Method for extracting potassium from potassium feldspar through calcium-based quaternary roasting treatment

A technology of potassium feldspar and roasting, applied in the field of potassium feldspar, can solve the problems of restricting agricultural production development, lack of potassium in the land, lack of potassium salt resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

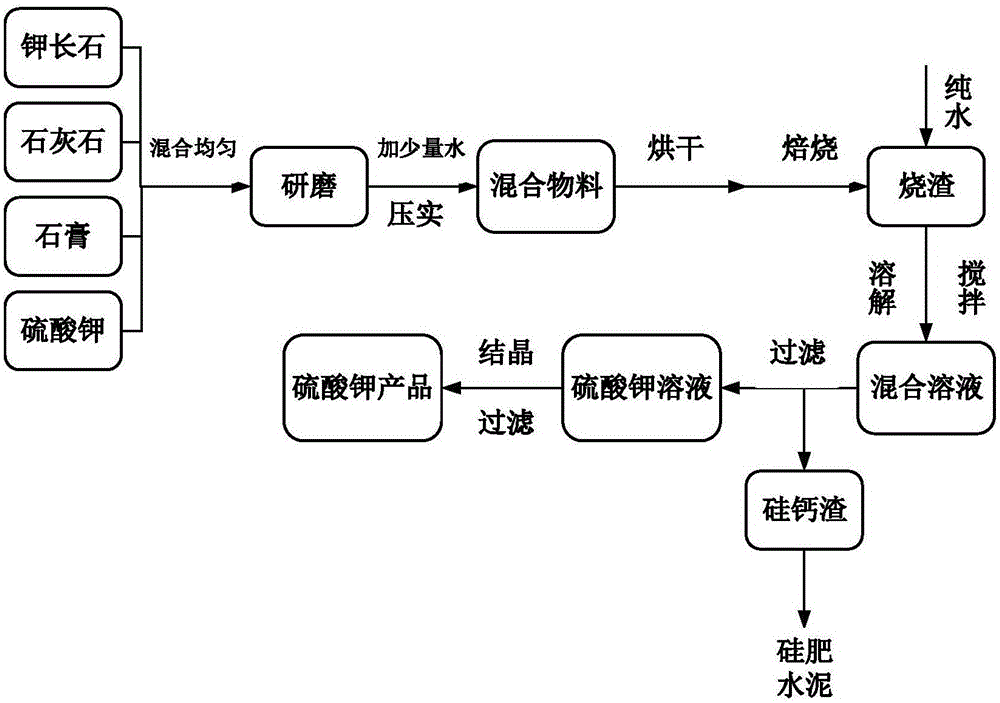

Image

Examples

Embodiment 1

[0025] Present embodiment 1 is the roasting process of calcium-based quaternary mixed material, specifically as follows:

[0026] 1. Take 10g potassium feldspar particles, 25g calcium carbonate and 3g calcium sulfate, mix the materials evenly, grind to 100 mesh, add a small amount of pure water and compact;

[0027] 2. Put the compacted mixture into a muffle furnace, first dry it at 100°C for 1 hour, then raise the temperature to 800°C at a rate of 6°C / min, and roast it for 2 hours to obtain 34.24g of solid slag;

[0028] 3. Dissolve the solid slag with 200ml of pure water, stir at a controlled temperature of 60°C (stirring frequency: 30-80r / min) for 2 hours, filter the mixed solution and add 200ml of pure water to wash the filter residue to obtain potassium sulfate solution;

[0029] 4. The potassium sulfate solution is passed through a cold water bath, and the temperature is controlled at 10° C. for crystallization until no potassium sulfate crystals are produced. Filter th...

Embodiment 2

[0032] Present embodiment 2 is the roasting process of calcium-based quaternary mixed material, specifically as follows:

[0033] 1. Take 10g potassium feldspar particles, 25g calcium carbonate and 3g calcium sulfate, mix the materials evenly, grind to 100 mesh, add a small amount of pure water and compact;

[0034] 2. Put the compacted mixture into a muffle furnace, first dry it at 100°C for 1 hour, then raise the temperature to 900°C at a rate of 6°C / min, and roast it for 2 hours to obtain 30.32 g of solid slag;

[0035] 3. Dissolve the solid slag with 200ml of pure water, stir at a controlled temperature of 60°C (stirring frequency: 30-80r / min) for 2 hours, filter the mixed solution and add 200ml of pure water to wash the filter residue to obtain potassium sulfate solution;

[0036] 4. The potassium sulfate solution is passed through a cold water bath, and the temperature is controlled at 8° C. for crystallization until no potassium sulfate crystals are produced. Filter th...

Embodiment 3

[0039] Present embodiment 3 is the roasting process of calcium-based quaternary mixed material, specifically as follows:

[0040] 1. Take 10g potassium feldspar particles, 34g calcium carbonate and 3g calcium sulfate, mix the materials evenly, grind to 100 mesh, add a small amount of pure water and compact;

[0041] 2. Put the compacted mixture into a muffle furnace, first dry it at 100°C for 1 hour, then raise the temperature to 1000°C at a rate of 6°C / min, and roast it for 2 hours to obtain 37.72g of solid slag;

[0042] 3. Dissolve the solid slag with 200ml of pure water, stir at a controlled temperature of 60°C (stirring frequency: 30-80r / min) for 2 hours, filter the mixed solution and add 200ml of pure water to wash the filter residue to obtain potassium sulfate solution;

[0043] 4. Pass the potassium sulfate solution through a cold water bath, and control the temperature at 5° C. for crystallization until no potassium sulfate crystals are produced. Filter the solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com