Preparation method for carbon dioxide capture and catalytic recycling

A carbon dioxide and catalytic carbon dioxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low effect and low absorption speed, reduce decomposition cost, reduce conversion temperature, and increase capture rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

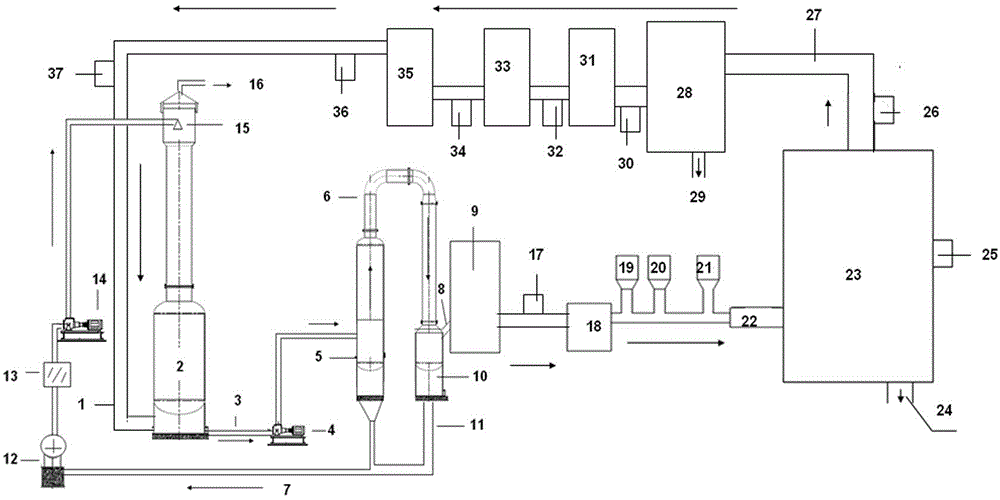

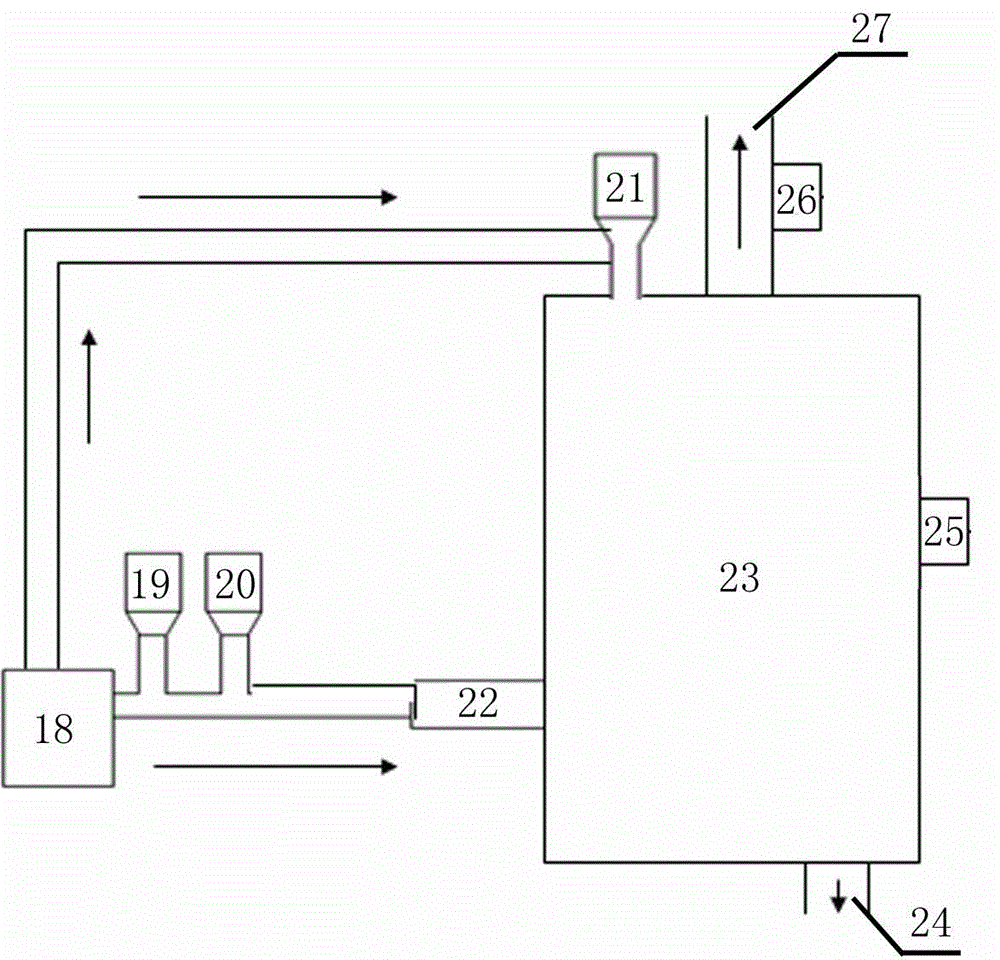

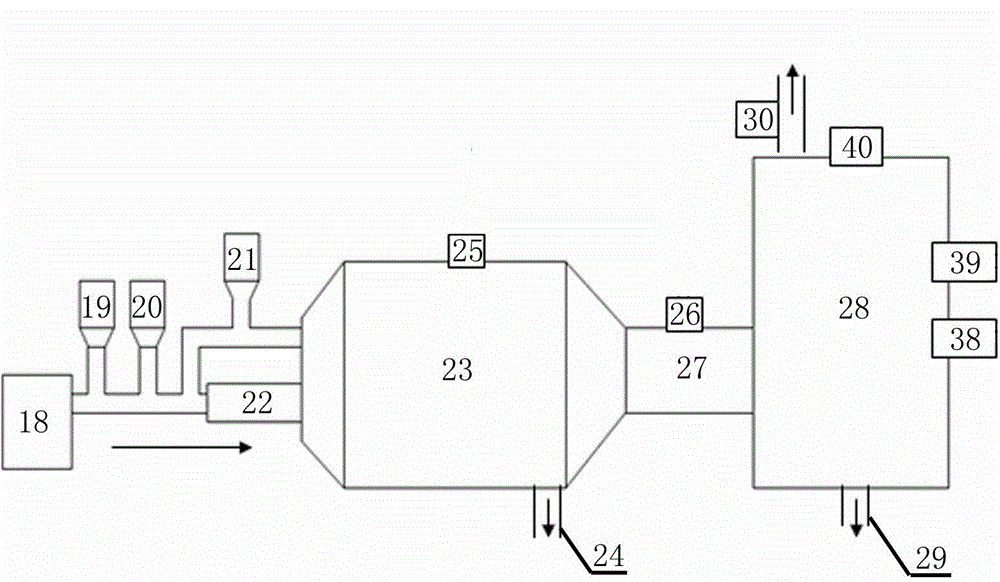

[0042] Embodiment 1: The preparation method of carbon dioxide capture and catalytic recycling, comprising the following steps:

[0043] 1) Fully dissolve the sodium carbonate solution with the catalyst and the active agent to make a carbon dioxide absorbent solution, in which the catalyst is fully soluble humic acid with a content of more than 5%, or fully soluble fulvic acid; the active agent is a full-soluble humic acid with a content of more than 5%. Soluble biochemical amino acid; the weight ratio of catalyst and carbon dioxide consumption is 0.01%, the weight ratio of activator and carbon dioxide consumption: 0.01%; the carbon dioxide absorbent solution made is sent into the solution batching tank 13, and sent into the carbonization through the sodium carbonate solution pump 14 Tower 2 is sprayed downwards by sodium carbonate dissolving nozzle 15;

[0044] 2) The temperature of the carbonization tower 2 is controlled at 60°C, and the flue gas is sent into the carbonizatio...

Embodiment 2

[0083] A preparation method for carbon dioxide capture and catalytic recycling, comprising the following steps:

