Recycling process for regeneration waste liquid

A technology for regenerating waste liquids and processes. It is used in water/sewage multi-stage treatment, filtration treatment, chemical instruments and methods, etc. It can solve the problems of high enterprise pressure, large waste water production, internal consumption, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

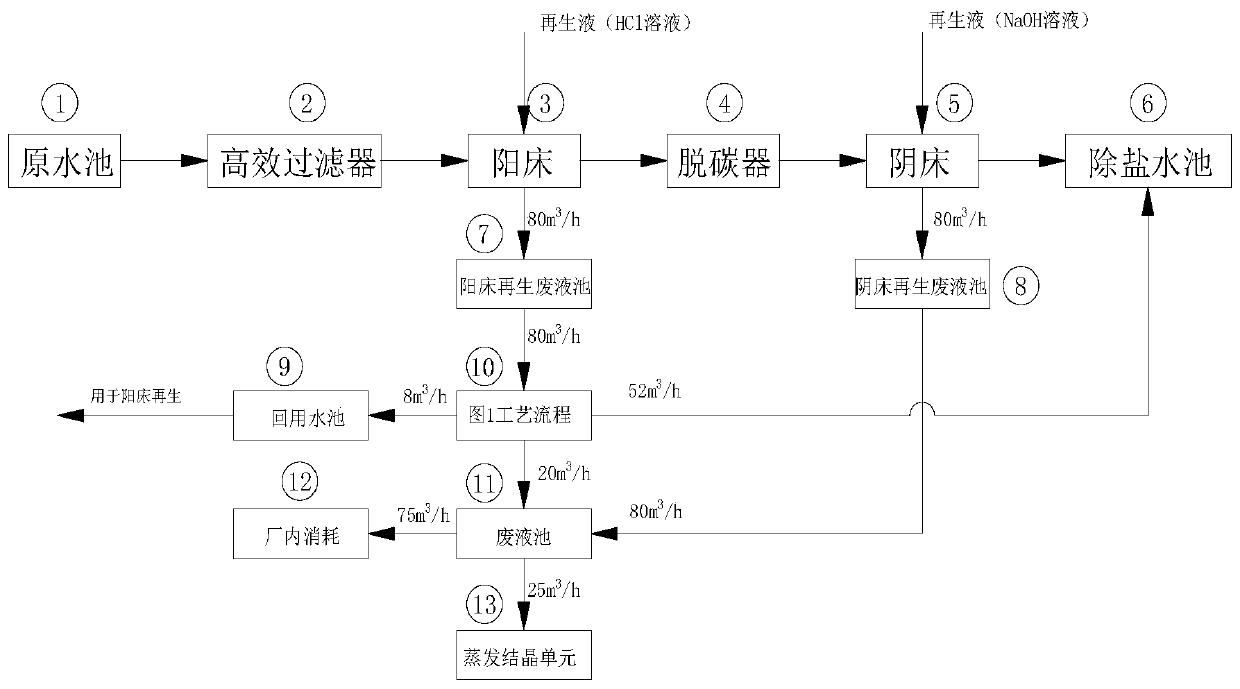

[0034] In a desalinated water preparation workshop, the amount of anode bed regeneration waste liquid is 80m 3 / h.

[0035] Such as figure 1 and figure 2As shown in the figure, the raw water pool ① is pumped to the high-efficiency filter ②, and then enters the desalinated water pool ⑥ after being treated by the positive bed ③, the decarburizer ④ and the negative bed ⑤.

