Method and system for producing ammonium paratungstate through alkaline extraction

A technology for producing ammonium paratungstate and ammonium tungstate, which is applied in the field of metallurgy, can solve the problems of high labor intensity, loss of tungsten mineral raw materials, waste of resources, etc., and achieve the effect of good working environment, low labor intensity and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The present embodiment provides a kind of production method of ammonium paratungstate, and concrete steps are as follows:

[0085] First crush the scheelite by mechanical crushing method until more than 98% of the mineral particle size is less than or equal to 45μm, and then carry out the following steps:

[0086] (1) Leaching

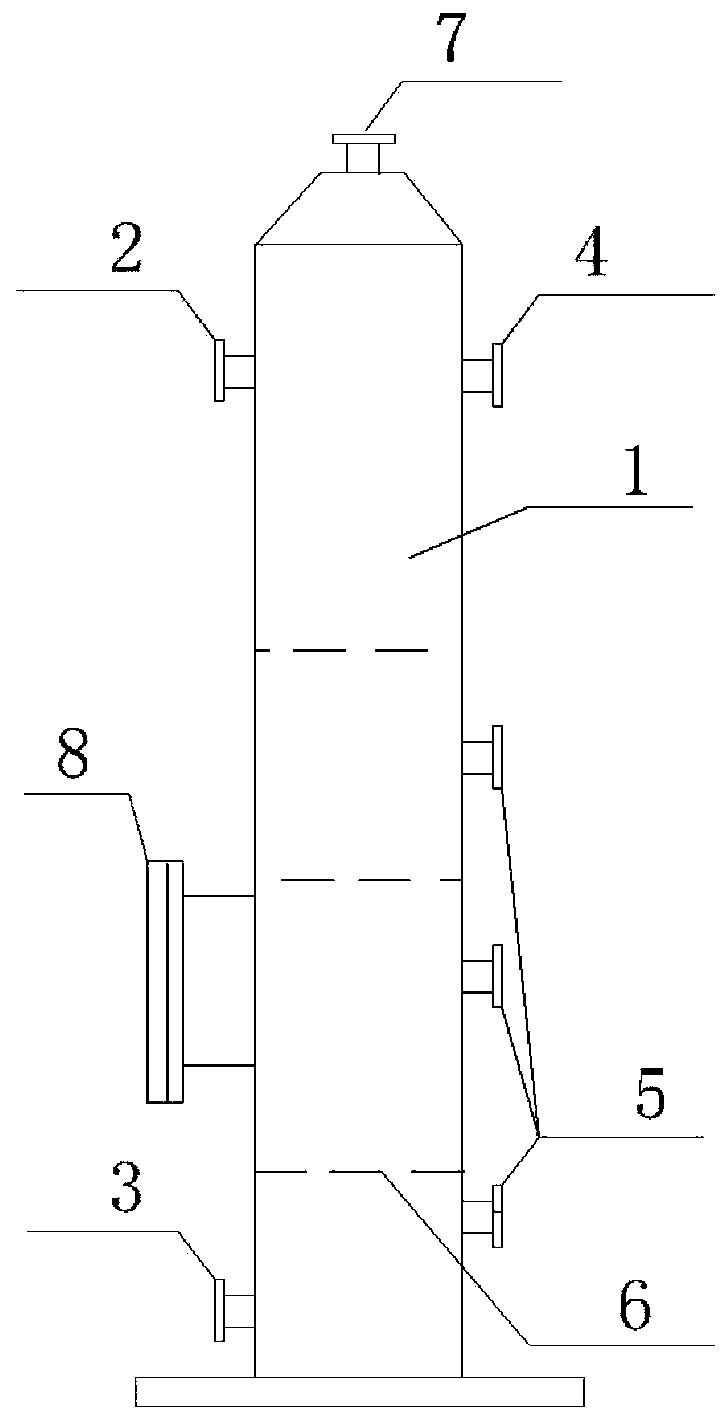

[0087] Add the crushed scheelite and sodium carbonate solution to such as figure 2 In the leaching device, leaching was carried out at 200°C for 3 hours to obtain a mixed slurry of sodium tungstate solution and leaching slag and transferred to the filtration device.

