A method of carbon dioxide capture and pyrolysis

A carbon dioxide and pyrolysis technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of high energy consumption, high cost, uncertain long-term safety and reliability, etc. Concentration rate, the effect of reducing the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

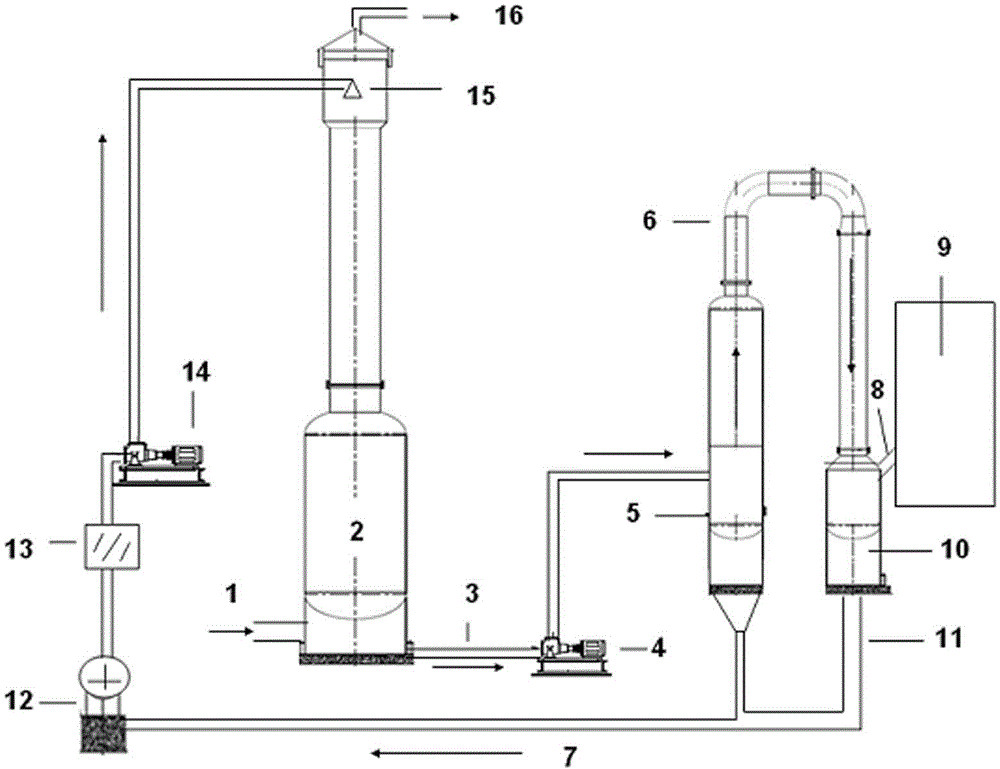

[0020] Embodiment 1: A method for carbon dioxide capture and pyrolysis, comprising the following steps:

[0021] 1) Fully dissolve the sodium carbonate solution with the catalyst and the active agent to make a carbon dioxide absorbent solution, in which the catalyst is fully soluble humic acid with a content of more than 5%, or fully soluble fulvic acid; the active agent is a full-soluble humic acid with a content of more than 5%. Soluble biochemical amino acid; the weight ratio of catalyst and carbon dioxide consumption is 0.01%, the weight ratio of activator and carbon dioxide consumption: 0.01%; the carbon dioxide absorbent solution made is sent into the solution batching tank 13, and sent into the carbonization through the sodium carbonate solution pump 14 Tower 2 is sprayed downwards by sodium carbonate dissolving nozzle 15;

[0022] 2) The temperature of the carbonization tower 2 is controlled at 60°C, and the flue gas is sent into the carbonization tower 2 from the flue...

Embodiment 2

[0041] Embodiment 2: a method for carbon dioxide capture and pyrolysis, comprising the following steps:

[0042] 1) Fully dissolve the sodium carbonate solution with the catalyst and the active agent to make a carbon dioxide absorbent solution, in which the catalyst is fully soluble humic acid with a content of more than 5%, or fully soluble fulvic acid; the active agent is a full-soluble humic acid with a content of more than 5%. Soluble biochemical amino acid; the weight ratio of catalyst and carbon dioxide consumption is 0.5%, the weight ratio of activator and carbon dioxide consumption: 0.5%; the carbon dioxide absorber solution that makes is sent into solution batching tank 13, sends into carbonization through sodium carbonate solution pump 14 Tower 2 is sprayed downwards by sodium carbonate dissolving nozzle 15;

[0043] 2) The temperature of the carbonization tower 2 is controlled at 60-70°C, the flue gas is sent into the carbonization tower 2 from the flue gas inlet 1, a...

Embodiment 3

[0062] Embodiment 3: a method for carbon dioxide capture and pyrolysis, comprising the following steps:

[0063] 1) Fully dissolve the sodium carbonate solution with the catalyst and the active agent to make a carbon dioxide absorbent solution, in which the catalyst is fully soluble humic acid with a content of more than 5%, or fully soluble fulvic acid; the active agent is a full-soluble humic acid with a content of more than 5%. Soluble biochemical amino acid; the weight ratio of catalyst and carbon dioxide consumption is 0.3%, the weight ratio of activator and carbon dioxide consumption: 0.3%; the carbon dioxide absorbent solution that makes is sent into solution batching tank 13, is sent into carbonization through sodium carbonate solution pump 14 Tower 2 is sprayed downwards by sodium carbonate dissolving nozzle 15;

[0064] 2) The temperature of the carbonization tower 2 is controlled at 66°C, the flue gas is sent into the carbonization tower 2 from the flue gas inlet 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com