Device and method for purifying gas

A gas purification device and gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of safety, reduction of chemical substance removal rate, chemical substances mixed with decomposition products, etc., and achieve stable flow, High removal rate and coagulation inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (Example 1, Comparative Examples 1-2)

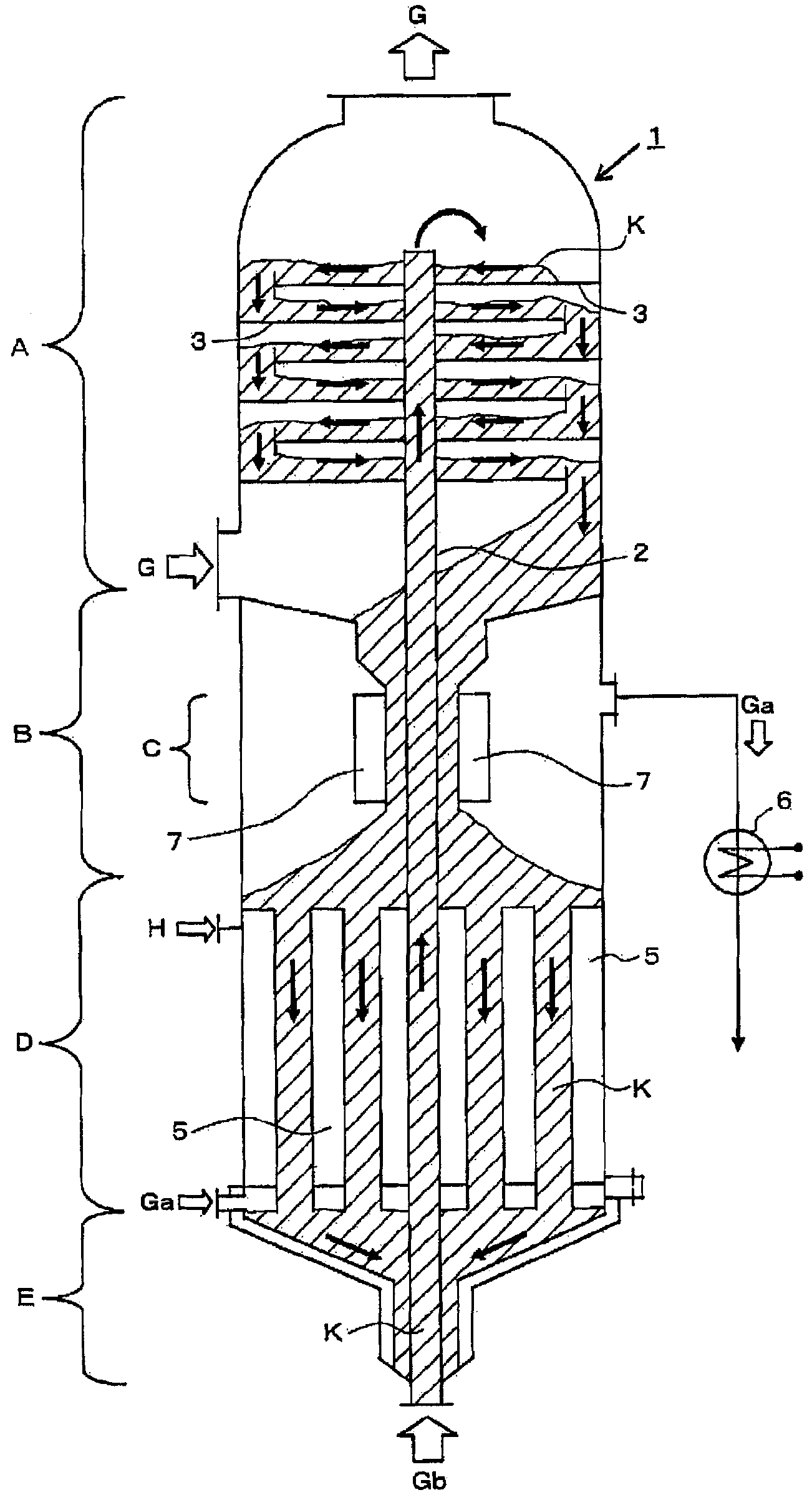

[0085] use figure 1 The shown gas purification device having an adsorption unit, a removal unit, and an adsorbent temperature control unit is used to purify the exhaust gas containing ethyl acetate. As the adsorbent, spherical activated carbon G-BAC manufactured by KLEHA CO., LTD. was used. In addition, nitrogen was used as the noncondensable gas in convective contact with the downflowing adsorbent. Adsorbent temperature control department such as figure 1 As shown, a heater 7 composed of a resistance exothermic body and a temperature detector (not shown) for measuring the temperature of the adsorbent passing through the heater 7 and flowing downward are constituted. In addition, the dew point of the non-condensable gas Ga containing chemical substances was obtained by a gas-liquid equilibrium test. Table 1 shows the temperature of the downflowing adsorbent in each example. In addition, the composition of the non-condensable ...

Embodiment 2、 comparative example 3~4

[0090] Purification was performed in the same manner as in Example 1, except that the dew point of the non-condensable gas Ga containing chemical substances was obtained by calculation, using off-gas containing n-propyl acetate instead of off-gas containing ethyl acetate.

[0091] As a result of the test, as shown in Comparative Example 4 in Table 2, in the case where the temperature of the adsorbent flowing downward is lower than the dew point (95° C.) of the non-condensable gas containing n-propyl acetate, the flow of the adsorbent unstable. In addition, as shown in Comparative Example 3, in the case where the temperature of the adsorbent flowing downward is higher than the dew point + 50° C., compared with Example 2, the concentration of acetic acid in the recovered n-propyl acetate is greatly increased, and the recycled product the purity is reduced.

[0092] [Table 2]

[0093]

Embodiment 3、 comparative example 5~6

[0095] Purification was performed in the same manner as in Example 2, except that the exhaust gas containing MEK (methyl ethyl ketone) was used instead of the exhaust gas containing n-propyl acetate.

[0096] As a result of the test, as shown in Comparative Example 6 in Table 3, in the case where the temperature of the adsorbent flowing downward was lower than the dew point (95° C.) of the non-condensable gas containing MEK, the flow of the adsorbent was unstable. Furthermore, as shown in Comparative Example 5, in the case where the temperature of the downflowing adsorbent was higher than the dew point + 50° C., the impurity concentration in recovered MEK was greatly increased compared with Example 3.

[0097] [table 3]

[0098]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com