Method for deeply removing chromium from APT (Ammonium Paratungstate) crystallization mother liquor

A crystallization mother liquor, deep technology, applied in the production field of tungsten smelting, can solve the problem of ineffective separation of tungsten and chromium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

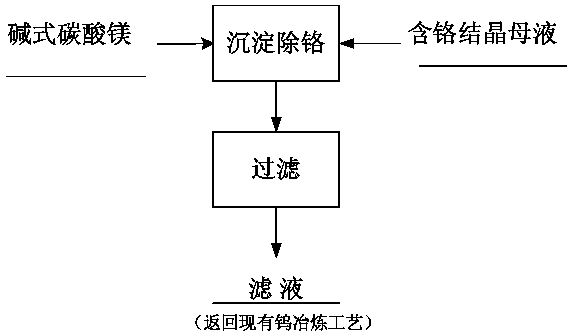

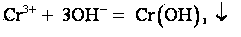

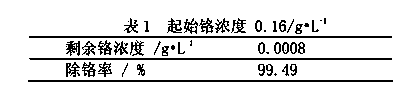

[0024] To 500 ml with an initial chromium concentration of 0.16 g·L -1 Add 50% basic magnesium carbonate suspension to the crystallization mother liquor to adjust the pH=8.5, the reaction temperature is 100°C, the reaction time is 0.5 h, and the rotation speed is 250 rad / min. The tungsten concentration remains unchanged before and after the reaction):

[0025]

[0026] The results show that the chromium removal rate can reach more than 99.4%, and the chromium concentration in the crystallization mother liquor can be reduced to below 0.001 g·L-1, which can be returned to the existing tungsten smelting process for recovery.

Embodiment 2

[0028] Add 500 ml with an initial chromium concentration of 10.00 g·L -1 Add 50% basic magnesium carbonate suspension to the crystallization mother liquor to adjust the pH=9.7, the reaction temperature is 100 °C, the reaction time is 3.0 h, and the rotation speed is 400 rad / min. After the operation and analysis of the above experimental conditions, the obtained results are shown in Table 2 below The tungsten concentration remains unchanged before and after the reaction):

[0029]

[0030] The results show that the chromium removal rate can reach more than 99.9%, and the chromium concentration in the crystallization mother liquor can be reduced to 0.0015 g·L -1 Next, it can return to the existing tungsten smelting process for recycling.

Embodiment 3

[0032] Add 500 ml with an initial chromium concentration of 0.16 g·L -1 Add 50% basic magnesium carbonate suspension to the crystallization mother liquor to adjust the pH=11.0, the reaction temperature is 90 °C and 100 °C respectively, the reaction time is 2.0 h, and the rotation speed is 100 rad / min. After operating and analyzing under the above experimental conditions, the obtained results are as follows As shown in Table 3 (tungsten concentration remains unchanged before and after the reaction):

[0033]

[0034] The results show that the chromium removal rate can reach more than 99.3%, and the chromium concentration in the crystallization mother liquor can be reduced to 0.001 g·L -1 Next, it can return to the existing tungsten smelting process for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com