonic spray pyrolysis

The invention relates to a method for acid-decomposing high-molybdenum scheelite to extract tungsten and molybdenum, comprising: leaching the high-molybdenum scheelite with an acid solution, extracting molybdenum from the leach solution; Solution of tungstic acid and peroxymolybdic acid, heating or passing through SO 2 , to obtain tungstic acid and a solution containing peroxymolybdic acid; extract tungstic acid with hydrogen peroxide, heat or pass through SO 2 , to obtain tungstic acid and a solution containing peroxymolybdic acid; repeat several times until pure tungstic acid is obtained; prepare tungsten trioxide or tungsten powder from pure tungstic acid; heat the solution containing peroxymolybdic acid or pass through SO 2 , dissolving the obtained molybdenum acid with hydrogen peroxide solution to obtain a peroxymolybdenum acid solution, and ultrasonic spray pyrolysis to prepare molybdenum trioxide powder or molybdenum powder. The method has good separation effect, simple and easy-to-control operation process, and easy industrial popularization and application.

Owner:CENT SOUTH UNIV

A method for decomposing wolframite under oxygen pressure and preparing tungsten oxide and tungsten powder

ActiveCN108611503BReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementSlagMaterials science

The invention relates to a method for oxygen-pressing and decomposing wolframite and preparing tungsten oxide and tungsten powder. The method takes wolframite as a raw material and comprises the following steps of: (1) performing oxygen-pressing and leaching reaction; (2) filtering and washing; (3) performing hydrogen peroxide extraction and decomposing extracted tungsten; (4) performing hydrogenperoxide multi-time extraction and decomposing and purifying tungstic acid; (5) roasting pure tungstic to prepare tungsten trioxide; and (6) spraying a tungsten acid peroxide solution and performing pyrolysis to prepare tungsten oxide and tungsten powder. An acid decomposition reagent adopted by the method is cheap and easily available, so that tungsten ore decomposition cost is greatly reduced; acid is adopted to decompose under an oxygen-pressure condition, so that hazardous waste alkali cleaning slag is not generated, and enterprise production and operation cost is greatly reduced; hydrogenperoxide is adopted as an extracting agent of tungstic acid, so that ammonia-nitrogen wastewater is not generated, the process of using ammonia-nitrogen wastewater generated by many years by tungstensmelting is abolished, and environment-friendly cost is greatly reduced; and various tungsten terminal products (tungsten oxide) and tungsten are directly generated, so that the product additional value of tungsten smelting enterprises is increased.

Owner:CENT SOUTH UNIV

A method of acid decomposition of black and white tungsten mixed ore to prepare tungsten products

ActiveCN108559841BReduce break down costReduce manufacturing costProcess efficiency improvementSlagMaterials science

The invention relates to a method for preparing tungsten products through acid decomposition of wolframite and scheelite mixed ore. The wolframite and scheelite mixed ore serves as a raw material in the method, the method comprises the following steps that firstly, the leaching reaction is conducted; secondly, filtering and washing are conducted; thirdly, hydrogen peroxide extraction-decompositionare conducted for tungsten extraction; fourthly, multi-time hydrogen peroxide dissolving-decomposition are conducted for tungstic acid purification; fifthly, tungsten trioxide is prepared through pure tungstic acid roasting; and sixthly, a peroxotungstic acid solution is subjected to spray pyrolysis, and tungsten oxide and tungsten powder are prepared. According to the method, only the cheap sulfuric acid easy to obtain is consumed, and the wolframite and scheelite mixed ore decomposition cost is greatly reduced; the sulfuric acid is adopted for decomposition, decomposition slag is gypsum andcan be used as building materials, dangerous waste alkali boiling slag is not generated, and the enterprise producing and operating cost is greatly reduced; hydrogen peroxide is adopted as an extraction agent for tungstic acid, ammonia-nitrogen waste water is not produced, an ammonia-nitrogen waste water production technology used for many years for tungsten smelting is removed, and the environment protection cost is greatly reduced; and various tungsten terminal products and tungsten powder are directly produced, and the product added value of the tungsten smelting enterprise is improved.

