System for disassembling waste battery

A waste battery and battery dismantling technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of high energy consumption in the subsequent production of regenerated lead, unreasonable use of alloy components, and environmental resource loss. Achieve the effect of low decomposition cost, avoid labor, and avoid resource loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The content of the present invention will be described below in conjunction with specific embodiments.

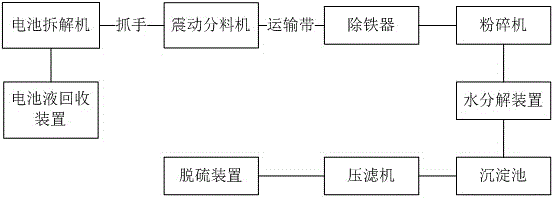

[0012] A dismantling system for waste batteries, characterized in that the system includes a battery liquid recovery tank, a battery dismantling machine, a vibrating feeder, an iron remover, a pulverizer, a water decomposition device, a sedimentation tank, a filter press, a desulfurization device; the battery liquid recovery pool is located under the battery dismantling machine, the battery dismantling machine and the vibrating splitter are transported by a gripper, and the vibrating splitter and the pulverizer are connected by a conveyor belt , and iron remover is installed on the conveyor belt.

[0013] Further, the upper part of the pulverizer is provided with a ventilation device.

[0014] Further, the water decomposing device is provided with a water inlet and a water outlet, and is equipped with a first-stage vibrating screen.

[0015] Further, the vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com