Method for producing ammonium paratungstate from hard alloy scrap

A technology of ammonium paratungstate and cemented carbide is applied in the field of producing ammonium paratungstate by using cemented carbide waste, which can solve the problems of long processing cycle and high processing cost, and achieve the effect of reducing processing cost and shortening turnaround time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

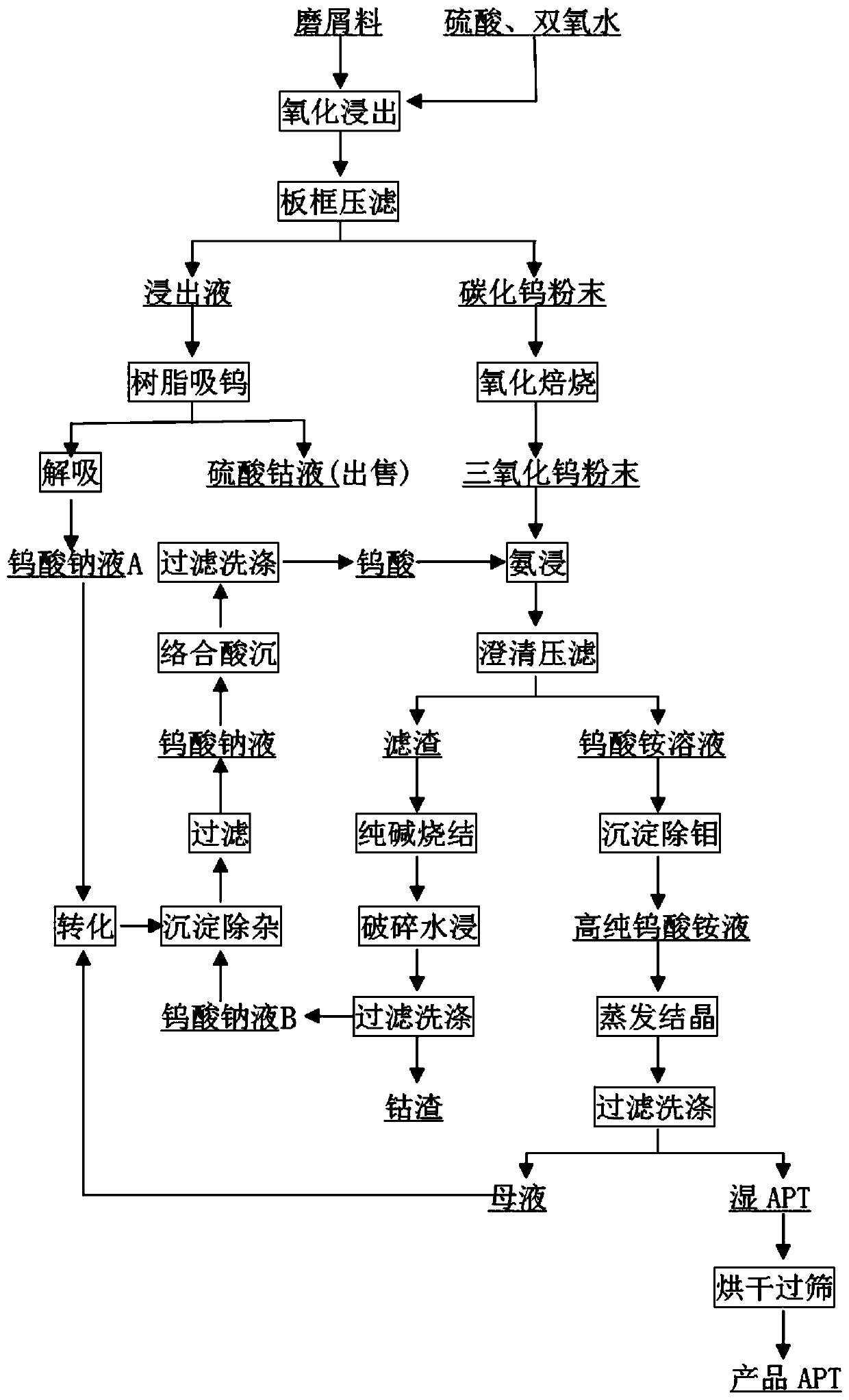

[0028] see figure 1 , in the embodiment of the present invention, a kind of process method that adopts cemented carbide scrap to produce ammonium paratungstate comprises the following steps:

[0029] 1) Oxidation leaching

[0030] Add grinding debris to 10% dilute sulfuric acid at a liquid-solid ratio of 1:1, heat up and stir for 3 hours, and slowly add 15% hydrogen peroxide at a liquid-solid ratio of 1:10 during the reaction;

[0031] 2) Oxidation roasting

[0032] The main component of the filter residue leached by oxidation is tungsten carbide, which is placed in a rotary furnace and roasted with air at a temperature of 350°C to convert it into tungsten trioxide. At the same time, burning can remove the oily substances in the grinding debris;

[0033] 3) Ammonia leaching

[0034] Add tungsten trioxide powder and 15% ammonia water to the stainless steel reaction kettle at a solid-to-liquid ratio of 1:3, add 8% ammonium sulfide solution according to 5% of the total input a...

Embodiment 2

[0041] see figure 1 , in the embodiment of the present invention, a kind of process method that adopts cemented carbide scrap to produce ammonium paratungstate comprises the following steps:

[0042] 1) Oxidation leaching

[0043] Add grinding debris to 10% dilute sulfuric acid at a liquid-solid ratio of 1:1, heat up and stir for 3 hours, and slowly add 15% hydrogen peroxide at a liquid-solid ratio of 1:10 during the reaction;

[0044] 2) Oxidation roasting

[0045] The main component of the filter residue leached by oxidation is tungsten carbide, which is placed in a rotary furnace and roasted with air at a temperature of 350°C to convert it into tungsten trioxide. At the same time, burning can remove the oily substances in the grinding debris;

[0046] 3) Ammonia leaching

[0047] Add tungsten trioxide powder and 15% ammonia water to the stainless steel reaction kettle according to the solid-to-liquid ratio of 1:3, add 8% ammonium sulfide solution according to 5% of the t...

Embodiment 3

[0054] see figure 1 , in the embodiment of the present invention, a kind of process method that adopts cemented carbide scrap to produce ammonium paratungstate comprises the following steps:

[0055] 1) Oxidation leaching

[0056] Add grinding debris to 10% dilute sulfuric acid at a liquid-solid ratio of 1:1, heat up and stir for 3 hours, and slowly add 15% hydrogen peroxide at a liquid-solid ratio of 1:10 during the reaction;

[0057] 2) Oxidation roasting

[0058] The main component of the filter residue leached by oxidation is tungsten carbide, which is placed in a rotary furnace and roasted with air at a temperature of 350°C to convert it into tungsten trioxide. At the same time, burning can remove the oily substances in the grinding debris;

[0059] 3) Ammonia leaching

[0060] Add tungsten trioxide powder and 15% ammonia water to the stainless steel reaction kettle at a solid-to-liquid ratio of 1:3, add 8% ammonium sulfide solution according to 5% of the total input amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com