Owner:CENT SOUTH UNIV

A method for extracting tungsten by acid decomposition wolframite

ActiveCN108677037BReduce break down costReduce environmental costsTungsten compounds preparationTungsten oxides/hydroxidesEngineeringCalcination

The invention relates to a method for extracting tungsten by acid-decomposing wolframite. The method uses wolframite as a raw material and comprises the following steps: (1) leaching reaction; (2) filtering and washing; (3) hydrogen peroxide extraction-decomposition extraction Tungsten; (4) Multiple dissolution of hydrogen peroxide-decomposition and purification of tungsten acid; (5) Calcination of pure tungstic acid to prepare tungsten trioxide; (6) Spray pyrolysis of peroxytungstic acid solution to prepare tungsten oxide and tungsten powder. In fact, only a small amount of nitric acid or hydrochloric acid is consumed in the decomposition process of the method of the present invention, and cheap and easily available sulfuric acid is mainly consumed, which greatly reduces the cost of tungsten ore decomposition; the present invention uses hydrogen peroxide as the extraction agent of tungstic acid, and does not produce ammonia nitrogen Wastewater eliminates the process of producing ammonia nitrogen wastewater that has been used for many years in tungsten smelting, greatly reducing environmental protection costs; the invention directly produces various tungsten end products (tungsten oxide and tungsten powder), which improves the added value of products for tungsten smelting enterprises.

Owner:CENT SOUTH UNIV

A method for extracting tungsten and molybdenum from high-molybdenum scheelite

ActiveCN108425011BReduce break down costReduce manufacturing costProcess efficiency improvementPhysical chemistryUltrasonic spray pyrolysis

The invention relates to a method for extracting tungsten and molybdenum from high-molybdenum scheelite, comprising: leaching high-molybdenum scheelite with sulfuric acid solution, extracting molybdenum from the leaching solution; extracting leaching slag with hydrogen peroxide to obtain peroxide-containing Solution of tungstic acid and peroxymolybdic acid, heating or passing through SO 2 , to obtain tungstic acid and a solution containing peroxymolybdic acid; dissolve tungstic acid with hydrogen peroxide, and heat the resulting solution or pass through SO 2 , to obtain tungstic acid and a solution containing peroxymolybdic acid; repeat several times until pure tungstic acid is obtained; prepare tungsten trioxide or tungsten powder from pure tungstic acid; heat the solution containing peroxymolybdic acid or pass through SO 2 , dissolving the obtained molybdenum acid with hydrogen peroxide solution to obtain a peroxymolybdenum acid solution, and ultrasonic spray pyrolysis to prepare molybdenum trioxide powder or molybdenum powder. The method has good separation effect, simple and easy-to-control operation process, and easy industrial popularization and application.

Owner:CENT SOUTH UNIV

A method for extracting tungsten by decomposing wolframite or black and white tungsten mixed ore under pressure with hydrochloric acid-phosphoric acid

ActiveCN108642307BEasy to produceReduce manufacturing costProcess efficiency improvementO-Phosphoric AcidPhysical chemistry

The invention relates to a method for extracting tungsten by decomposing wolframite or black-and-white tungsten mixed ore under pressure with hydrochloric acid-phosphoric acid. During the process of extracting tungsten from China, the reaction system is pressurized so that the temperature is higher than 100°C. The present invention can directly extract tungsten from wolframite or the mixed ore of black and white tungsten without adding additional calcium-containing compounds to transform wolframite during the process of extracting tungsten by applying pressure, which simplifies the production process. Reduced production costs.

