Wind cover type partition denitrification reactor

A technology for reactors and wind hoods, applied in the field of wind hood type partitioned rotary denitrification reactors, which can solve the problems of catalyst turbulence, easy blockage of channels, damage, etc., and achieve the effect of reducing use and avoiding blockage of downstream equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

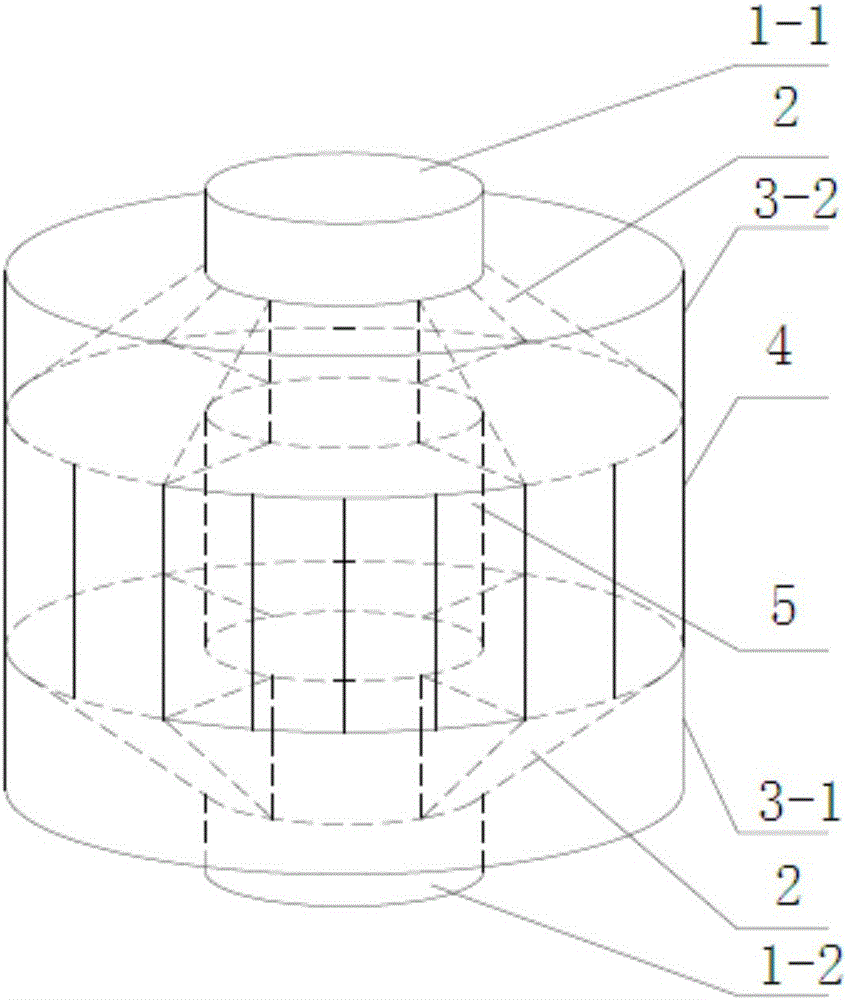

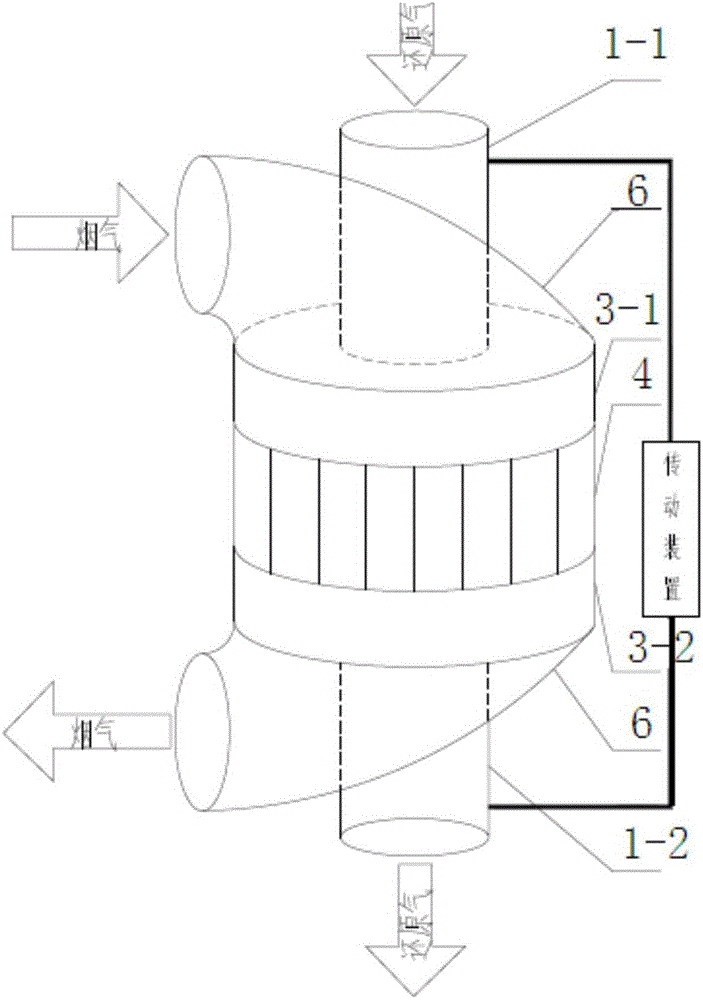

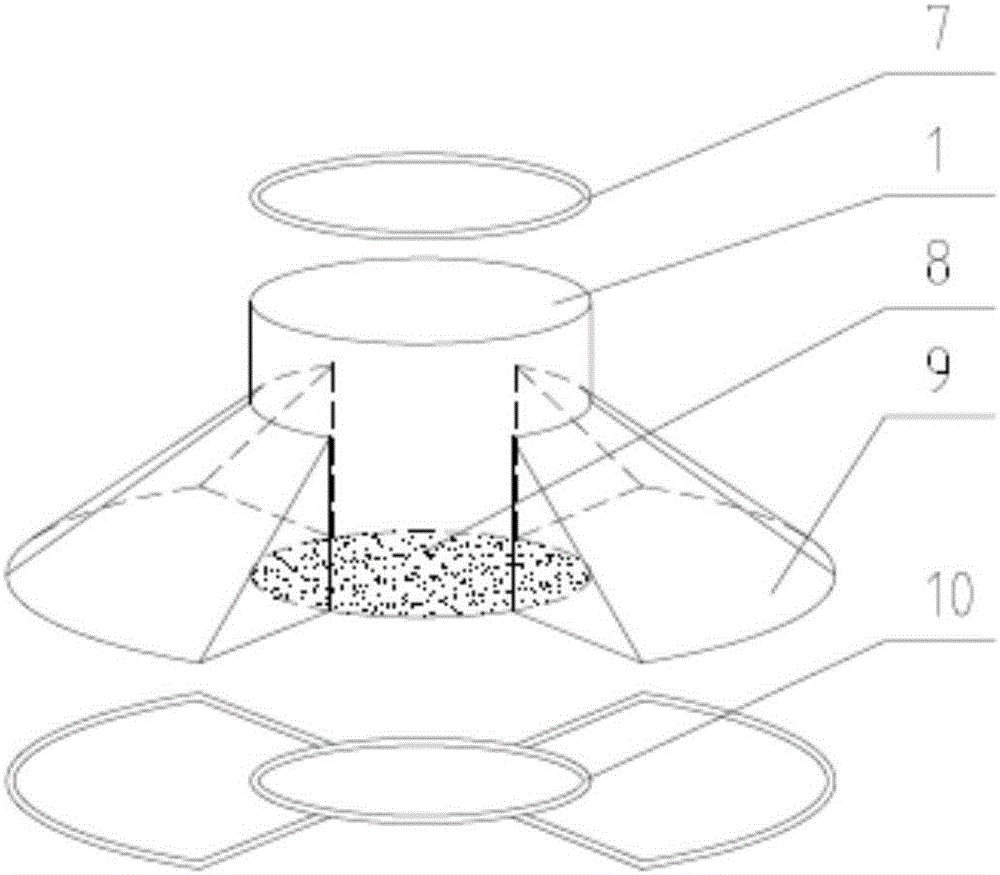

[0027] A wind hood rotary denitrification reactor, such as figure 1 As shown, it includes the reducing gas inlet 1-1 and the flue gas inlet 3-1, the body 4, the rotating shaft 5, the flue gas outlet 3-2 and the reducing gas outlet 1-2, wherein the reducing gas inlet 1-1, the reducing gas outlet 1 -2 are equipped with flue gas flue sealing ring 7.

[0028] During the test, the reducing gas flow rate is 0.1-100m / s, the flue gas temperature is 80-400°C, and the reducing gas temperature is 150-500°C. The body of the denitrification device is cylindrical, with a rotating shaft inside. There are several zones in between, and each zone can be loaded with catalyst. The reducing gas inlet flue and the reducing gas outlet flue are driven by an external transmission mechanism to rotate, and drive the inlet and outlet windshields connected to them to rotate synchronously. The upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com