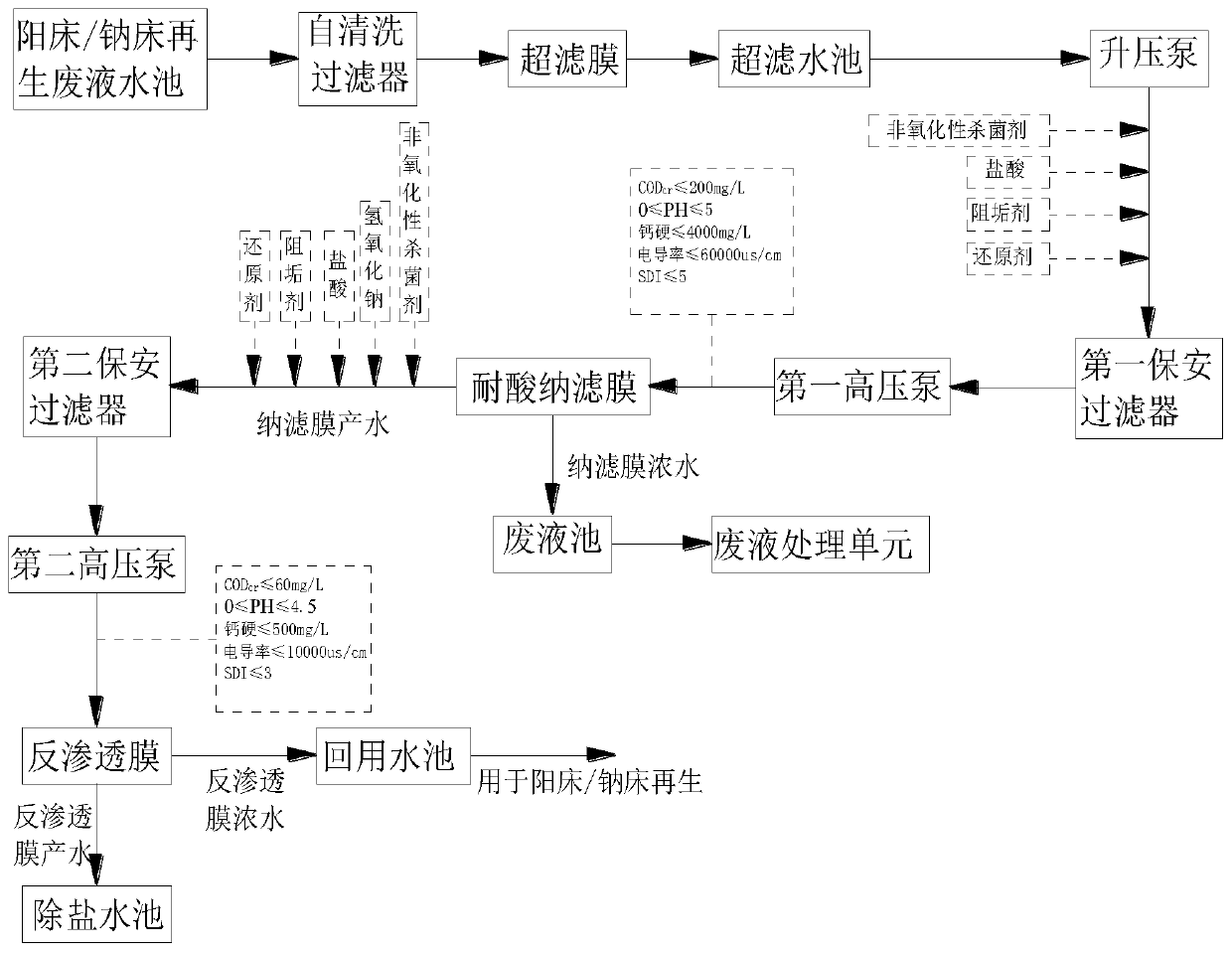

[0036] The regeneration of negative and positive beds uses NaOH solution and HCl solution respectively, and the regeneration of positive bed uses the HCl solution that unit of the present invention reclaims, and consumption is the hydrochloric acid solution 8m of concentration 3%. 3 / h, the amount of waste liquid generated by regeneration of the entire anode bed is 80m 3 / h, the regeneration waste liquid of positive bed enters positive bed regeneration waste liquid pond ⑦, enters the present invention then figure 1 The technological process ⑩. The water production rate of nanofiltration is 75%, the water...