[0088] (2) Solid-liquid separation

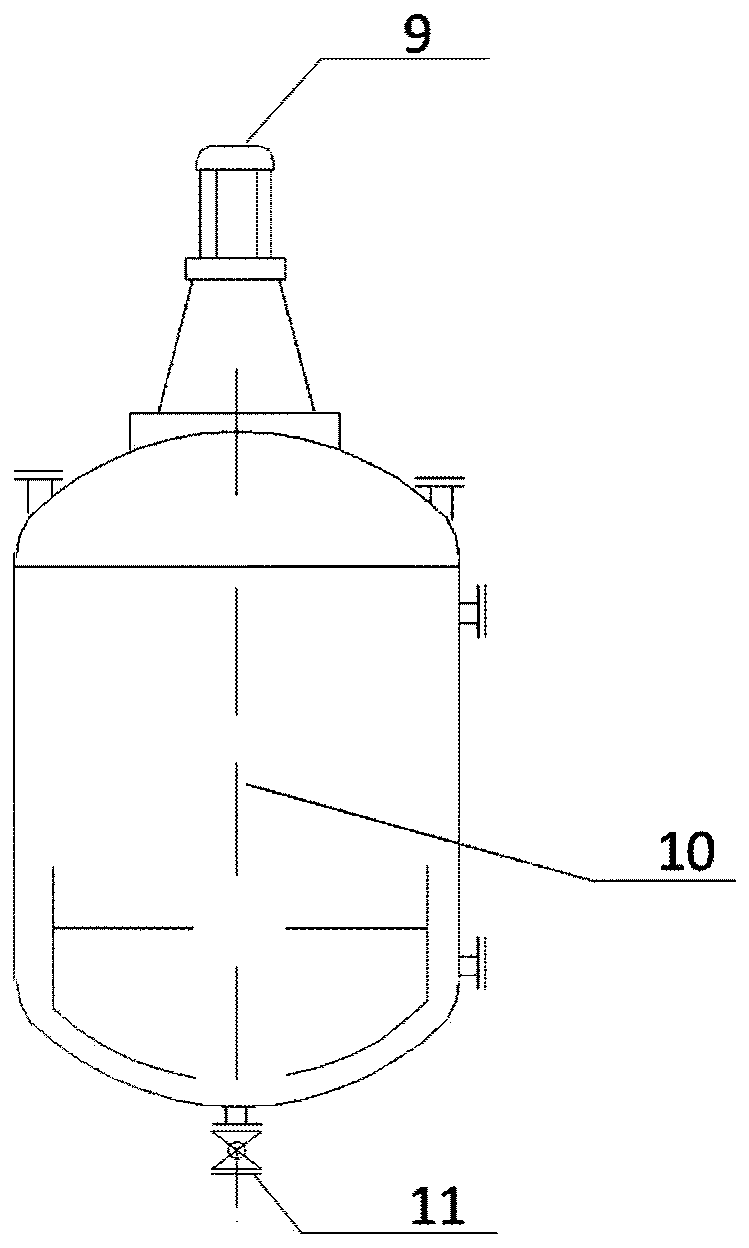

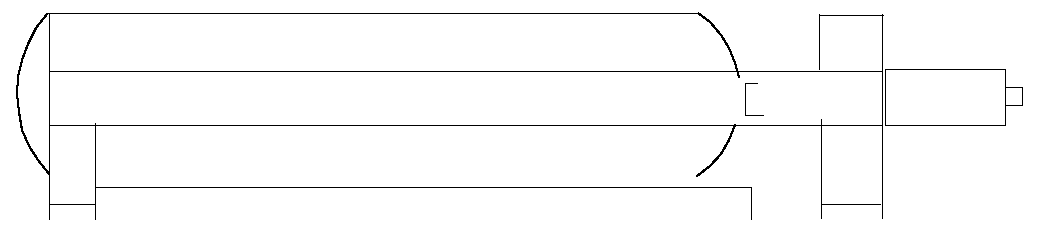

[0089] in such as image 3 In the filter press shown, the mixed slurry of sodium tungstate solution and leaching slag is mixed, and the leaching slag is washed and discharged out of the production system to obtain sodium tungstate solution and transferred to a freeze crystallization device.

[0090] (3') Frozen crystallization

[0091] Fre...

Embodiment 2

[0105] The difference with embodiment 1 is that step (3') is not carried out.

Embodiment 3

[0107] The difference from Example 1 is that ozone is not passed into step (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com