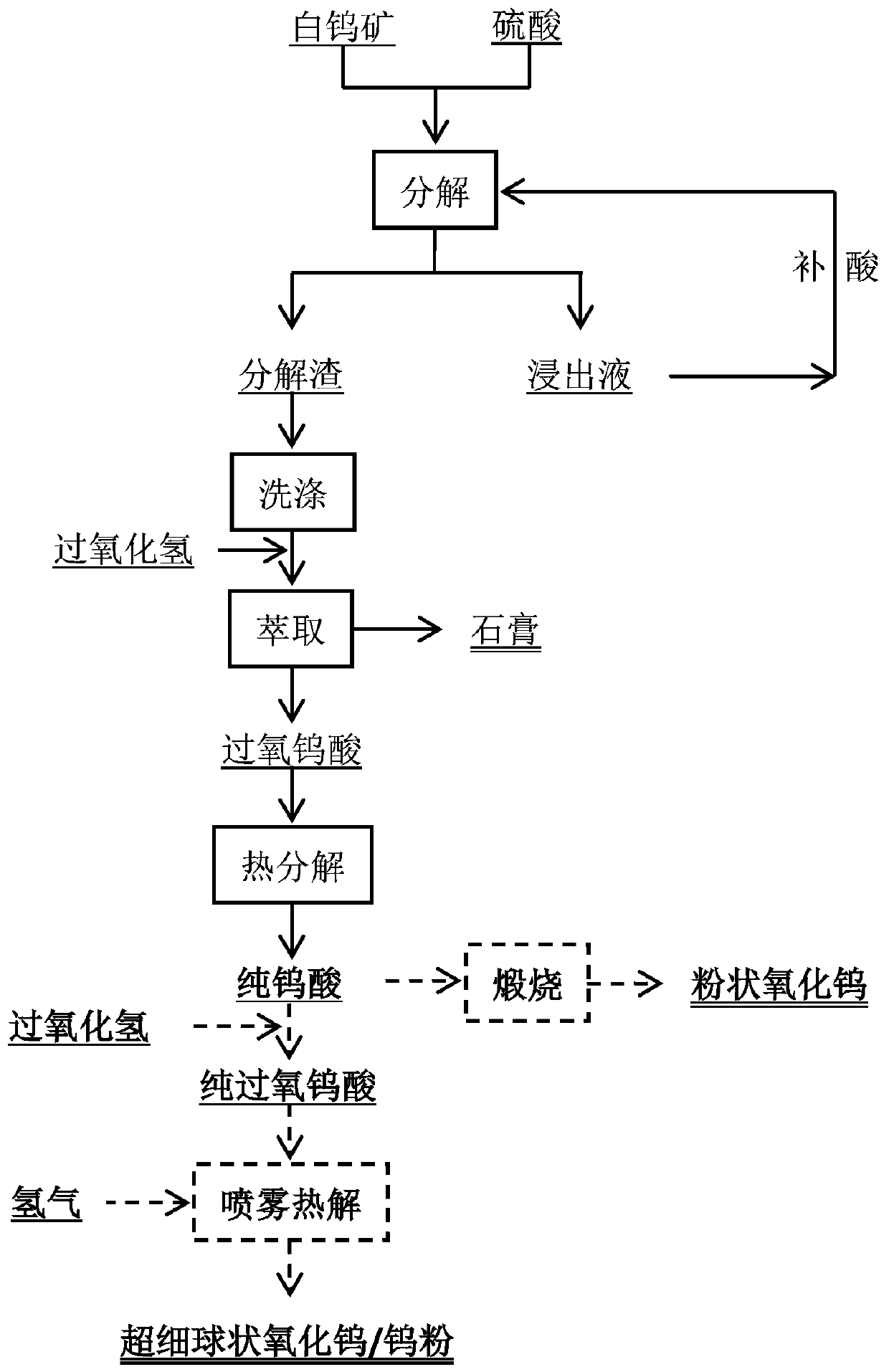

A method for preparing tungsten oxide and tungsten powder from scheelite

A technology of scheelite and tungsten oxide, which is applied in the field of chemical production, can solve the problems of high price, increased tungsten smelting cost, and environmental pollution, so as to reduce production and operation costs, increase product added value, and reduce environmental protection costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example provides a method for preparing tungsten oxide and tungsten powder from scheelite. The raw material used in this method is scheelite with a grade of 40% and a particle size of 100 μm. The method is specifically as follows:

[0040] (1) Leaching reaction: Add scheelite to sulfuric acid solution with a concentration of 250g / L, and then add calcium sulfate accounting for 5% of the mass of scheelite. The liquid-solid ratio of the system is 6:1. The leaching reaction was carried out under the condition of 0.5Mpa for 3 hours, and 99.4% of tungsten was converted into tungstic acid;

[0041] (2) Filtration and washing: filter the reaction product obtained in step (1) to obtain decomposition residue and leaching solution; add sulfuric acid to the leaching solution and return to step (1) as a raw material for leaching reaction;

[0042] (3) hydrogen peroxide extraction-decomposition and extraction of tungsten: wash the decomposed slag obtained in step (2) and mix it ...

Embodiment 2

[0046] This example provides a method for preparing tungsten oxide and tungsten powder from scheelite. The raw material used in this method is scheelite with a grade of 10% and a particle size of 200 μm. The method is specifically as follows:

[0047] (1) Leaching reaction: Add scheelite to a sulfuric acid solution with a concentration of 50g / L. The liquid-solid ratio of the system is 10:1. The leaching reaction is carried out at 90°C and 0Mpa for 4 hours, and 99.2% of tungsten is converted into Tungstic acid;

[0048] (2) Filtration and washing: filter the reaction product obtained in step (1) to obtain decomposition residue and leaching solution; add sulfuric acid to the leaching solution and return to step (1) as a raw material for leaching reaction;

[0049] (3) hydrogen peroxide extraction-decomposition and extraction of tungsten: wash the decomposed slag obtained in step (2) and mix it with a hydrogen peroxide solution with a mass concentration of 30%, the molar ratio of...

Embodiment 3

[0054] This example provides a method for preparing tungsten oxide and tungsten powder from scheelite. The raw material used in this method is scheelite with a grade of 65% and a particle size of 50 μm. The method is specifically as follows:

[0055] (1) Leaching reaction: Add scheelite to sulfuric acid solution with a concentration of 300g / L, and then add solid tungstic acid accounting for 10% of the mass of scheelite. The liquid-solid ratio of the system is 4:1. , Under the condition of 0.65Mpa, the leaching reaction was carried out for 4 hours, and 99.1% of the tungsten was converted into tungstic acid;

[0056] (2) Filtration and washing: filter the reaction product obtained in step (1) to obtain decomposition residue and leaching solution; add sulfuric acid to the leaching solution and return to step (1) as a raw material for leaching reaction;

[0057] (3) hydrogen peroxide extraction-decomposition and extraction of tungsten: wash the decomposed slag obtained in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com