Embodiment 2

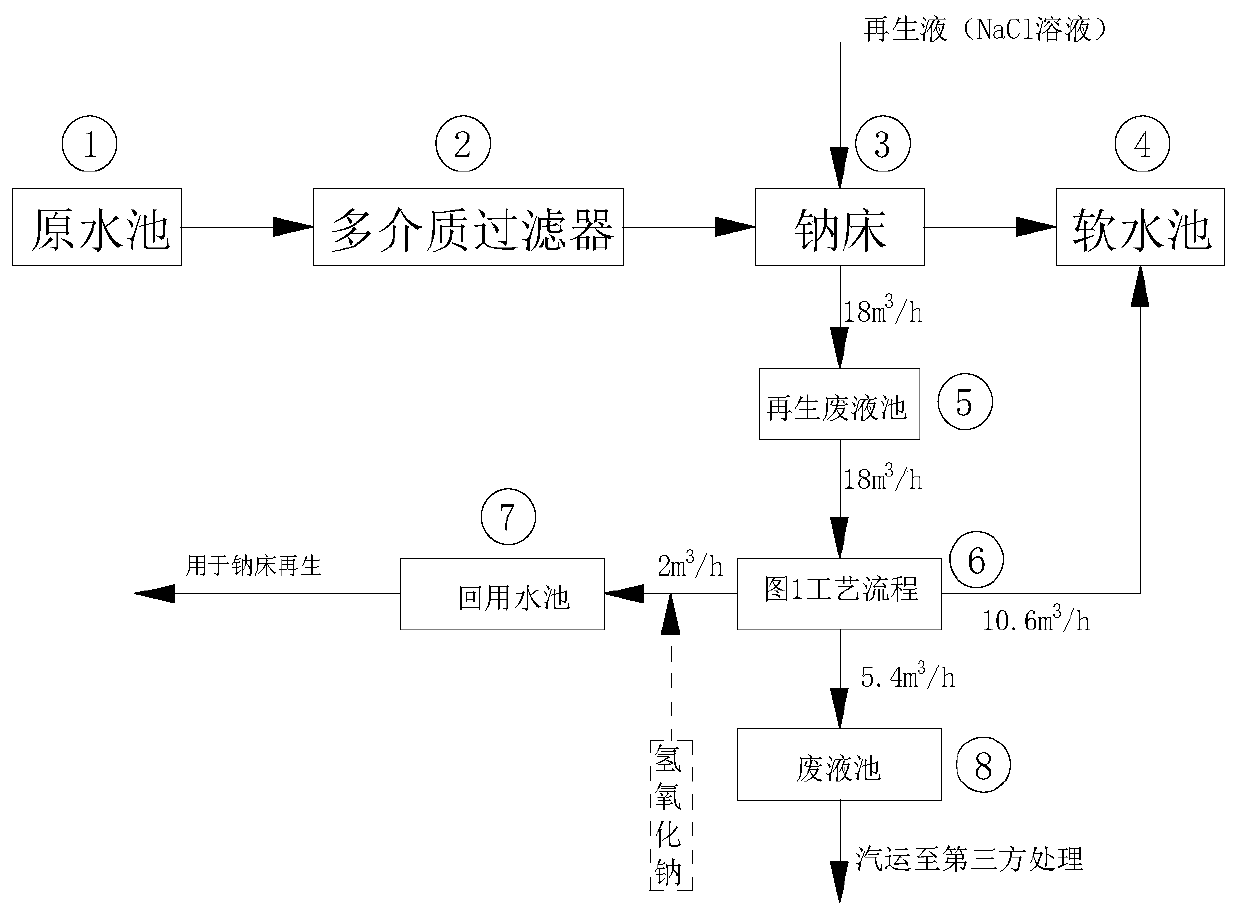

[0048] In a softened water preparation workshop, the amount of sodium bed regeneration waste liquid is 18m 3 / h

[0049] Such as figure 1 and image 3 As shown, the raw water pool ① is pumped to the multi-media filter ②, and then enters the soft water pool ④ through the sodium bed ③.

[0050] The softened water preparation workshop uses domestic tap water as the raw water source. After the large particle pollutants are removed by the multimedia filter, it enters the sodium bed for softening, and the softened water is stored in the softening pool ④. The regeneration solution of the sodium bed is 8% NaCl solution, and the system produces 18m 3 The regeneration waste liquid of / h is discharged into the regeneration waste liquid pool ⑤, through the present invention figure 1 The technological process ⑥ treatment, the water production rate of nanofiltration is 70%, and the water production rate of reverse osmosis is 84%. The pressure of the first high-pressure pump is 0.8MPa...

Embodiment 3

[0062] In an industrial wastewater treatment center, the amount of regeneration waste liquid in both positive bed and negative bed is 180m 3 / h

[0063] Such as figure 1 and Figure 4 As shown, the water treatment center has achieved zero discharge of industrial wastewater. After pretreatment, the industrial wastewater enters the deep desalination process, and finally forms two kinds of product water, one is purified water stored in the reservoir ④, and the other is stored in desalted water Desalinated water from pool ⑪, two kinds of water are used for different water points of the factory. Both yin and yang beds generate 180m 3 / h regeneration waste liquid, a total of 360m 3 / h, but the factory can consume a maximum of 245m 3 The industrial waste water of / h, if do not use waste water recycling process of the present invention, there will be 115m 3 / h of regenerated waste water has no place to consume, so it needs to invest in the construction of evaporation and crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com