A method of using struvite to remove ammonia and recycle gypsum at the same time

A struvite and gypsum technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large NaOH consumption and long decomposition time, and achieve treatment The effect of low cost, stable ammonia nitrogen concentration and low project investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

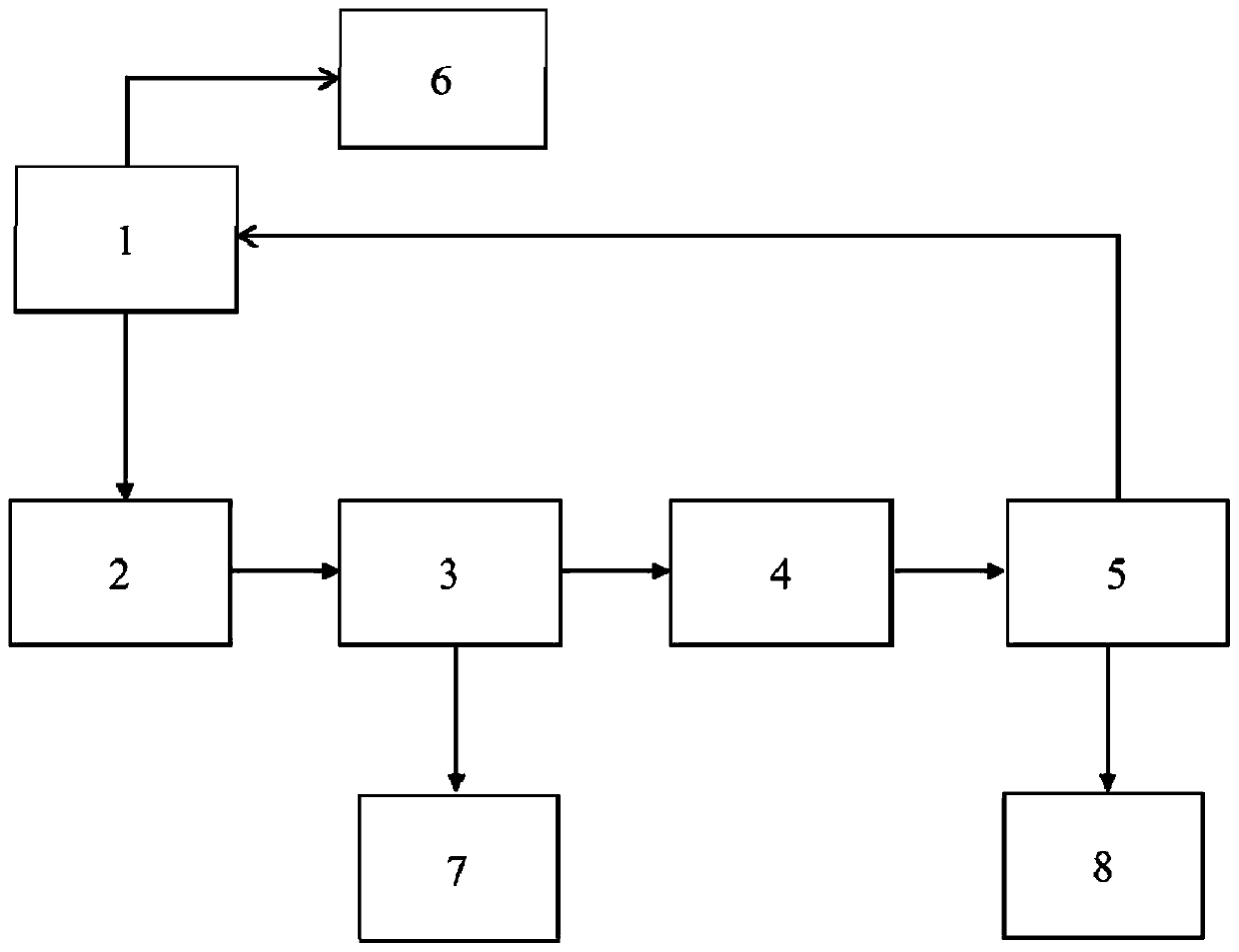

[0046] This embodiment provides a method for utilizing struvite to remove ammonia and recycle gypsum at the same time, such as figure 1 , including the following steps.

[0047] a. Calcium hydroxide and struvite are added into the decomposition reaction tank 1 at a Ca:P molar ratio of 0.75:1, then clean water is added at a solid-liquid volume ratio of 1:10, and the stirring device in the reaction tank is started to make the reaction The mixture is fully mixed, and at the same time, the heating device in the reaction tank is turned on, so that the aqueous solution therein is completely evaporated to dryness. The steam and ammonia evaporated in the reaction tank enter the ammonia recovery device 6 from the gas outlet of the reaction tank to be recovered as ammonia water.

[0048] b. Transfer the reacted solid remaining in the decomposition reaction tank 1 to the dissolving tank 2, then add clean water according to the solid-liquid volume ratio of 1:3, start the stirring device ...

Embodiment 2

[0053] This embodiment provides a method for using struvite to remove ammonia and recycle gypsum at the same time, including the following steps.

[0054] a. Calcium hydroxide and struvite are added into the decomposition reaction tank 1 at a Ca:P molar ratio of 1:1, then clean water is added at a solid-liquid volume ratio of 1:15, and the stirring device in the reaction tank is started to make the reaction The mixture is fully mixed, and at the same time, the heating device in the reaction tank is turned on, so that the aqueous solution therein is completely evaporated to dryness. The steam and ammonia evaporated in the reaction tank enter the ammonia recovery device 6 from the gas outlet of the reaction tank to be recovered as ammonia water.

[0055] b. Transfer the reacted solid remaining in the decomposition reaction tank 1 to the dissolving tank 2, then add clean water according to the solid-liquid volume ratio of 1:8, start the stirring device in the dissolving tank, ful...

Embodiment 3

[0060] This embodiment provides a method for using struvite to remove ammonia and recycle gypsum at the same time, including the following steps.

[0061] a. Calcium hydroxide and struvite are added into the decomposition reaction tank 1 at a Ca:P molar ratio of 3:1, then clean water is added at a solid-liquid volume ratio of 1:15, and the stirring device in the reaction tank is started to make the reaction The mixture is fully mixed, and at the same time, the heating device in the reaction tank is turned on, so that the aqueous solution therein is completely evaporated to dryness. The steam and ammonia evaporated in the reaction tank enter the ammonia recovery device 6 from the gas outlet of the reaction tank to be recovered as ammonia water.

[0062] b. Transfer the reacted solid remaining in the decomposition reaction tank 1 to the dissolving tank 2, then add clean water according to the solid-liquid volume ratio of 1:10, start the stirring device in the dissolving tank, fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com