[0084] 1) Fully dissolve the sodium carbonate solution with the catalyst and the active agent to make a carbon dioxide absorbent solution, in which the catalyst is fully soluble humic acid with a content of more than 5%, or fully soluble fulvic acid; the active agent is a full-soluble humic acid with a content of more than 5%. Soluble biochemical amino acid; the weight ratio of catalyst and carbon dioxide consumption is 0.5%, the weight ratio of activator and carbon dioxide consumption: 0.5%; the carbon dioxide absorber solution that makes is sent into solution batching tank 13, sends into carbonization through sodium carbonate solution pump 14 Tower 2 is sprayed downwards by sodium carbonate dissolving nozzle 15;

[0085] 2) The temperature of the carbonization tower 2 is controlled at 70°C, the flue gas is sent into the carbonization tower 2 from the flue gas inl...

Embodiment 3

[0124] A preparation method for carbon dioxide capture and catalytic recycling, comprising the following steps:

[0125] 1) Fully dissolve the sodium carbonate solution with the catalyst and the active agent to make a carbon dioxide absorbent solution, in which the catalyst is fully soluble humic acid with a content of more than 5%, or fully soluble fulvic acid; the active agent is a full-soluble humic acid with a content of more than 5%. Soluble biochemical amino acid; the weight ratio of catalyst and carbon dioxide consumption is 0.3%, the weight ratio of activator and carbon dioxide consumption: 0.3%; the carbon dioxide absorbent solution that makes is sent into solution batching tank 13, is sent into carbonization through sodium carbonate solution pump 14 Tower 2 is sprayed downwards by sodium carbonate dissolving nozzle 15;

[0126] 2) The temperature of the carbonization tower 2 is controlled at 66°C, the flue gas is sent into the carbonization tower 2 from the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com