Owner:CENT SOUTH UNIV

A method of using struvite to remove ammonia and recycle gypsum at the same time

ActiveCN110240242BReduce break down costAvoid it happening againWater contaminantsCalcium/strontium/barium sulfatesCalcium hydroxideEnvironmental engineering

The invention relates to a method for circularly removing ammonia and recycling gypsum by using struvite. The method comprises the following steps: S1: dissolving calcium hydroxide and struvite in water, and stirring while heating until water is all evaporated, to obtain solid; S2: dissolving the solid in water, stirring and adding sulfuric acid to obtain a solid-liquid mixture; S3: separating the solid-liquid mixture; taking the supernate and adding into ammonia-nitrogen wastewater for treatment; performing solid-liquid separation, and cleaning to obtain solid which is gypsum; S4: adding ammonia-nitrogen wastewater into the supernate after the solid-liquid separation in S3, and stirring; adding magnesium oxide; standing for solid-liquid separation to obtain solid which is struvite, namely the source of struvite in S1; S5: repeating S1 to S4 for circular removal of ammonia as well as recovery of gypsum. By adopting the method provided by the invention in treatment of ammonia-nitrogen wastewater, the concentration of ammonia and nitrogen in the yielding water is stable, the removal rate of ammonia and nitrogen can reach 90% or more, and the concentration of phosphorous in the yielding water is less than 1mg / L; moreover, a high-purity gypsum product can be recycled.

Owner:DONGGUAN UNIV OF TECH

A kind of method that acid decomposes black and white tungsten mixed ore to prepare tungsten oxide and tungsten powder

ActiveCN108441629BReduce break down costReduce manufacturing costProcess efficiency improvementSlagMaterials science

Owner:CENT SOUTH UNIV

A method for decomposing scheelite under pressure with phosphorus-sulfur mixed acid

ActiveCN108707765BGuaranteed withdrawal rateAdd lessProcess efficiency improvementO-Phosphoric AcidSlag

The invention relates to a method for decomposing scheelite through pressurizing by adopting phosphorus-sulfur mixed acid. According to the main improved point, in the process of extracting the tungsten from the scheelite by using the mixed acid of phosphoric acid and sulfuric acid, pressurization treatment is carried out on a reaction system, so that the temperature of the reaction system is higher than 100 DEG C. According to the method, pressurized high-temperature treatment is carried out on the reaction system of extracting the tungsten from the scheelite by the phosphoric acid and the sulfuric acid, under the condition that the extraction rate of the tungsten is guaranteed, the addition amount of the phosphoric acid and the sulfuric acid is reduced, and the addition of calcium sulfate crystal seeds is omitted; and compared with an existing non-pressurization method, the method still has the advantages of being high in decomposition rate, free of generation of hazardous waste decomposition slag and low in decomposition cost.

Owner:CENT SOUTH UNIV

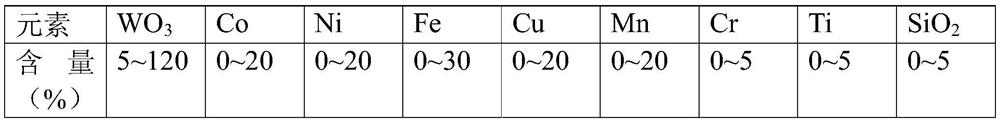

Hard alloy waste recovery method

ActiveCN113403470AReduce consumptionEasy to operateProcess efficiency improvementCalcium silicateSilicic acid

The invention relates to a hard alloy waste recovery method. Hard alloy waste contains elemental tungsten and / or tungsten carbide. The method comprises the following steps that 1, the hard alloy waste is mixed with sodium silicate and an additive to obtain a mixture, wherein the additive contains at least one of calcium element or magnesium element; 2, the mixture is roasted at the temperature of 400-1000 DEG C for 1-24 h, a roasted material is obtained, and in the roasting process, the elemental tungsten and / or the tungsten carbide in the hard alloy waste, the sodium silicate and the additive react under the high-temperature condition to generate sodium tungstate and calcium silicate and / or magnesium silicate; and 3, the roasted material is subjected to water leaching, a solid-liquid mixture is obtained, filter residues are removed after solid-liquid separation, and a sodium tungstate solution is obtained. The method is simple to operate, low in input cost, low in reagent consumption, low in decomposition cost, free of the problem of a roasting furnace bonding at the same time, high in tungsten recovery rate, suitable for industrial production and great in popularization significance.

