Method of recycling component substances in a waste SCR denitration catalyst

A denitration catalyst and catalyst technology are applied in the preparation of tungsten compounds, the preparation of molybdenum compounds, chemical instruments and methods, etc., which can solve the problems of high product impurities, low selectivity and high energy consumption, and achieve high purity, low cost, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

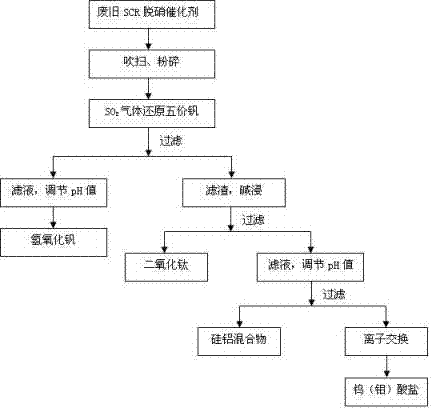

Image

Examples

Embodiment 1

[0033] In the spent SCR denitration catalyst of the present embodiment, mainly include: V 2 o 5 The mass fraction accounts for 1.10%, WO 3 The mass fraction of TiO is 4.85%. 2 The mass fraction accounts for 85.6%, SiO 2 The mass fraction of Al accounted for 4.51%, Al 2 o 3 The mass fraction accounts for 0.75%, a method for recovering the component substances in the spent SCR denitration catalyst, which specifically includes the following steps:

[0034] (1) Take the waste SCR denitrification catalyst, use a high-pressure air gun to purge the surface and pores of the catalyst to remove impurities such as dust attached to the surface, and then physically crush the catalyst to a particle size of 50-80 μm, and take out the powder after the crushing is completed;

[0035] (2) Take 300g of the catalyst powder in step (1), mix it with 450mL of sulfuric acid solution with a mass fraction of 0.4%, heat and stir at 75°C to form a suspension;

[0036] (3) Feed the vanadium pentoxid...

Embodiment 2

[0048] In the spent SCR denitration catalyst of the present embodiment, mainly include: V 2 o 5 The mass fraction of MoO is 0.86%. 3 The mass fraction of TiO is 6.50%. 2 The mass fraction accounts for 80.7%, SiO 2 The mass fraction of Al accounted for 4.79%, Al 2 o 3 The mass fraction accounts for 4.52%, a method for recovering the component substances in the spent SCR denitration catalyst, which specifically includes the following steps:

[0049] (1) Take the waste SCR denitration catalyst, use a high-pressure air gun to purge the surface and pores of the catalyst to remove impurities such as dust attached to the surface, and then physically pulverize the catalyst to a particle size of 60-90 μm, and take out the powder after pulverization;

[0050] (2) Take 200g of the catalyst powder in step (1), mix it with 380mL of sulfuric acid solution with a mass fraction of 0.3%, heat and stir at 85°C to form a suspension;

[0051] (3) Pass the vanadium pentoxide contained in the...

Embodiment 3

[0063] In the spent SCR denitration catalyst of the present embodiment, mainly include: V 2 o 5 The mass fraction of WO is 5.80%. 3 The mass fraction of TiO is 7.50%. 2 The mass fraction of SiO is 75.8%. 2 The mass fraction of Al accounted for 3.84%, Al 2 o 3 The mass fraction accounts for 2.36%, a method for recovering the component substances in the spent SCR denitration catalyst, which specifically includes the following steps:

[0064](1) Take the waste SCR denitrification catalyst, use a high-pressure air gun to purge the surface and pores of the catalyst to remove impurities such as dust attached to the surface, and then physically pulverize the catalyst to a particle size of 50-70 μm, and take out the powder after the pulverization;

[0065] (2) Take 500g of the catalyst powder in step (1), mix it with 650mL of sulfuric acid solution with a mass fraction of 3%, and heat and stir at 95°C to form a suspension;

[0066] (3) Pass the vanadium pentoxide contained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com