Method for deeply removing chromium in tungsten-containing waste recycling process

A tungsten waste and deep technology, applied in the preparation of tungsten compounds, chemical instruments and methods, tungsten compounds, etc., can solve the problems of complicated procedures, high cost, large acid and alkali consumption, etc., and achieve simple and easy process, reduce Disposal cost, effect of low disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

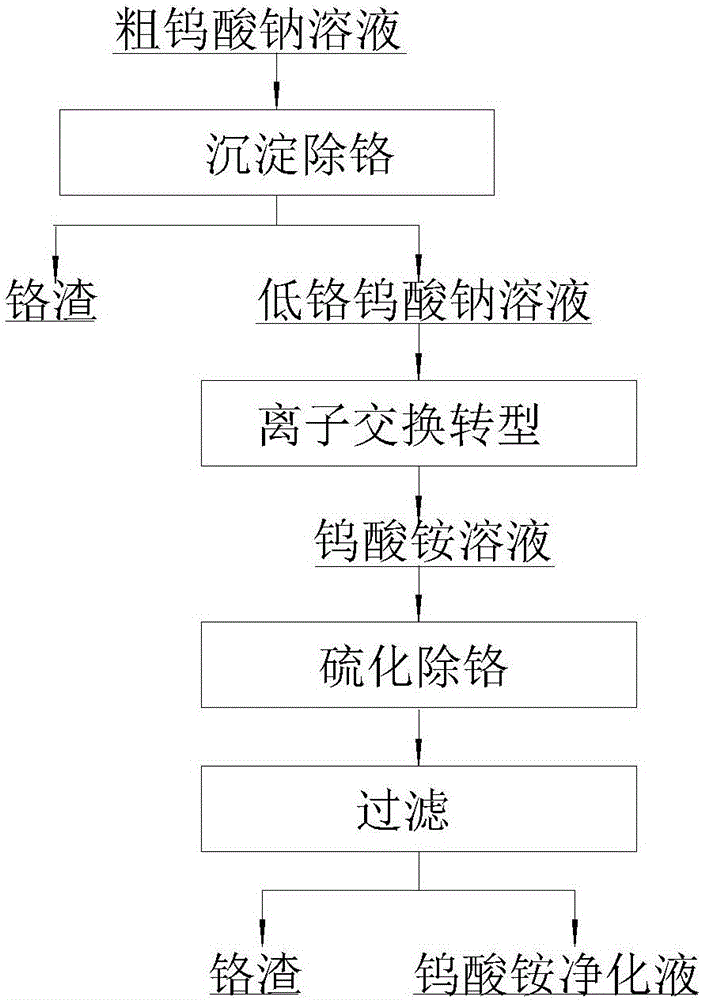

Image

Examples

Embodiment 1

[0036] A method for deep removal of chromium in the recovery process of tungsten-containing waste, including the following steps:

[0037] 1) Use multi-point random sampling to obtain crude sodium tungstate solution, analyze and test the content of each element in it, and the test result is: WO 3 =65.57g / L, OH=23.84g / L, Mo=0.09g / L, CO 3 2- =26.15g / L, Cr=0.8g / L, V=0.13g / L;

[0038] 2) Put 7m 3 Transfer the crude sodium tungstate solution to 10m 3 After heating to 85℃, add 12kg sodium sulfide. After boiling for about 1h, sample and analyze the chromium content to be 0.25g / L. When the temperature in the reaction system drops to 50℃, press filtration treatment, it can be seen that the solution is removed Chromium in 68.8%;

[0039] 3) Dilute the low-chromium sodium tungstate solution obtained in step 2) by 3 times, and the obtained dilute sodium tungstate solution (ie, the pre-delivery solution) contains WO 3 19.52g / L;

[0040] 4) Pass the pre-delivery solution obtained in step 3) through...

Embodiment 2

[0044] A method for deep removal of chromium in the recovery process of tungsten-containing waste, including the following steps:

[0045] 1) Use multi-point random sampling to obtain crude sodium tungstate solution, analyze and test the content of each element in it, and the test result is: WO 3 =92.61g / L, OH=23.68g / L, Mo=0.13g / L, CO 3 2- =34.68g / L, Cr=1.5g / L, V=0.17g / L;

[0046] 2) Put 7m 3 Transfer the crude sodium tungstate solution to 10m 3 After heating to 80℃, add 20kg sodium sulfide. After boiling for about 4h, sample and analyze the chromium content to be 0.38g / L. When the temperature in the reaction system drops to 50℃, press filtration treatment, it can be seen that the solution is removed 74.7% of chromium in

[0047] 3) Dilute the low-chromium sodium tungstate solution obtained in step 2) by 5 times, and the obtained dilute sodium tungstate solution (i.e. the pre-delivery solution) contains WO 3 18.26g / L;

[0048] 4) Pass the pre-delivery solution obtained in step 3) thro...

Embodiment 3

[0052] A method for deep removal of chromium in the recovery process of tungsten-containing waste, including the following steps:

[0053] 1) Use multi-point random sampling to obtain crude sodium tungstate solution, analyze and test the content of each element in it, and the test result is: WO 3 =126.49g / L, OH=19.24g / L, Mo=0.16g / L, CO 3 2- =41.41g / L, Cr=2.1g / L, V=0.35g / L;

[0054] 2) Put 7m 3 Transfer the crude sodium tungstate solution to 10m 3 Add 26kg of sodium sulfide to the reaction kettle at 95℃. After boiling for about 2h, sample and analyze the chromium content to be 0.46g / L. When the temperature in the reaction system drops to 50℃, press filter treatment, it can be seen that the solution is removed 78.1% of chromium;

[0055] 3) Dilute the low chromium sodium tungstate solution obtained in step 2) 7 times, and the obtained dilute sodium tungstate solution (that is, the pre-delivery solution) contains WO 3 18.75g / L;

[0056] 4) Pass the pre-delivery solution obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com