Double regeneration and utilization method for waste iron oxide desulfurizer powder

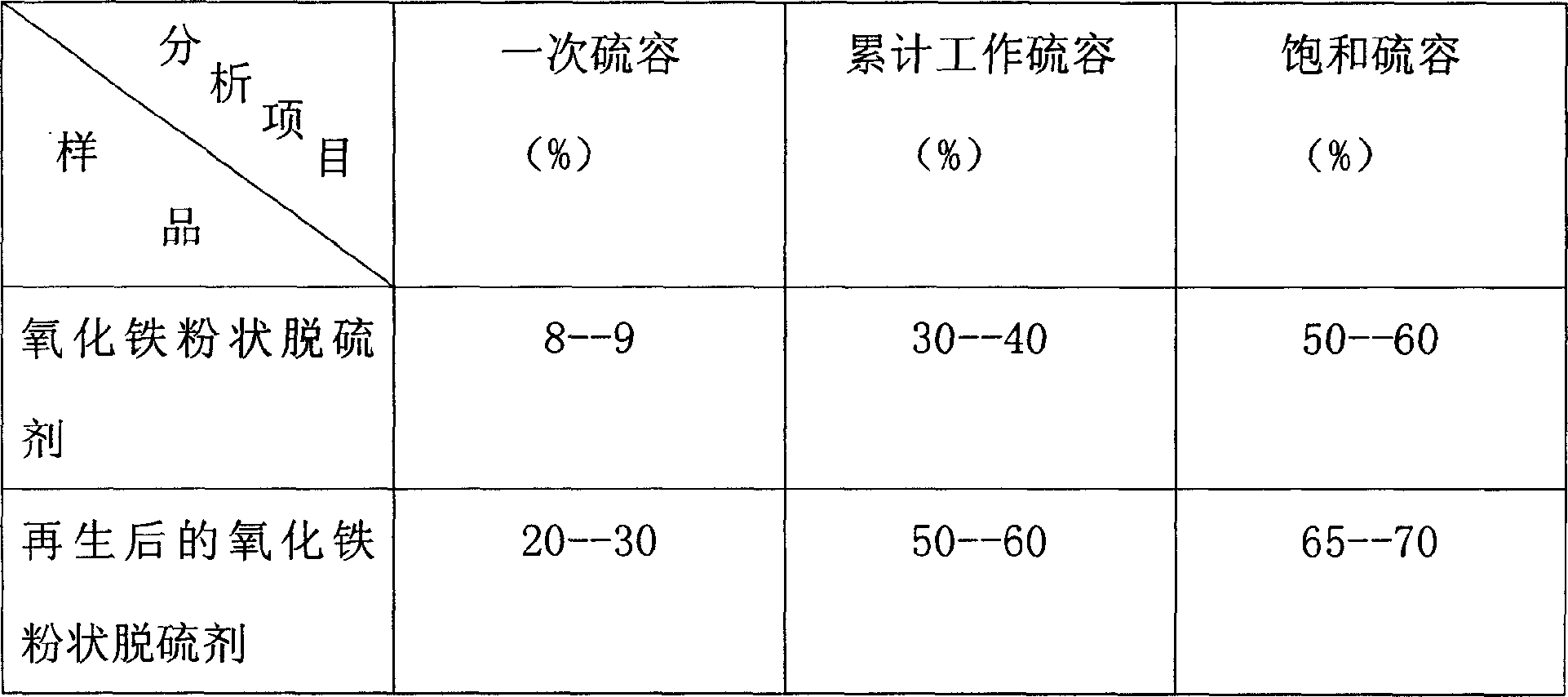

A secondary regeneration and iron oxide technology, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of unsatisfactory secondary regeneration effect and incomplete secondary regeneration, so as to reduce the replacement frequency and absorb Increased sulfur capacity, stress-relieving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: a secondary regeneration and utilization method of waste iron oxide powdery desulfurizer, comprising the following steps: (1) putting the scrapped and invalid waste iron oxide powdery desulfurizer into a mixer and stirring for 0.2 hours; ( 2) then add the basic salt group accounting for 0.4% of the waste iron oxide powdery desulfurizer gross weight that is loaded into the mixer, and this basic salt group includes sodium carbonate and / or potassium carbonate and / or sodium bicarbonate and / or Potassium bicarbonate was then stirred for 0.3 hour; (3) adding again accounted for 0.2% sodium hydroxide of the waste iron oxide powdery desulfurizer gross weight packed in the mixer, stirred for 0.3 hour; 7% of the total weight of the waste iron oxide powdery desulfurizer put into the mixer was added into the mixer with 7% synthetic ferric hydrate r-FeOOH, stirred for 0.5 hour, and the material was taken out from the mixer, and then left to stand for 72 hours. That is, ...

Embodiment 2

[0009] Embodiment 2: a secondary regeneration and utilization method of waste iron oxide powdery desulfurizer, comprising the following steps: (1) putting the scrapped and invalid waste iron oxide powdery desulfurizer into a mixer and stirring for 0.4 hours; ( 2) then add the basic salt group accounting for 0.6% of the waste iron oxide powdery desulfurizer gross weight that is loaded into the mixer, and this basic salt group includes sodium carbonate and / or salt of wormwood and / or sodium bicarbonate and / or Potassium bicarbonate was then stirred for 0.5 hour; (3) adding again accounted for 0.4% sodium hydroxide of the waste iron oxide powdery desulfurizer gross weight packed in the mixer, stirred for 0.5 hour; 9% of the total weight of the waste iron oxide powder desulfurizer in the mixer was added to the mixer, and 9% of the synthetic iron hydrate r-FeOOH was stirred for 1 hour, and the material was taken out from the mixer, and then left to stand for 120 hours. That is, the r...

Embodiment 3

[0010] Embodiment 3: a secondary recycling method of waste iron oxide powdery desulfurizer, comprising the following steps: (1) putting the scrapped and invalid waste iron oxide powdery desulfurizer into a mixer and stirring for 0.3 hours; ( 2) then add the basic salt group accounting for 0.5% of the waste iron oxide powdery desulfurizer gross weight that is loaded into the mixer, and this basic salt group includes sodium carbonate and / or salt of wormwood and / or sodium bicarbonate and / or Potassium bicarbonate, then stir 0.4 hour; (3) add the potassium hydroxide that accounts for 0.3% of the waste iron oxide powdery desulfurizer gross weight of packing in the mixer again, stir 0.4 hour; 8% of the total weight of the waste iron oxide powder desulfurizer in the mixer was added to the mixer, and 8% of the synthetic iron hydrate r-FeOOH was stirred for 0.75 hours, and the material was taken out from the mixer, and then left to stand for 96 hours. That is, the regeneration of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com