Owner:XIAMEN TUNGSTEN +1

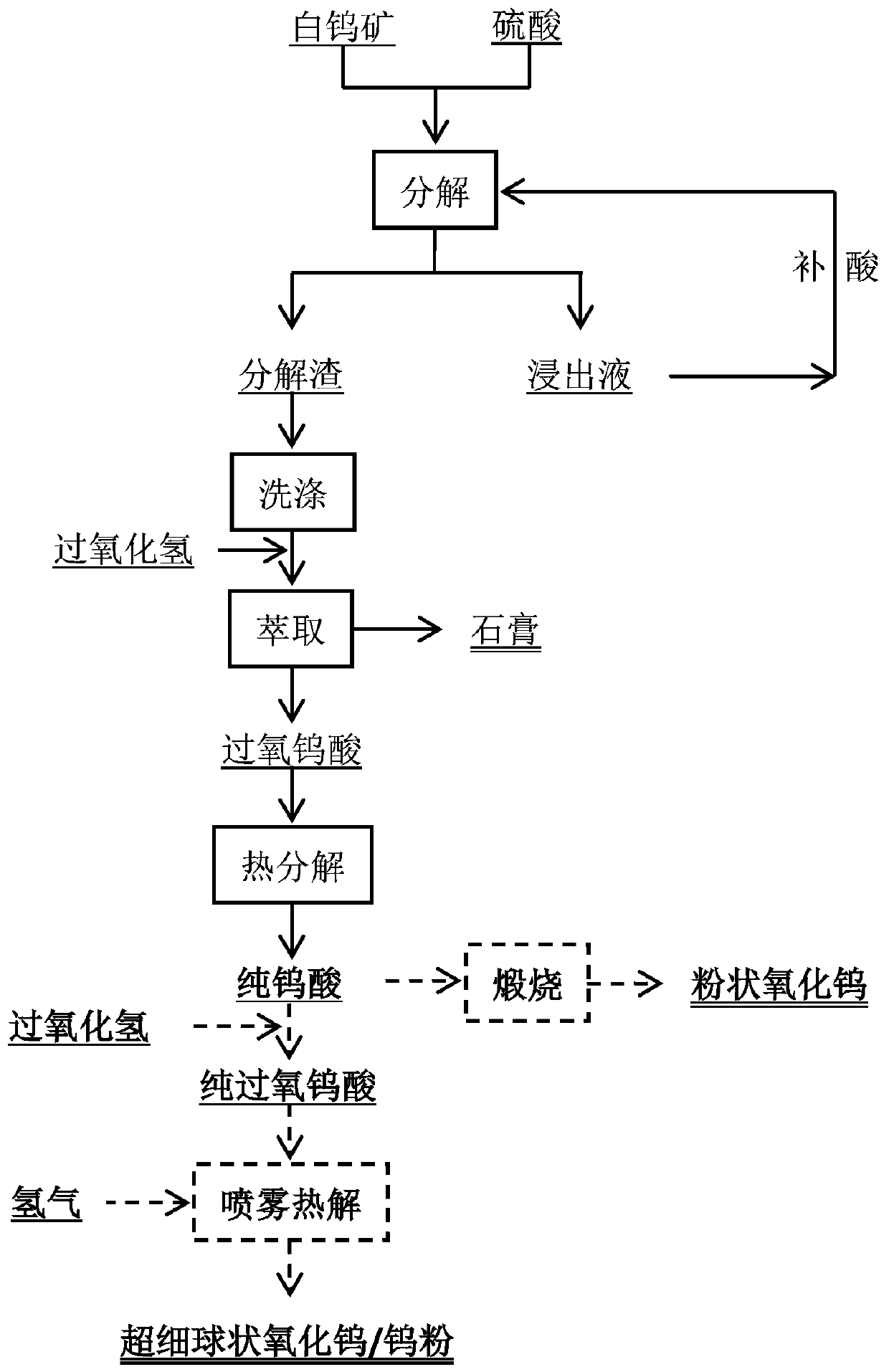

A method for preparing tungsten oxide and tungsten powder from scheelite

ActiveCN108640156BReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementAmmoniacal nitrogenPhysical chemistry

The present invention relates to a method for preparing tungsten oxide and tungsten powder from scheelite. The method uses the scheelite as a raw material and comprises the following steps: (1) conducting leaching reaction; (2) conducting filtering and washing; (3) conducting hydrogen peroxide extraction-decomposition to extract tungsten; (4) conducting hydrogen peroxide multiple dissolution-decomposition to purify tungstic acid; (5) pure tungstic acid calcination to prepare tungsten trioxide; and (6) conducting peroxotungstic acid solution spraying pyrolysis to prepare tungsten oxide and tungsten powder. The method only consumes cheap and easily available sulfuric acid, greatly reduces the decomposition cost of the scheelite and uses sulfuric acid to decompose; decomposed residues are gypsum; the gypsum can be used as building materials; the method does not produce dangerous waste alkali cooking residues, greatly reduces production and operation costs of enterprises, uses hydrogen peroxide as an extractant of tungstic acid, does not produce ammonia nitrogen wastewater, eliminates the technology of producing the ammonia nitrogen wastewater for many years in tungsten smelting, greatly reduces environmental protection costs, directly produces various tungsten end products and tungsten powder, and improves added value of products of the tungsten smelting enterprises.

Owner:CENT SOUTH UNIV

Recovery device for waste mobile terminals

ActiveCN111229788AReduce manual dependenceImprove efficiencySolid waste disposalStationary filtering element filtersToxic gasGear wheel

