Method for treating ammonium paratungstate crystal crystallization mother liquor

A technology of crystallization mother liquor and ammonium paratungstate, which is applied in the post-production treatment of ammonium paratungstate and the treatment of ammonium paratungstate crystallization mother liquor, which can solve problems affecting product quality, achieve the effects of lowering temperature, increasing income, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

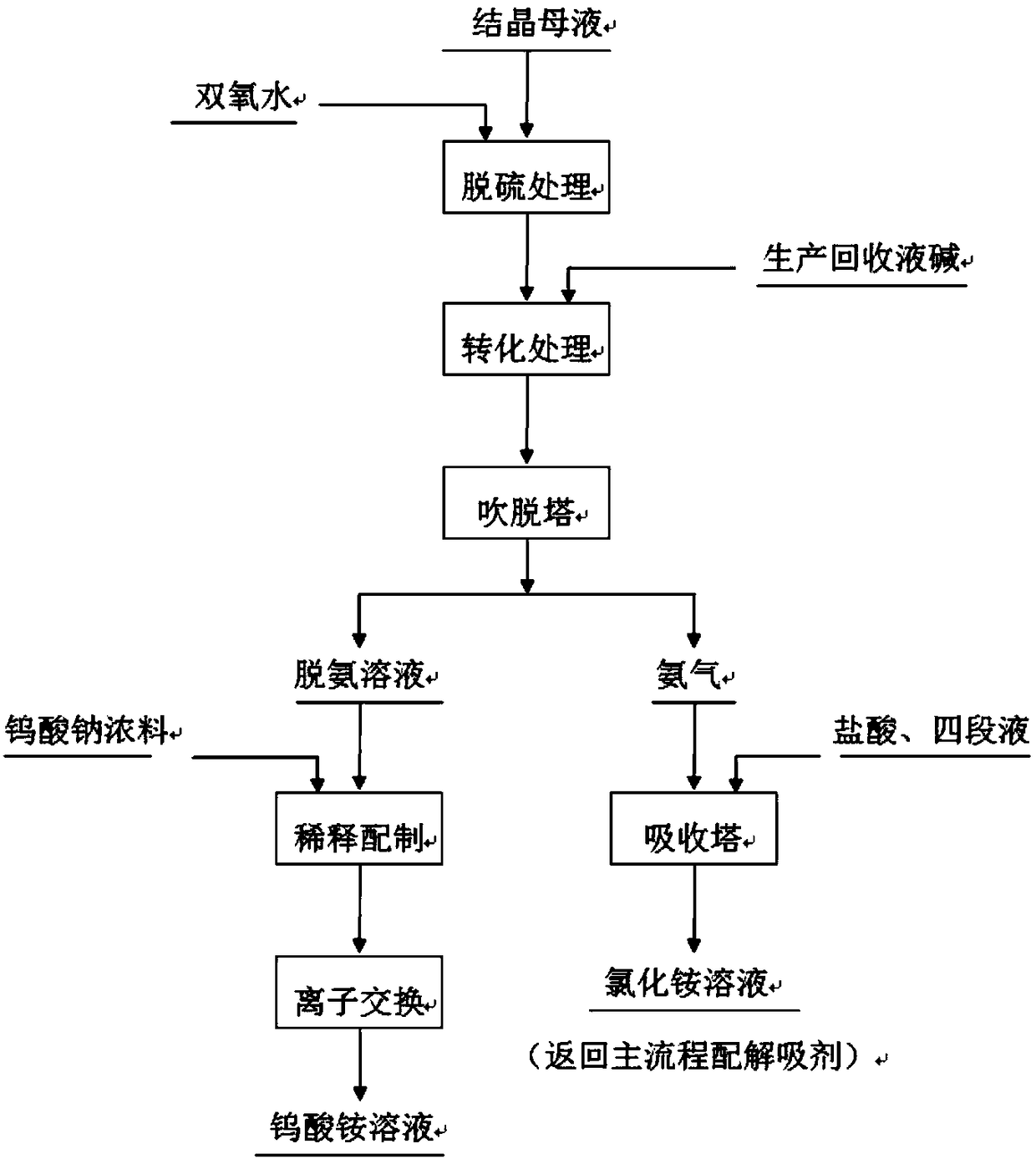

[0024] A method for treating ammonium paratungstate crystallization mother liquor, comprising the following steps:

[0025] (1) Desulfurization treatment: put 3m 3 Pump the mother liquor of ammonium paratungstate crystallization into the stirring tank, add 5kg of hydrogen peroxide to the mother liquor, stir at 45r / min for 10min, and record it as material 1;

[0026] (2) Transformation reaction: adding alkali concentration in material 1 is the production recovery surplus alkali of 200g / L, wherein, the addition amount of production recovery surplus alkali is 0.288m 3 , the pH value of material 1 was adjusted to 11, stirred for 5 minutes at a speed of 45 r / min, and recorded as material 2;

[0027] (3) stripping reaction: the material 2 is pumped into the stripping tower to obtain ammonia gas and deamination solution;

[0028] (4) Spray: the ammonia in the step (3) is passed through the steam-water separator, sprayed with the mixed solution, the concentration prepared into ammon...

Embodiment 2

[0031] A method for treating ammonium paratungstate crystallization mother liquor, comprising the following steps:

[0032] (1) Desulfurization treatment: put 3m 3 Pump the mother liquor of ammonium paratungstate crystallization into the stirring tank, add 15kg of hydrogen peroxide to the mother liquor, stir at 90r / min for 30min, and record it as material 1;

[0033] (2) Transformation reaction: adding alkali concentration in material 1 is the production recovery surplus alkali of 350g / L, wherein, the addition amount of production recovery surplus alkali is 0.432m 3 , adjust the pH value of material 1 to 13, stir at 90r / min for 30min, and record it as material 2;

[0034] (3) stripping reaction: the material 2 is pumped into the stripping tower to obtain ammonia gas and deamination solution;

[0035] (4) Spray: the ammonia in the step (3) is passed through the steam-water separator, sprayed with the mixed solution, the concentration prepared into ammonium chloride is 270g / L,...

Embodiment 3

[0038] A method for treating ammonium paratungstate crystallization mother liquor, comprising the following steps:

[0039] (1) Desulfurization treatment: put 3m 3 Pump the mother liquor of ammonium paratungstate crystallization into the stirring tank, add 10kg of hydrogen peroxide into the mother liquor, stir at 65r / min for 10-30min, and record it as material 1;

[0040] (2) Conversion reaction: adding alkali concentration in material 1 is the production recovery residual alkali of 280g / L, wherein, the addition amount of production recovery residual alkali is 0.325m 3 , the pH value of material 1 was adjusted to 12, stirred at 65r / min for 15 minutes, and recorded as material 2;

[0041] (3) stripping reaction: the material 2 is pumped into the stripping tower to obtain ammonia gas and deamination solution;

[0042](4) Spray: the ammonia in the step (3) is passed through the steam-water separator, sprayed with the mixed solution, the concentration prepared into ammonium chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com