Method for separating mixture of crude phenol and organic amine

A separation method and organic amine technology, which are applied in the purification/separation/stabilization of organic compounds, preparation of organic compounds, organic chemical methods, etc., can solve the problems of high production cost, many equipment units, large water consumption, etc. Achieve the effect of easy industrialization, simple separation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

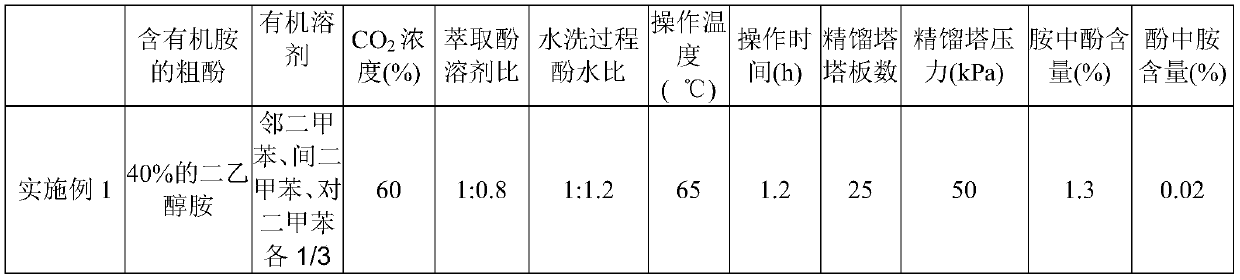

Embodiment 1

[0085] A method for separating crude phenol and organic amine mixture, which is used to treat the crude phenol containing organic amine (containing 40% diethanolamine) obtained by extracting the phenol oil fraction (distillation range 170-230°C) from medium-temperature tar, Including the following steps:

[0086] Step a1, 1000kg of the crude phenol containing organic amine, 1200kg of water, 800kg of organic solvent xylene (ortho-xylene, m-xylene, and p-xylene each 1 / 3) are simultaneously added to the stirring reactor for mixing and stirring, and At the same time, a content of 60% CO was introduced into the bottom of the reactor 2 (The impurity components are water vapor and nitrogen), the gas-liquid is fully contacted and reacted, mixed and stirred at 65°C for 1.2h, then left to separate layers, and separated to obtain the phenol phase containing the organic solvent (that is, the crude phase from which diethanolamine has been removed) A mixed solution of phenol and xylene) an...

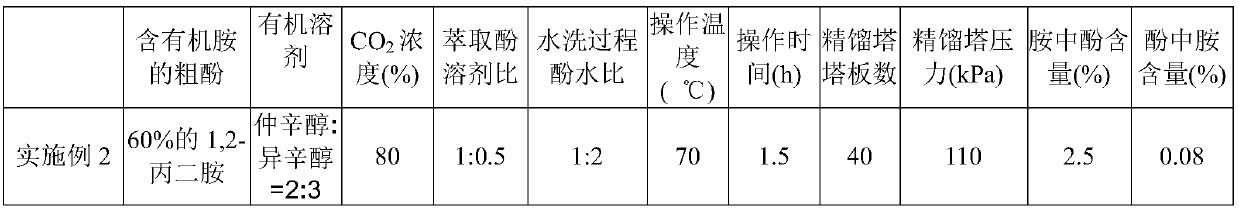

Embodiment 2

[0094] A separation method for a mixture of crude phenol and organic amine, used for extracting crude phenol containing organic amine (containing 60% 1,2-propylenediamine) obtained by extracting phenol oil fractions (130-280°C) from low-temperature tar processing, including the following steps:

[0095] Step b1, 1000kg of the crude phenol containing organic amine, 2000kg of water, and 500kg of organic solvent (secondary octanol:isooctanol=2:3) are simultaneously added to the stirred reactor for mixing and stirring. 80% CO is fed into the bottom 2 (The impurity components are water vapor and nitrogen), fully contact and react the gas-liquid, mix and stir at 70°C for 1.5h, then stand and separate the layers, and separate to obtain the phenol phase containing the organic solvent (that is, the 1,2- A mixed solution of crude phenol of propylenediamine and an organic solvent) and an aqueous phase containing an acidified aqueous solution of an organic amine (that is, an aqueous solu...

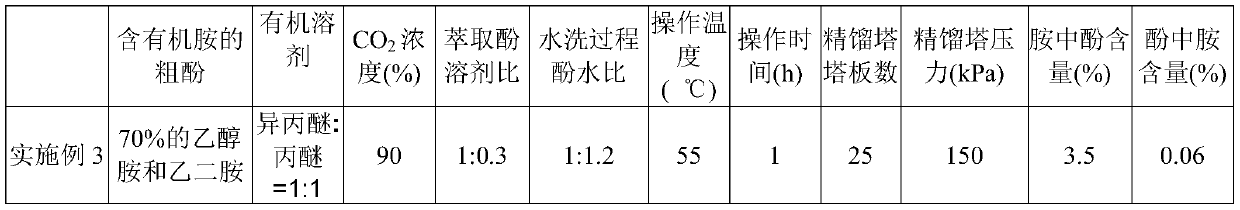

Embodiment 3

[0103] A method for separating crude phenol and organic amine mixture, which is used to treat the crude phenol containing organic amine obtained from medium temperature tar extraction (containing 70% ethanolamine and ethylenediamine, referred to as mixed amine in this embodiment), including Follow the steps below:

[0104] Step c1, adding 1000kg of the crude phenol containing organic amine, 1200kg of water, and 300kg of organic solvent (isopropyl ether: propyl ether = 1:1) into the stirring reactor at the same time and mixing and stirring, at the same time at the bottom of the reactor Introduce 90% CO 2 (The impurity components are water vapor and nitrogen), make the gas-liquid fully contact and react, mix and stir at 55°C for 1h, then stand and separate the layers, and separate to obtain the phenol phase containing the organic solvent (that is, the crude phenol phase from which the mixed amine has been removed) Mixed solution with organic solvent) and aqueous phase containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com