Preparation method of noble metal nano-particle array

A technology of nanoparticle arrays and noble metals, applied in the field of preparation of noble metal nanoarrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

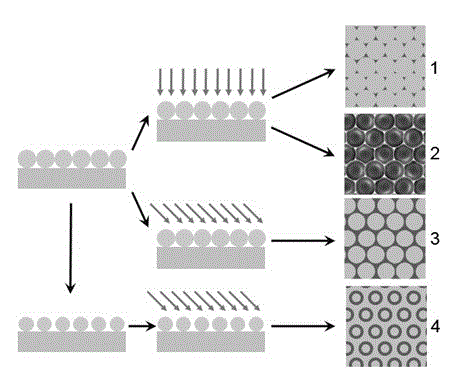

Method used

Image

Examples

Embodiment 1

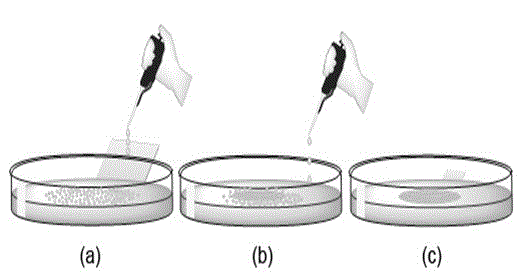

[0053] In Example 1, a single-layer hexagonal close-packed polystyrene colloidal sphere mask was first prepared. The preparation process of the template is as follows:

[0054] 1) Experimental reagents and instruments: slides, polystyrene microspheres, quartz plates, 95% ethanol, 2%, 10% dodecylsodiumsulfate (SDS), double distilled water, petri dishes, pipetting Gun, polystyrene colloidal ball.

[0055] 2) Substrate cleaning: Put the substrate in acetone and 95% ETOH, respectively, and ultrasonic for 10 minutes, and then rinse with water; put the rinsed substrate in the previously prepared 10% SDS solution and soak for 24 hours; after soaking The substrate was rinsed with water to remove the SDS remaining on the substrate and put into double distilled water for later use. The cleaned quartz plate is used as a substrate, and the glass slide is used as a drainage plate in the process of dropping the polystyrene colloidal sphere solution.

[0056] The method is mainly based on the se...

Embodiment 2

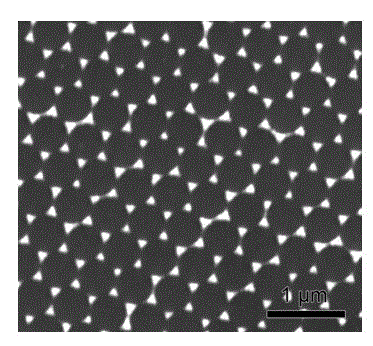

[0059] ①Deposited metal: In order to obtain a triangular silver nanoparticle array, an electron beam evaporation method is used (vacuum pressure 1×10 -4 Pa) Deposit precious metal silver film (thickness about 100 nm) on a single-layer mask of polystyrene colloidal spheres. ②Remove the polystyrene colloidal sphere template: through the trichloromethane (CHCl 3 ) And other organic solvents to ultrasonically remove the polystyrene colloidal sphere template. ③The obtained large-scale two-dimensional periodic triangular nanoparticle array structure can be characterized by scanning electron microscope, atomic force microscope, etc. The resulting scanning electron microscope picture of the triangular silver nanoparticle array is as follows image 3 Shown.

[0060] By changing the deposition time, an array of silver particles with uniform particle sizes and different heights can be obtained. Based on this template, the particle sizes are relatively concentrated and distributed between 11...

Embodiment 3

[0062] ①Deposited metal: In order to obtain a silver nano-array with a bowl-shaped shell structure, an electron beam evaporation method is used (vacuum pressure 1×10 -4 Pa) Deposit precious metal silver film (thickness about 100 nm) on a single-layer mask of polystyrene colloidal spheres. ②Remove the polystyrene colloidal sphere template: immerse the substrate in chloroform (CHCl 3 ) Ultrasound in the solution to promote the "peeling" of the shell layer on the top of the polystyrene colloidal sphere from the substrate, and finally the obtained silver nanoshell layer is ultrasonically cleaned 2-3 times in 95% ethanol. The bowl-shaped shell structure nanoarray will be obtained. ③The obtained large-scale two-dimensional silver nanoarray with periodic bowl-shaped shell structure can be characterized by scanning electron microscope, atomic force microscope and projection electron microscope. The result is a transmission electron microscope picture of the silver nanoarray with a bowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com