The invention discloses a recovery device for waste mobile terminals. The device comprises an outer shell, wherein a circulation cavity is arranged in the outer shell; racks are arranged in the frontend wall and the rear end wall of the right side of the circulation cavity in a sliding manner; gears are connected with the racks on the right side of the racks and are fixedly arranged on a shaft; and a motor is fixedly arranged in the front end wall of the circulation cavity. The device is small in dependence on manual operation, and high in efficiency; when a large number of waste mobile terminals are accumulated, the waste mobile terminals can be conveyed into a separating chamber through a conveying channel in order to be decomposed through the pressure of gravity, so that the decomposing cost is greatly saved; and moreover, a circulation assembly is arranged, and an air purifying device for filtering toxic gas is arranged at an exhausting part.

Owner:泰安智慧谷产业园运营管理有限公司

A method for decomposing wolframite under pressure and countercurrent with sulfur-phosphorus mixed acid

The invention relates to a method for carrying out pressurization and reverse-flow decomposition on wolframite with mixed acid of phosphoric acid and sulfuric acid. According to the method, the main improvements are that a reaction system is pressurized and the temperature is controlled to be higher than 100 DEG C in the process of extracting tungsten from wolframite powder with the mixed acid ofphosphoric acid and sulfuric acid, and a reverse-flow decomposition method is adopted in the operation process. According to the method, by pressurizing, calcium-containing compounds do not need to beadded to conduct conversion on the wolframite in the extracting process of the tungsten, the tungsten can be directly extracted from the high-tin wolframite or a high-tin black and white tungsten mixed ore, so that the production process is simplified, and the production cost is reduced; and through the process of reverse-flow decomposition, the mixed acid can be recycled, and the production costis further reduced.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com