Method for preparing ammonium paratungstate by utilizing low-grade scheelite concentrate

A low-grade ammonium paratungstate technology, which is applied in the preparation of tungsten compounds, chemical instruments and methods, tungsten compounds, etc., can solve the problems of low utilization rate of mine resources and low decomposition rate of scheelite, so as to reduce alkalinity and avoid Wear consumption, low pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

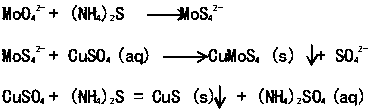

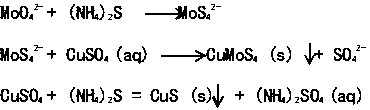

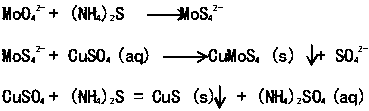

Image

Examples

Embodiment 1

[0022] A kind of method that the present invention proposes utilizes low-grade scheelite concentrate to prepare ammonium paratungstate, comprising the following steps:

[0023] S1. Add sodium hydroxide solution to the low-grade scheelite concentrate for mechanical grinding until the average particle size is 100 mesh, control the alkalinity of the pulp to 400g / L, and then transfer it to an alkali boiling reaction kettle for heating by far-infrared radiation. Alkali pressure cooking treatment, the pressure in the alkali boiling reaction kettle is 0.2Mpa, the temperature is 160°C, and the holding time is 1.5h. The obtained pulp is filtered with a filter press, washed with water, and a sodium tungstate solution with a relatively dilute concentration is obtained;

[0024] Here, the combination of mechanical grinding and far-infrared radiation heating is used to activate the ore to promote the decomposition of scheelite. Among them, the mechanical grinding can improve the surface act...

Embodiment 2

[0035] A kind of method that the present invention proposes utilizes low-grade scheelite concentrate to prepare ammonium paratungstate, comprising the following steps:

[0036] S1. Add sodium hydroxide solution to the low-grade scheelite concentrate for mechanical grinding until the average particle size is 200 mesh, control the alkalinity of the pulp to 470g / L, and then transfer it to an alkali boiling reaction kettle for heating by far-infrared radiation. Alkali pressure cooking treatment, the pressure in the alkali boiling reaction kettle is 0.5Mpa, the temperature is 180°C, and the holding time is 2.5h. The obtained pulp is filtered with a filter press, washed with water, and a sodium tungstate solution with a relatively dilute concentration is obtained;

[0037] Here, the combination of mechanical grinding and far-infrared radiation heating is used to activate the ore to promote the decomposition of scheelite. Among them, the mechanical grinding can improve the surface act...

Embodiment 3

[0048] A kind of method that the present invention proposes utilizes low-grade scheelite concentrate to prepare ammonium paratungstate, comprising the following steps:

[0049] S1. Add sodium hydroxide solution to the low-grade scheelite concentrate for mechanical grinding until the average particle size is 140 mesh, control the alkalinity of the pulp to 550g / L, and then transfer it to an alkali boiling reaction kettle for heating by far-infrared radiation. Alkali pressure cooking treatment, the pressure in the alkali boiling reaction kettle is 0.3Mpa, the temperature is 165°C, and the holding time is 2.0h. The obtained pulp is filtered with a filter press, washed with water, and a sodium tungstate solution with a relatively dilute concentration is obtained;

[0050] Here, the combination of mechanical grinding and far-infrared radiation heating is used to activate the ore to promote the decomposition of scheelite. Among them, the mechanical grinding can improve the surface act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com